Cam of camshaft for motorcycle engine

A technology for engines and motorcycles, applied in valve drive devices, valve details, etc., can solve problems such as the inability to reduce engine temperature, and achieve the effects of reducing the heat load of the body, improving cooling, and improving the scavenging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

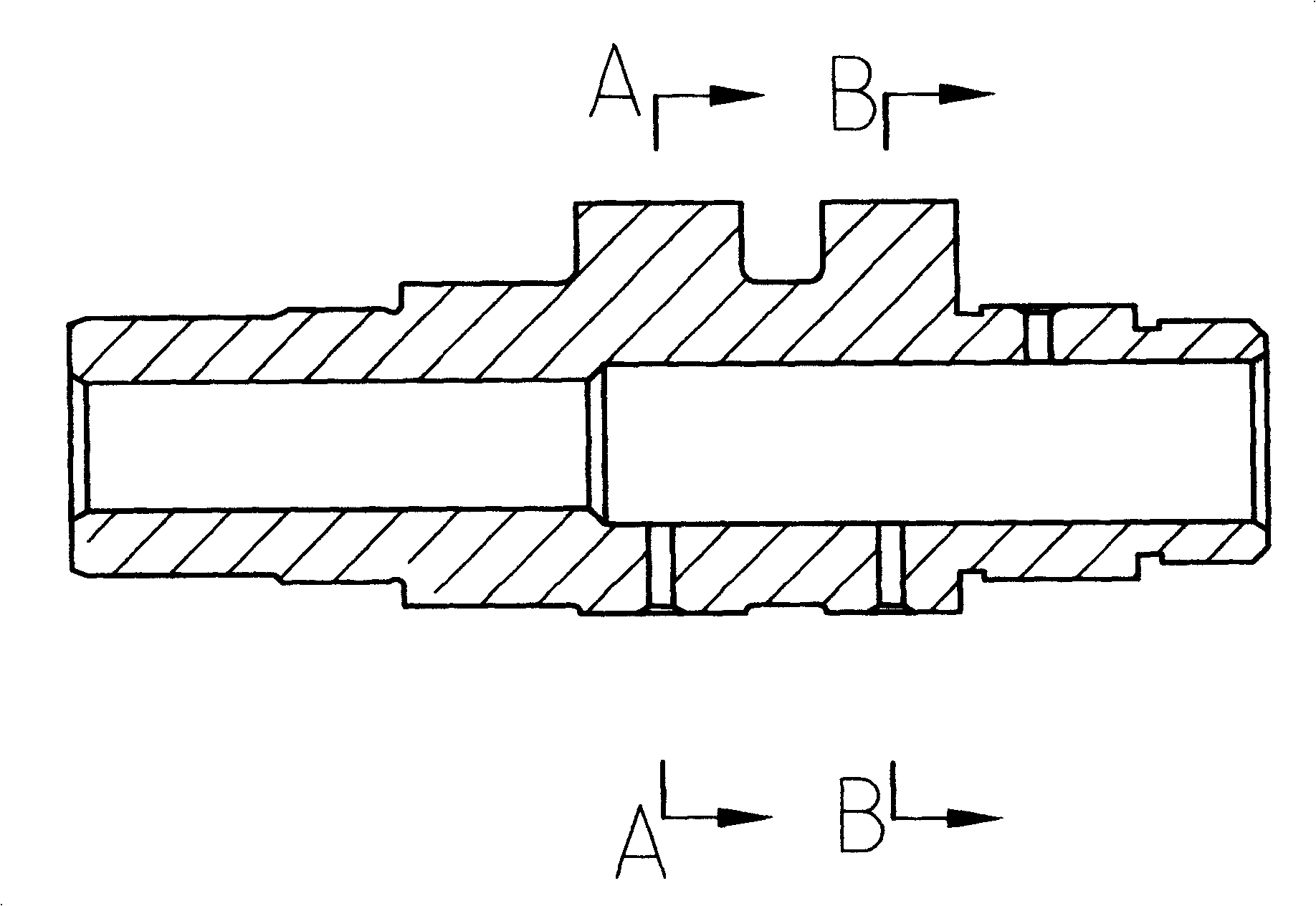

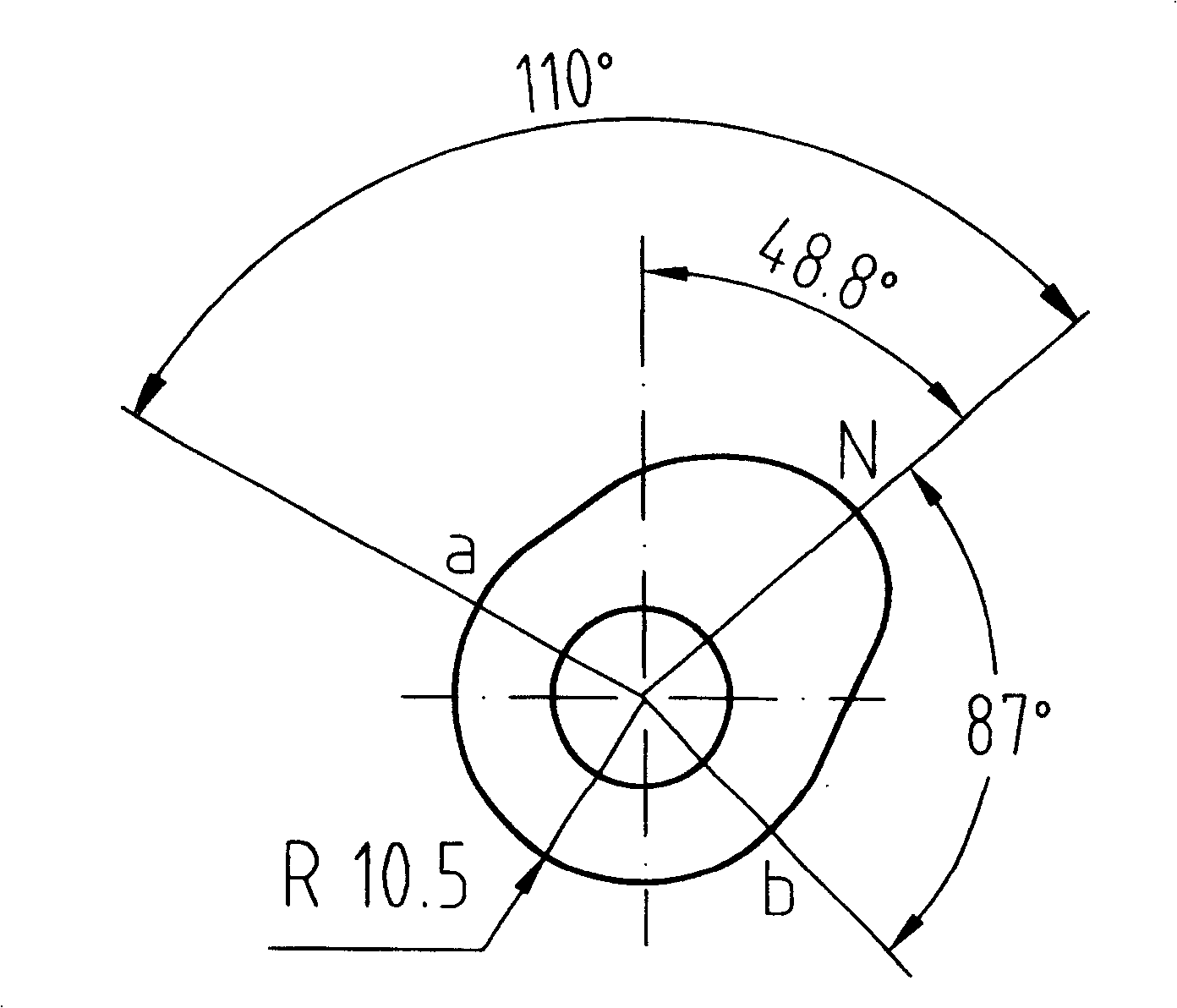

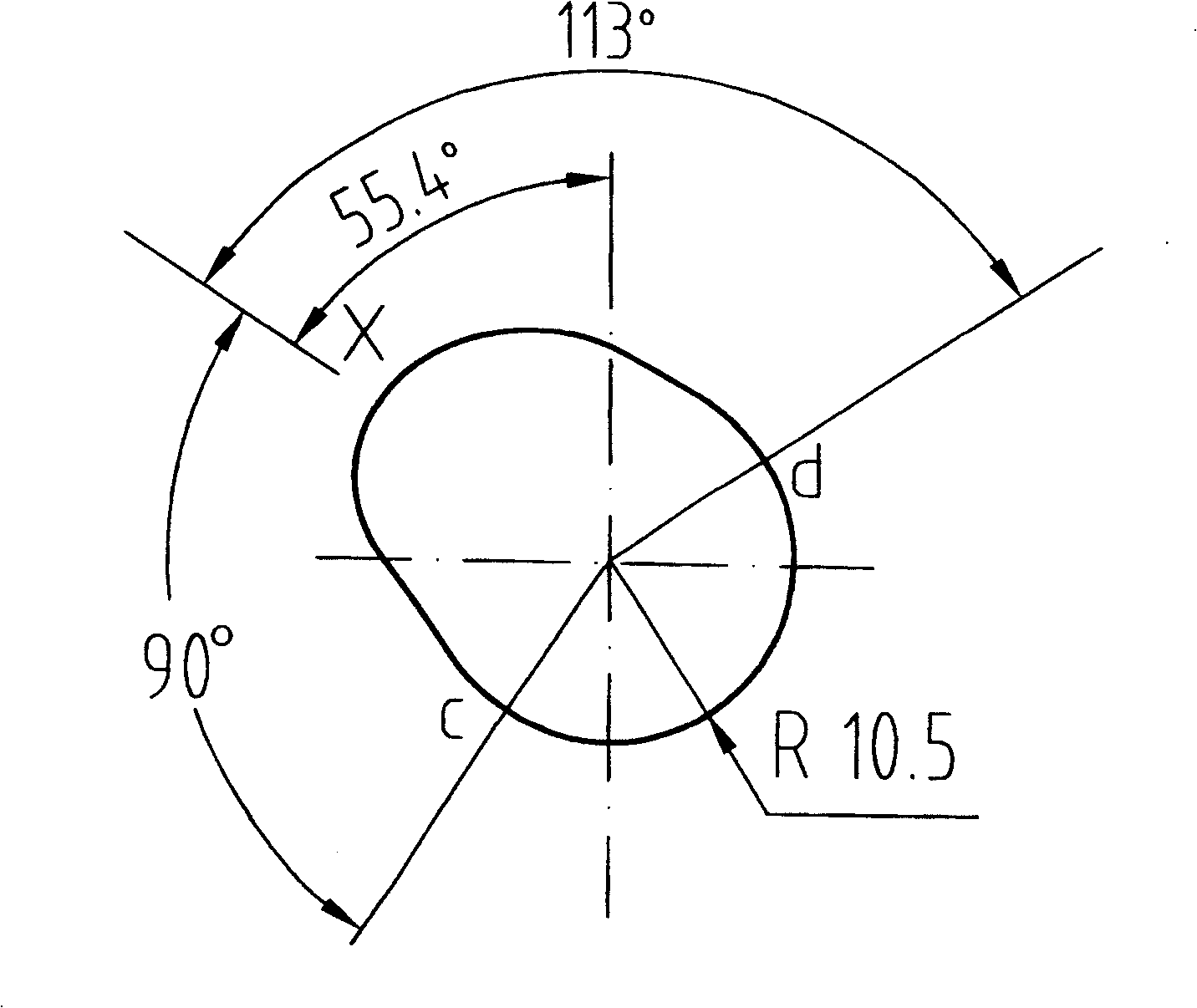

[0020] Such as Figure 1~3 As shown, the camshaft of the present invention includes an intake cam 1 and an exhaust cam 2 arranged at intervals, and the radius of the base circle of the intake and exhaust cams of the camshaft is 10.50 mm. The maximum lift point of intake cam 1 is point N (peach tip), the maximum lift is 5.566mm, along the clockwise direction, from point a to point N is the rising section, and the included angle is 110°; from point N to point b is the falling section section, with an included angle of 87°. The maximum lift point of the exhaust cam 2 is point X (peach tip), the maximum lift is 5.377mm, along the clockwise direction, from point c to point X is the rising section, and the included angle is 90°; from point X to point d is the falling section section, with an included angle of 113°. The included angle of the intake and exhaust cam lobe is 48.8°+56.1°=104.9°. Compared with ordinary cams, the most obvious differences are: the lift value of intake ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com