Black pasty composition and plasma display panel of black pattern formed therewith

A technology of plasma and composition, applied in the field of black paste composition, can solve the problems of unsatisfactory characteristics, increased yellowness, easy yellowing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

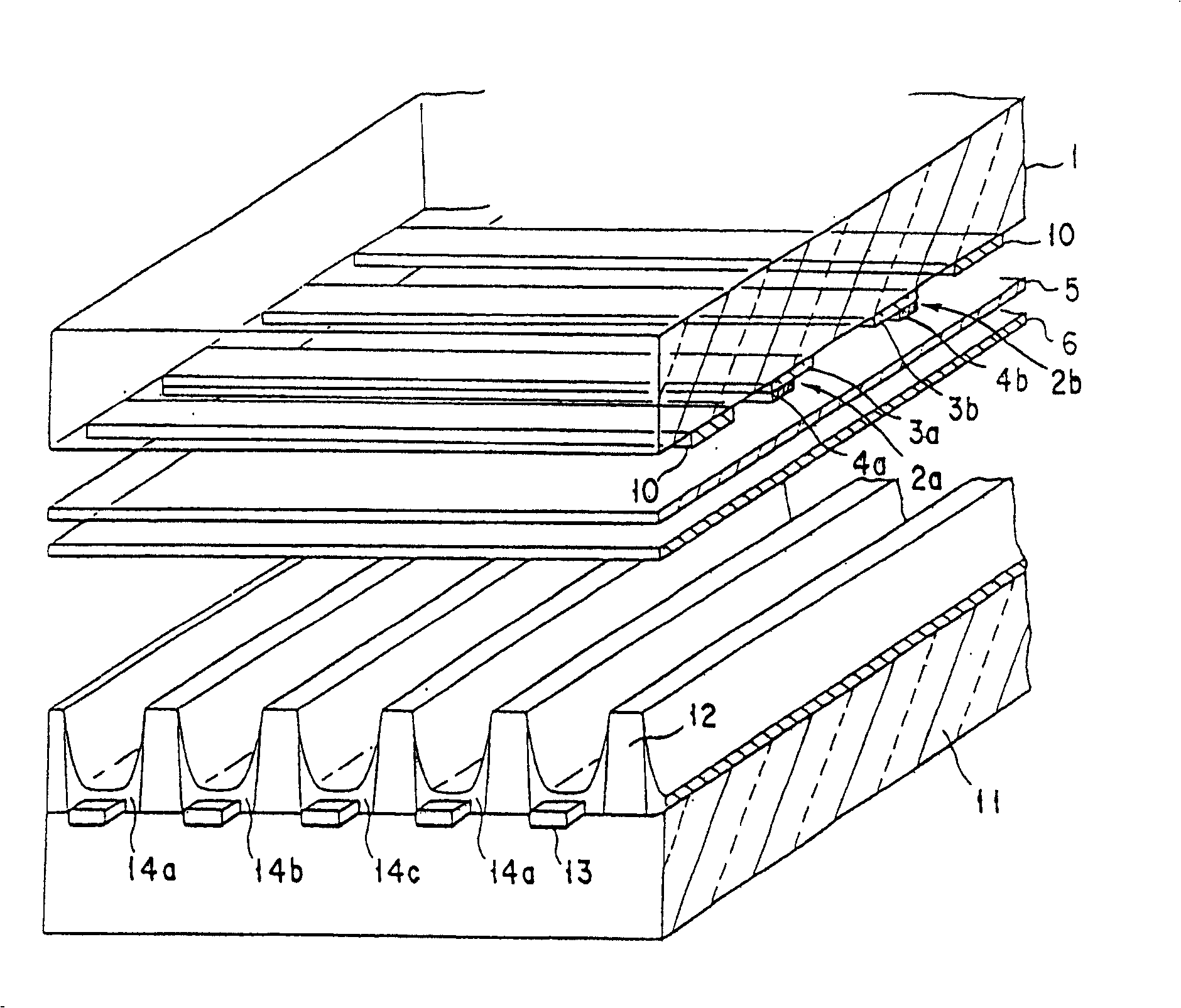

Image

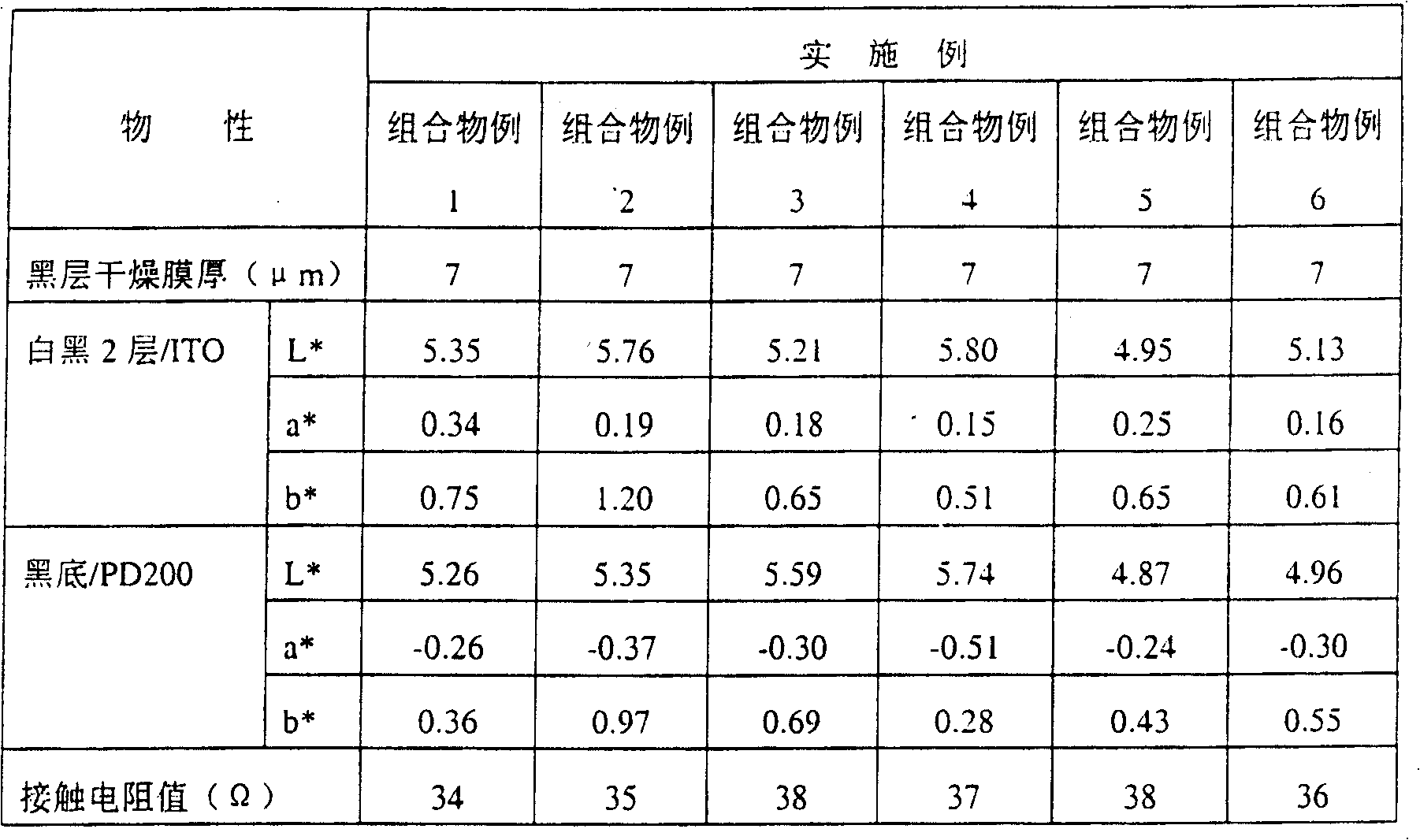

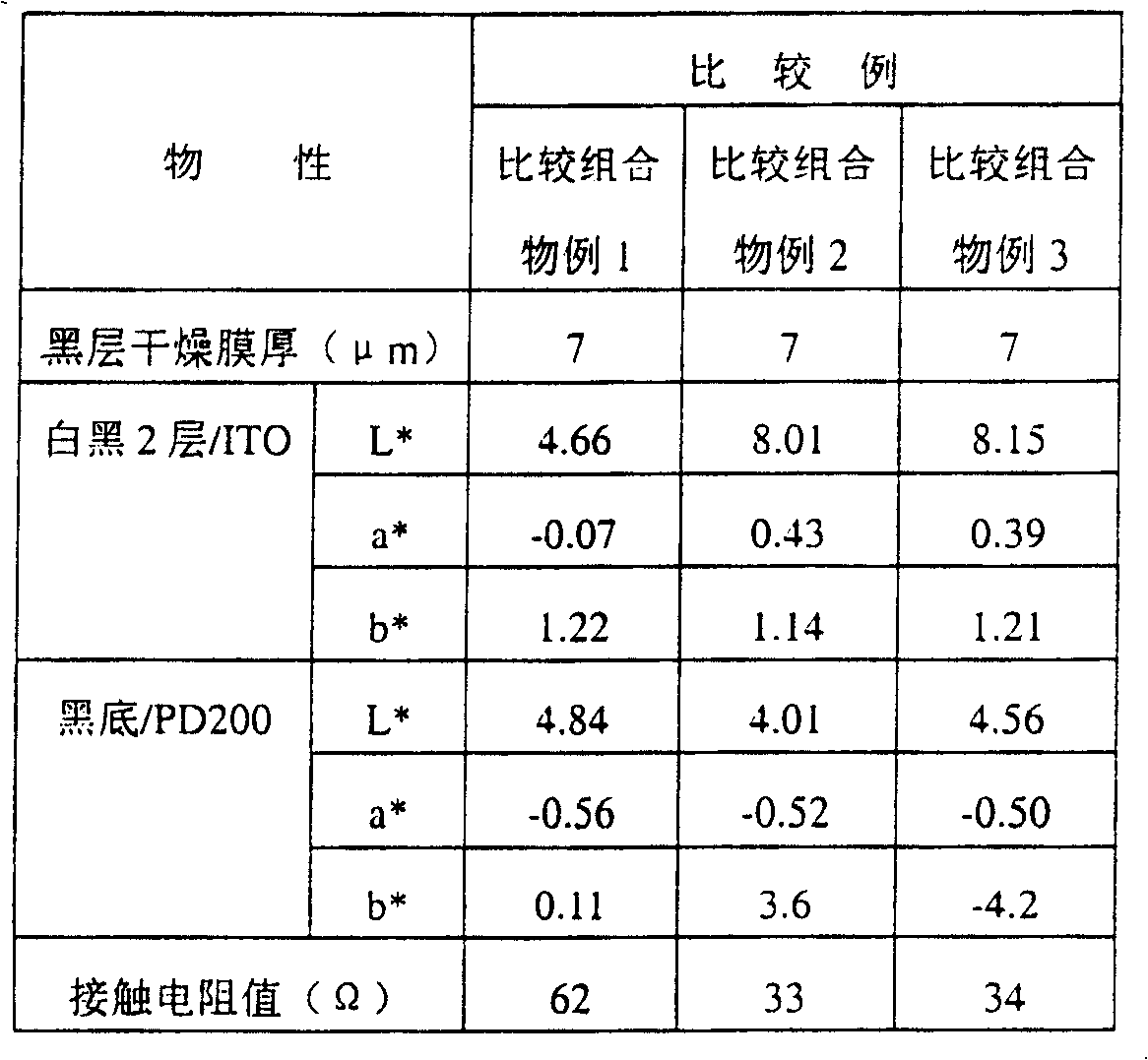

Examples

Embodiment

[0068] The present invention is specifically described below in conjunction with the examples, but the present invention is not limited to the following examples. "Parts" in the following descriptions are all parts by weight unless otherwise specified.

Synthetic example 1

[0070] In a flask equipped with a thermometer, a stirrer, a dropping funnel, and a reflux cooler, fill methyl methacrylate and methacrylic acid in a molar ratio of 0.87:0.13, add solvent dipropylene glycol monomethyl ether, catalyst azobis Isobutyronitrile was stirred at 80° C. for 2 to 6 hours under a nitrogen atmosphere to prepare the organic binder-A as a resin solution. The copolymer resin in the organic binder-A has a weight average molecular weight of about 10,000 and an acid value of 74 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com