Equipment capable of forming homogenous etching liquid film and etching device

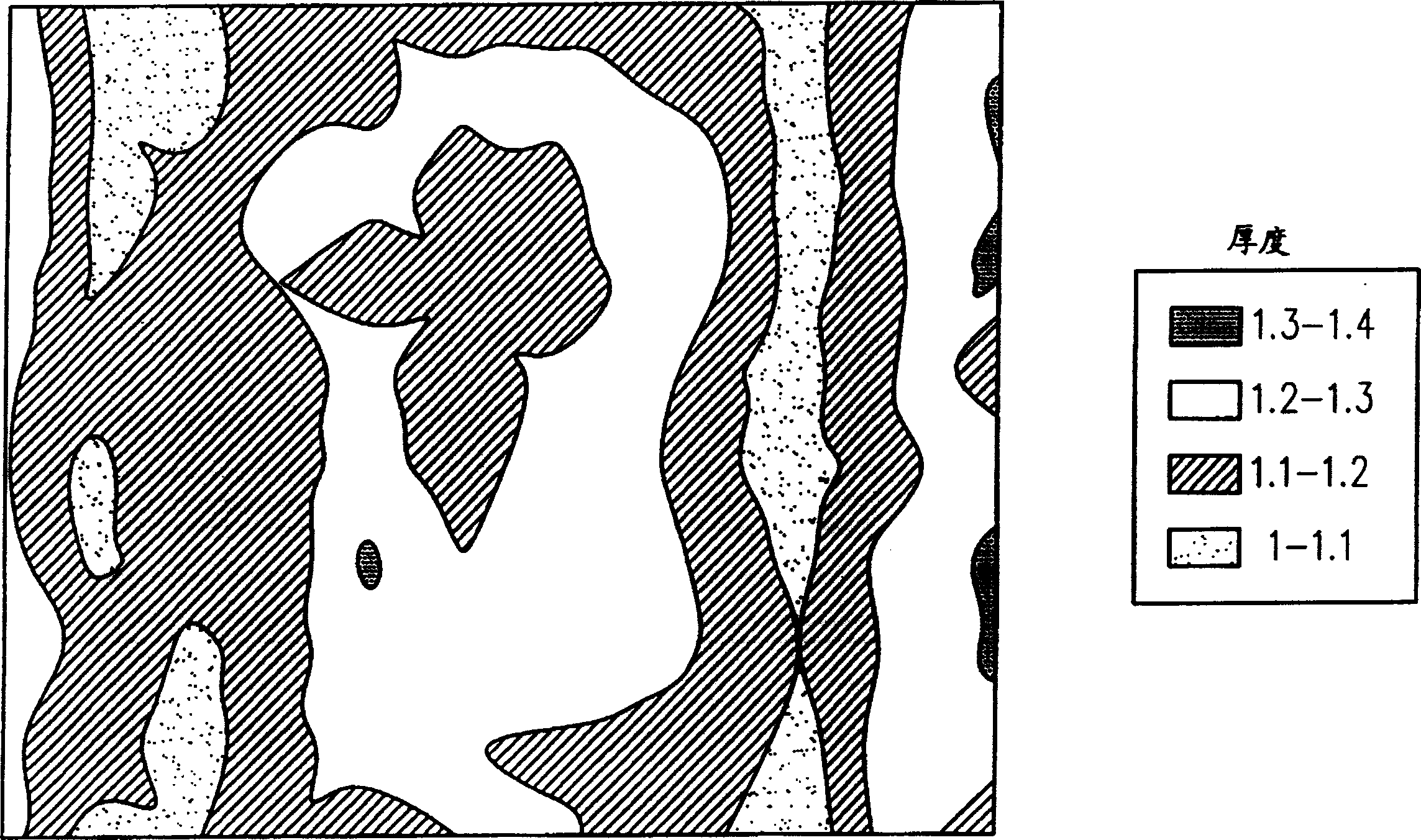

A technology of etching solution and etching device, which is applied to spray device, removing conductive material by chemical/electrolytic method, etc., can solve the problems of uneven thickness of etching solution film and hindering the flow of etching solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

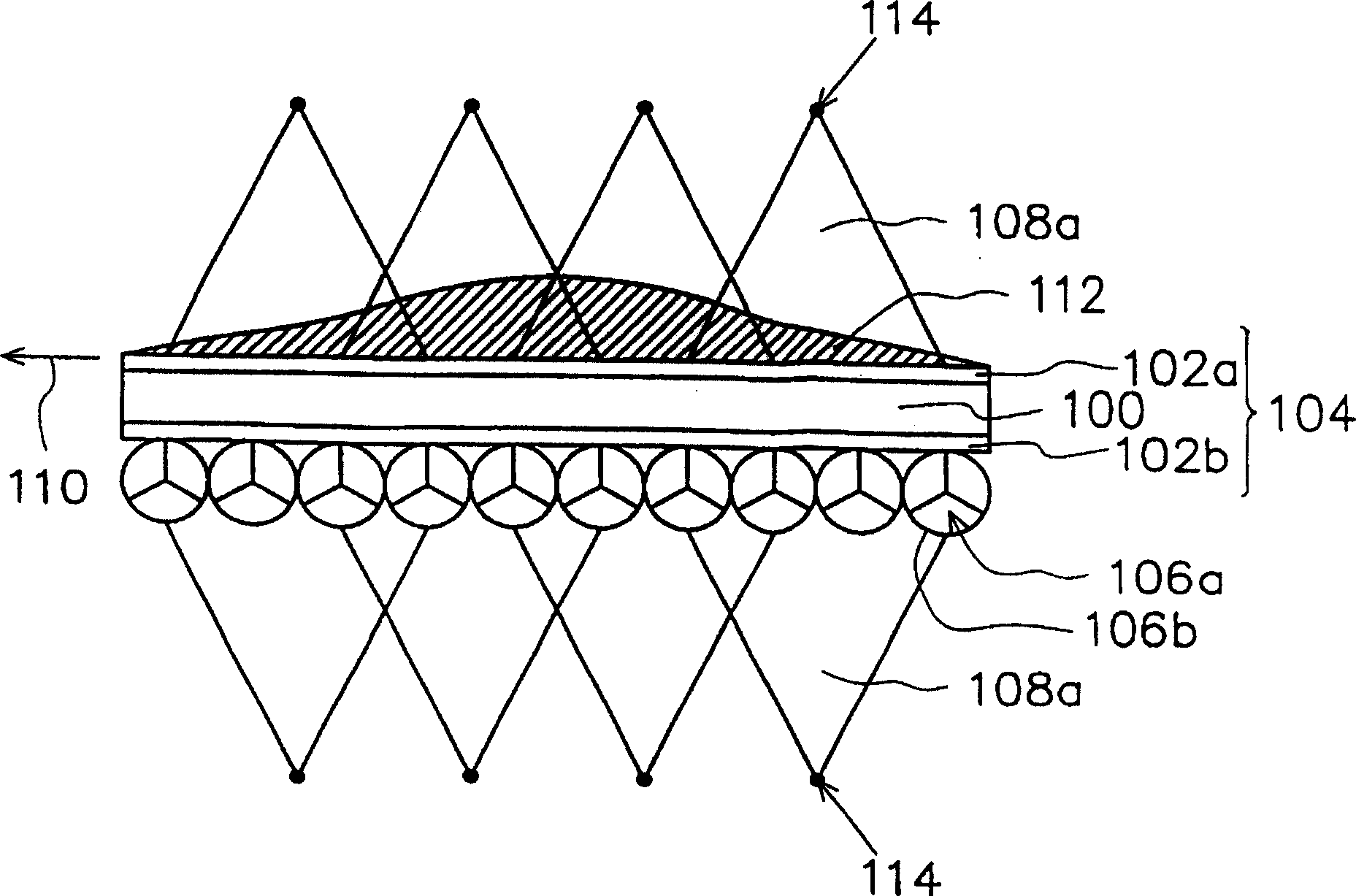

[0019] Please refer to Figure 4A 4B, a double-sided panel 204 overlapping the conductive layers 202a, 202b and the insulating layer 200 is subjected to an etching process after the photographic process, so that the conductive layer 202a and the insulating layer 200 on both sides of the insulating layer 200 202b is patterned into a circuit layer. Wherein, the double-sided board 204 is, for example, a hard substrate, and the preferred material of the insulating layer 200 in the hard substrate includes bismaleimide-triazine (bismaleimide-triazine, BT) or glass epoxy resin FR-4 and FR -5, etc., and the material of the conductive layers 202a and 202 is metal copper, for example.

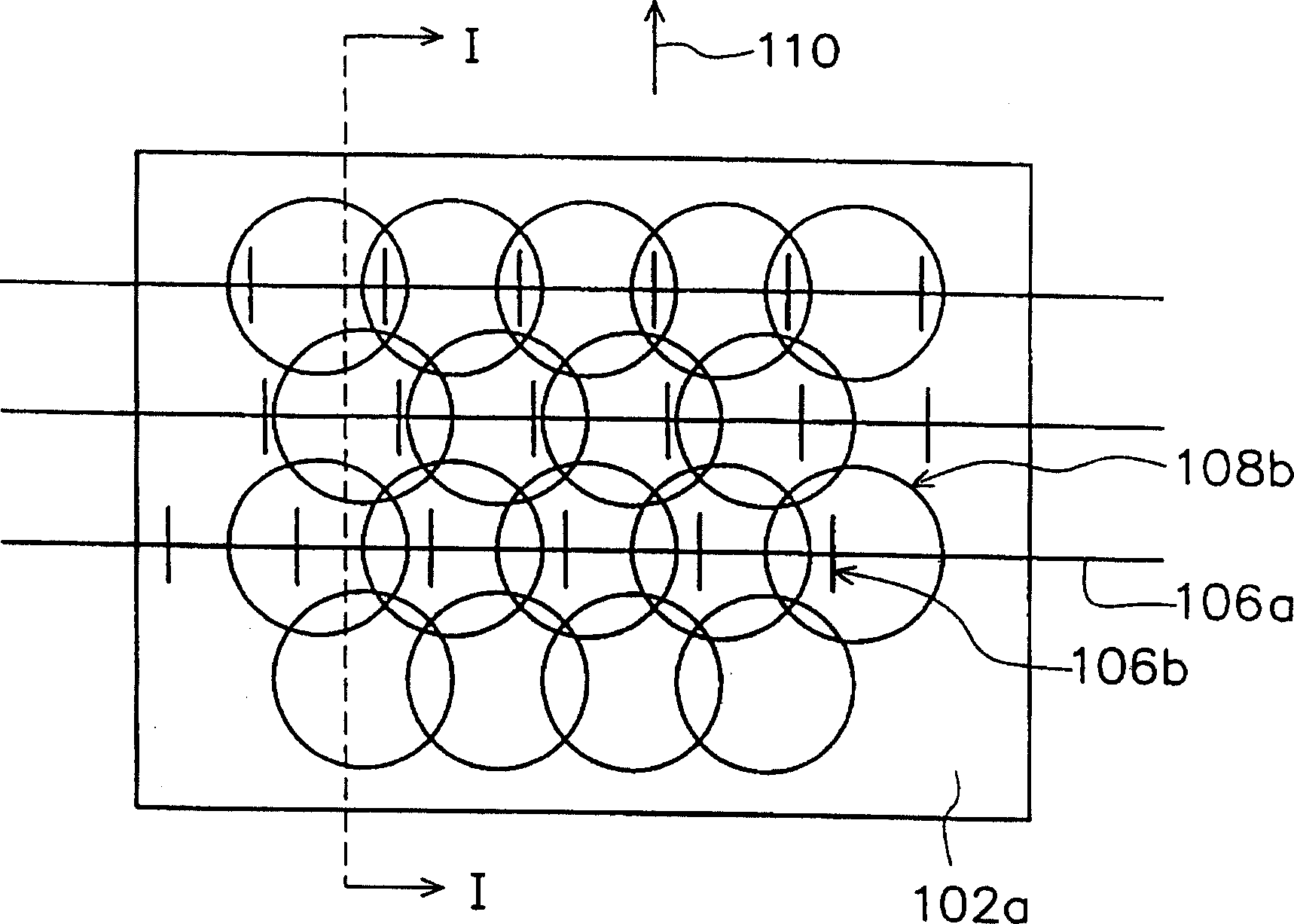

[0020] When carrying out the etching process, the double-sided board 204 is supported by contacting the conductive layer 202 of the double-sided board with a plurality of roller blade rollers 206b, and the roller blade-type rollers 206b are driven by the roller shaft 206a, so that the double board is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com