Device and method for applying liquid medium to roll and/or to rolled material and/or for removing liquid medium

A liquid medium, roller technology, applied in the field of applying and/or removing liquid medium, which can solve the problems of being expensive, interfering with drainage, not very effective, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

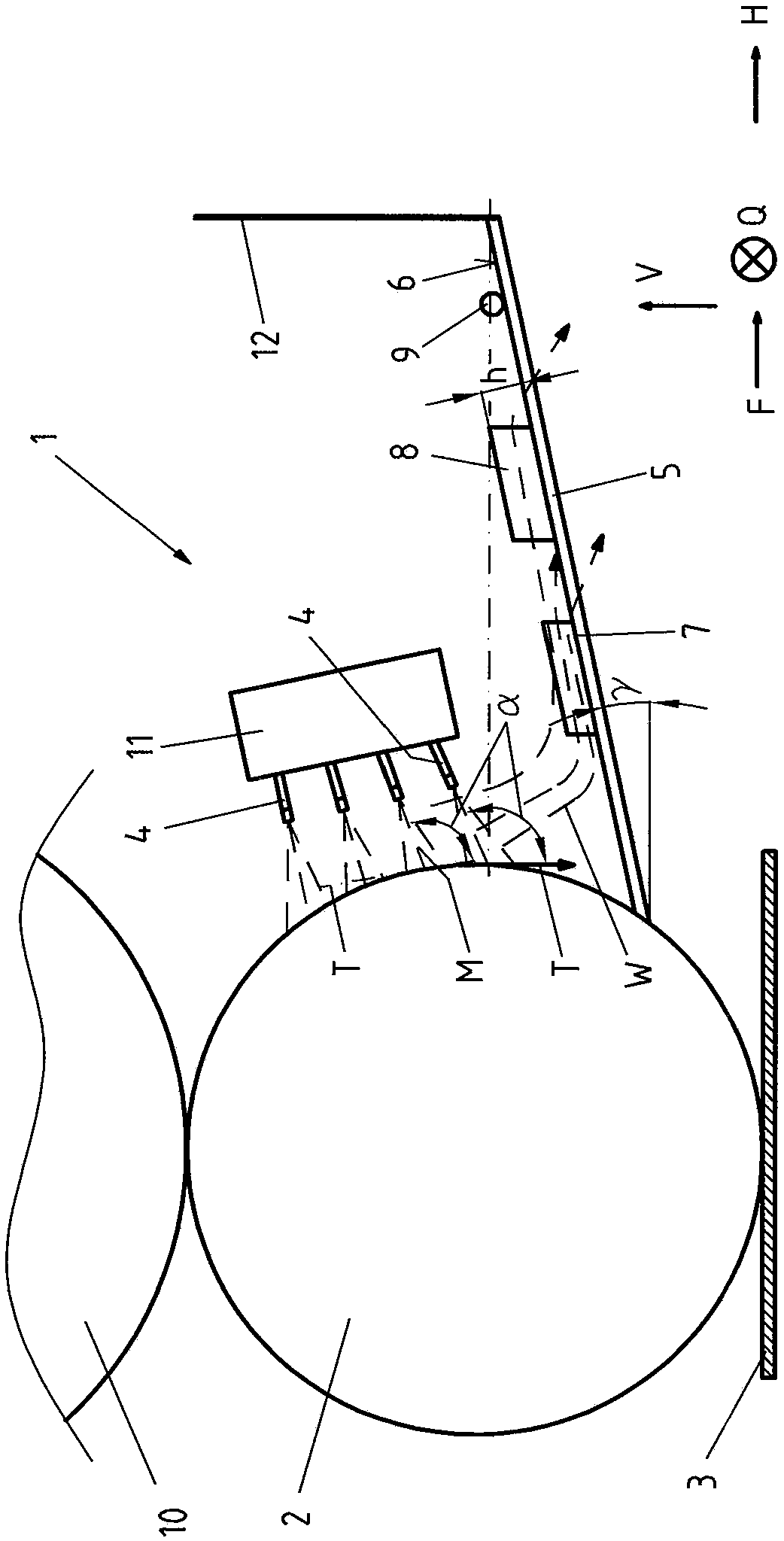

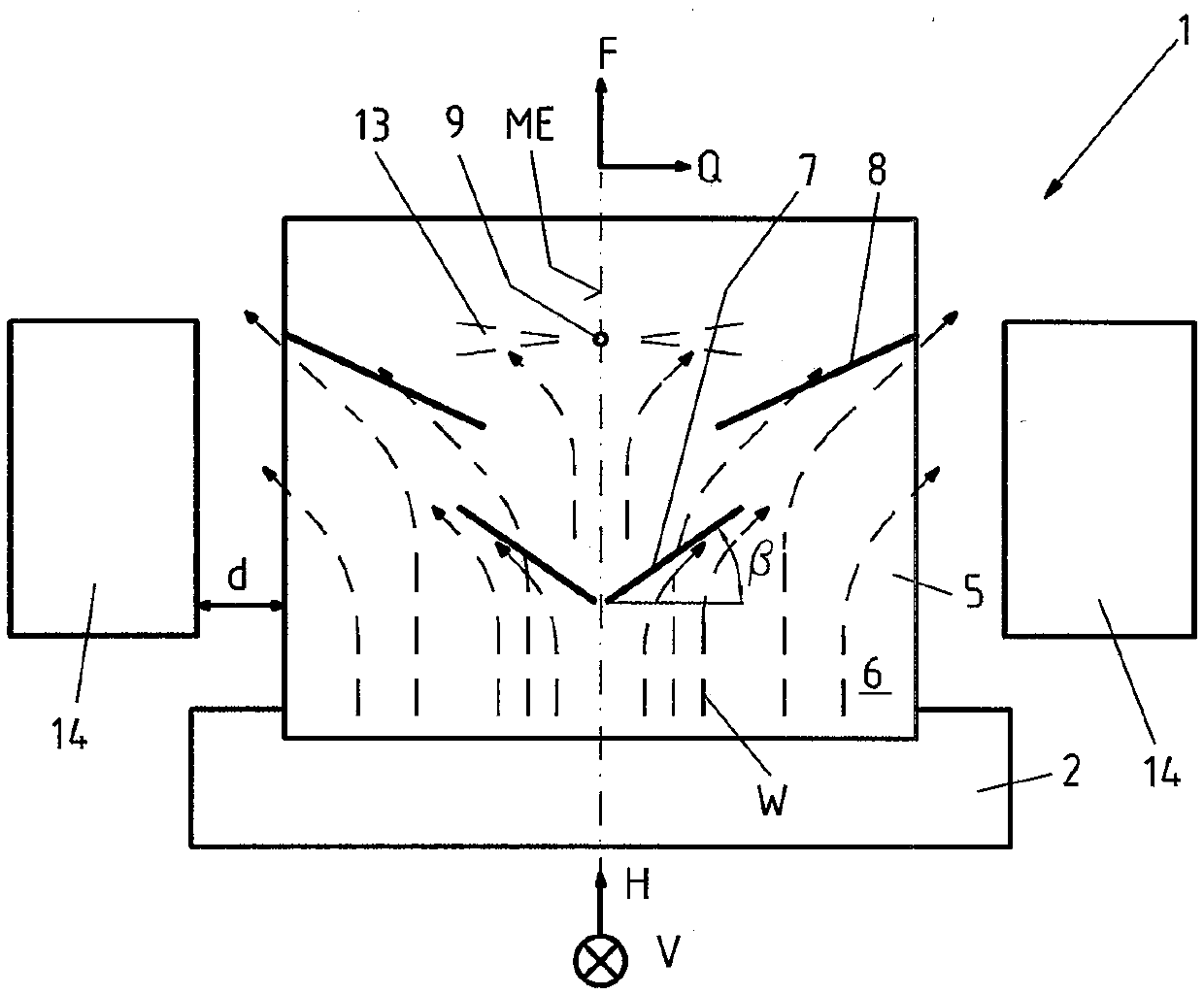

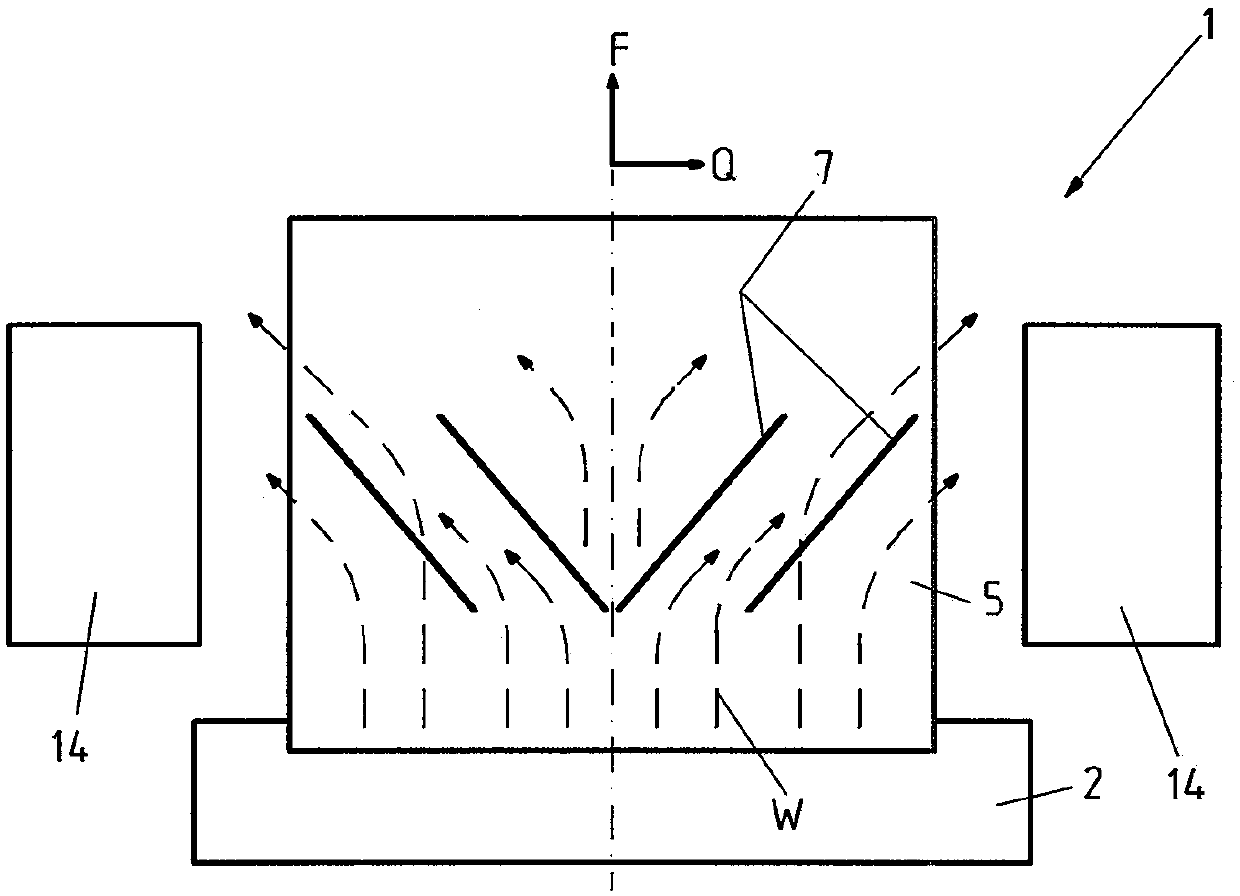

[0029] exist figure 1 and figure 2 A side view and a top view of a work roll 2 for applying water W to a roll stand and a device 1 for removing water W are diagrammatically depicted in . The work rolls 2 are supported by backup rolls 10 . The work rolls 2 roll the rolling stock 3, which moves in the conveying direction F. The conveying direction F corresponds to the direction of the horizontal line H. FIG.

[0030] The device 1 comprises a plurality of nozzles 4 which are arranged in a water-cooled beam 11 . Water W is sprayed onto the surface of the work roll 2 through the nozzle 4 . In order to divert the sprayed water and to prevent the water from flowing unhindered onto the strip, a scraper element 5 (wiper blade) is provided which is inclined at an angle γ relative to the horizontal. On the upper surface 6 of the plate element 5 are arranged guide elements 7 , 8 (in particular welded) which enable the water W to be guided laterally from the plate element 5 in a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com