Technology method of anti-ESD integrated SOI LIGBT device unit

A process method and device technology, applied in the field of SOI CMOSVLSI process realization, can solve the problems of increasing volume, weight and cost, reducing reliability, etc., and achieve the effect of improving anti-ESD performance and excellent anti-ESD performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

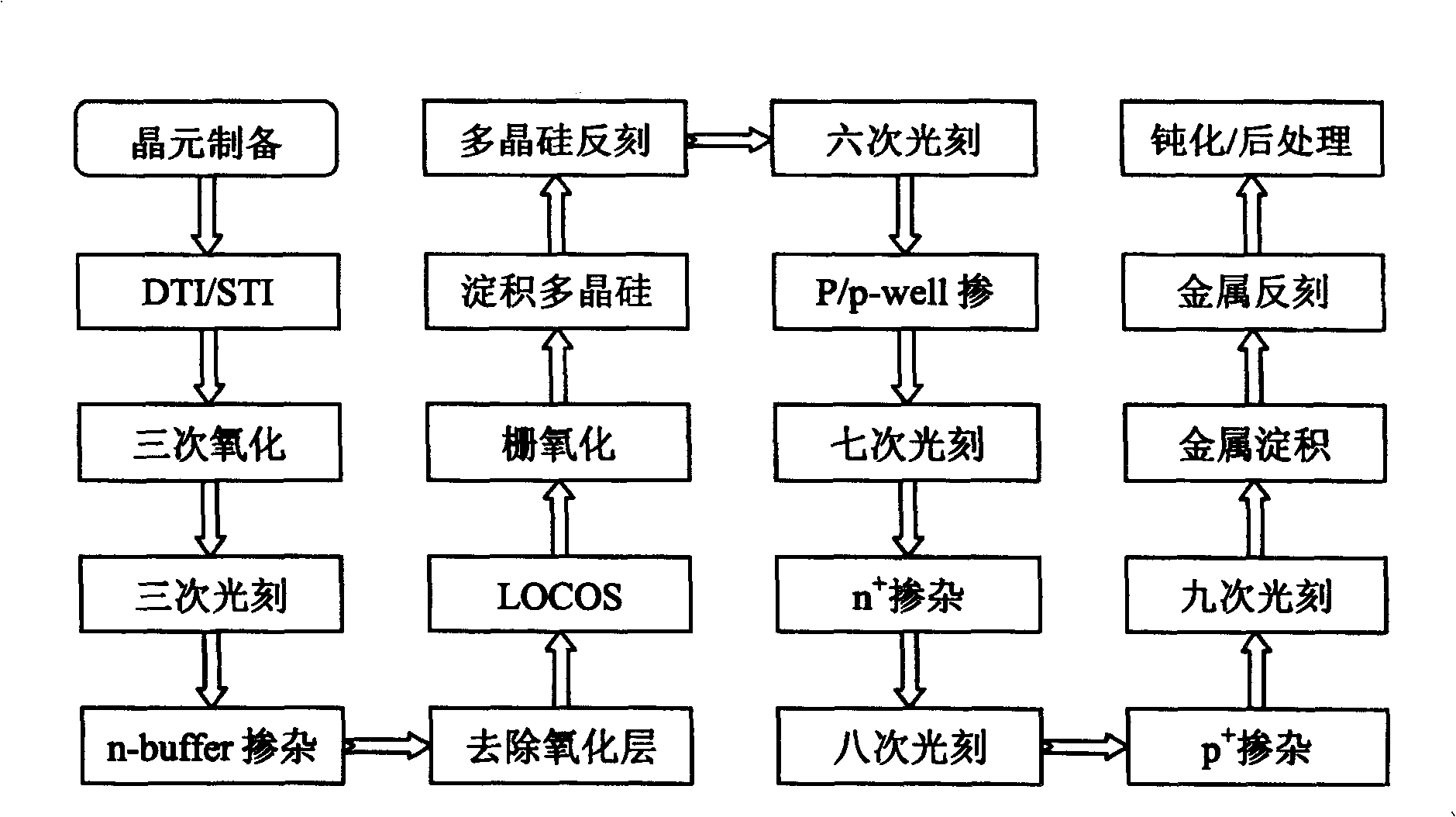

[0026] like figure 1 and figure 2 As shown, the SOICMOS VLSI process implementation method of the SOI LIGBT device structure of the integrated anti-ESD diode comprises the following steps:

[0027] 1. Form a buried insulating layer at a certain depth below the surface of one side of a silicon wafer of a certain conductivity type, and completely isolate the silicon wafer into two semiconductor regions, of which the thicker side is used as the substrate, and the thinner side is used as the substrate. One side has a certain conductivity type and doping concentration distribution, which is used as the top silicon film for making devices and circuits.

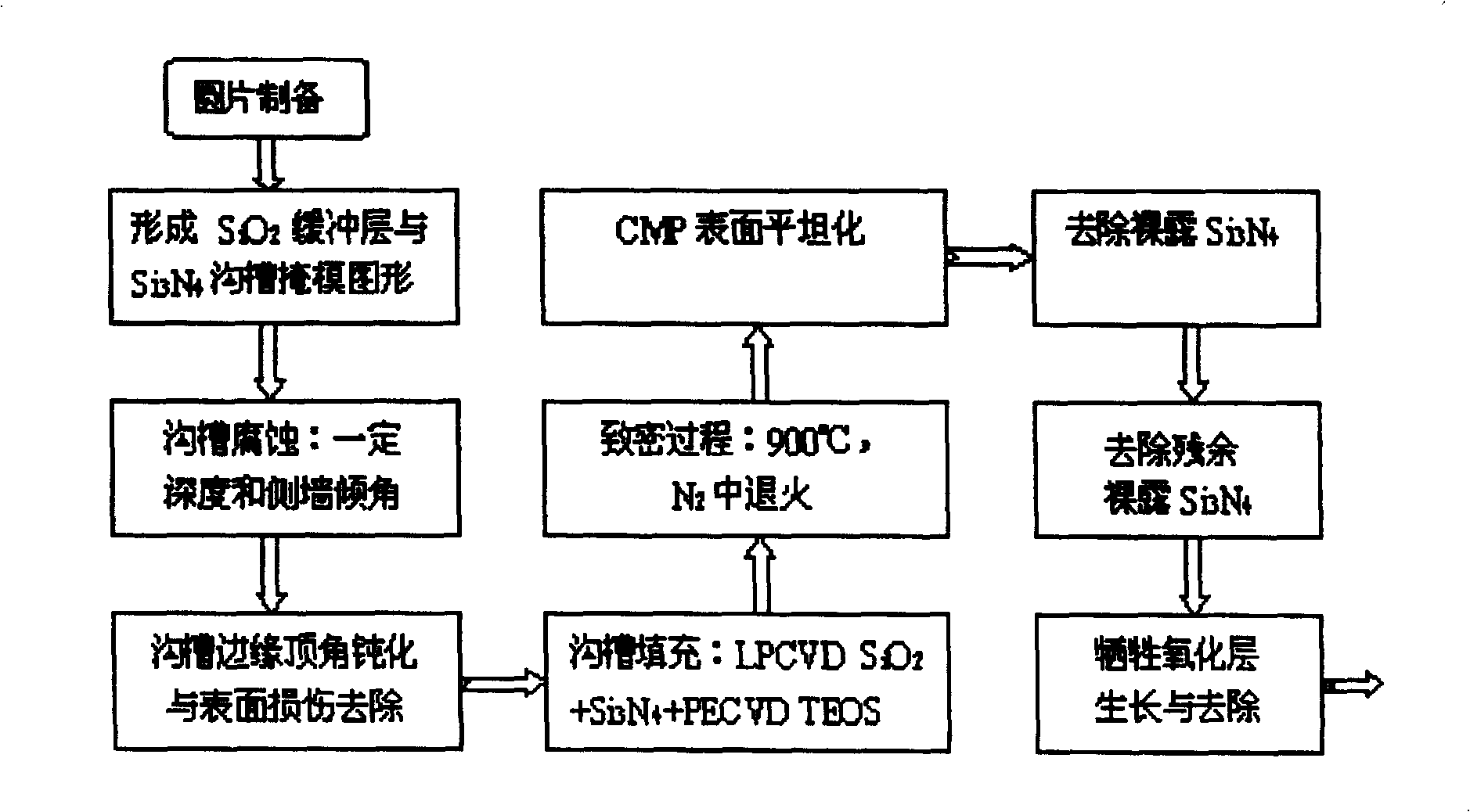

[0028] 2. The polished top silicon film is oxidized for the first time, nitrided for the first time, and etched for the first time to form an isolation area window, and the silicon film in the isolation area is formed by STI (shallow trench isolation technology) / DTI (deep trench isolation technology) to form an isolation oxide la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com