Method for detaching a semiconductor chip from a foil and apparatus for mounting semiconductor chips

A technology of semiconductors and chips, which is applied in the field of equipment for installing semiconductor chips, and can solve problems such as destroying semiconductor chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

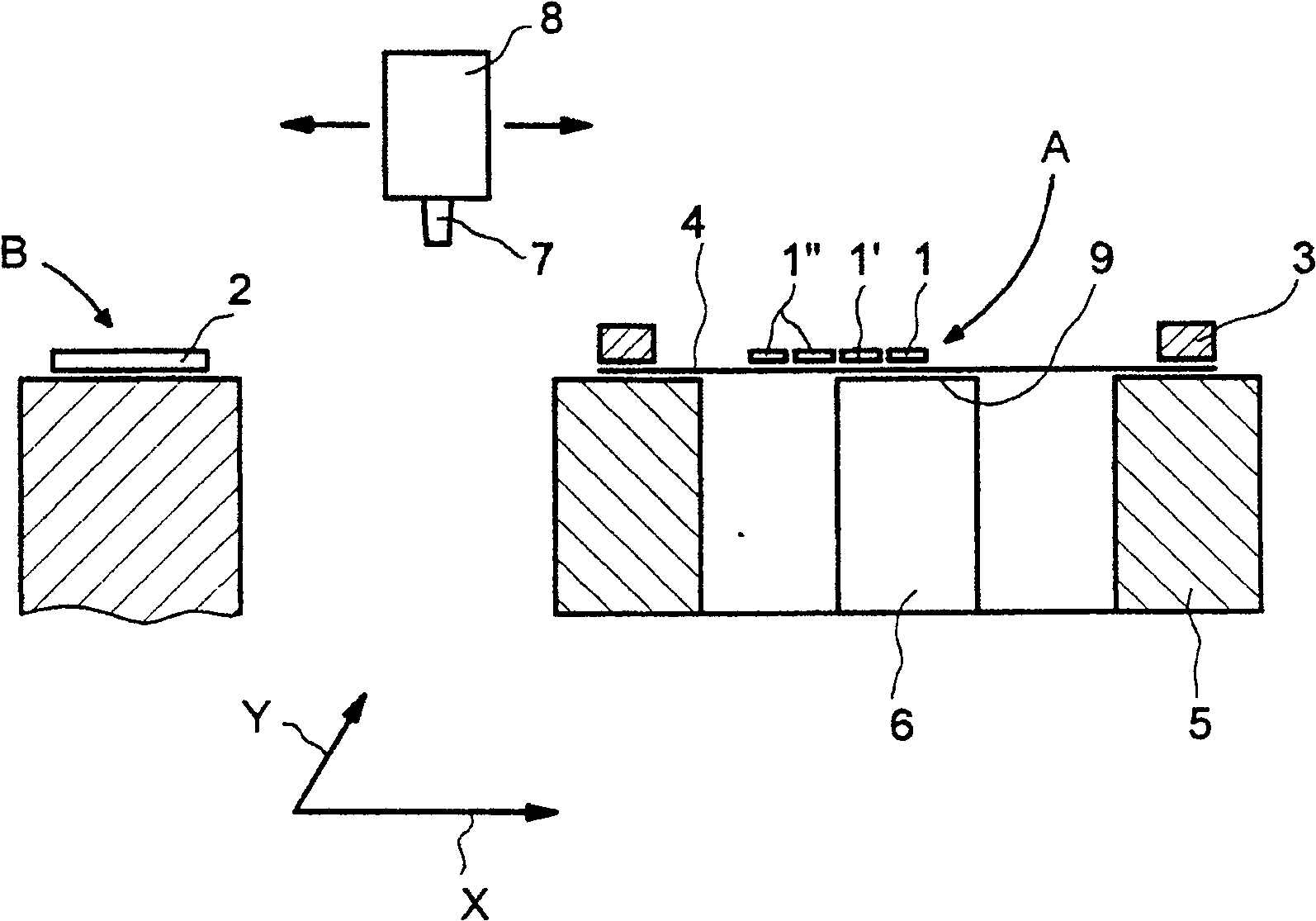

[0046] figure 1 A simplified schematic diagram of a device for mounting semiconductor chips 1 , 1 ′, 1 ″ on a substrate 2 is shown. The semiconductor chips 1 , 1 ′, 1 ″ arranged in rows and columns are attached to, for example, held in frame 3 on the foil 4. The apparatus has a accommodating frame 3 and a movable wafer stage 5 that provides the semiconductor chips 1 in a first position A one after the other. In the first position A, the chip ejector 6 according to the invention is arranged under the foil 4 , which in this example is an ejector without ejector pins. The chip ejector 6 serves to support the separation of the semiconductor chip 1 from the foil 4 when the semiconductor chip 1 is removed. The wafer stage 5 can move in two vertical directions, x and y. The foil 4 is arranged so that the edges of the semiconductor chips 1, 1', 1" are almost parallel to the directions x and y. The device also has a chip gripper 7 for transferring the semiconductor chips 1 provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com