Brushless motor

A technology for brushless motors and stator cores, applied in electric components, synchronous motors with stationary armatures and rotating magnets, electrical components, etc., can solve the problems of stator cores 3, etc., to reduce material consumption, The effect of reducing the size of the case and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Next, various embodiments of the present invention will be described with reference to FIGS. 1 to 13A, 13B, and 13C.

[0070] (Embodiment 1)

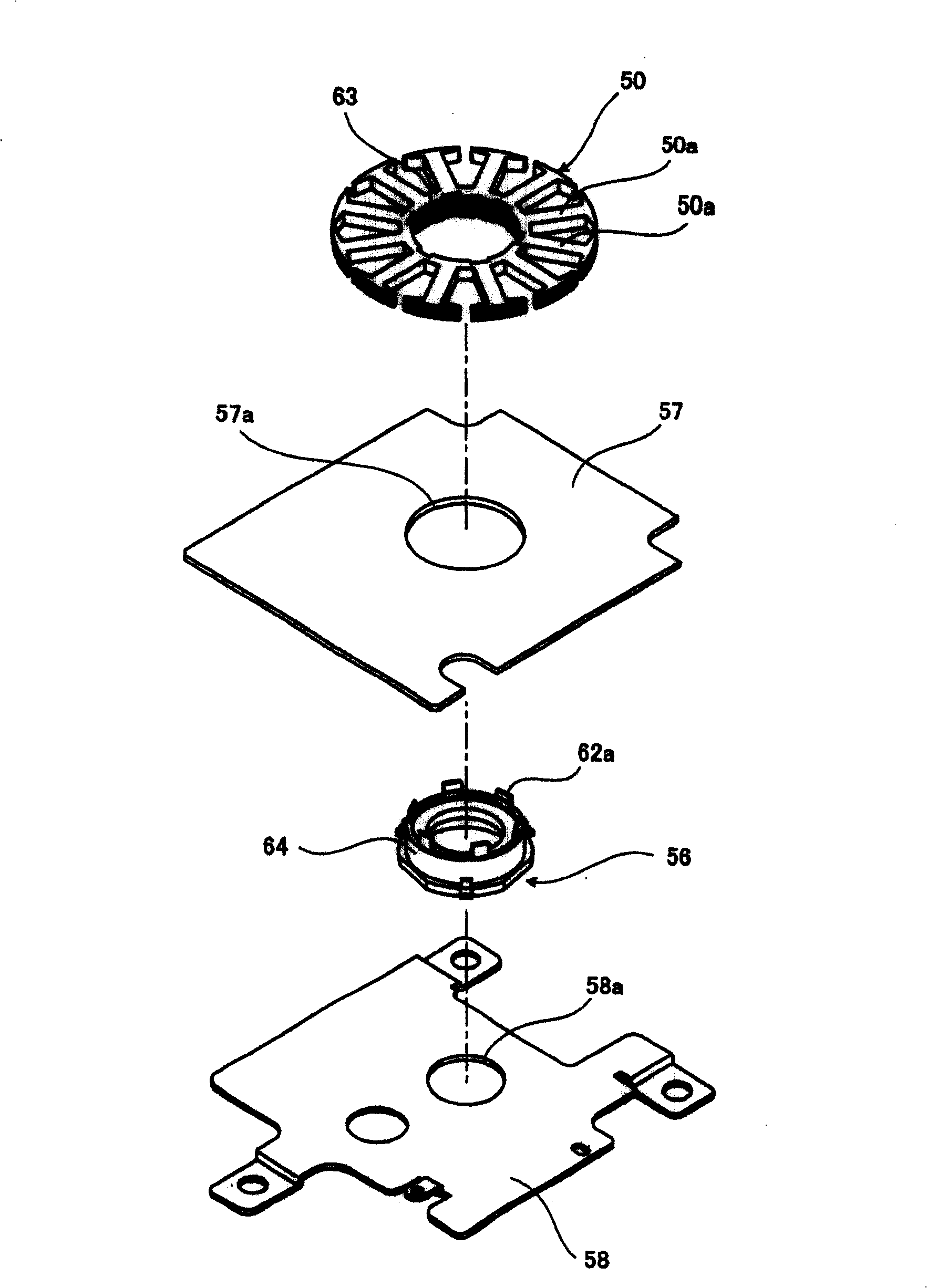

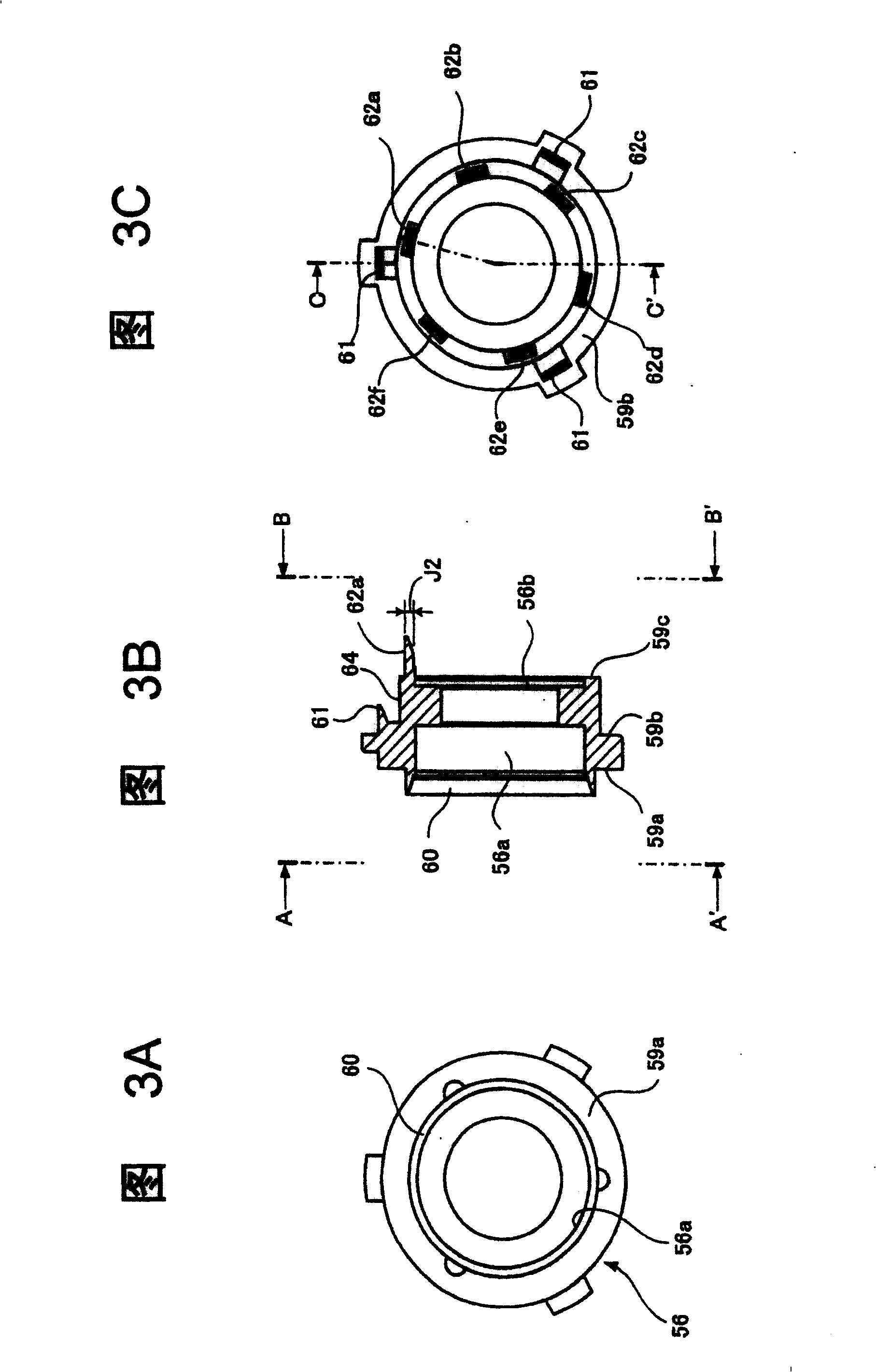

[0071] Figure 1~ Figure 7A , Figure 7B This shows (Embodiment 1) of the present invention.

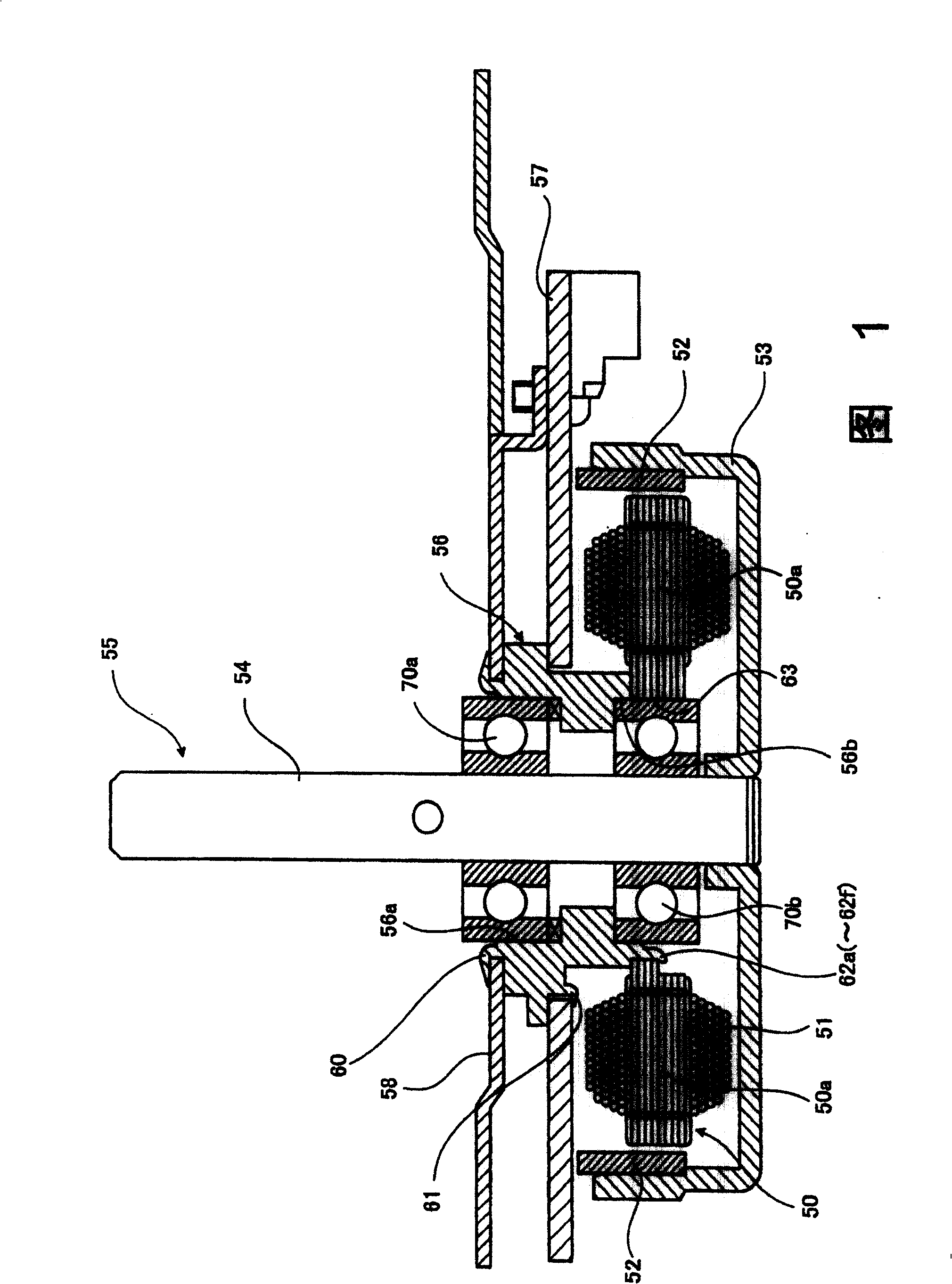

[0072] Fig. 1 shows a brushless motor of the present invention.

[0073] The stator core 50 has a plurality of salient poles 50a, and a winding 51 is wound around the salient poles 50a. The annular magnet 52 arranged to face the stator core 50 is magnetized for driving in a plurality of pieces in the circumferential direction. The ring magnet 52 is installed on the inner peripheral side of the cup-shaped rotor frame 53 . A rotating shaft 54 is attached to the center of the rotor frame 53 , and the ring magnet 52 , the rotor frame 53 and the rotating shaft 54 constitute a rotor 55 .

[0074] The rotating shaft 54 is rotatably supported by two bearings 70a and 70b arranged at a distance from each other. The cylindrical housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com