Device for filling and curling tows

A crimping and tow technology, which is applied in the direction of textiles and papermaking, can solve problems such as crimping of bad tows, and achieve the effects of increasing productivity, improving crimp quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

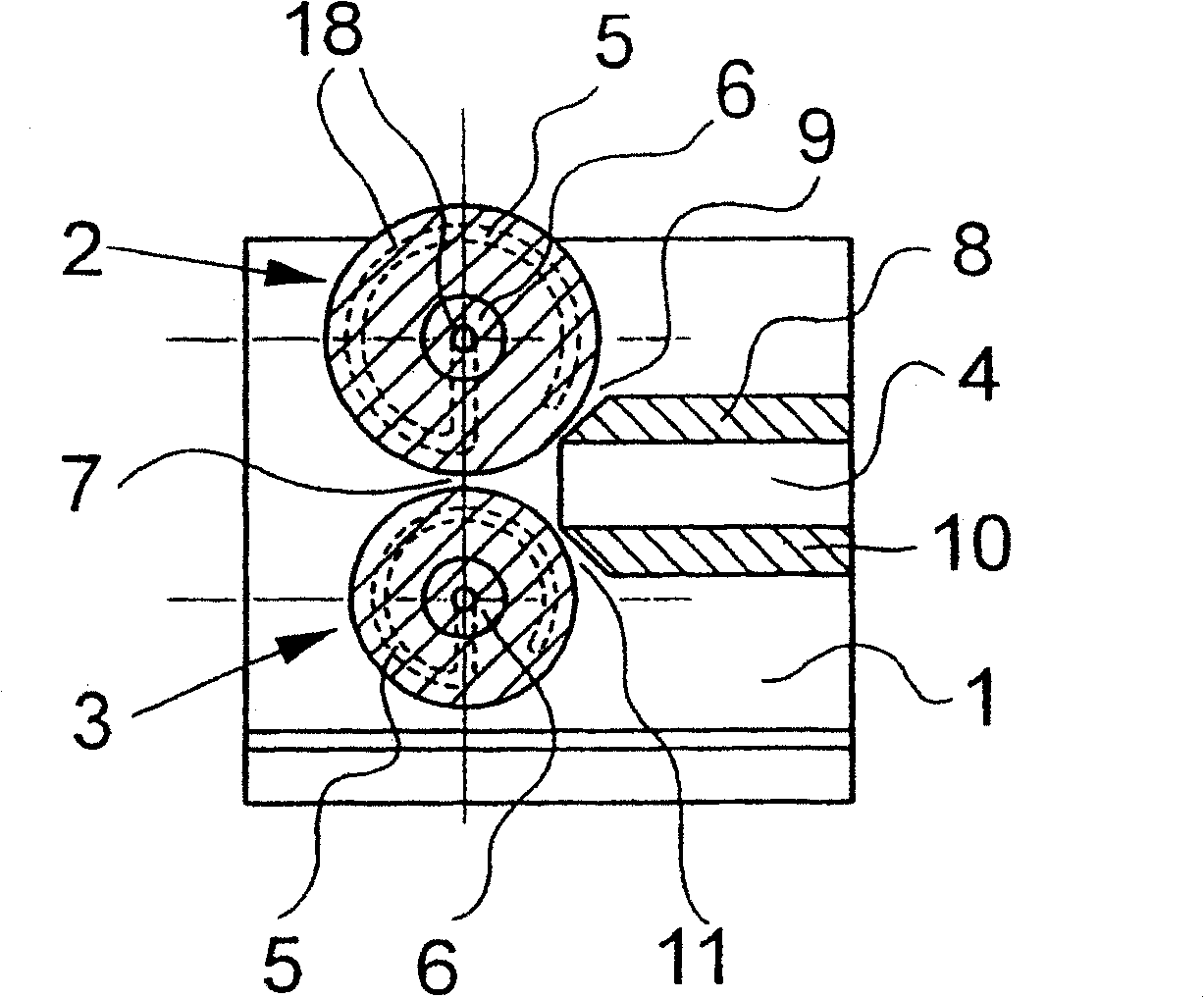

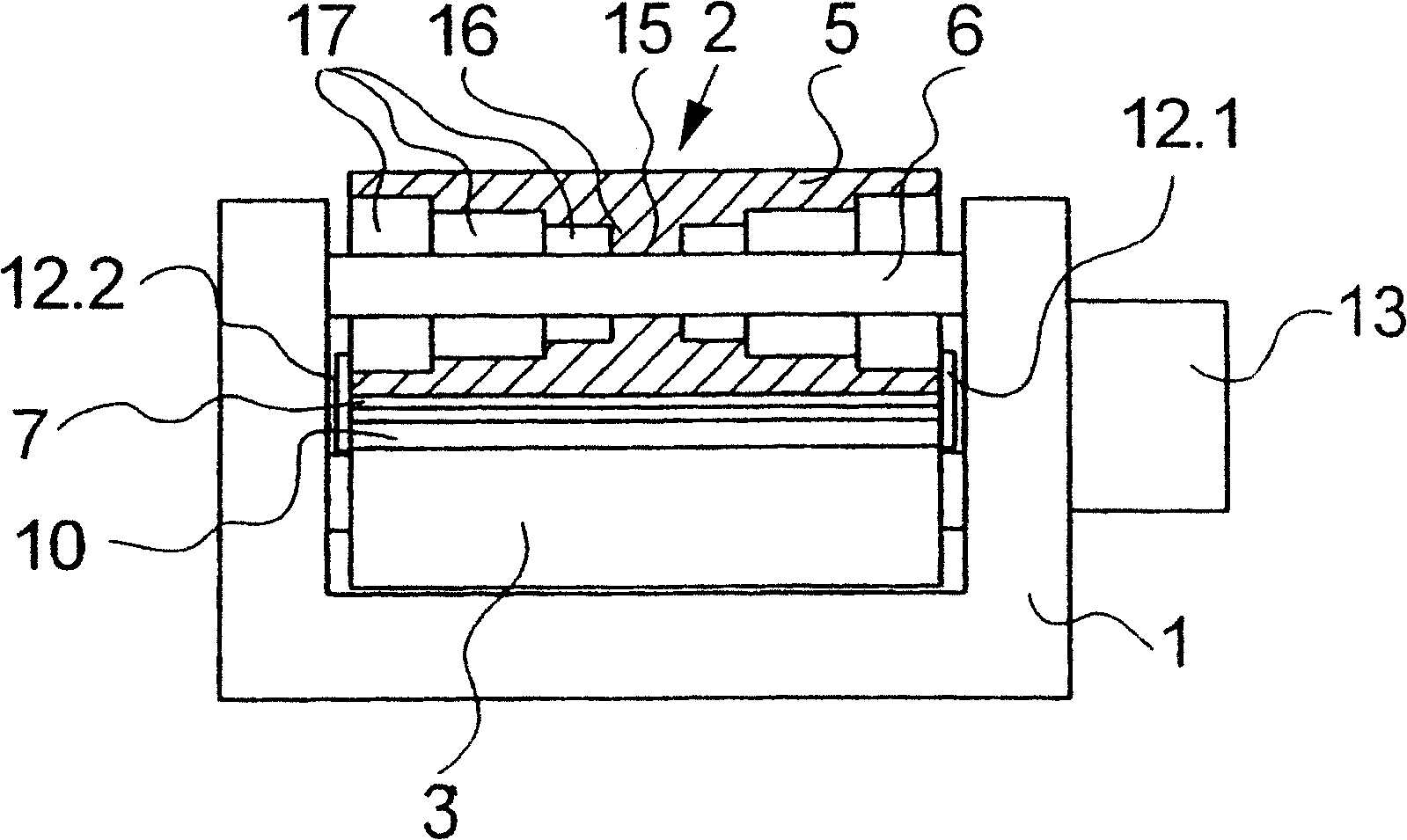

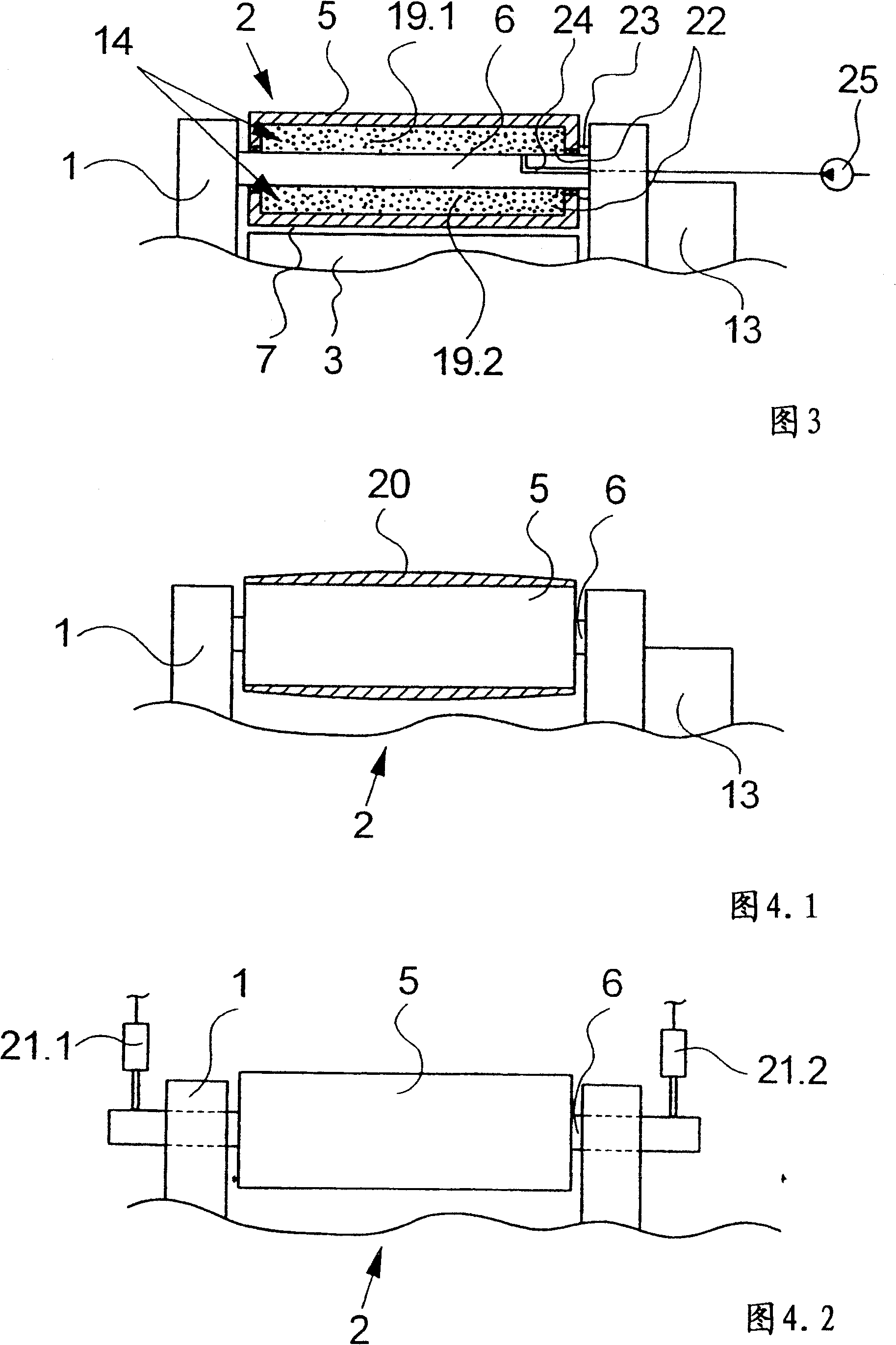

[0022] figure 1 A cross-sectional view of a first embodiment of the device according to the invention is shown schematically in . figure 2 A view including a partial cutaway of this embodiment is shown. The following description is applicable to the two figures as long as there is no particular emphasis on referring to one of the figures. The device for stuffing crimping of tow basically comprises two crimping rolls 2 and 3 rotatably supported on a frame 1 and a stuffer box 4 arranged behind the crimping rolls 2 and 3 . A roll gap 7 is formed between the upper crimping roll 2 and the lower crimping roll 3 so that a strand can be inserted and crimped by means of a bend. Each of the crimping rollers 2 and 3 is composed of a cylindrical roller body 5 and a roller shaft 6 connected to the roller body 5 in a relatively non-rotatable manner. However, it is also possible to make the roller shaft 6 and the roller body 5 seamless.

[0023] The individual roller shafts 6 of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com