Engine exhaust treatment apparatus and engine driving type heat pump apparatus

An exhaust treatment device, engine-driven technology, applied in exhaust devices, engine components, engine control and other directions, can solve problems such as abnormal noise and damage to liquid seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

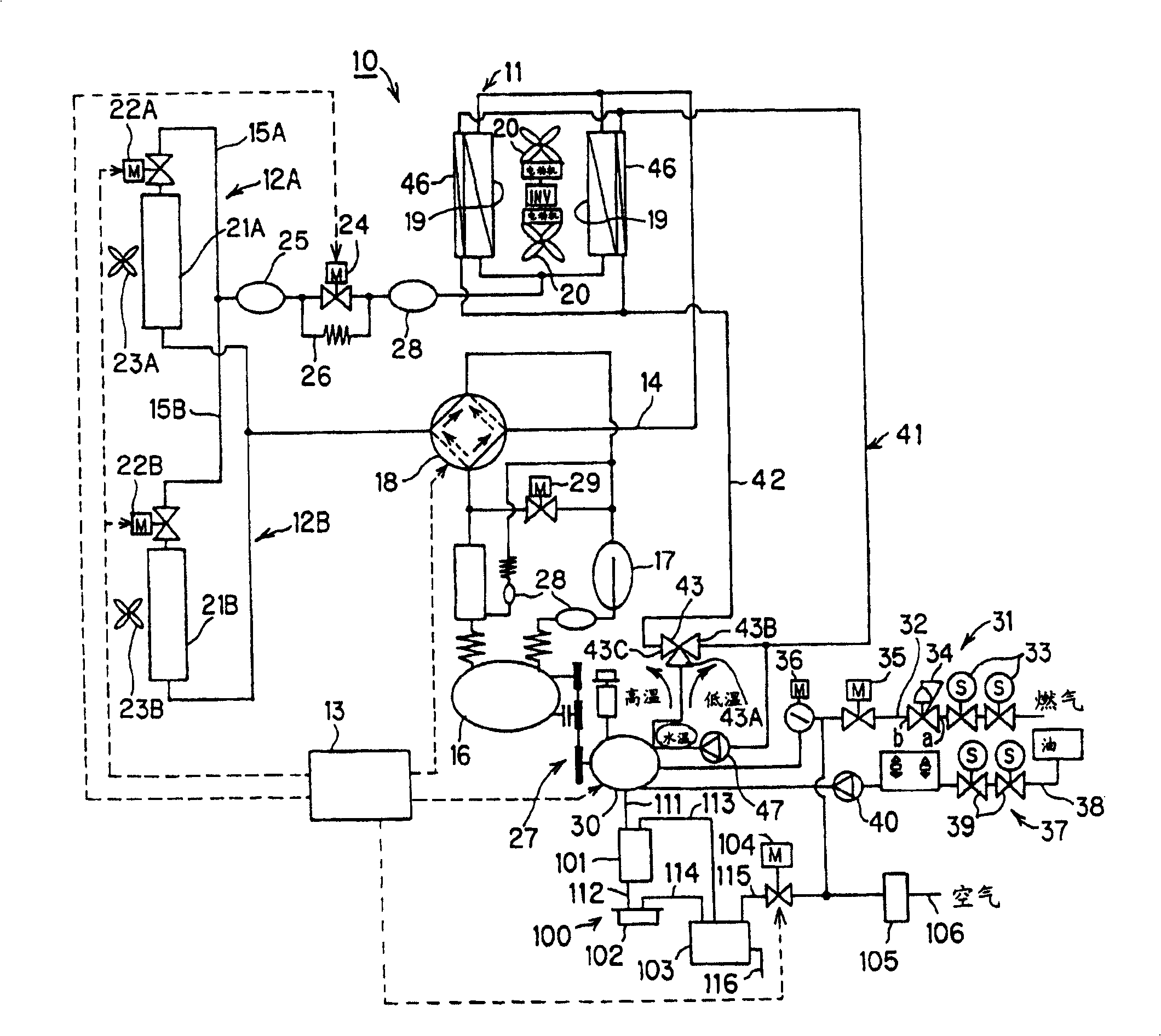

[0019] figure 1 It is a circuit diagram showing a refrigerant circuit in an air-conditioning apparatus to which an embodiment of the engine-driven heat pump apparatus of the present invention is applied.

[0020] Such as figure 1 As shown, the air-conditioning apparatus 10 as a refrigerating apparatus has an outdoor unit 11, a plurality of (for example, two) indoor units 12A, 12B, and a control device 13, and the outdoor refrigerant piping 14 of the outdoor unit 11 and the connections between the indoor units 12A, 12B. The indoor refrigerant pipes 15A and 15B are connected.

[0021] The outdoor unit 11 is installed outdoors, and is configured such that a compressor 16 is disposed on an outdoor refrigerant pipe 14, an accumulator 17 is disposed on the suction side of the compressor 16, and a four-way valve 18 is disposed on the outflow side. On the four-way valve 18 s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap