Micro-slump concrete for roller compacted concrete dam and construction method thereof

A technology for rolling concrete and concrete, applied in the field of concrete, can solve the problems of difficult to guarantee construction quality, difficult rolling, and large construction interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

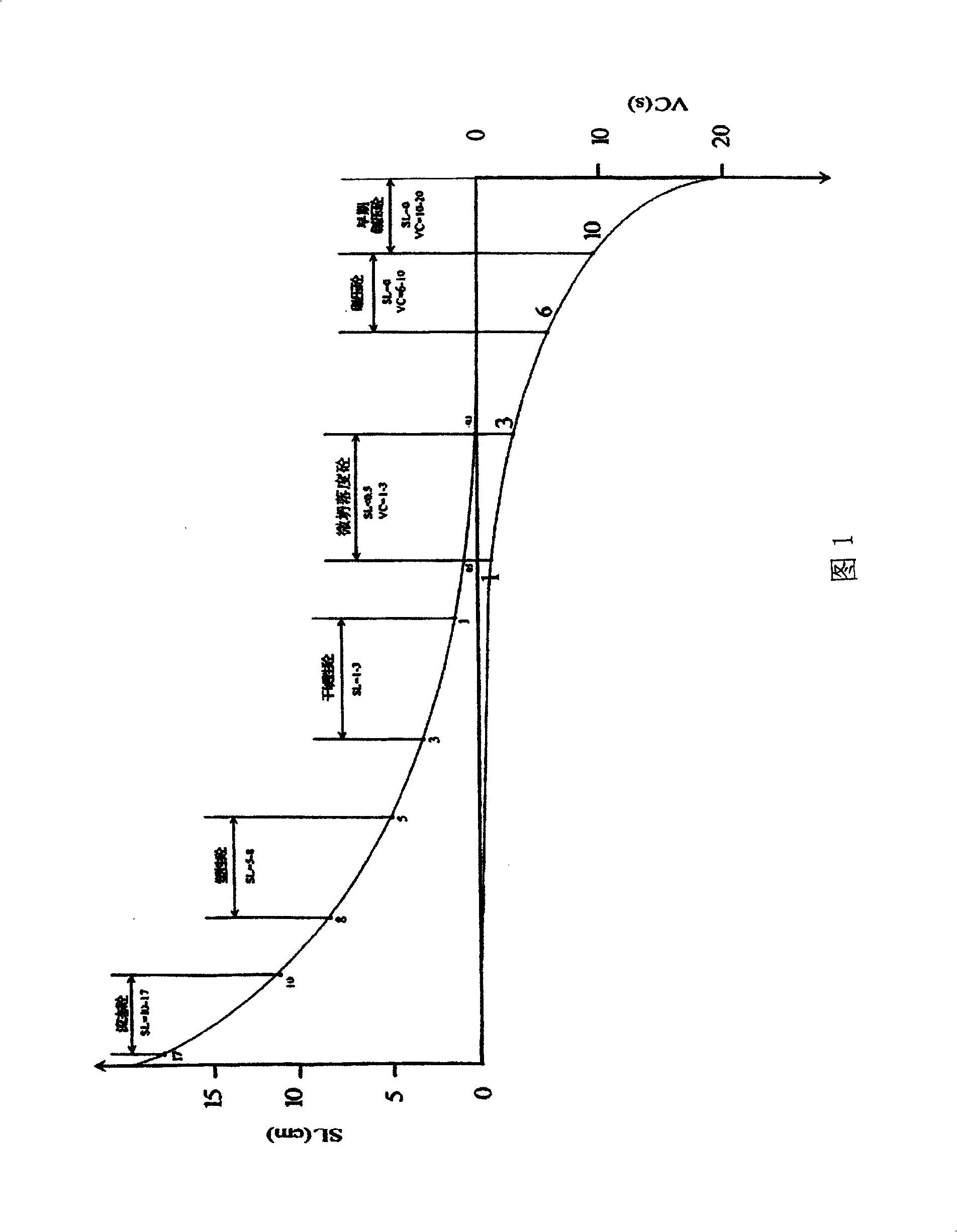

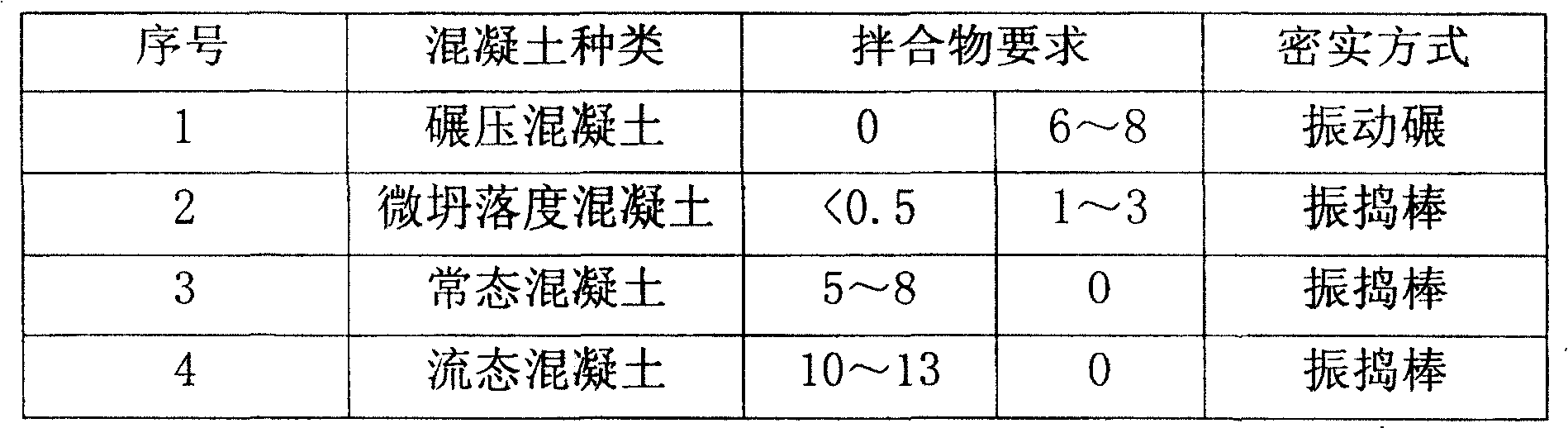

[0023] The invention is used for the micro-slump concrete of the roller compacted concrete dam, including cement, fly ash, coarse aggregate, fine aggregate, retarding high-efficiency water reducer, air-entraining agent, water, and the slump of the prepared concrete Less than 0.5cm, the consistency VC value is 1-3 seconds.

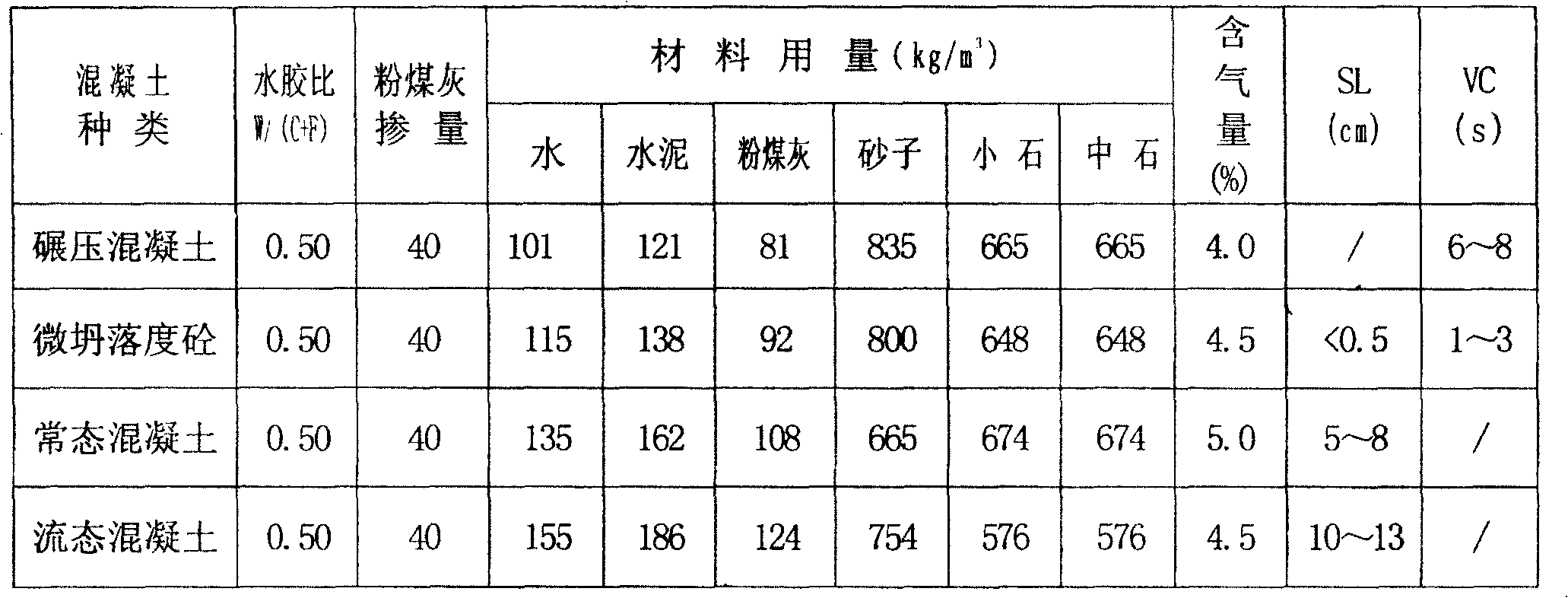

[0024] The specific ratio of each component is: coarse aggregate 1200 ~ 1400kg / m 3 , fine aggregate 750~900kg / m 3 , mixing water 90~130kg / m 3 , the retarding high-efficiency water reducer is 0.6-1.5% of the weight of the cementitious material, and the amount of the causative agent to control the air content of the concrete is 3-5%; the maximum particle size of the coarse aggregate is 40-80mm, and the maximum particle size of the fine aggregate is 40-80mm. The fineness modulus is 2.4-3.2; the water-binder ratio of the micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com