Control system of well mouth release valve

A technology of control device and safety valve, which is applied in wellbore/well valve device, wellbore/well components, earth-moving drilling, etc., can solve problems such as inability to achieve, achieve pollution prevention, protect oil and gas resources, and protect wellhead equipment and the effect of pipeline safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

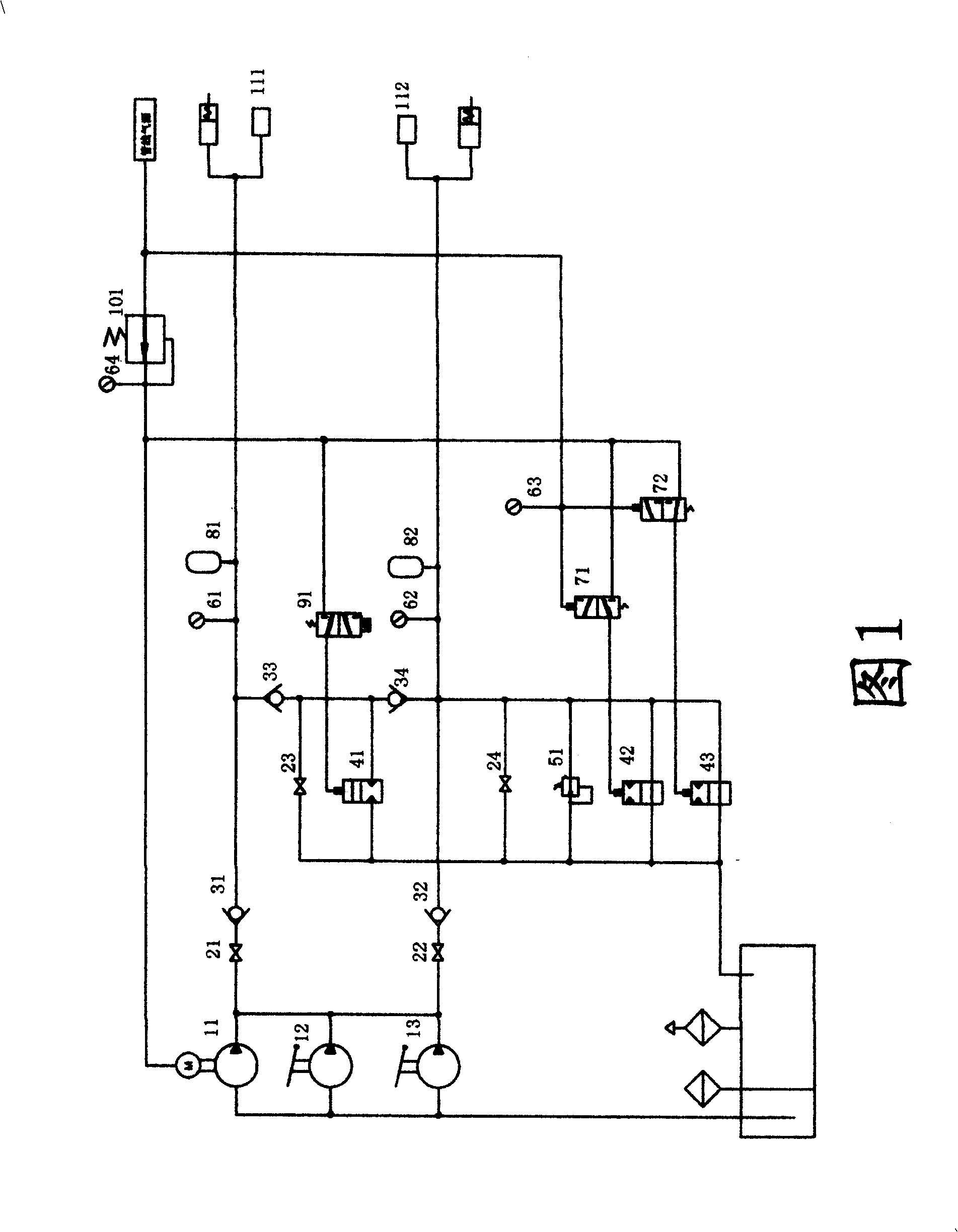

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] Please refer to Fig. 1, a wellhead safety valve control device, including a high-pressure pump 11, a manual pump 12, 13, a ground safety valve control circuit, the ground safety valve control circuit includes a stop valve 22, a one-way valve 32, a pressure gauge 62 , accumulator 82, the four are connected in sequence, and a relief valve 51 is set between the check valve 32 and the pressure gauge 62, one end of the shut-off valve 22 is connected to the high-pressure pump 11, and one end of the accumulator 82 is connected to the ground safety valve. The shut-off valve 22 is a high-pressure needle valve, the high-pressure pump 11 is a pneumatic booster pump, and is connected to the pipeline gas source, and a high-pressure needle is set between the check valve 32 and the pressure gauge 62 in the ground safety valve control circuit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com