Natural structure type floorboard prepared from solid wood

A technology of natural structure and solid wood floor, applied in building structure, floor, building, etc., can solve problems such as deformation and instability of solid wood floor, and achieve the effect of saving wood resources, saving wood and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

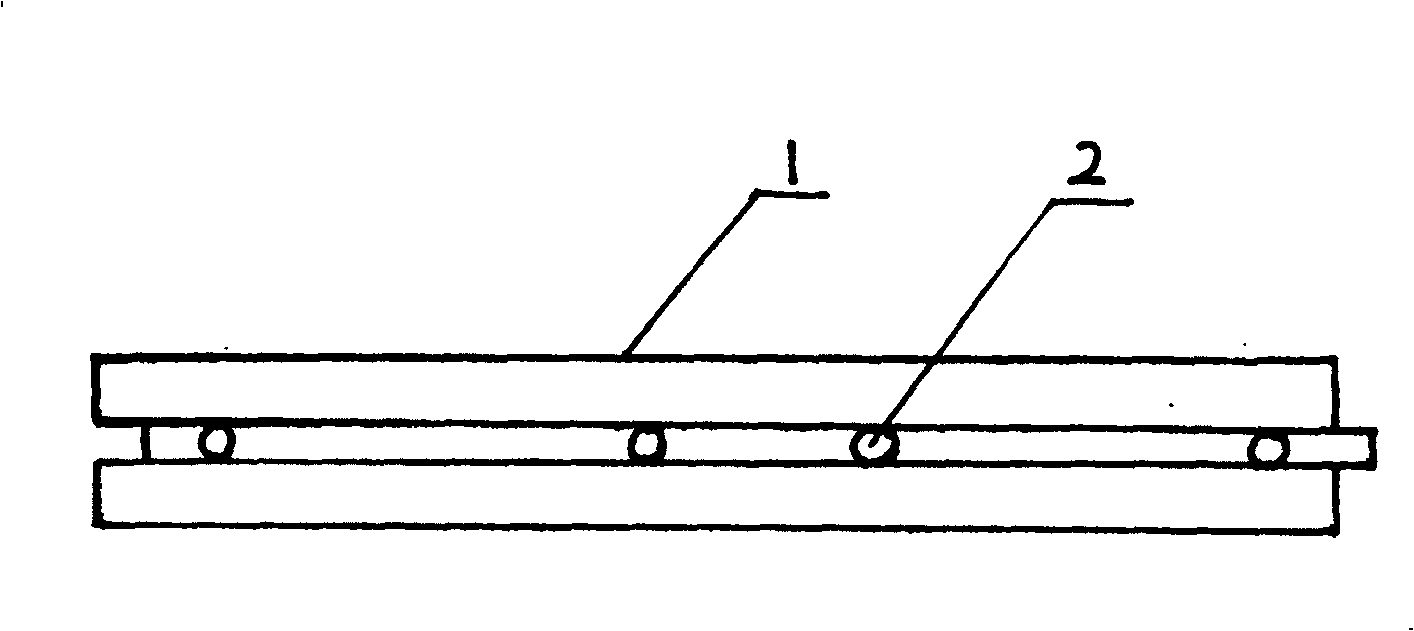

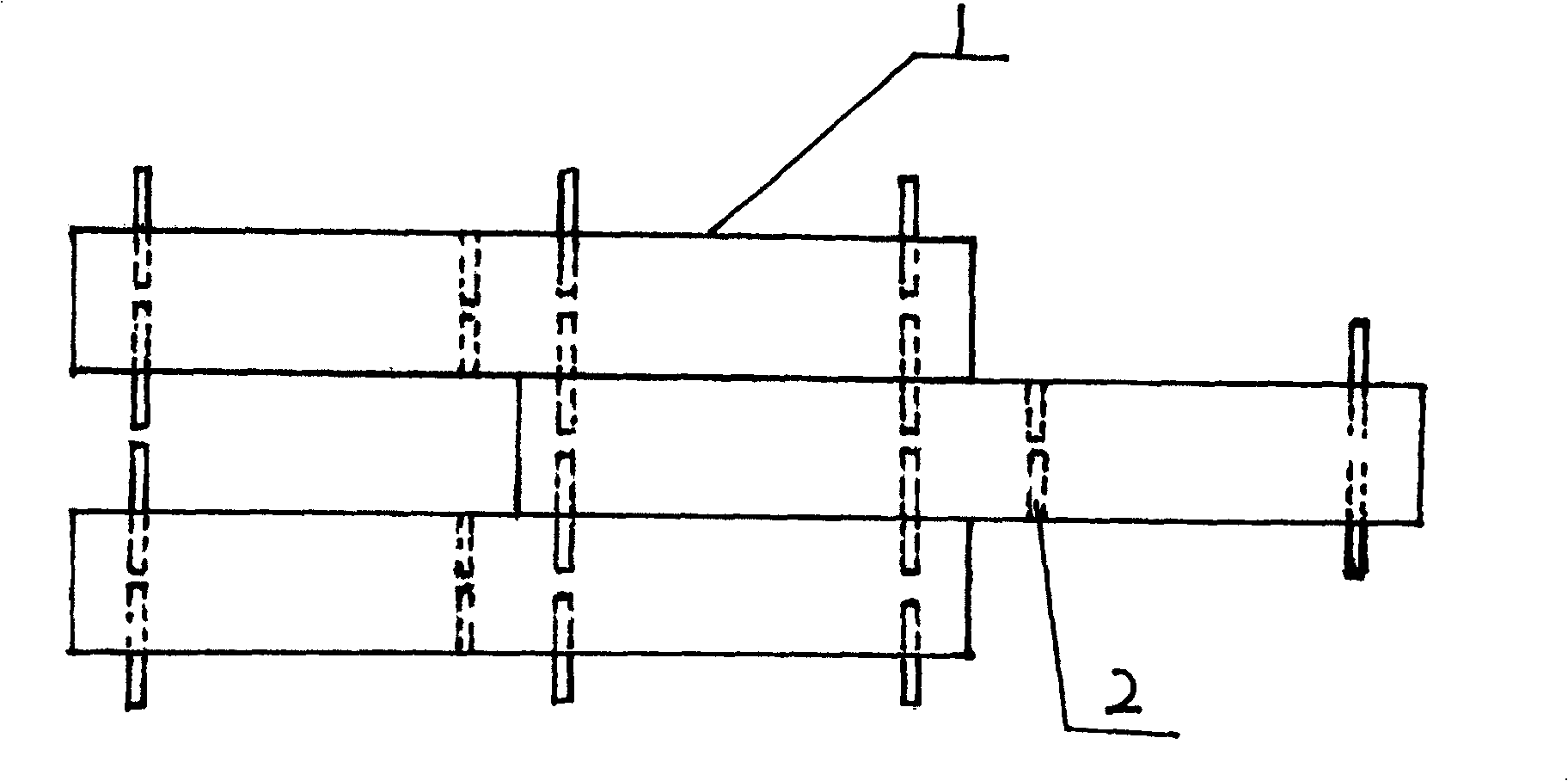

[0015] figure 1 , figure 2 In the illustrated example of implementation, four pairs of transversely inward holes are provided on the reference line of the grooves and tenons on both sides of the wooden floor body 1 in the longitudinal direction. The four pairs of holes are more conducive to cutting the central longitudinal fibers of the wooden floor body. In order to facilitate processing and installation, these four pairs of holes are blind holes with the same depth and can be used as pin holes 2. 1. Firmness of the connection; if the four pairs of pin holes are not distributed according to a certain size on the wooden floor body 1, it can only be ensured that the wooden floor body 1 is aligned and installed side by side between the blocks. In order to make the installed wooden floor body 1 have For better aesthetics and better stability and firmness, the wood floor body 1 often needs to be misplaced for installation, so the four pairs of pin holes must be distributed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com