All-steel card clothing for rollers and/or drums of carders or carding machines

A carding machine and card clothing technology, which is applied in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problems of easy damage and puncture of card clothing, achieve less easy damage, prevent clogging, and improve carding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

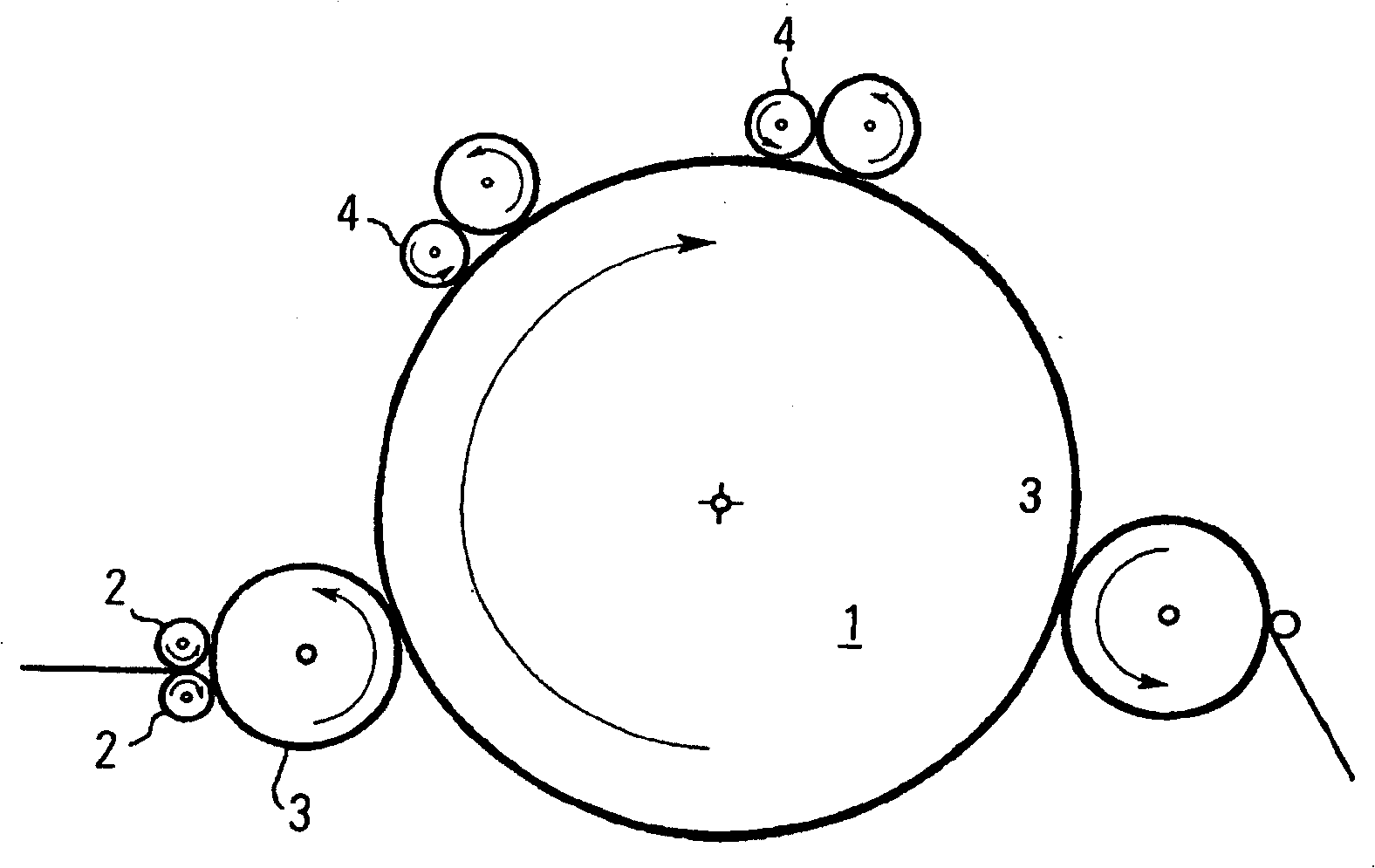

[0026] figure 1 A schematic diagram of a carding machine with a cylinder 1 , feed roll 2 , a licker-in roll 3 and cleaning roll 4 is shown. exist figure 1 The directions of circumferential rotation of the middle rollers are respectively indicated by arrows.

[0027] The card clothings described below are in each case rollers or cylinders which actively take up fibers from rollers arranged in front of them in the working direction. For example in figure 1 In the illustration shown these are the licker-in roller 3 , the cleaning roller 4 and in particular the cylinder 1 .

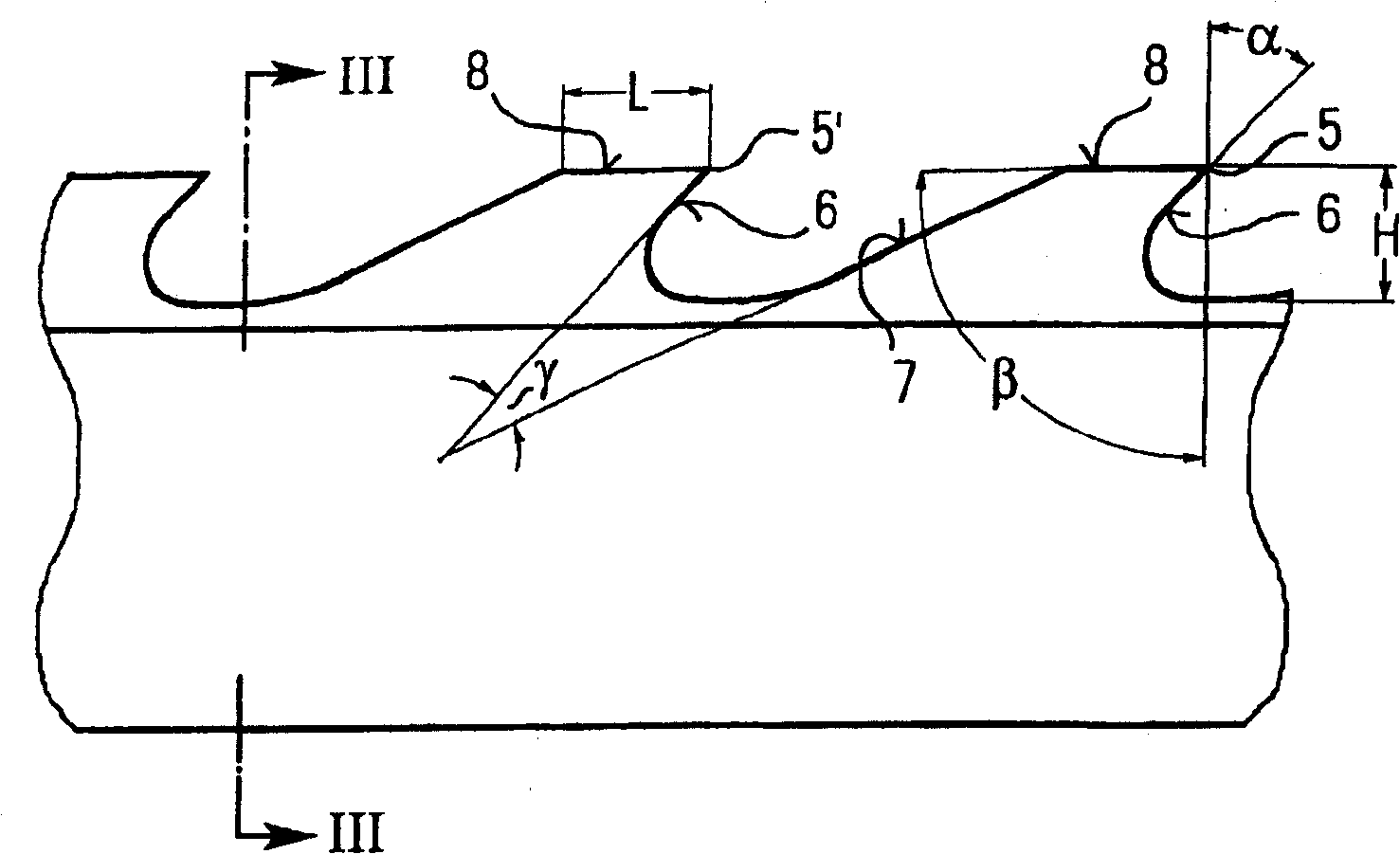

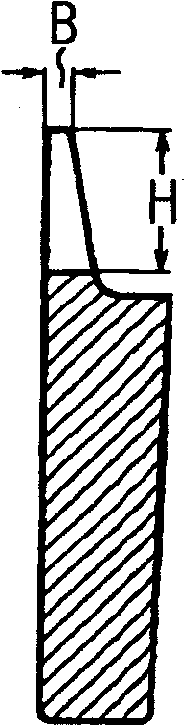

[0028] Now figure 2 A partial view of a toothed strip of all-steel card clothing, which is used, for example, in figure 1 rollers shown in . Here it is a sawtooth rack with an overall height of 2 mm and a pitch of 1.7 mm measured from one prong 5 to the next prong 5' ( ). The rake angle α of the tooth front face 6 measured relative to the vertical line is 40° in the exemplary embodiment shown here. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com