Turning and milling machine for machining civil nuclear power container

A main container, turning and milling technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of low processing precision, different types, straight groove type, ring groove type, poor reliability of quality assurance, etc. Achieve the effect of reducing the processing procedure, improving the processing accuracy and reducing the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

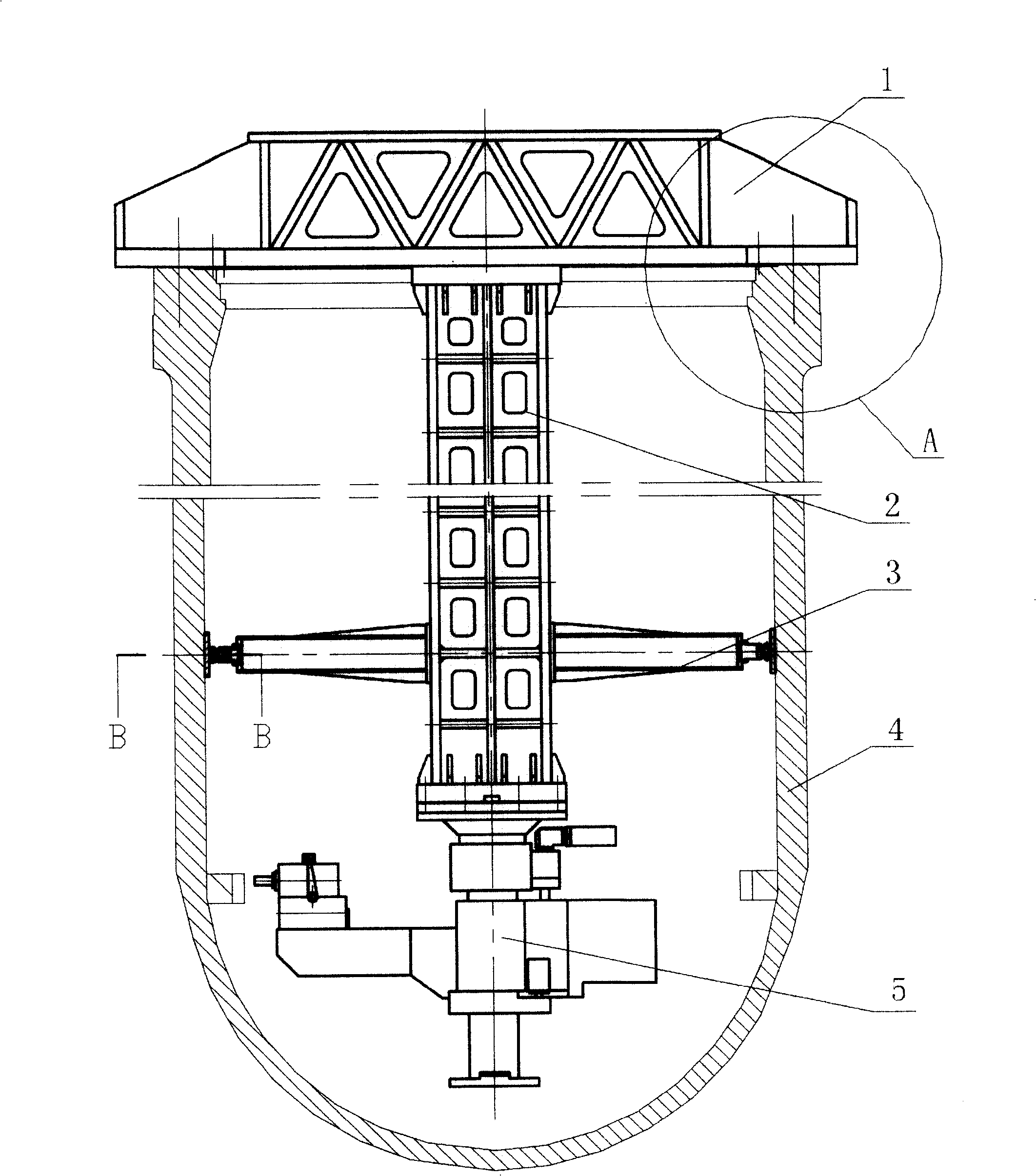

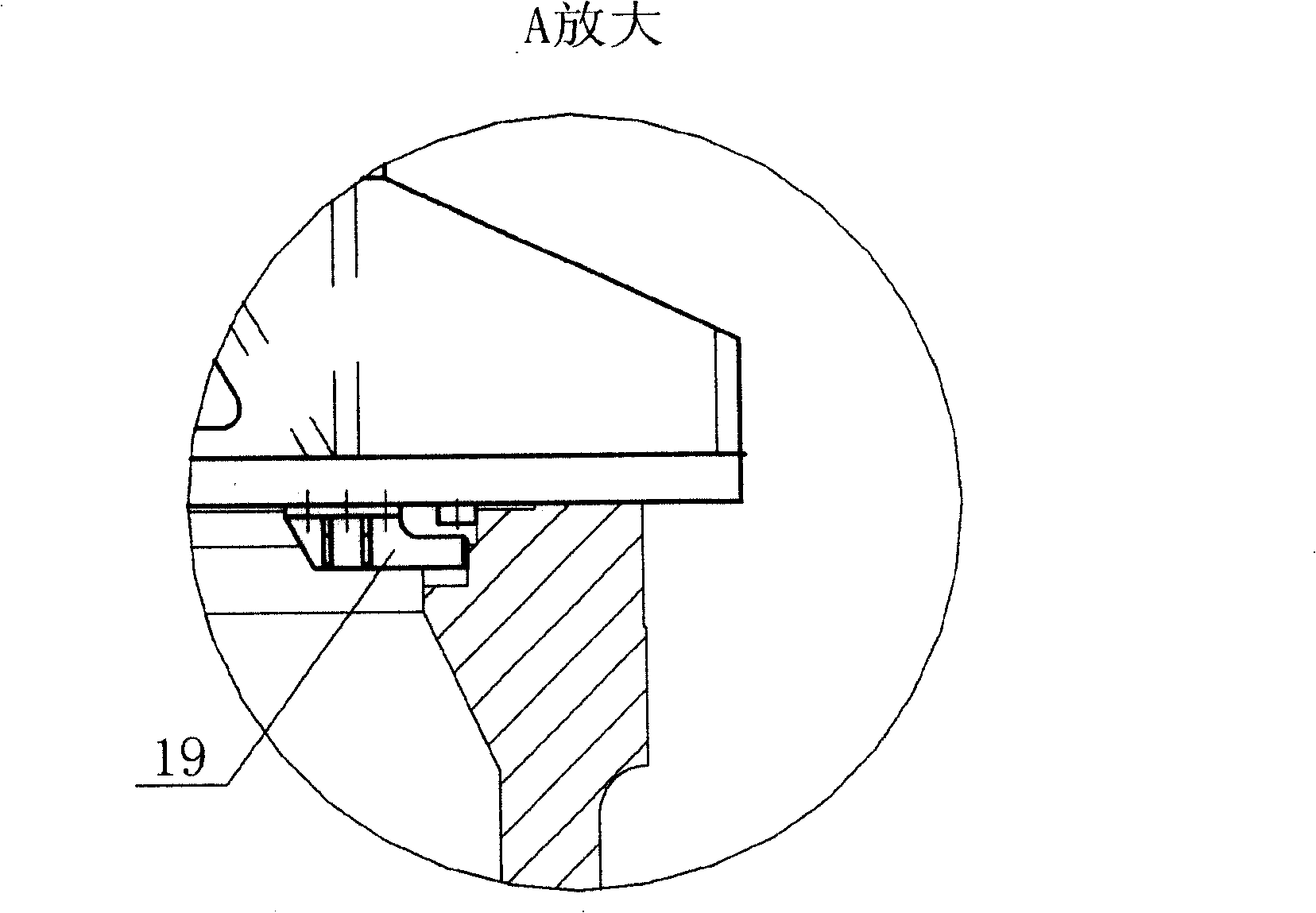

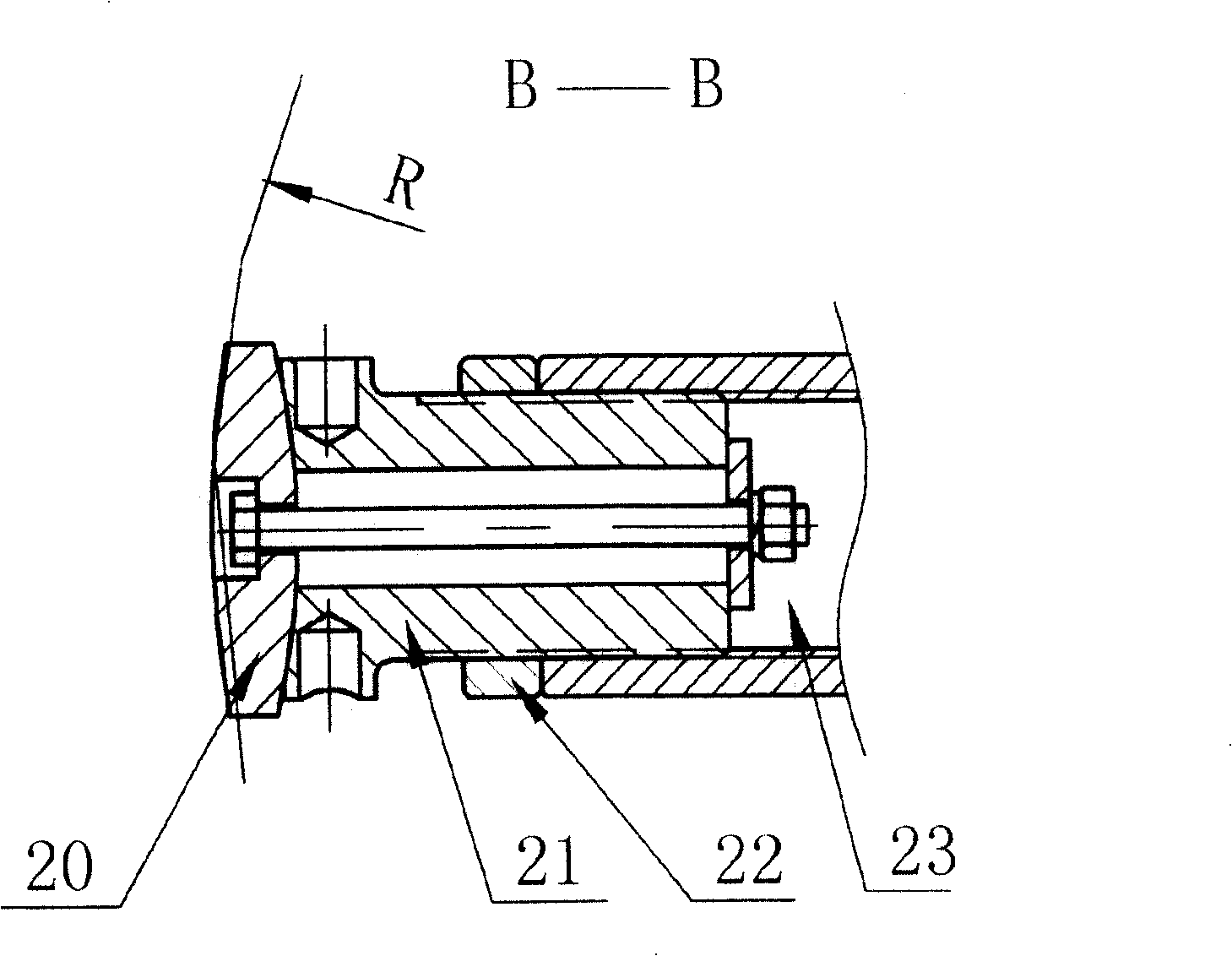

[0015] see figure 1 one Figure 7 , the bridge frame (1) is placed on the port of the main container (4), adjusted and positioned by the positioning key plate (19), the vertical beam (2) is fastened in the middle of the bridge frame (1) by the first bolt, and the center line of the vertical beam (2) Align with the bridge frame (1) center, one side of the adjustable and fixed central support rod (3) is connected to the lower part of the vertical beam (2) through the second bolt, and the other side is made into a supporting foot adjusting screw hole (23), and the supporting foot The adjusting bolt (21) is screwed into the supporting foot adjusting screw hole (23), and is fastened on the supporting foot adjusting screw hole (23) by the lock nut (22), and the end of the supporting foot adjusting bolt (21) is tightened by the third bolt Connect the supporting feet (20), and the supporting feet (20) lean against the inner wall of the main container (4); the top of the turning and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com