A kind of powder superalloy step grate turning machining method

A high-temperature alloy and turning technology, which is applied in metal processing equipment, manufacturing tools, turning equipment, etc., to achieve the effect of reducing the cutting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

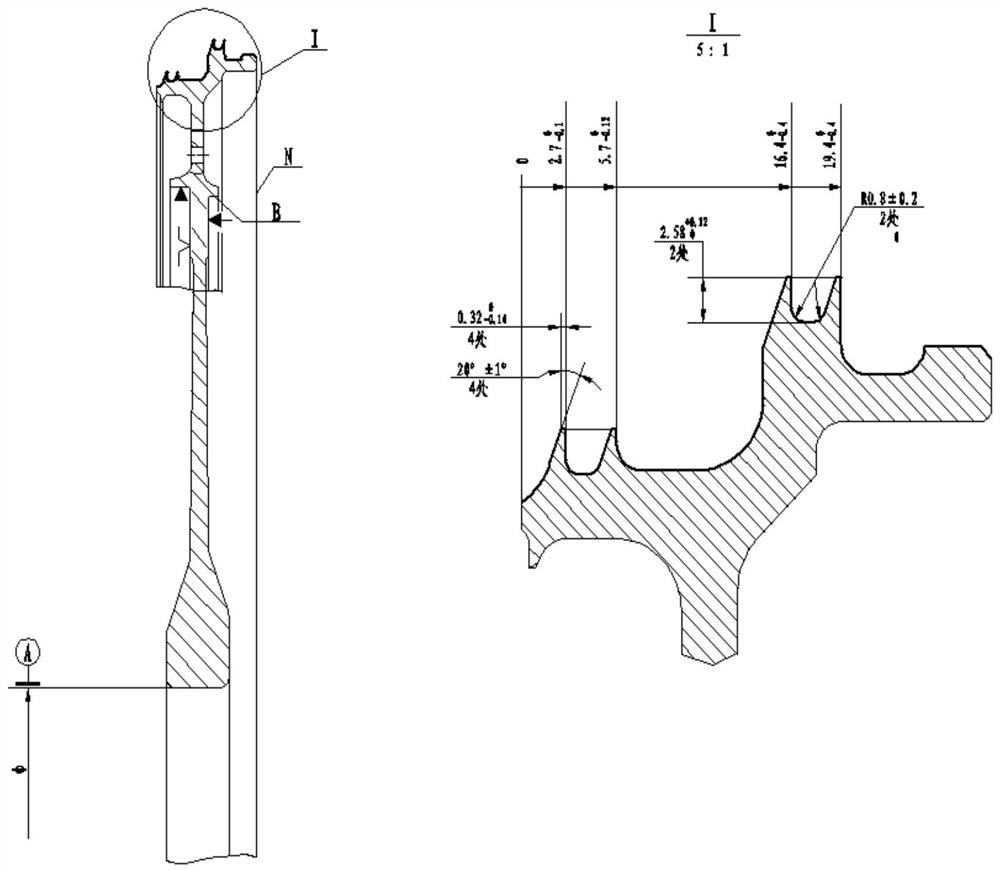

[0027] The technical solution of the present invention will be further described below with reference to the accompanying drawings and specific embodiments. It should be noted that in the present invention, the axial direction of the rear sealing grate is used as the Z axis of the coordinate system, and the diameter of the rear sealing grate is used as the Z axis. to the X axis.

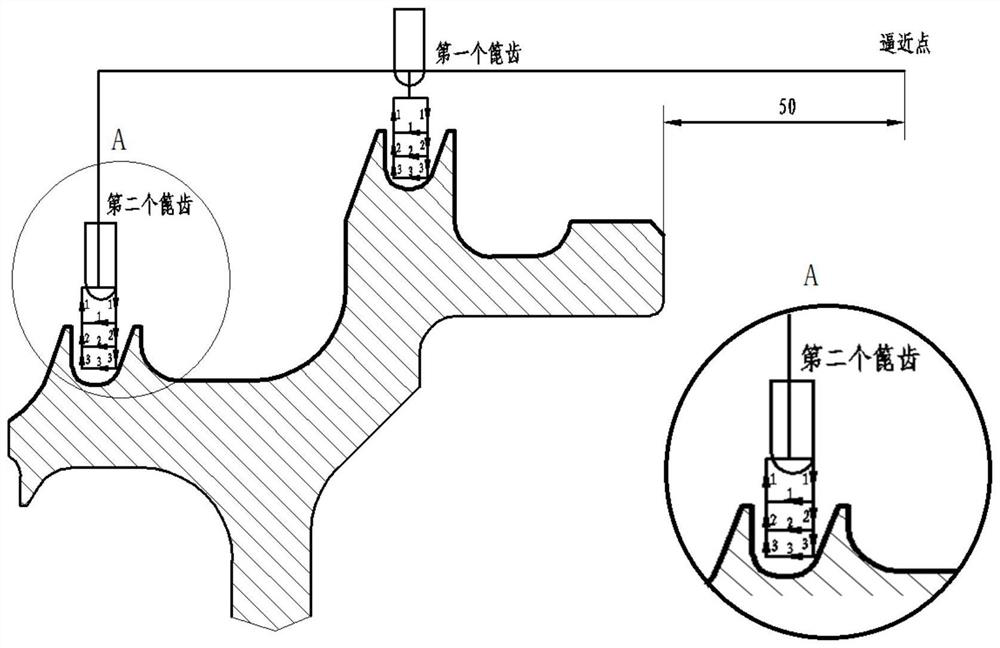

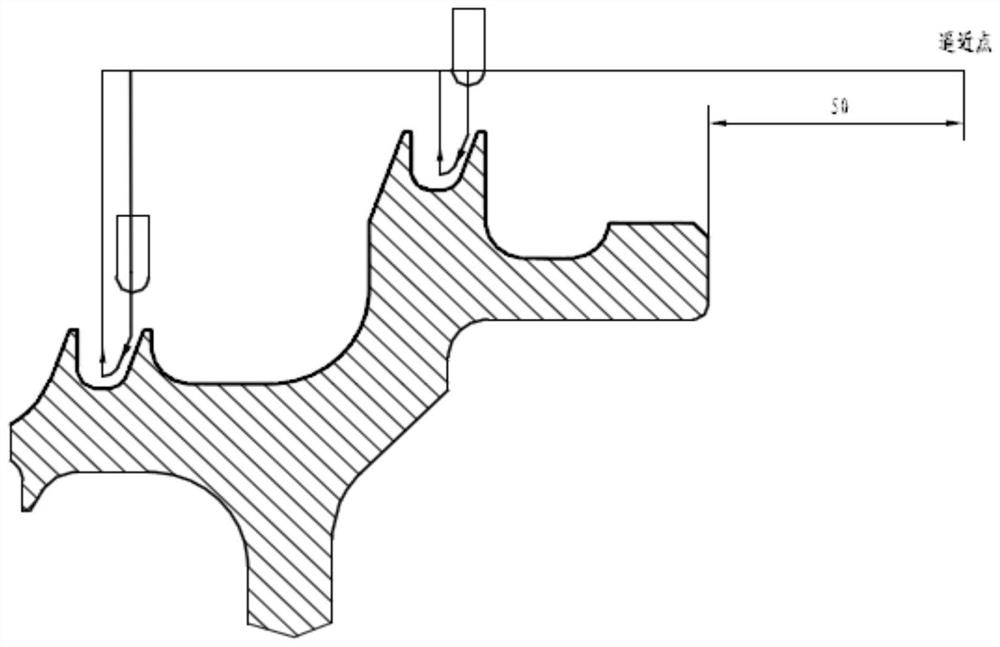

[0028] like figure 1 As shown, there are a pair of stepped grate teeth on the outer circumference of the rear sealing grate tooth plate, namely figure 1 The first grate teeth and the second grate teeth are located at different outer diameters, wherein the outer diameter of the position of the first grate tooth is larger than the outer diameter of the position of the second grate tooth. In this embodiment, the basic process of turning the first grate and the second grate is as follows: Figure 5 shown.

[0029] The following are the specific steps for turning the powder superalloy step grate:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com