Pressurized soluble salt continuous vulcanizing device

A technology of dissolving salt and vulcanizing tubes, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., which can solve problems such as inconvenient operation, easy damage, and limitation of processing specifications, and achieve high heat energy utilization, reduce energy consumption, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

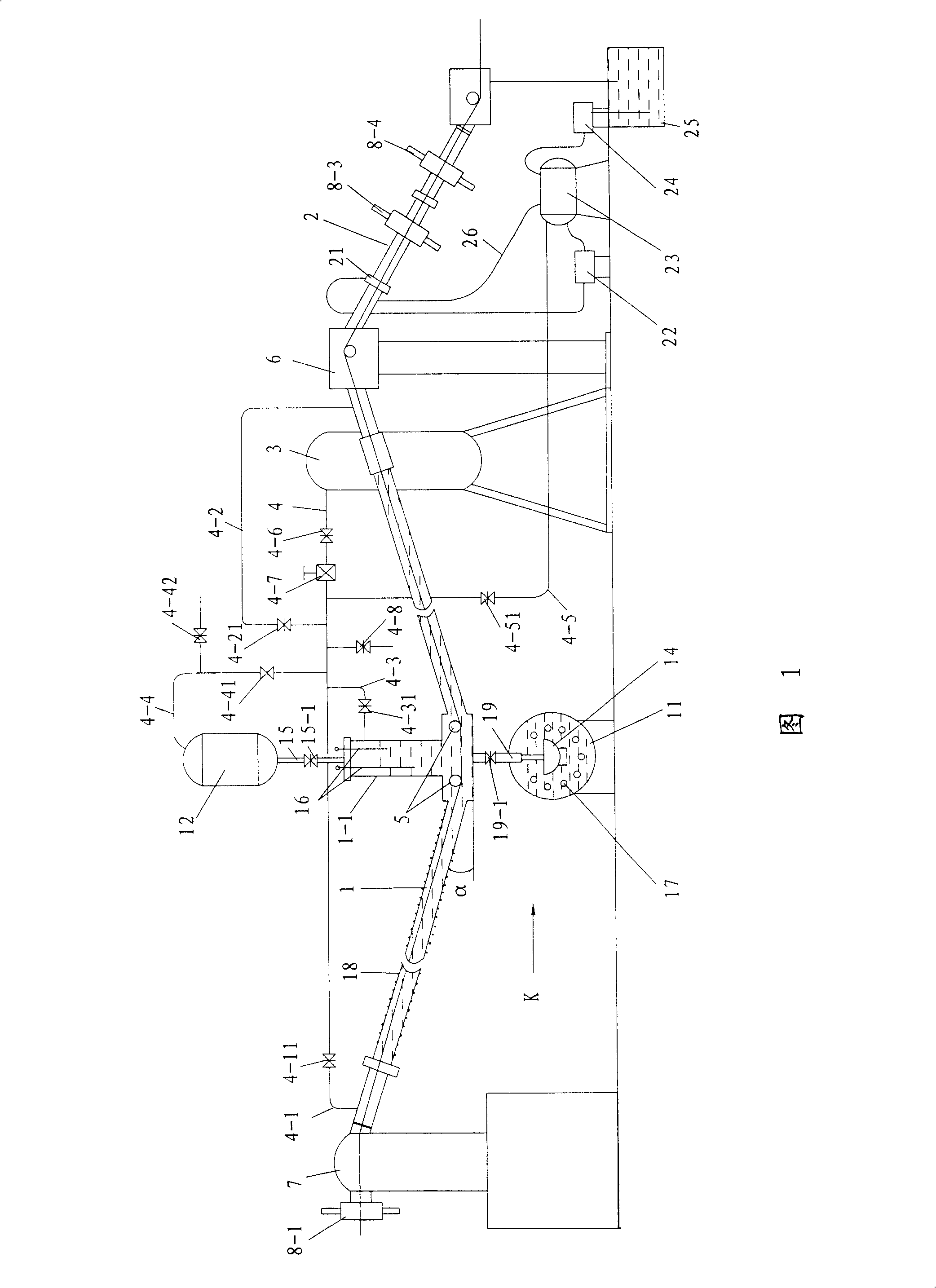

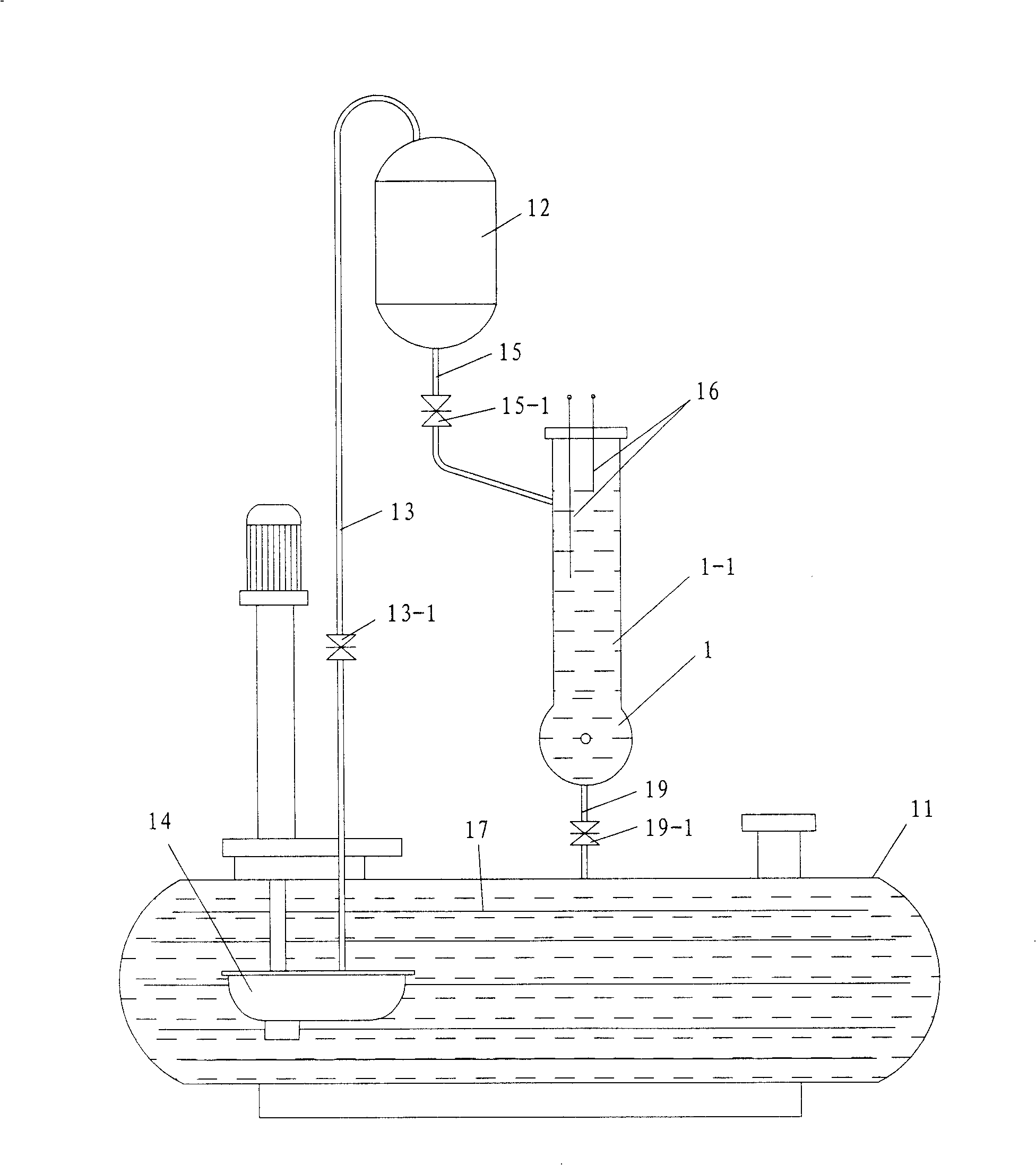

[0022] See Figure 1 and figure 2 , the present invention includes vulcanization device, cooling device and compressed air supply device.

[0023] The vulcanization device includes a vulcanization pipe 1 and a salt storage assembly.

[0024] The vulcanization tube 1 is a "V"-shaped curved tube with both ends higher than the middle, and the inclination angle α of the curved tube is between 1°-15°, for example, 1.5°-2°. The angle of the inclination α is related to the length of the vulcanizing tube 1. If the length is longer, the inclination α can be smaller, but there is no strict requirement. The outside of the vulcanization tube 1 is wound with a heating heating wire 18, which realizes regional temperature control, and the outside of the heating heating wire 18 is provided with an insulation layer (not shown in the figure). The vulcanization pipe 1 is provided with a cable transmission wheel 5 .

[0025] The salt storage assembly includes a horizontal salt storage tank 11 a...

Embodiment 2

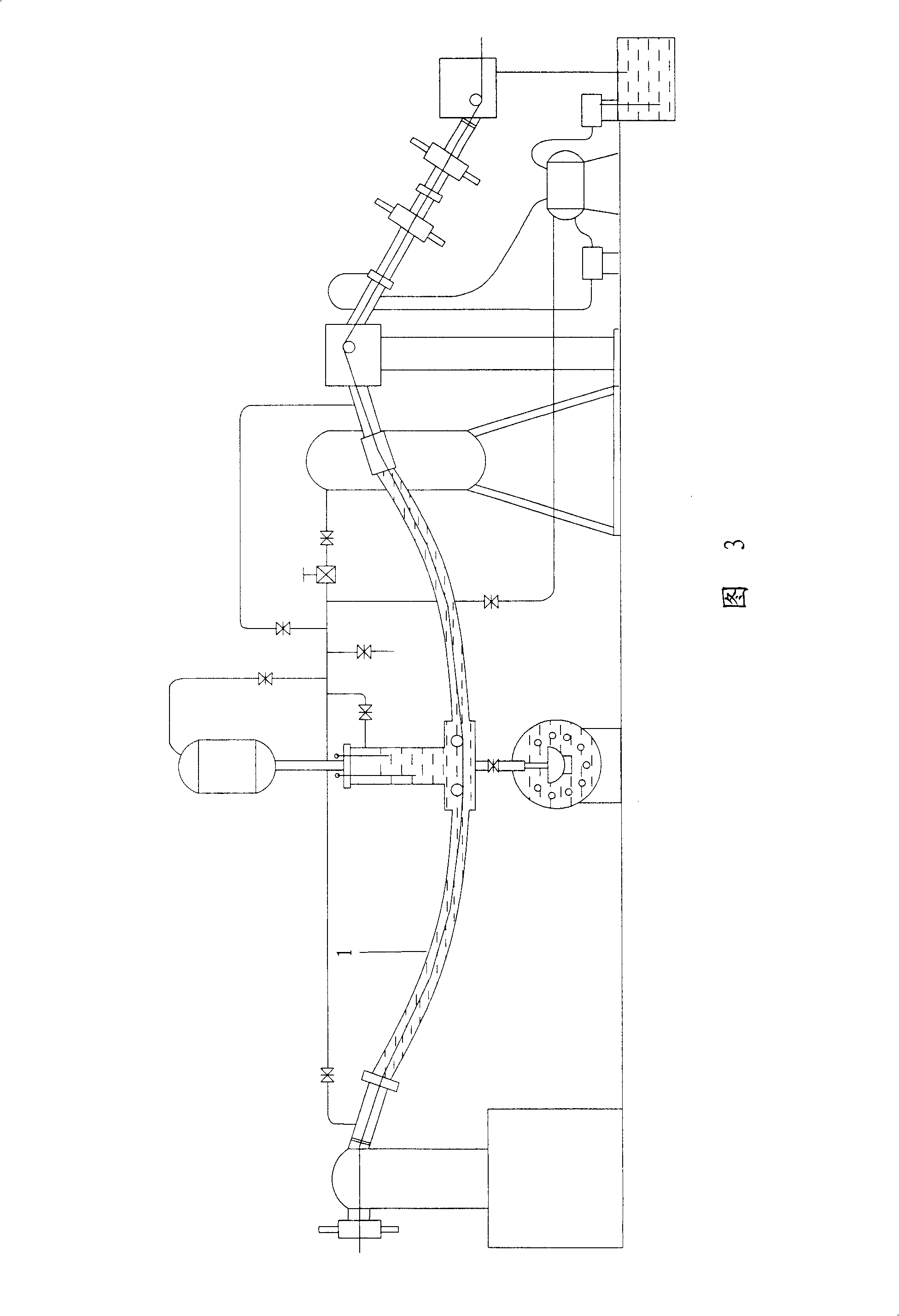

[0032] See Fig. 3, the difference between this embodiment and embodiment 1 is that the vulcanization tube 1 is arc-shaped, and the others are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com