Alternating current permanent-magnet water-submersible electric machine

A submersible motor and permanent magnet technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machines, electrical components, etc., can solve the problems of complex insulation protection structure, inconvenient use, poor reliability, etc. Effects of motor stray loss, production cost reduction, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

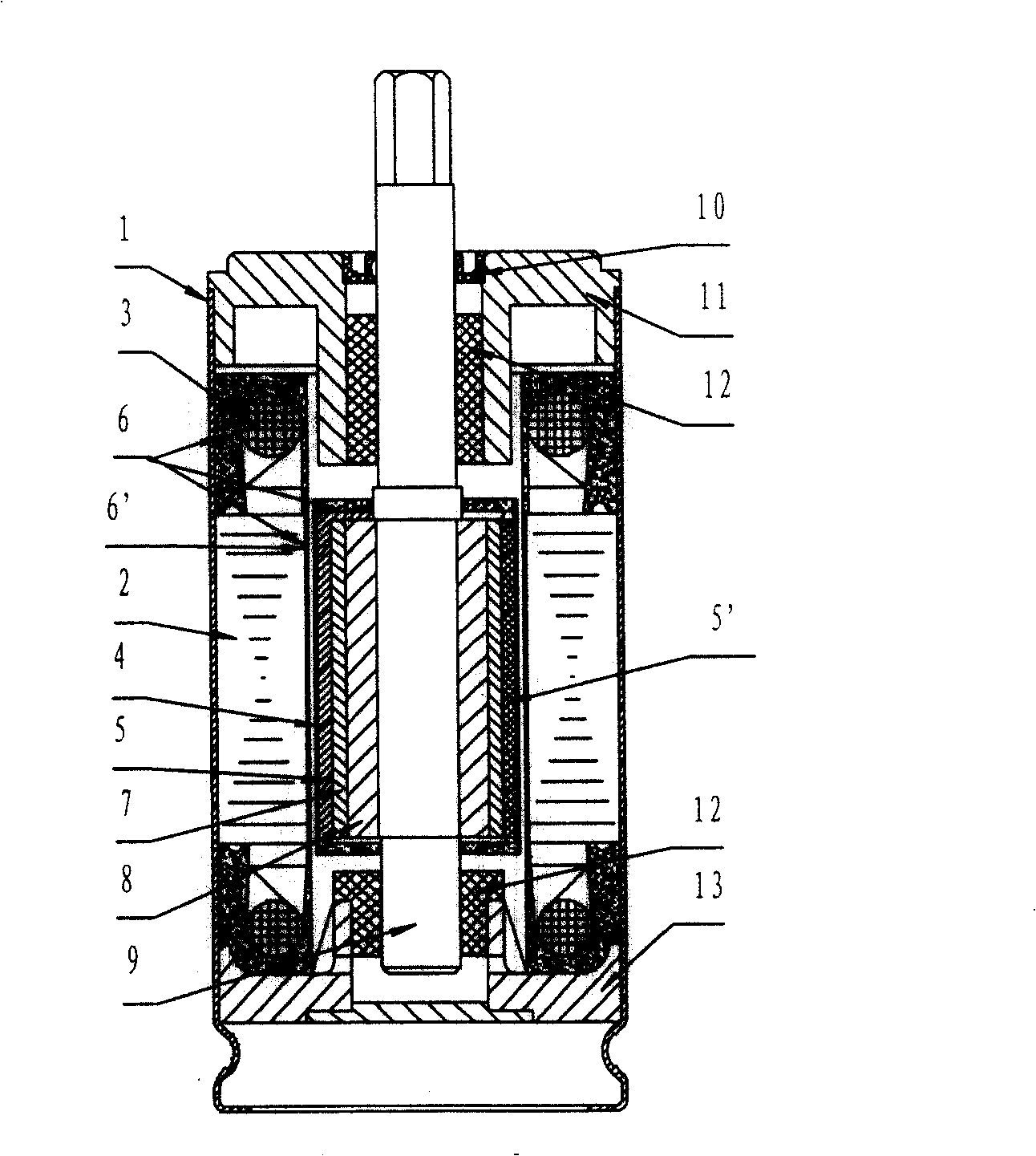

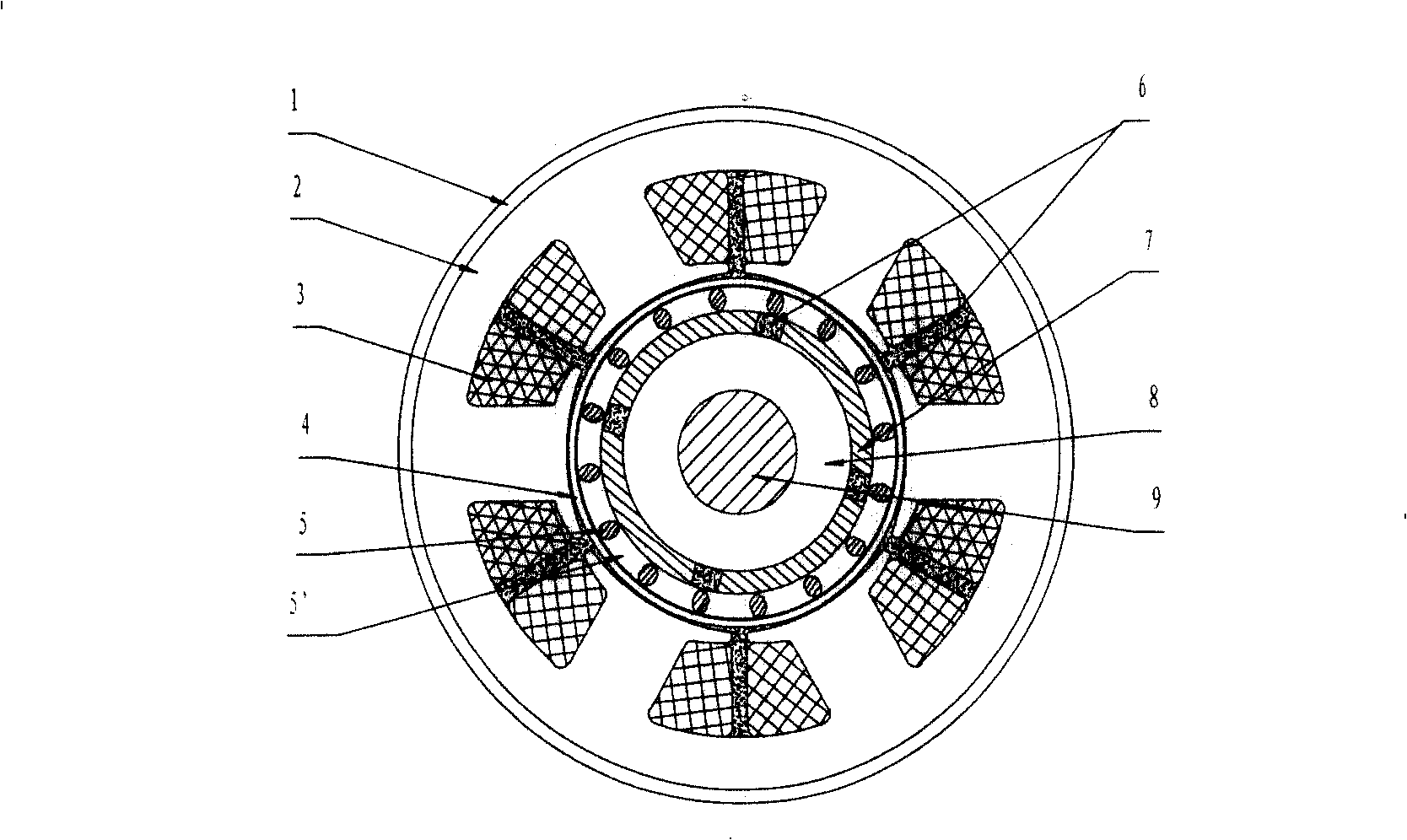

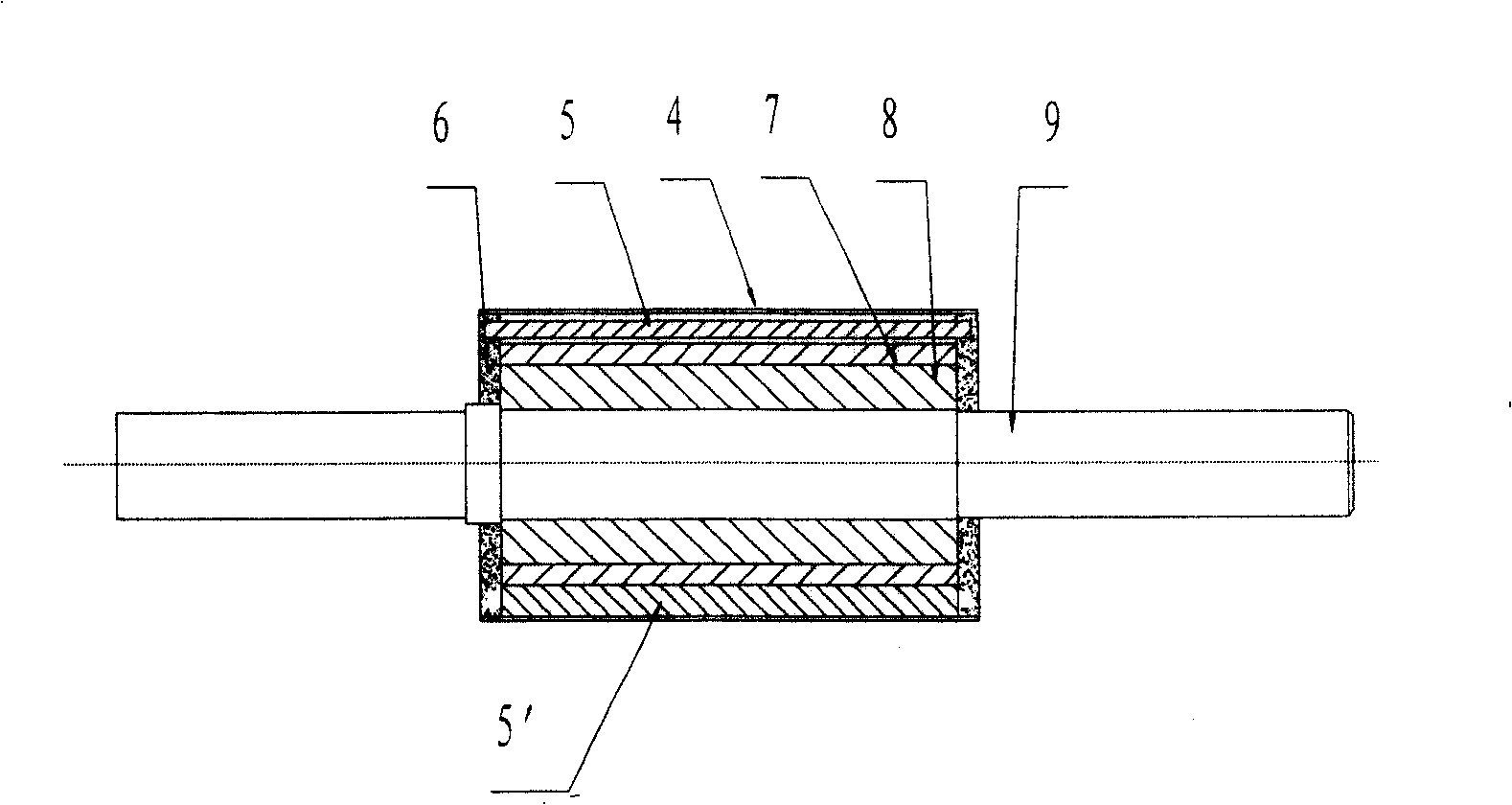

[0030] Figure 1 to Figure 4 shows the concrete structure of the present invention, by figure 1 and figure 2 It can be seen that the AC permanent magnet submersible motor has a 3-phase 4-pole structure, and the stator core has 6 teeth. The three-phase AC windings U, V, and W are respectively wound on the 6 teeth in sequential cycles, including the matingly connected stator and the rotor, the stator and the rotor are respectively integrally potted and then assembled and connected together; the stator is a concentrated winding structure, such as Figure 4 As shown, it includes casing, stator winding and iron core. The casing is connected with the stator winding and iron core by potting its internal potting material to form an integrated structure; the stator winding and iron core in the potting body are not Erosion by external liquid; the feature of potting is that a non-magnetic anti-corrosion insulating sleeve or plastic sealing material is installed on the inner circumfere...

Embodiment 2

[0032] Figure 5 Another structural form of the present invention is shown, by Figure 5 It can be seen that this embodiment is the same as Embodiment 1 except for the following structural features: the AC permanent magnet submersible motor has a single-phase 2-pole structure, and the stator core has 4 teeth, of which 2 teeth are wound with the main winding coil, and the other 2 Two teeth are used to wind the auxiliary winding coil, and the main and auxiliary windings are arranged alternately. The number of permanent magnets in the rotor is 2 pieces or an integer multiple of 2 pieces.

Embodiment 3

[0034] Figure 6 Another structural form of the present invention is shown, by Figure 6 It can be seen that this embodiment is the same as Embodiment 1 except for the following structural features: this AC permanent magnet submersible motor has a 3-phase 2-pole structure, its stator core has 3 teeth, and the three-phase windings U, V, W rotate according to the motor. Direction, sequentially wound on 3 teeth, the number of permanent magnets of the rotor is 2 pieces or an integer multiple of 2 pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com