Tin-containing alloy electroplating bath and electrolytic plating method using the electroplating bath

A technology of electrolytic electroplating and electroplating bath, which is applied in the field of tin-containing alloy electroplating bath and electrolytic electroplating using the electroplating bath, which can solve problems such as complex process and achieve the effects of inhibiting whisker generation, excellent oxidation resistance, and inhibiting discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

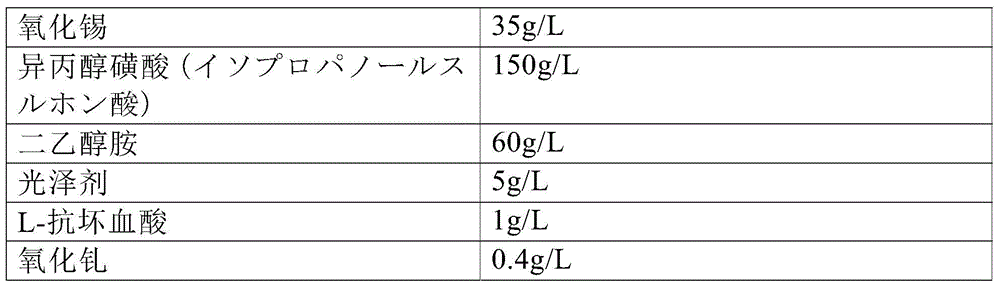

[0070] Prepare a plating bath containing the following ingredients at the concentrations shown in Table 1. The prepared electroplating bath exhibited strong acidity.

[0071] Table 1

[0072] (Form 1)

[0073]

[0074] In the above electroplating bath, electrolytic plating is performed on the iron-based base material and the copper-based base material. Immerse the substrate in an electroplating bath at 25-30°C, use the substrate as a cathode, and make the current density 0.5-5.0A / dm 2 The electric current flowed for 1 to 2 minutes, and a coating film with a film thickness of 2.0 μm was obtained. Based on the total mass of the coating film, the content of gadolinium in the obtained coating film was 0.10% by mass.

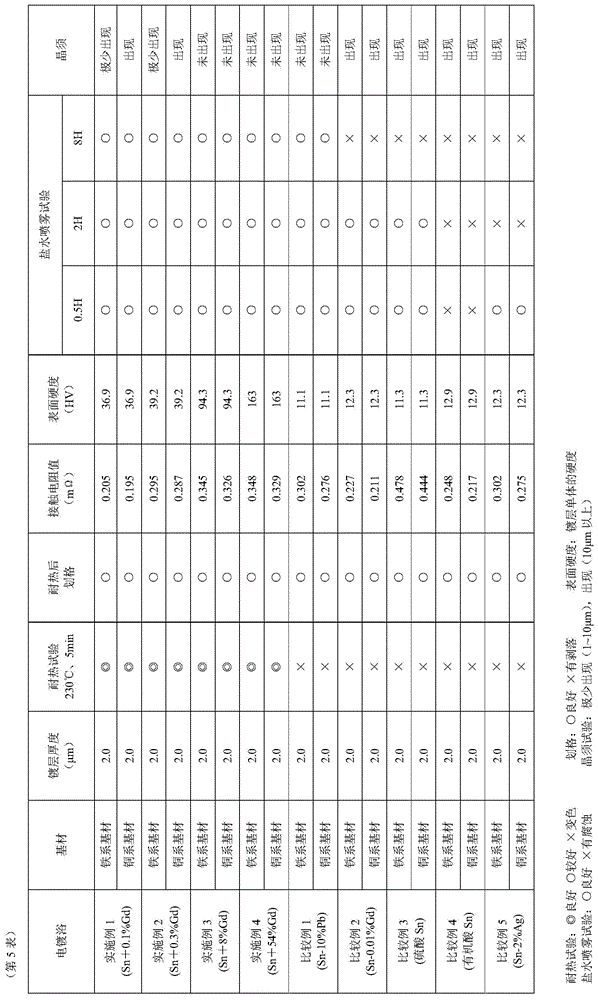

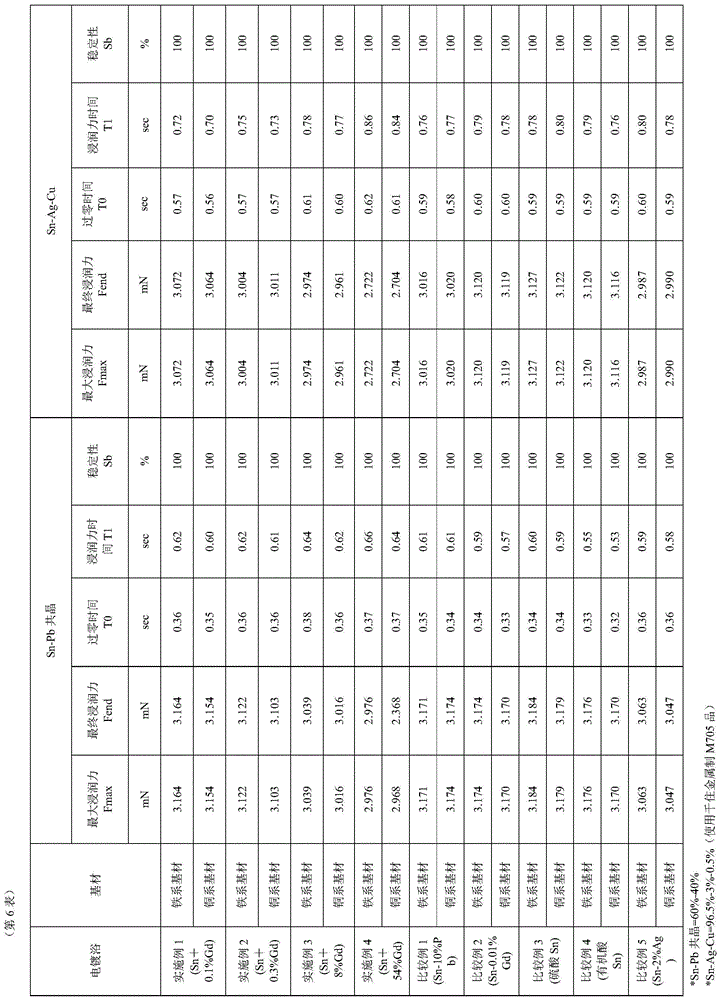

[0075] Tests were conducted regarding the heat resistance, contact resistance value, Vickers hardness and salt water durability of the obtained plating films. The results are shown in Table 5.

Embodiment 2

[0077] Prepare a plating bath containing the following ingredients at the concentrations shown in Table 2. The prepared electroplating bath exhibited strong acidity.

[0078] Table 2

[0079] (Form 2)

[0080] tin oxide 35g / L Isopropanolsulfonic acid 120g / L Diethanolamine 50g / L gloss agent 5g / L L-Ascorbic Acid 1g / L Gadolinium oxide 0.6g / L

[0081] In the above electroplating bath, electrolytic plating is performed on the iron-based base material and the copper-based base material. Immerse the substrate in an electroplating bath at 25-30°C, use the substrate as a cathode, and make the current density 0.5-5.0A / dm 2 The electric current flowed for 1 to 2 minutes, and a coating film with a film thickness of 2.0 μm was obtained. Based on the total mass of the coating film, the content of gadolinium in the obtained coating film was 0.30% by mass.

[0082] Tests were conducted regarding the heat resistance, contact resistance val...

Embodiment 3

[0084] Prepare a plating bath containing the following ingredients at the concentrations shown in Table 3. The prepared electroplating bath exhibited strong acidity.

[0085] table 3

[0086] (Form 3)

[0087] tin oxide 35g / L Isopropanolsulfonic acid 120g / L Diethanolamine 50g / L gloss agent 5g / L L-Ascorbic Acid 1g / L Gadolinium oxide 9.5g / L

[0088] In the above electroplating bath, electrolytic plating is performed on the iron-based base material and the copper-based base material. Immerse the substrate in an electroplating bath at 25-30°C, use the substrate as a cathode, and make the current density 0.5-5.0A / dm 2 The electric current flowed for 1 to 2 minutes, and a coating film with a film thickness of 2.0 μm was obtained. Based on the total mass of the coating film, the content of gadolinium in the obtained coating film was 8.00% by mass.

[0089] Tests were conducted regarding the heat resistance, contact resistance val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com