Bamboo wood compound floor board

A bamboo-wood composite and floor technology, which is applied in the direction of wood layered products, floors, and layered products, can solve the problems of floor bending deformation, low strength, hardness, and low service life, and achieves high quality and is not easy to bend and deform. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

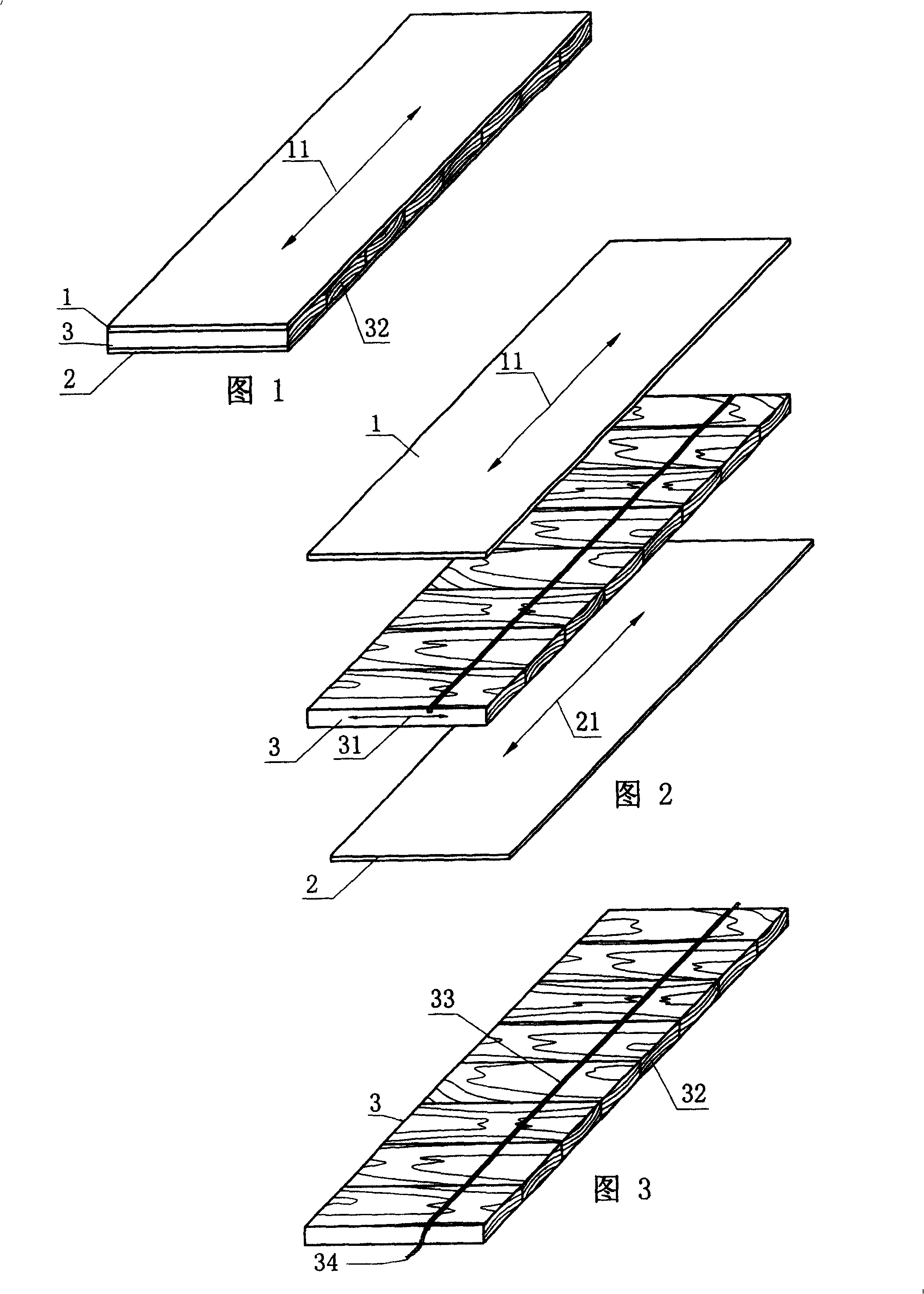

[0011] Refer to attached picture. The bamboo-wood composite floor provided by the present invention comprises a surface board 1, a bottom board 2, and an intermediate board 3. The surface board and the bottom board are made of heavy bamboo material, and the fiber orientations of adjacent layers cross, and the fibers of the surface board and the bottom board The orientations are consistent. In FIG. 2 , the reference number 11 is the fiber orientation of the surface layer 1 , the reference number 21 is the fiber orientation of the bottom layer 2 , and the reference number 31 is the fiber orientation of the middle layer 3 .

[0012] The surface board and the bottom board are made of the best heavy bamboo material of the same kind.

[0013] The middle laminate is spliced by wooden strips or planks 32, or spliced by wooden strips and planks. The heavy bamboo material can be made by dipping bamboo silk or bamboo chips or a mixture of bamboo silk and bamboo chips, mixing them, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com