Process for preparing porous anode aluminium oxide mould of height ordered by mixed acid electrolyzing liquid

A technology of electrolyte preparation and alumina template, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of thin PAA film layer and small nanopore diameter of porous alumina film, and reduce the barrier layer Thickness, effect of improving orderliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific Embodiment 1: In this embodiment, a highly ordered porous anodized aluminum template is prepared according to the following steps: 1. Preparation of electrolyte: use a mixed acid of sulfuric acid and oxalic acid as the electrolyte, and the concentration of sulfuric acid in the electrolyte is 100-200g / L 1. The concentration of oxalic acid is 50-150g / L; 2. Aluminum sample pretreatment: the aluminum sample is degreased, deoxidized, and electrochemically polished in sequence; 3. Two-step anodizing: use a mixed acid of sulfuric acid and oxalic acid as electrolysis liquid, control the area ratio of cathode and anode to 2~1:1, the distance between cathode and anode is between 3~5cm, the oxidation temperature is -5~10℃, the oxidation voltage is 20~30V, and the oxidation time of the first step is 3~6h, the second oxidation time is 3~8h.

[0013] In this embodiment, after the first step of anodic oxidation, wet etching is used to remove the oxide film formed in the first...

specific Embodiment approach 2

[0015] Specific embodiment two: In this embodiment, a highly ordered porous anodized aluminum template is prepared according to the following steps:

[0016] 1. Electrolyte preparation: a mixed acid of sulfuric acid and oxalic acid is used as the electrolyte, and the electrolyte is composed of 100-200 g / L sulfuric acid and 50-150 g / L oxalic acid, and the solvents are all aqueous solutions.

[0017] 2. Aluminum sample pretreatment: Before anodizing, the sample needs to be degreased in acetone, then in NaOH solution, remove the natural oxide layer formed on the aluminum surface, and rinse with distilled water. Electrochemical polishing was carried out in a 1:4 (volume ratio) perchloric acid ethanol solution with a voltage of 10 V and a time of 5 min. The purpose of electrochemical polishing is to eliminate the surface scratches left by the aluminum sample during production and transportation, and to improve the order of the porous alumina film.

[0018] 3. Anodizing: In this em...

specific Embodiment approach 3

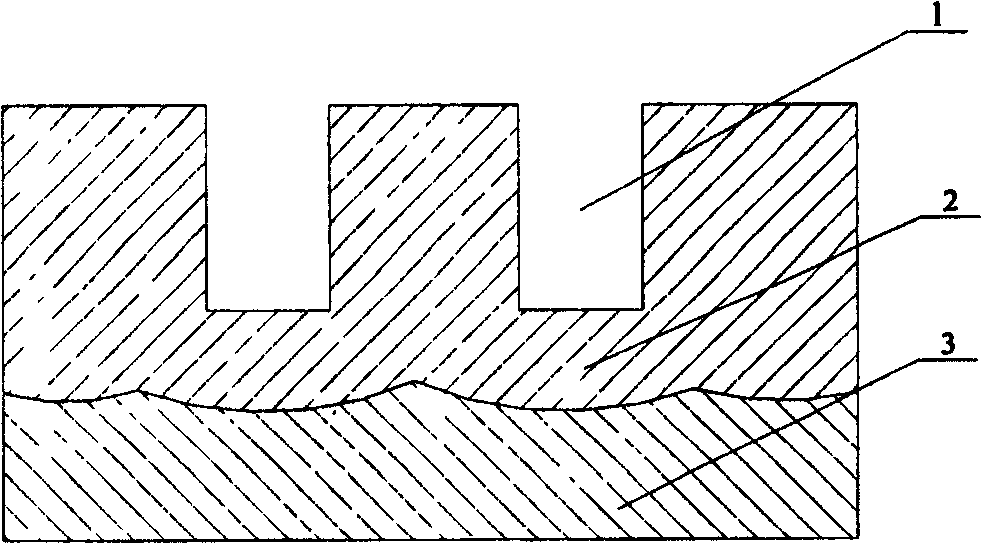

[0019] Specific embodiment three: In this embodiment, a highly ordered porous anodized aluminum template is prepared in this way: the mixed acid of sulfuric acid and oxalic acid is used as the electrolyte, and the electrolyte contains 100g / L sulfuric acid and 50g / L oxalic acid; the purity is 99.99% % of the aluminum sheet is subjected to two-step anodic oxidation after degreasing, deoxidizing layer, and electrochemical polishing. Use an aluminum sheet as the anode, graphite as the cathode, control the area ratio of the cathode and the anode to 2:1, the distance between the cathode and the anode is 3cm, the oxidation voltage is 22V, the first oxidation time is 5h, and the second anodic oxidation time is 4h. The prepared porous alumina membrane has a thickness of 53 μm, a nanopore diameter of 45-48 nm, and a barrier layer thickness of 23 nm. The cross-sectional view of the porous alumina template is shown in figure 1 , the order of nanopore size and arrangement see figure 2 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com