Tie-down compensation structure for an elevator system

A lifting system and a technology connected to it, applied in the field of lifting systems, can solve problems such as unresolved counterweight jumping, and achieve the effect of reducing the possibility of counterweight jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

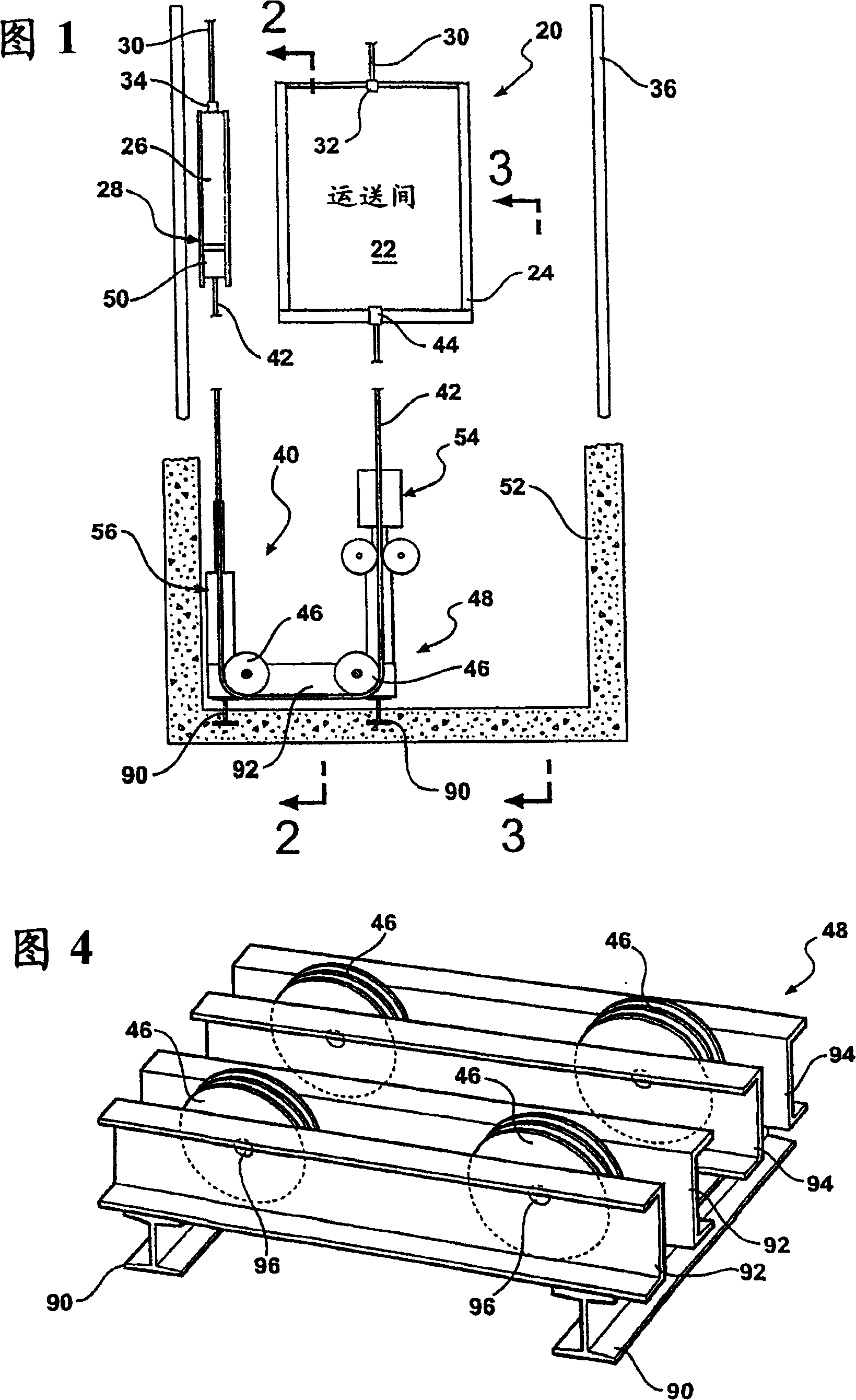

[0018] Figure 1 schematically shows an elevator system 20 comprising a cabin 22 supported on a frame 24 by conventional means. The counterweight 26 is provided with an associated frame 28 . Carriers 30, such as ropes or belts, support the weight of the cabin 22 and counterweight 26 in a conventional manner. Conventional attachment structures 32 secure appropriate portions of the carrier 30 to the bay frame 24 . Similarly, conventional attachment structures 34 secure appropriate portions of the carrier 30 to the counterweight frame 28 . The apparatus (not shown) includes at least one drive pulley for moving the carrier 30 so that the cabin and counterweight correspondingly move within the hoistway 36 to move the cabin 22 between the platforms of the building.

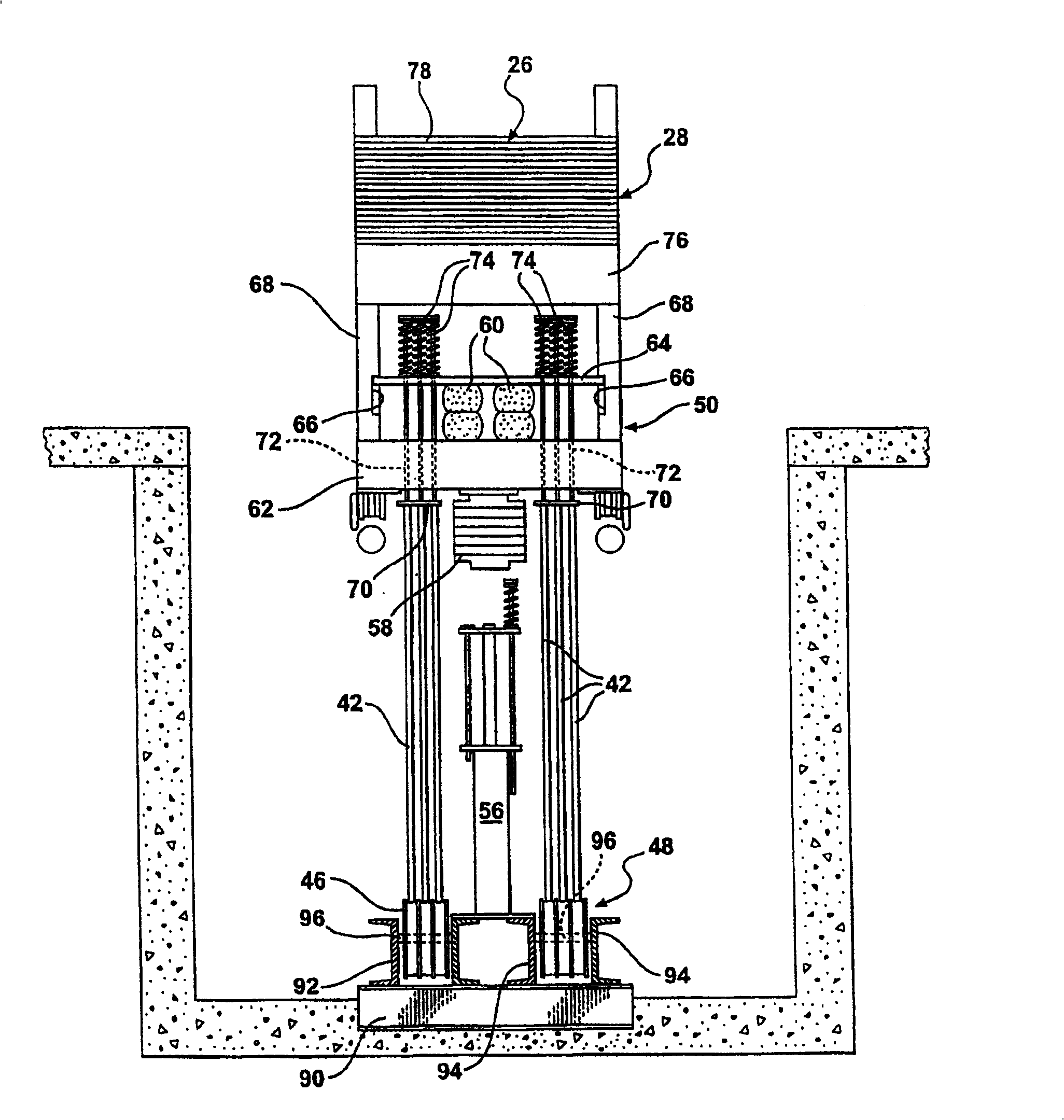

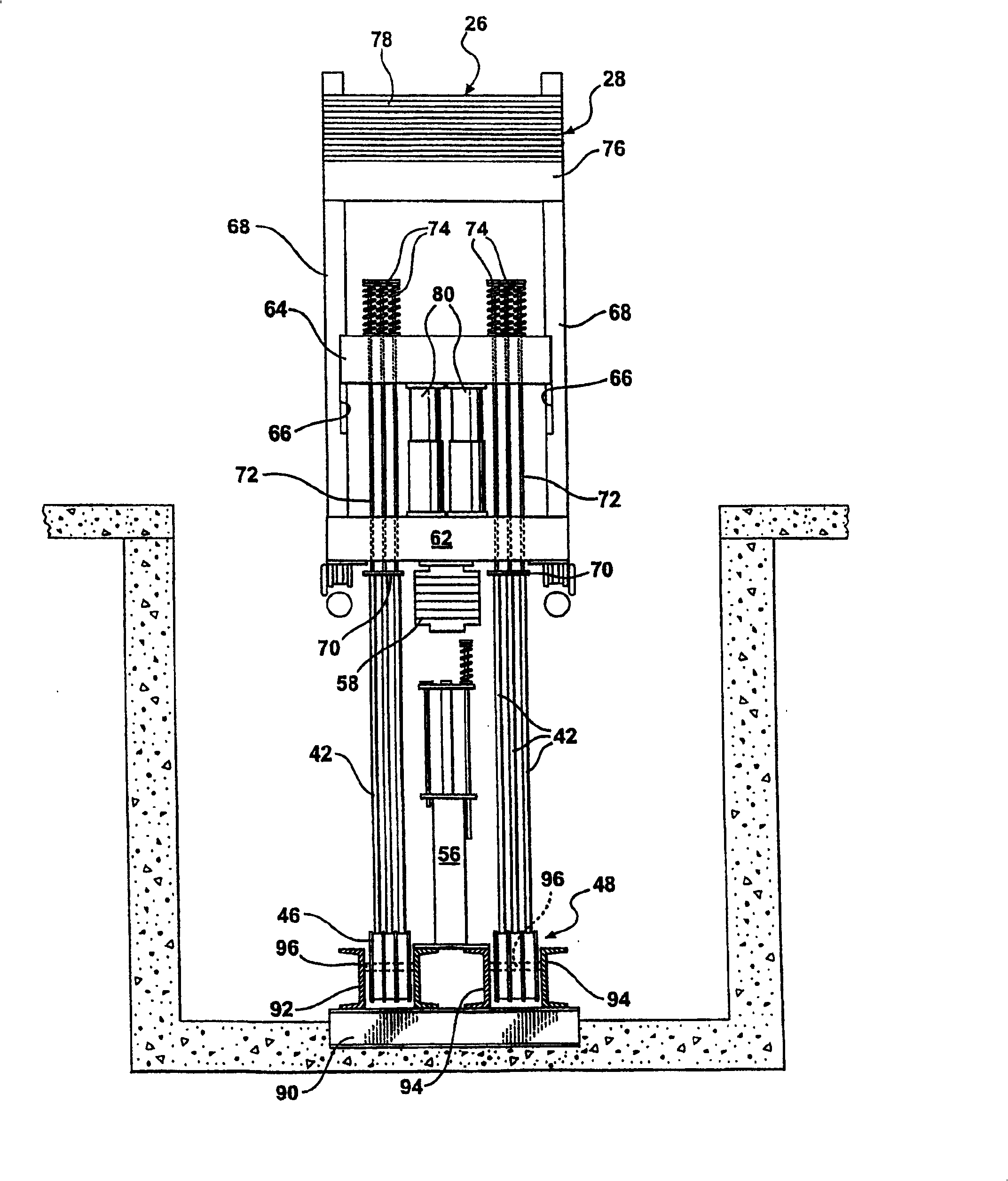

[0019] The illustrated embodiment includes a tension and compensation mechanism 40 . An elongated tension member 42 extends between the carrier bay 22 and the counterweight 26 . In one example, tensioning member 42 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com