Nano vacuum restoration agent and its preparation and application

A repairing agent and vacuum technology, applied in the field of nano-vacuum repairing agent and its preparation and application in the field of vacuum electronic devices, can solve the problems of serious volatilization, complex temperature resistance of volatile gas, etc., and achieve high bonding strength and good temperature resistance The effect of sex and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

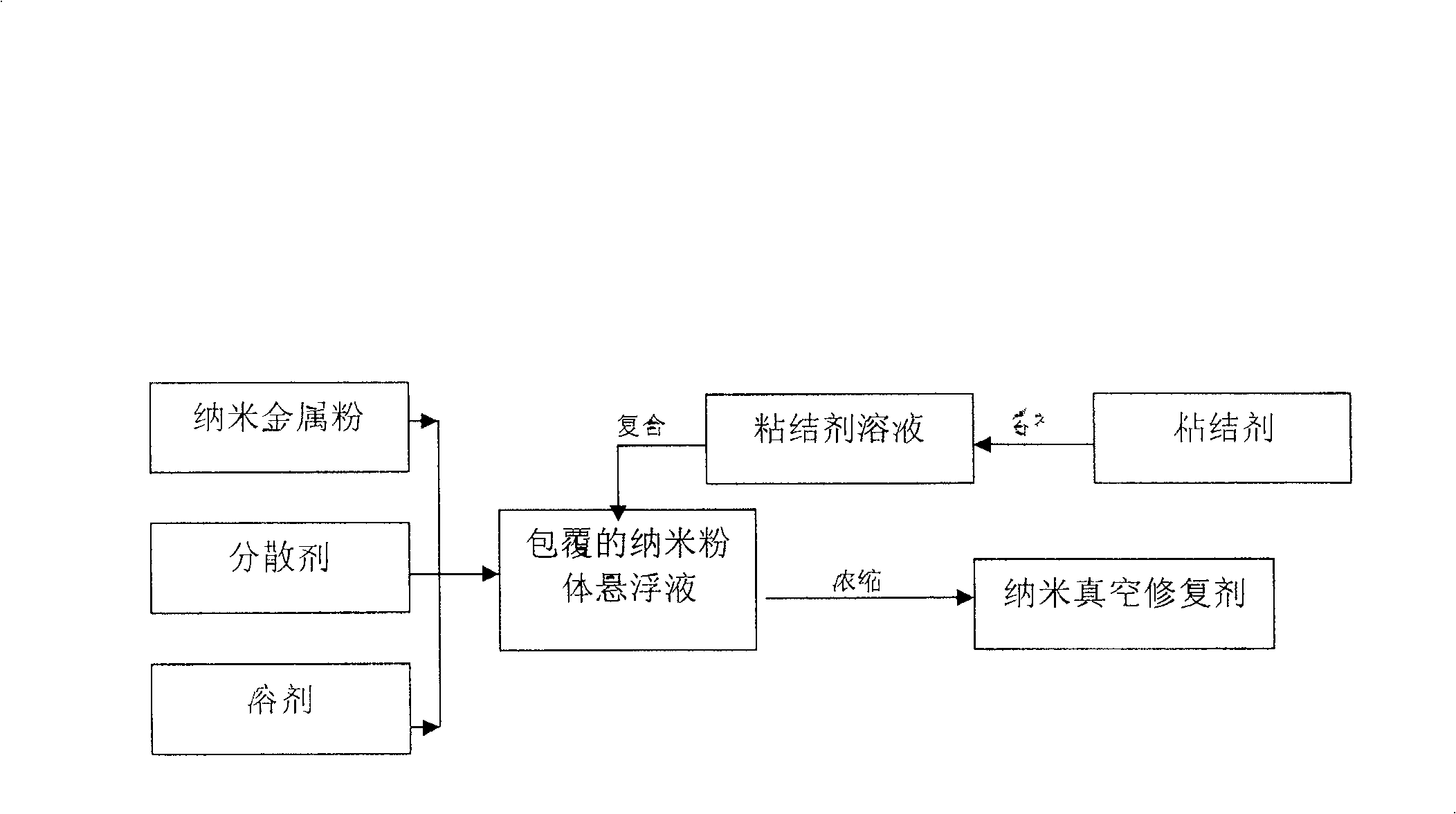

Method used

Image

Examples

Embodiment 1

[0037] 1 Composition (wt%): Ultrafine In powder (particle size 60-80nm nearly spherical): 35% PVP: 6%

[0038] Epoxy: 59%

[0039] Ethanol: 500ml

[0040] 2. Preparation process of nanometer vacuum repair agent:

[0041] (1) Ultrafine In powder 3.5g and PVP 0.6g were ultrasonically dispersed in 100ml ethanol for 25min according to the ratio to obtain a uniformly dispersed nano metal powder suspension.

[0042] (2) Dissolve 5.9g of epoxy resin in 400ml of ethanol completely to make a binder solution.

[0043] (3) Mix the binder solution and the nano-metal powder suspension, and disperse evenly by ultrasonic, and the ultrasonic time is 30 minutes to obtain a mixed solution.

[0044] (4) The mixed solution is placed in a vacuum oven with a constant temperature of 80°C and kept at 10 -1 Concentrate under vacuum for 10-12 hours until ethanol evaporates completely. The paste-like nano-vacuum repair agent can be obtained.

[0045] 3 Application of Nano V...

Embodiment 2

[0048] 1 Composition (wt%): Ag 70 In 15 sn 11 Cu 4 Metal powder (subscript is weight percentage, the same below) (particle size 20-60nm nearly spherical): 40%

[0049] PvP: 20%

[0050] Epoxy resin: 40%

[0051] Ethanol: 750ml

[0052] 2. Preparation process of nanometer vacuum repair agent:

[0053] (1) Ultrasonic dispersion of 4 g of silver alloy nano-powder and 2 g of PVP in 350 ml of ethanol according to the ratio for 30 min to obtain a uniformly dispersed nano-metal powder suspension.

[0054] (2) Dissolve 4g of epoxy resin weighed in 400ml of ethanol completely to make a binder solution.

[0055] (3) Mix the binder solution and the nano-metal powder suspension, and disperse evenly by ultrasonication, and the ultrasonication time is 15 minutes. to obtain a mixed solution.

[0056] (4) The mixed solution is placed in a vacuum oven with a constant temperature of 80°C and kept at 10 -1 Concentrate under vacuum for 10-12 hours until ethanol evaporates completely. T...

Embodiment 3

[0060] 1 Composition (wt%): Ag 64 Cu 24 sn 8 Metal powder (particle size 20-80nm nearly spherical): 45%

[0061] CTAB: 30%

[0062] Epoxy: 25%

[0063] Acetone: 600ml

[0064] 2. Preparation process of nanometer vacuum repair agent:

[0065] (1) Ultrasonic disperse 4.5g of silver alloy nanopowder and CTAB3g in 350ml acetone for 25min according to the ratio to obtain a uniformly dispersed nanometal powder suspension.

[0066] (2) Dissolve the weighed 25g of epoxy resin in 250ml of acetone completely to form a binder solution.

[0067] (3) Mix the binder solution and the nano-metal powder suspension, and disperse evenly by ultrasonication, and the ultrasonication time is 15 minutes. A mixed solution was obtained.

[0068] (4) The mixed solution is placed in a vacuum oven with a constant temperature of 80°C and kept at 10 -1 Concentrate under vacuum for 10-12 hours until the acetone evaporates completely. The paste-like nano-vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com