Method for mfg. printed circuitboard

A technology for printed circuit boards and manufacturing methods, applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., can solve problems such as pressing on printed circuit boards, achieve the effect of reducing surface differences and avoiding pool effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

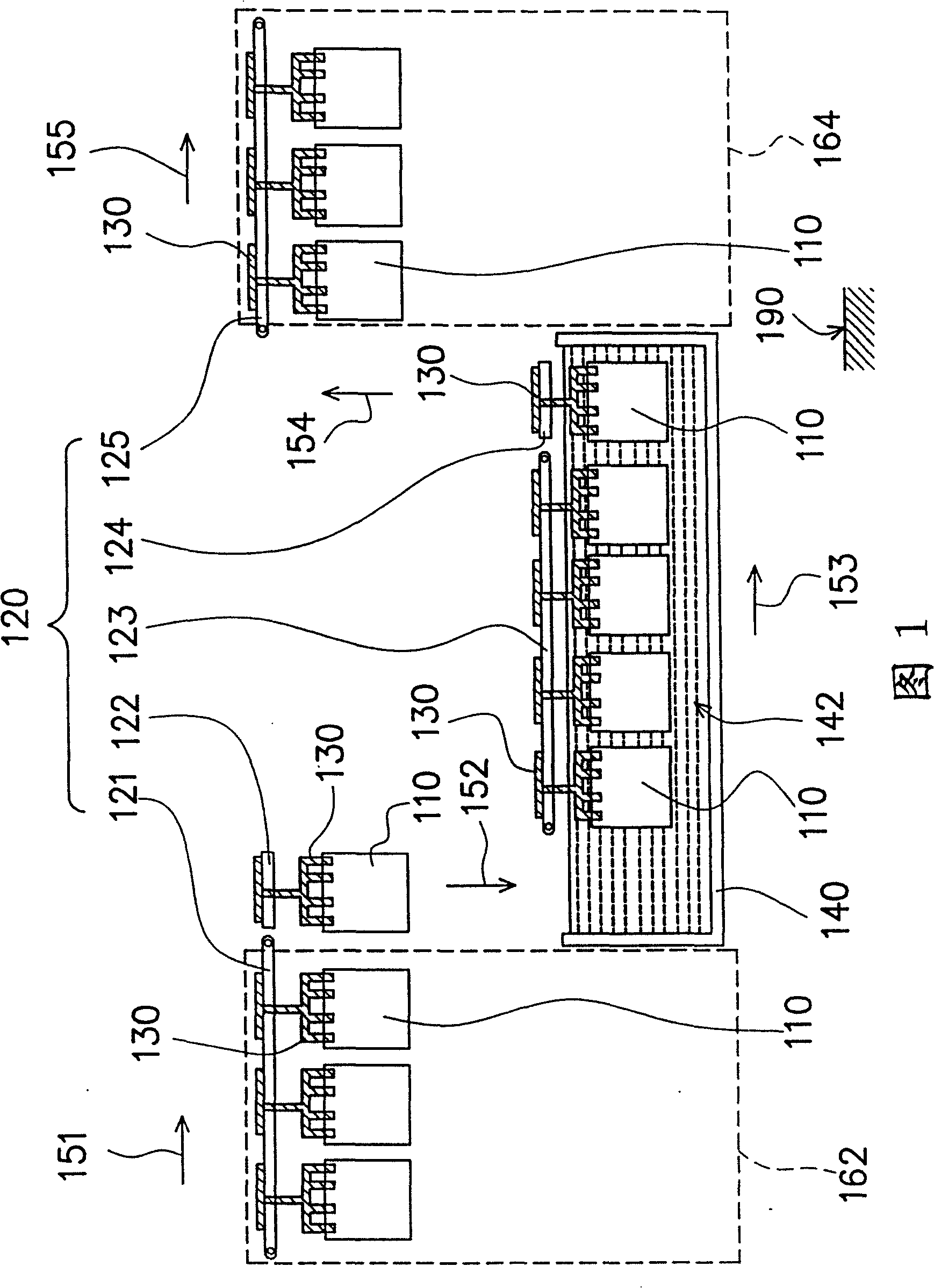

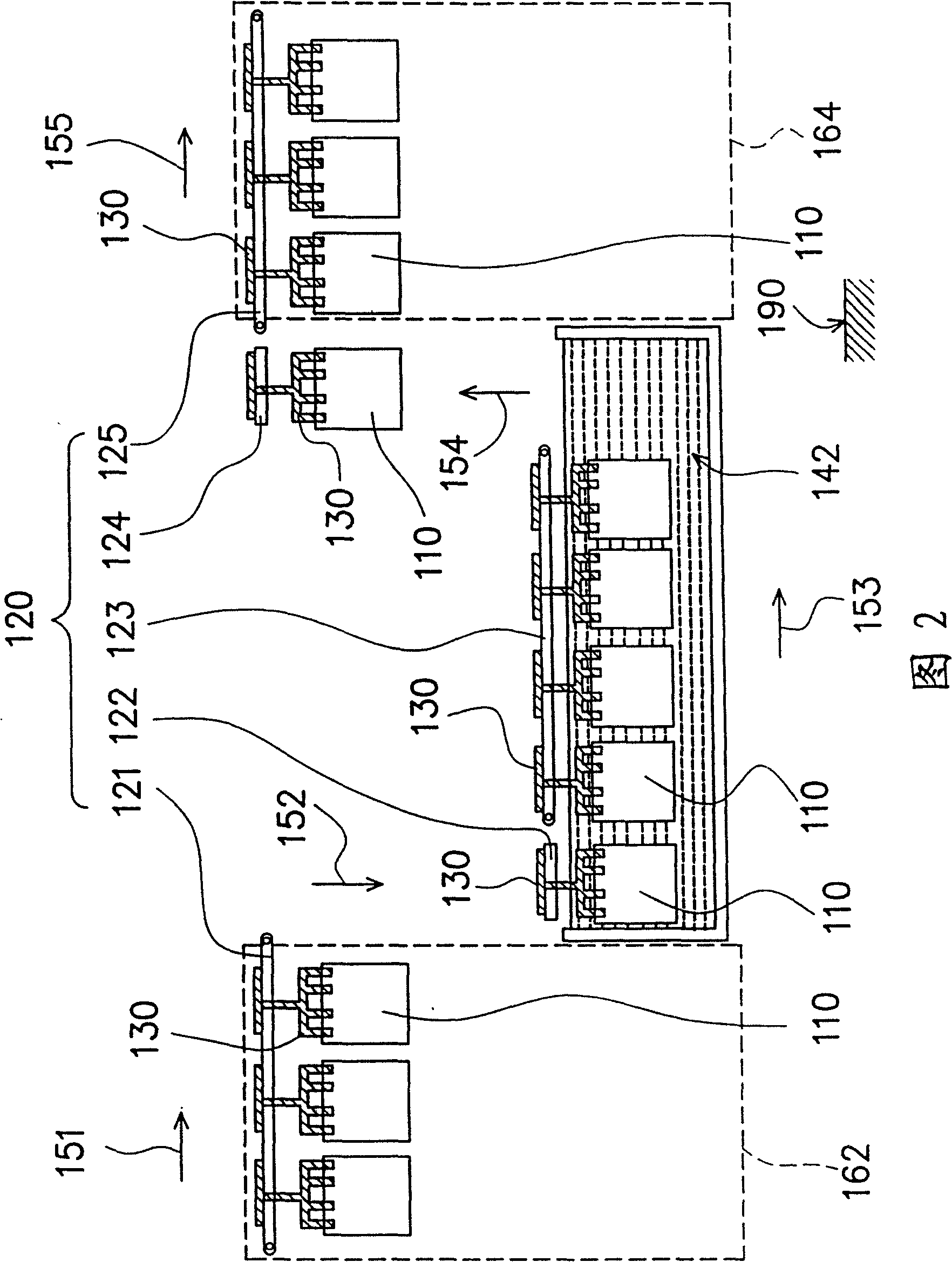

[0036] The specific manufacturing method, steps, features and effects of the manufacturing method of the printed circuit board according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0037] Generally speaking, when making printed circuit boards, they will first go through a water washing step to remove the chemicals remaining on the printed circuit board in the previous steps, and then proceed to the desmear process and chemical copper plated through-hole process. (PTH) or shadow (shadow) process, etc., followed by a water washing step to remove the chemicals remaining on the printed circuit board in the previous desmear process, chemical copper plated through hole process or shadow process .

[0038]Please refer to FIG. 1 and FIG. 2 , which are schematic diagrams of a method for manufacturing a printed circuit board according to a preferred embodiment of the present invention. In a preferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com