Pneumatic control localizer

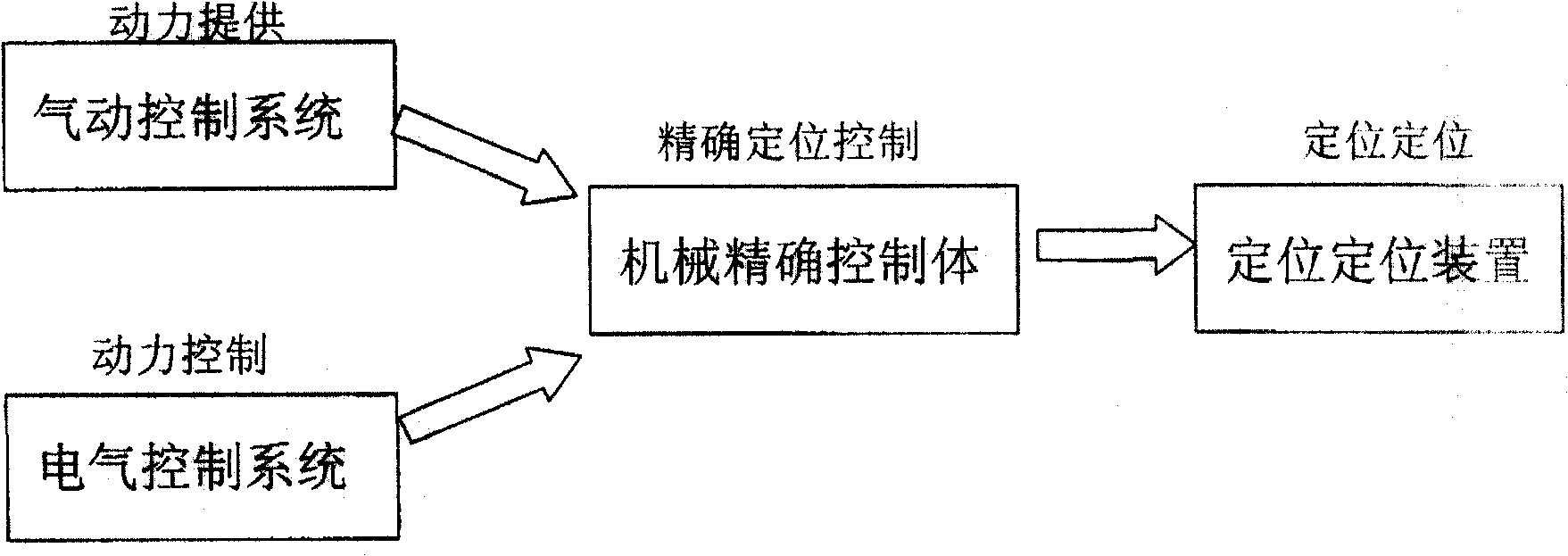

A pneumatic control and positioner technology, applied in automatic control devices, positioning devices, manufacturing tools, etc., can solve the problems of large operation space, floating positioning coordinates, low positioning accuracy, etc., and achieve stable positioning coordinates and assembly speed. And the effect of improving product quality and simplifying the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

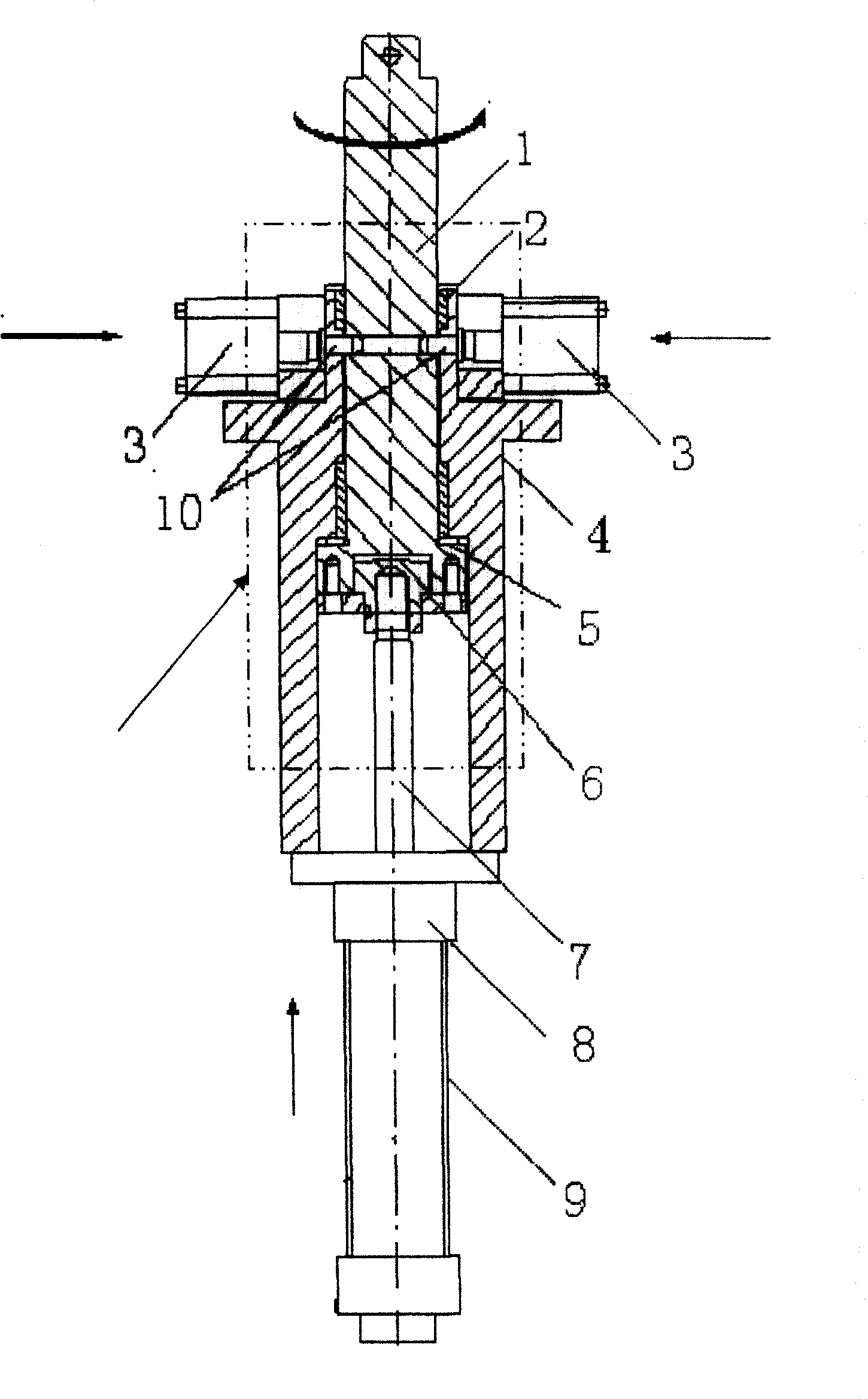

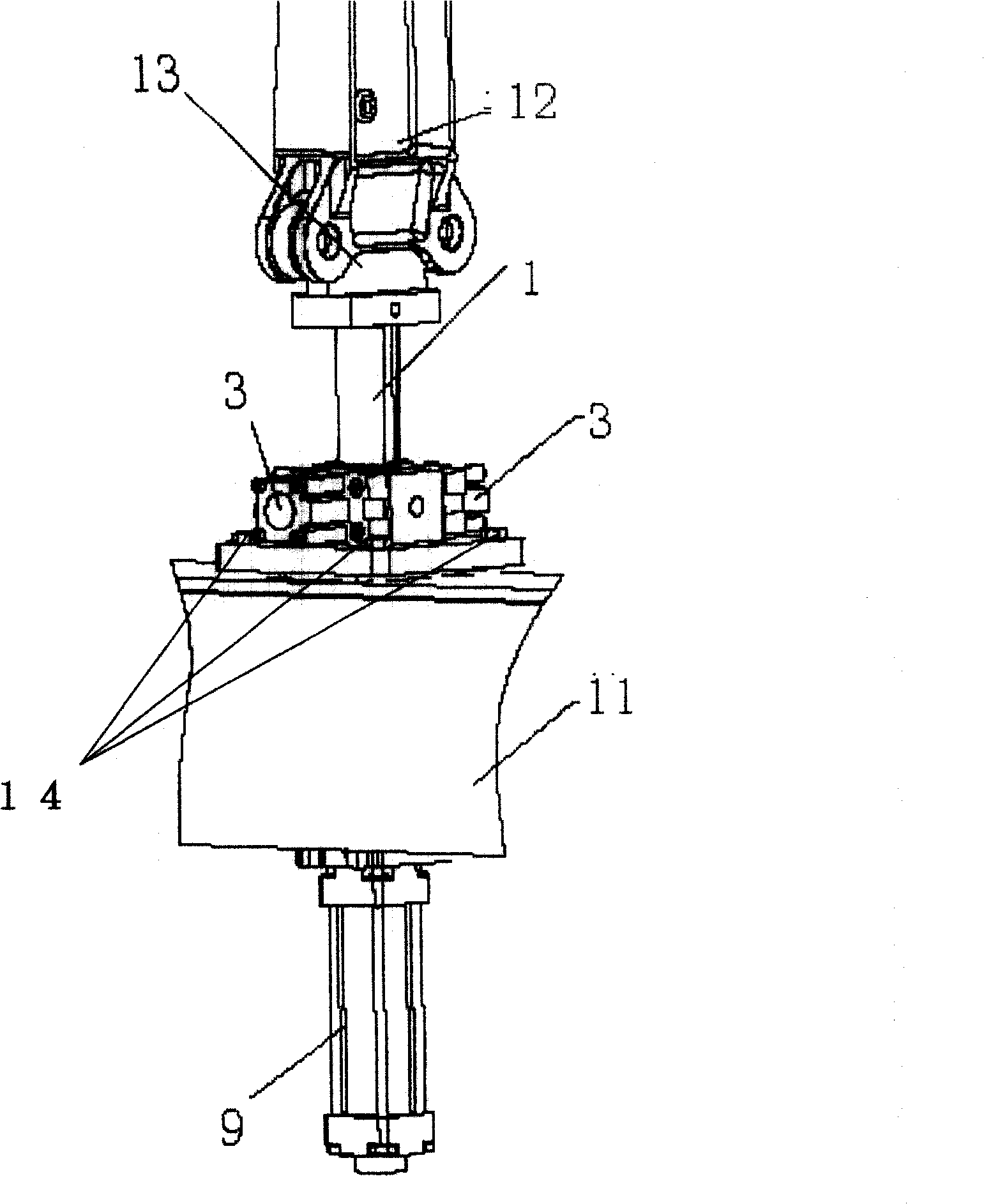

[0011] see figure 1 , the mechanical positioning control seat body 4 is a cylindrical cylinder shaped on steps and step holes. The positioning rod 1 is slidably fitted in the stepped hole, and can generate sliding movement under the action of the pneumatic connecting rod 7 . On the connecting rod 7 connected to the lower end of the positioning rod 1, a floating head 6 and an initial positioning gasket 5 that makes the end of the positioning rod reach the initial positioning position are connected. The connecting rod 7 pushes the positioning rod 1 for axial positioning movement through the connected axial cylinder 9, and constrains the positioning rod 1 axially in the direction of the arrow. The tangential cylinders 3 respectively installed on both sides of the mechanical positioning seat body 4 push the bullet pin 10, and the positioning rod 1 and the mechanical positioning control body seat 4 are aligned to the holes, so as to realize the tangential constraint along the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com