Front set absorber for motorcycle

A technology for front shock absorbers and motorcycles, applied in axle suspension devices, bicycle accessories, transportation and packaging, etc., can solve problems such as front fork tube 2 empty travel phenomenon, impact on shock absorption effect, liquid flow interference, etc., and achieve effective Conducive to popularization and application, improving shock absorption effect and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

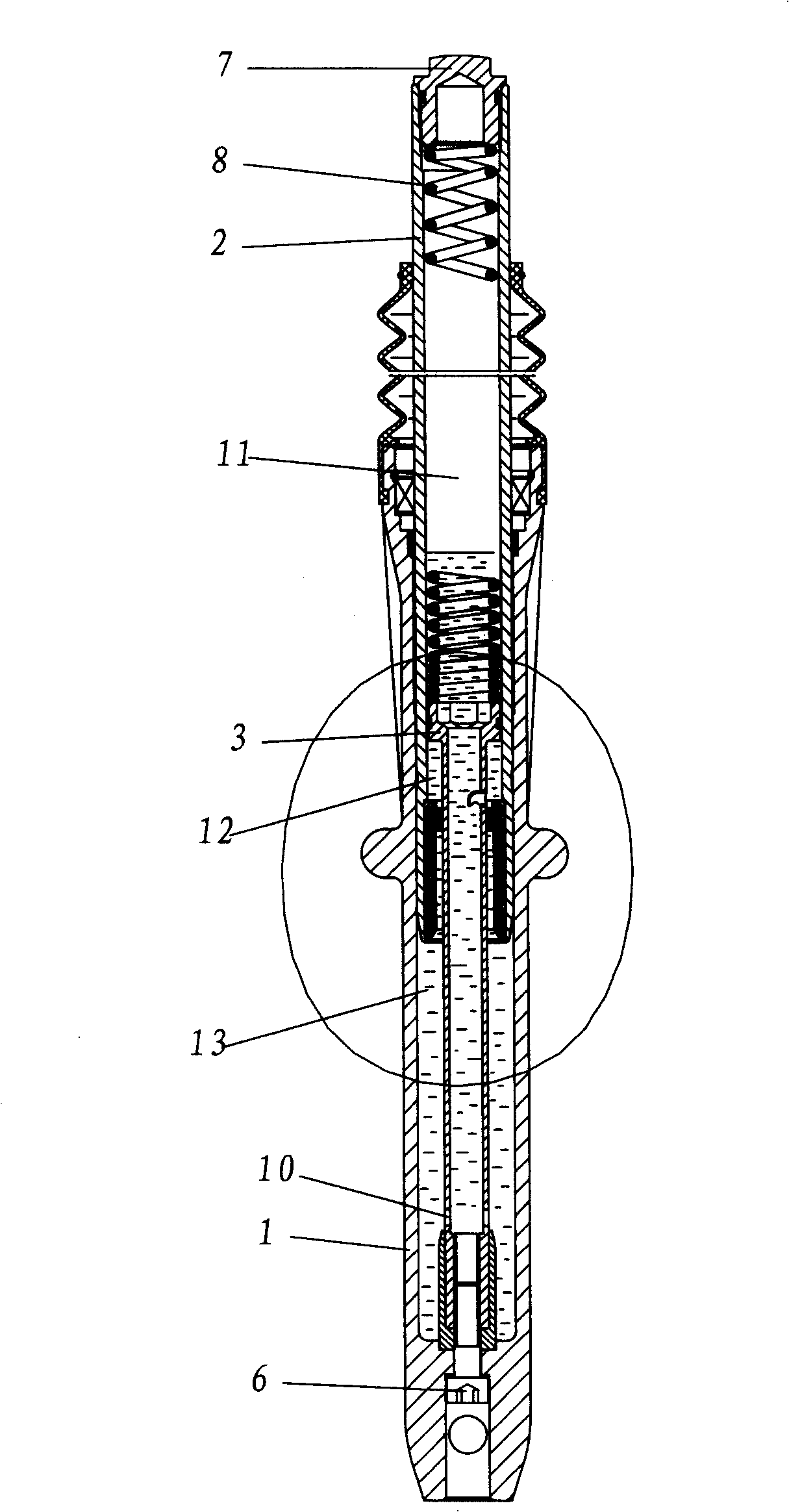

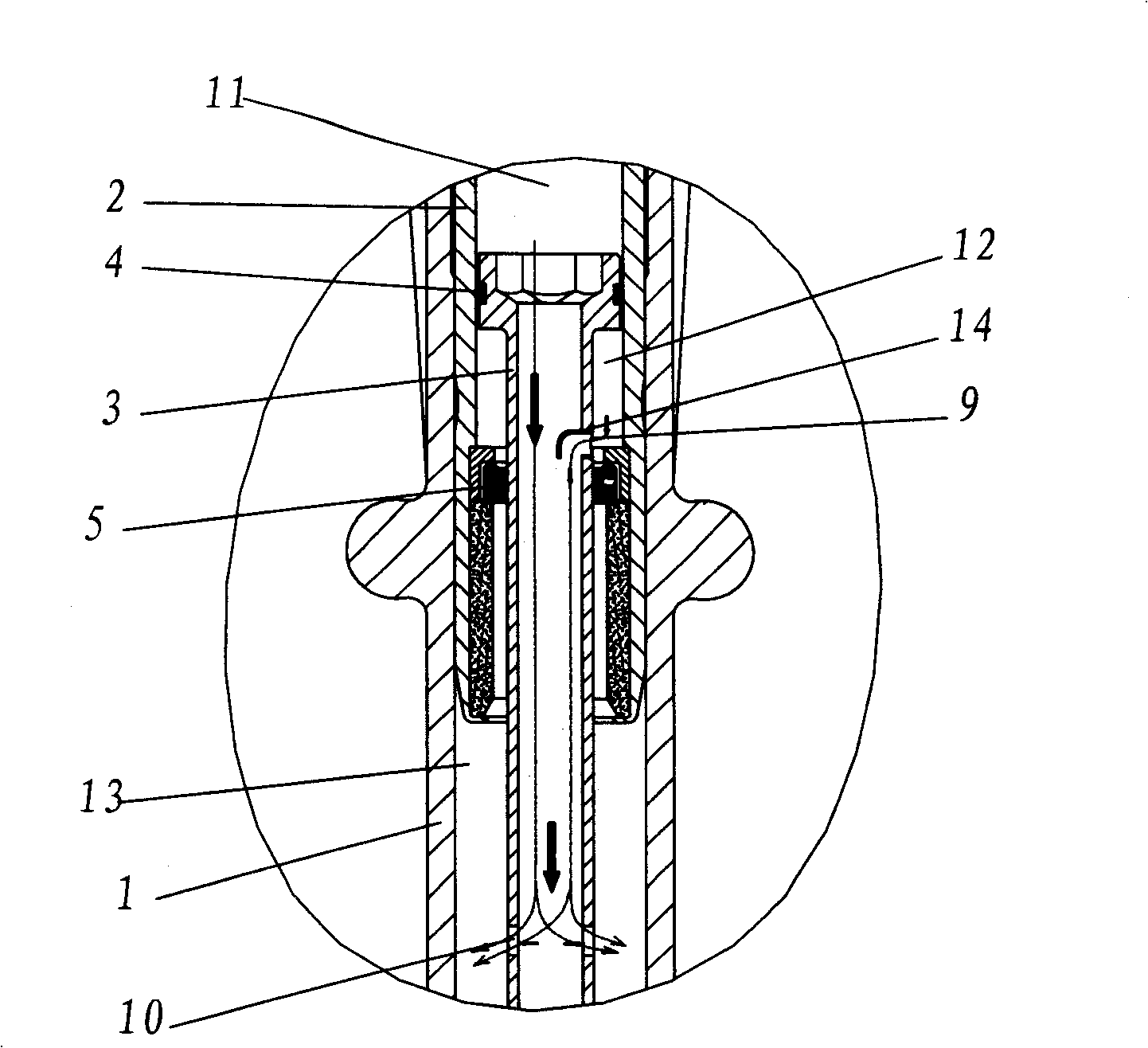

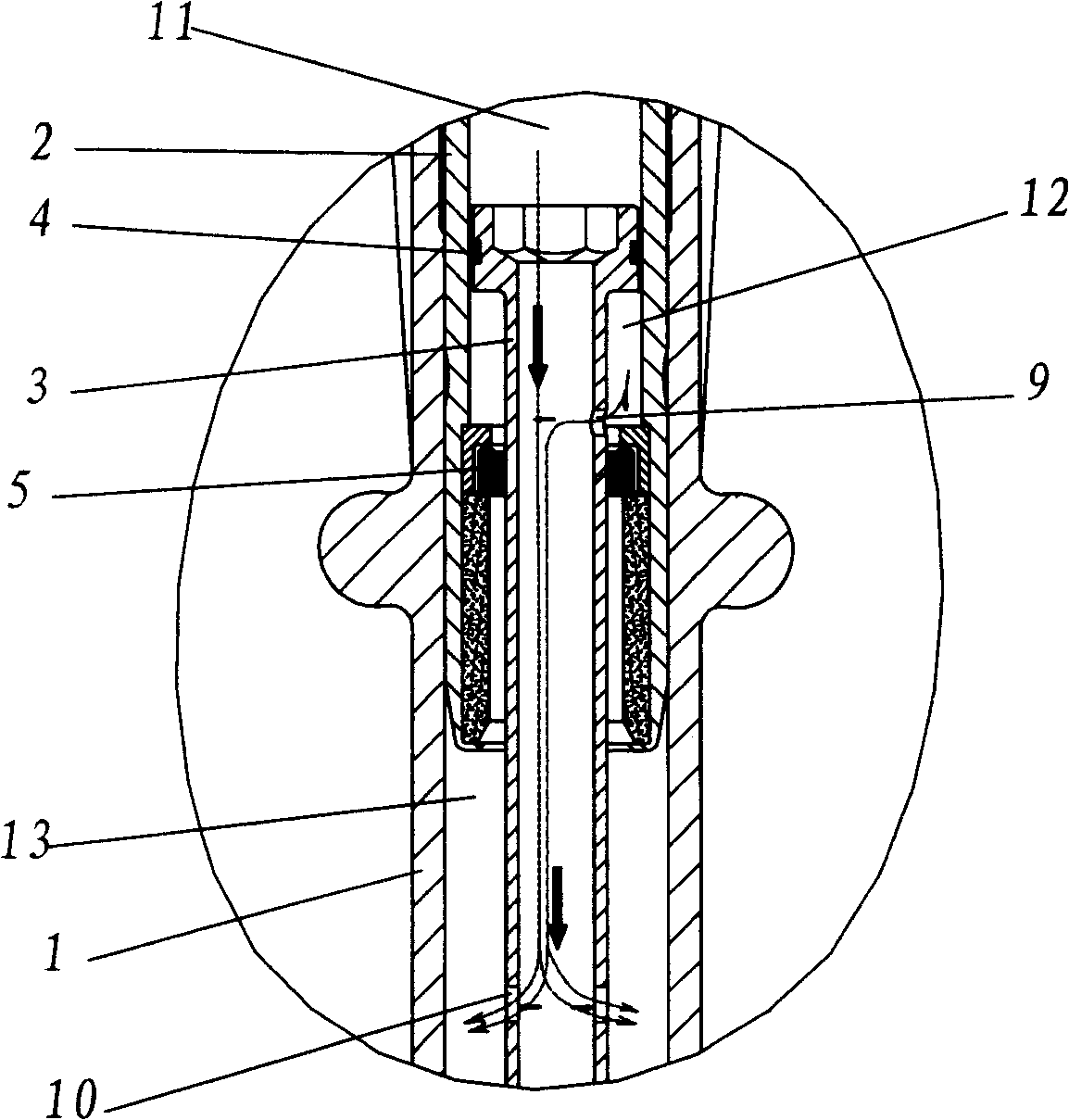

[0014] Such as figure 1 with figure 2 As shown, the present invention includes a bottom tube 1, a front fork tube 2 and a piston tube 3, the lower end of the front fork tube 2 is located in the upper end of the bottom tube 1, and the outer wall of the front fork tube 2 is slidingly fitted with the bottom tube 1 inner wall. The upper end of the piston tube 3 is located in the lower end of the front fork tube 2, and a sealing ring 4 is arranged between the two, and the sealing ring 4 is located in an annular groove on the outer wall of the piston tube 3. The outer diameter of the upper end of the piston tube 3 is larger than that of the remaining parts, thereby forming a ladder. A one-way flow valve 5 is arranged between the outer wall of the smaller outer diameter part of the piston tube 3 and the inner wall of the front fork tube 2, and passes through the one-way flow va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com