Dispensation of controlled quantities of material onto a substrate

一种基片、数量的技术,应用在对表面涂布液体的装置、涂层、电气元件等方向,能够解决测量装置不灵活、不可能实现材料实时和在线测量、需要靶滴定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

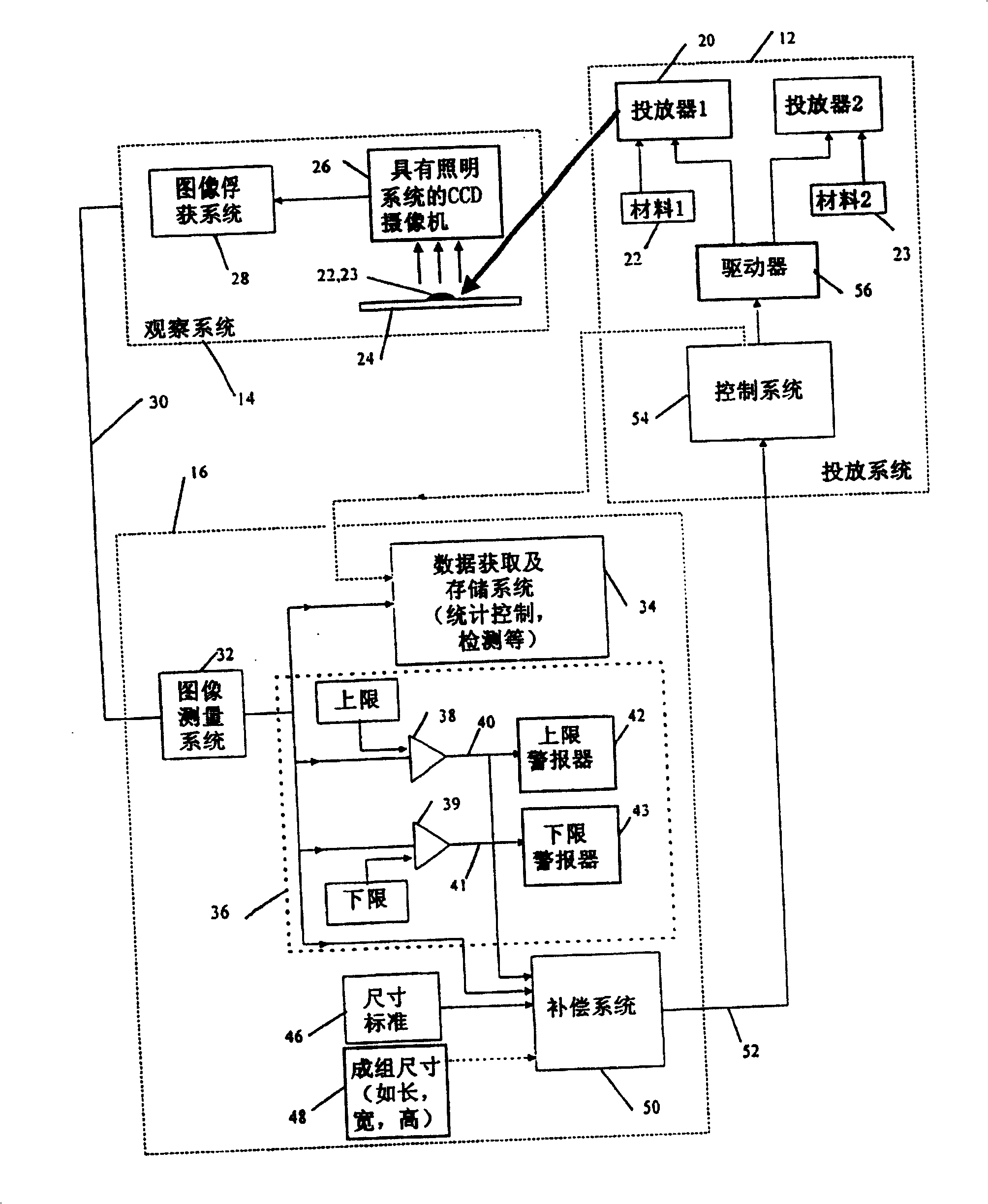

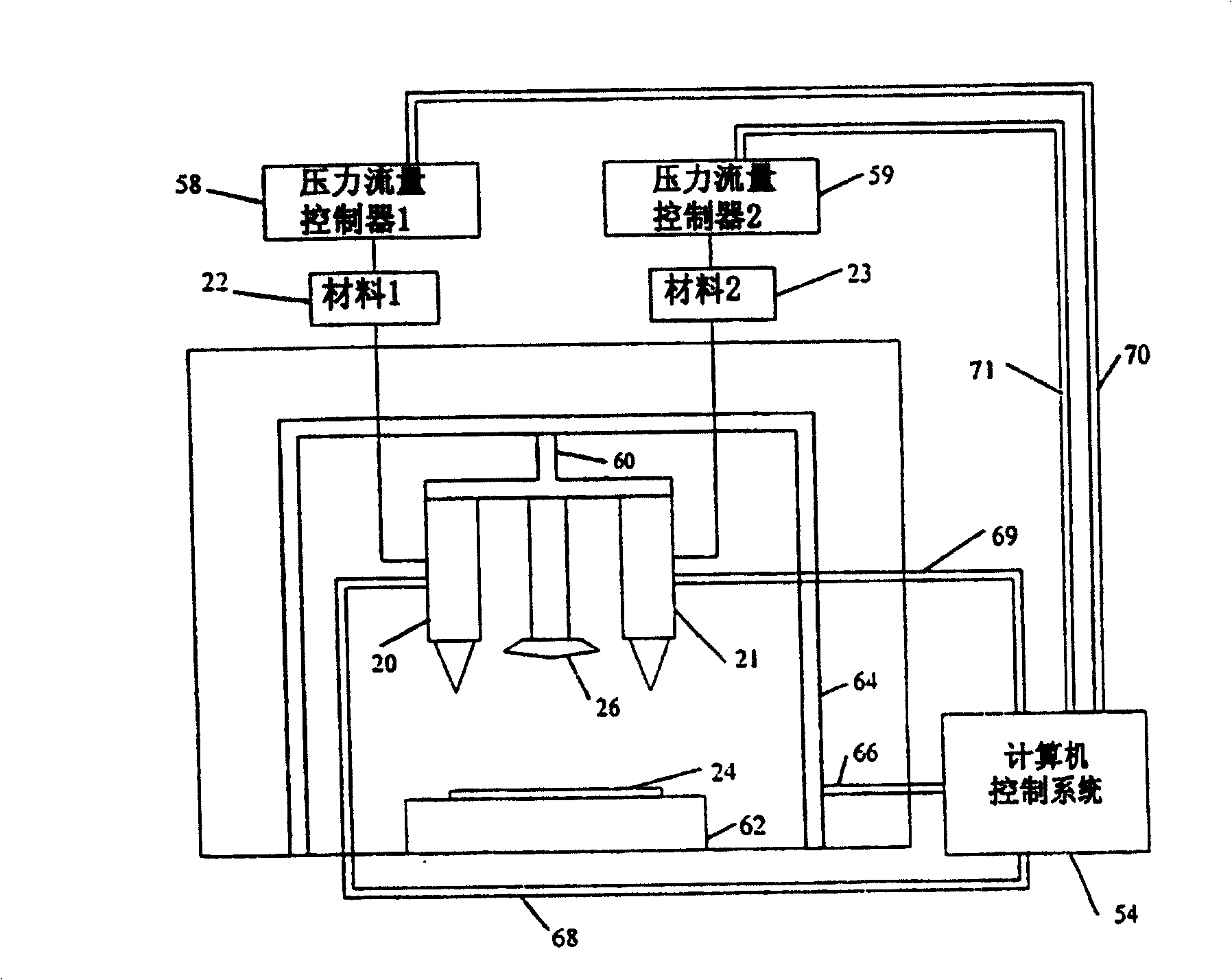

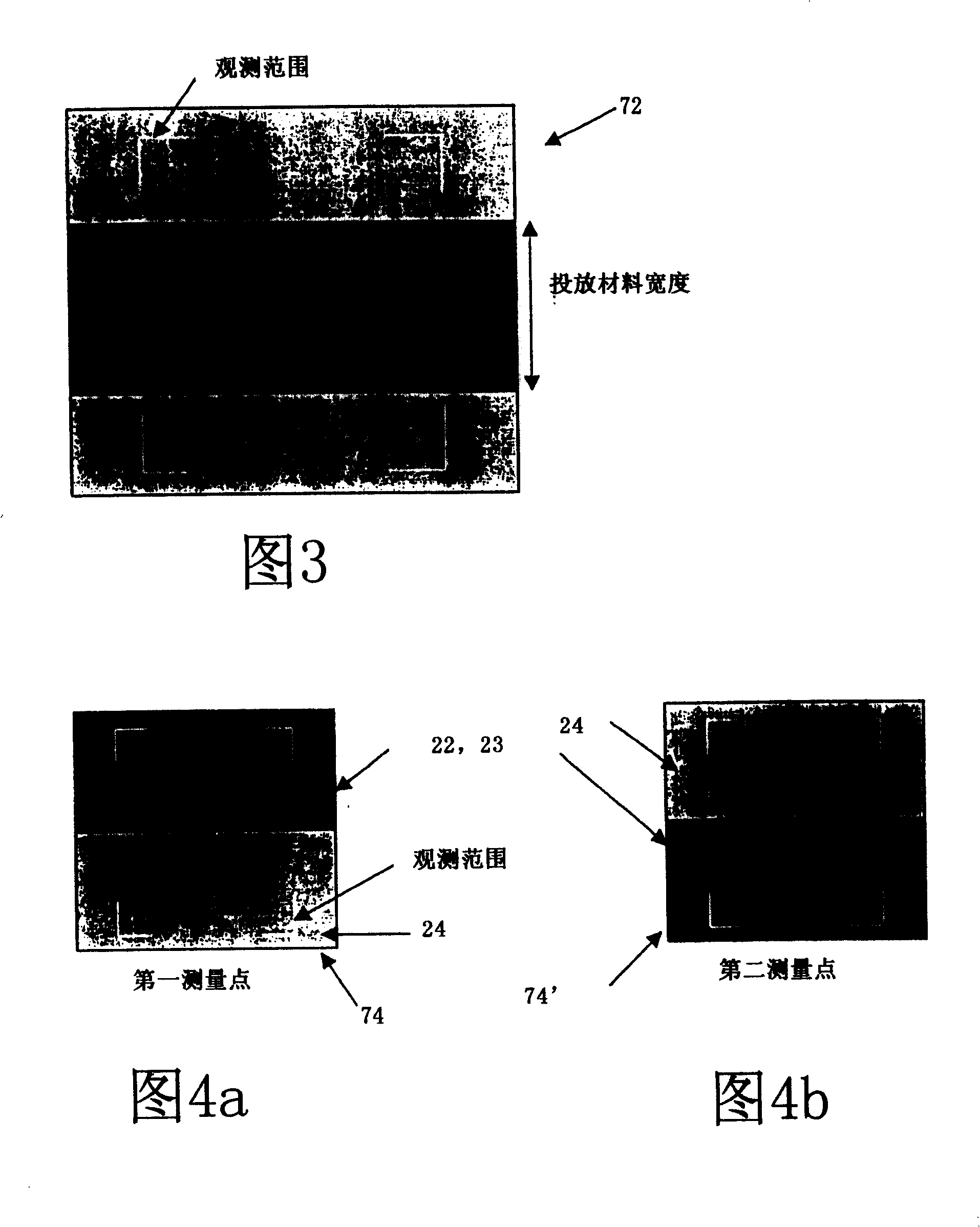

[0038] According to a preferred embodiment of the present invention, figure 1 The delivery system 12 of the device 10 , the observation system 14 incorporating the image capture system 28 , and the interconnection of the measurement system and the compensation system 16 are shown. Dosing system 12 comprises dispensers 20, 21 adapted to dispense material 22, 23, a driver 56 that drives various devices that vary the flow of material 22, 23 from dispensers 20, 21, and a computer control system 54 that responds to The amount of material 22, 23 dispensed by the dispenser is fed back and the amount of material 22, 23 released by the dispenser 20, 21 is varied (if desired). Although two dispensers 20, 21 are described in the preferred embodiment, the invention functions equally well with one or more dispensers with suitable modifications. An objective requirement of using more than one dispenser is that more than one material can be dispensed at approximately the same time if differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com