Lighting source device of adaptive regulating light-intensity in machine visual measuring system

A technology of machine vision measurement and self-adaptive adjustment, applied to measuring devices, lighting devices, light sources, etc., can solve the problem of low accuracy of image measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

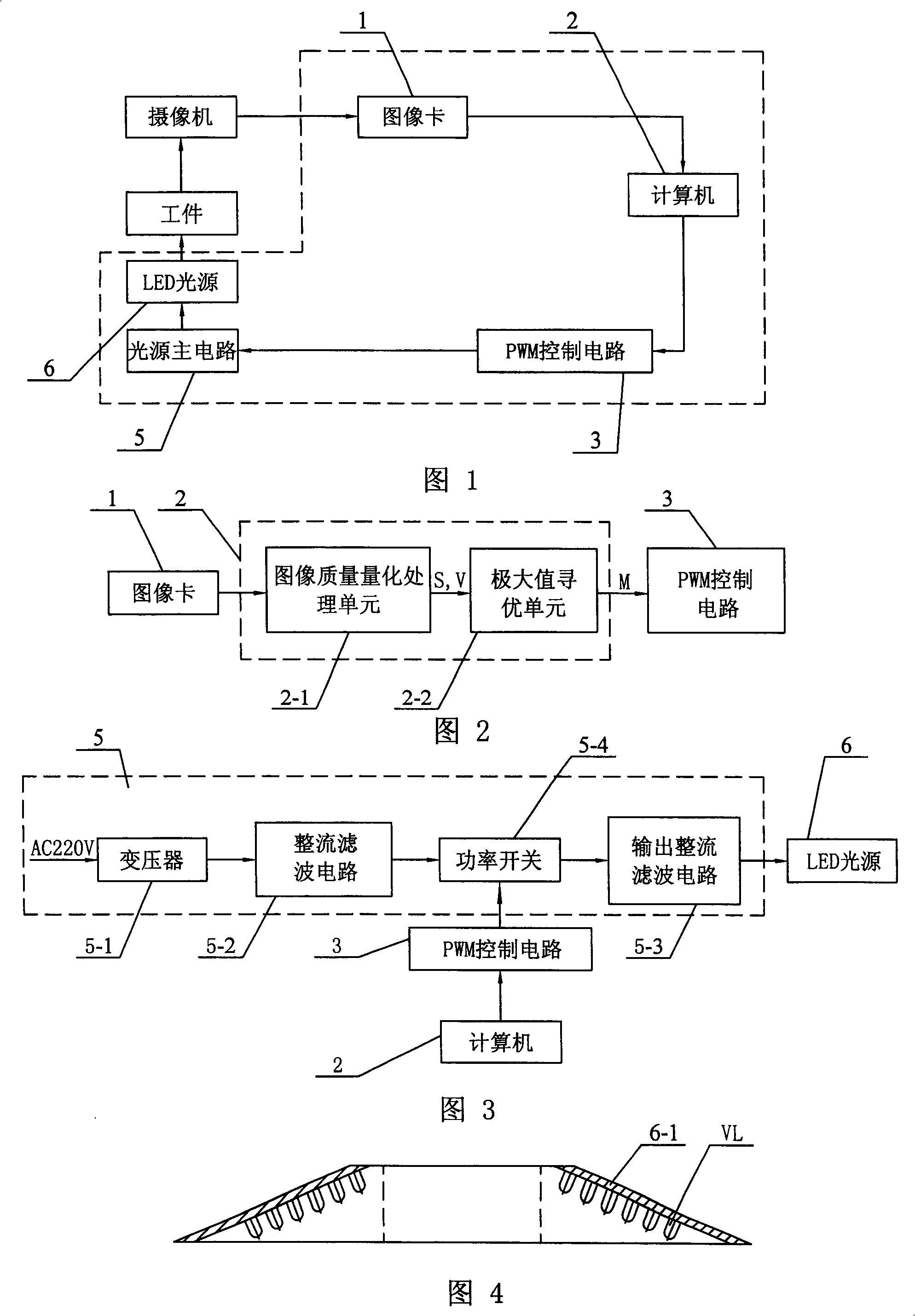

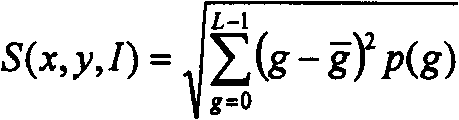

[0005] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 and FIG. 2 . It is composed of image card 1, computer 2, PWM control circuit 3, LED light source 6 and light source main circuit 5. The data output end of image card 1 is connected to the data input end of computer 2, and the output end of computer 2 is connected to the PWM control circuit 3. The input end and the output end of the PWM control circuit 3 are connected to the control end of the light source main circuit 5 , and the output end of the light source main circuit 5 is connected to the input end of the LED light source 6 . The arithmetic module in the computer 2 is composed of the image quality quantization processing unit 2-1 which calculates the image grayscale standard deviation function S and the image variance function V according to the signal input by the image card 1, and the image quality quantization processing unit 2-1 according to the image gra...

specific Embodiment approach 2

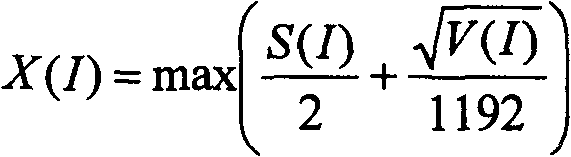

[0011] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 3 . The difference between this embodiment and Embodiment 1 is that the light source main circuit 5 is composed of a transformer 5-1, a rectification filter circuit 5-2, an output rectification filter circuit 5-3 and a power switch 5-4, and the input of the transformer 5-1 The terminal is connected to 220V AC mains, the output terminal of the transformer 5-1 is connected to the input terminal of the rectification filter circuit 5-2, the output terminal of the rectification filter circuit 5-2 is connected to one end of the power switch 5-4, and the other end of the power switch 5-4 One end is connected to the input end of the output rectification filter circuit 5-3, and the output end of the output rectification filter circuit 5-3 is connected to the input end of the LED light source 6. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Specific Embodiment Three: The present embodiment will be specifically described below in conjunction with FIG. 4 . The difference between this embodiment and Embodiment 1 is that the LED light source 6 is a circular array of several light emitting diodes VL, and the light emitting diodes VL are arranged on the inner surface of the condensing cover 6-1. This setting can save power, and it is a cold light source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com