Eccentric bushing brake for vortex compressor

A scroll compressor and eccentric bushing technology, which is applied in the direction of machines/engines, rotary piston machines, rotary piston/swing piston pump components, etc., can solve the problem of reducing recompression compression efficiency, machine performance, and refrigerant gas leakage To prevent the loss of the elastic function of the brake, reduce the leakage of the refrigerant, and ease the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

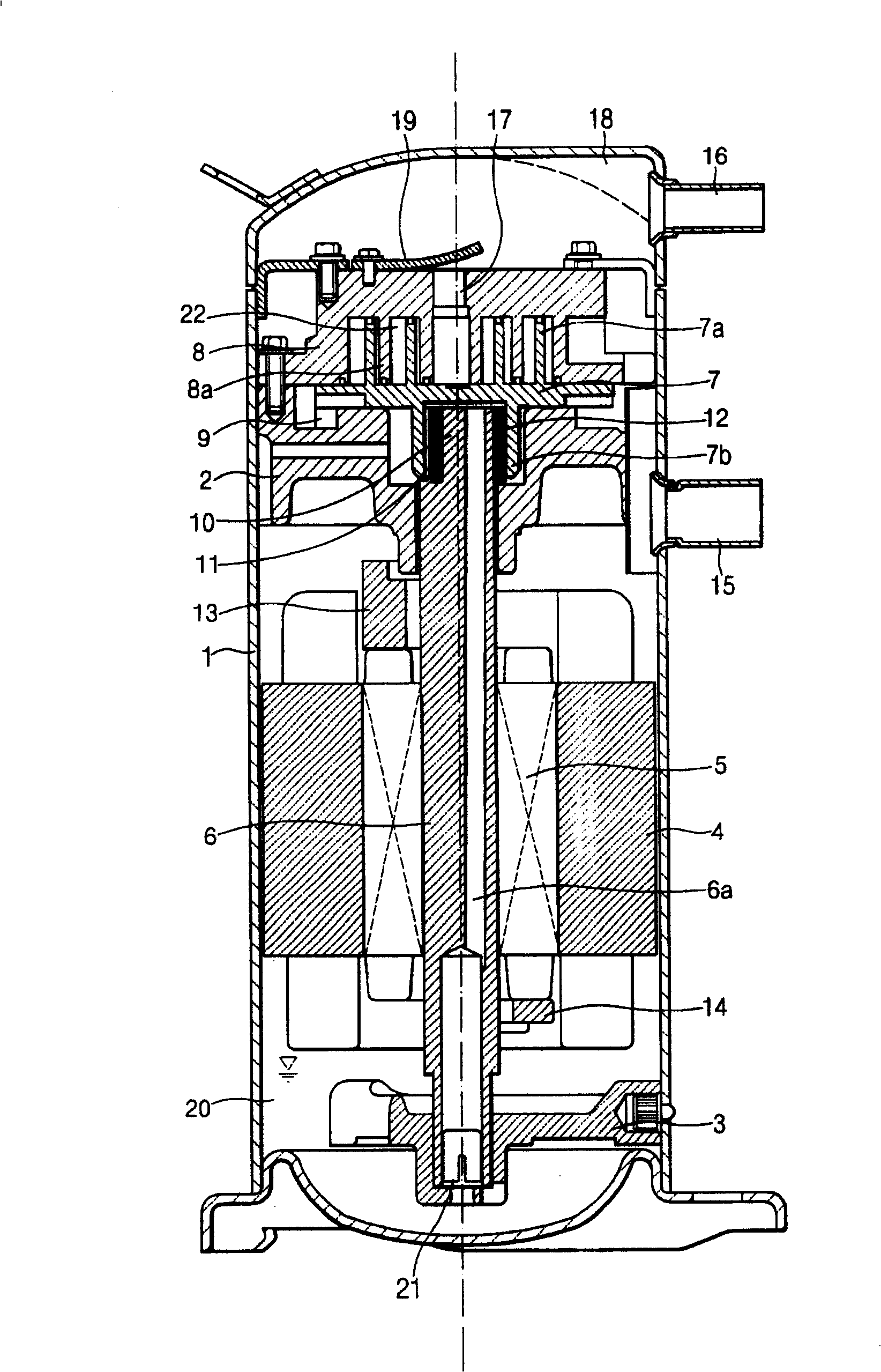

[0043] Hereinafter, the structure of the present invention will be described in detail with reference to the drawings and examples.

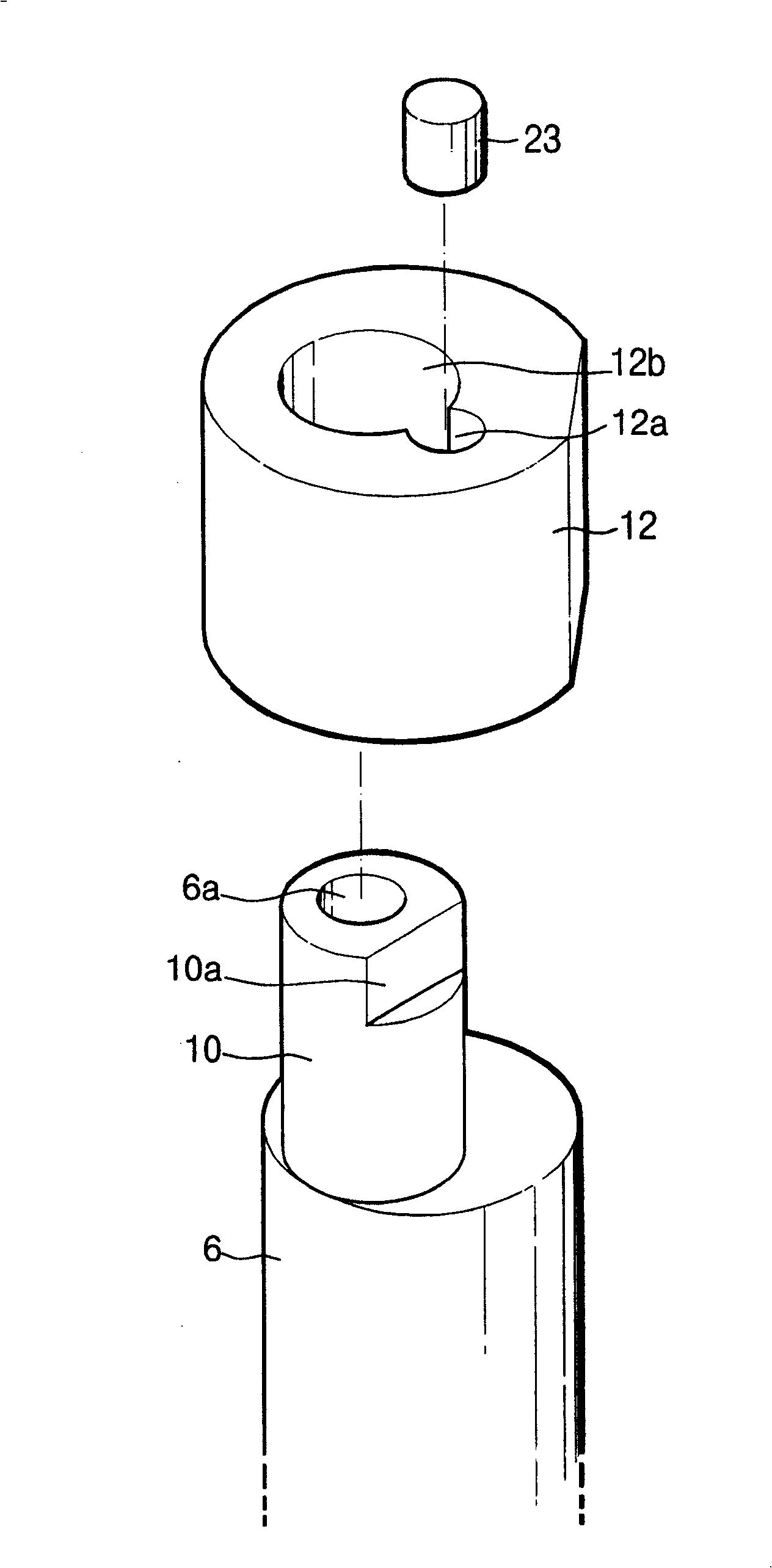

[0044] Figure 4 It is an exploded perspective view of an eccentric bushing according to an embodiment of the present invention.

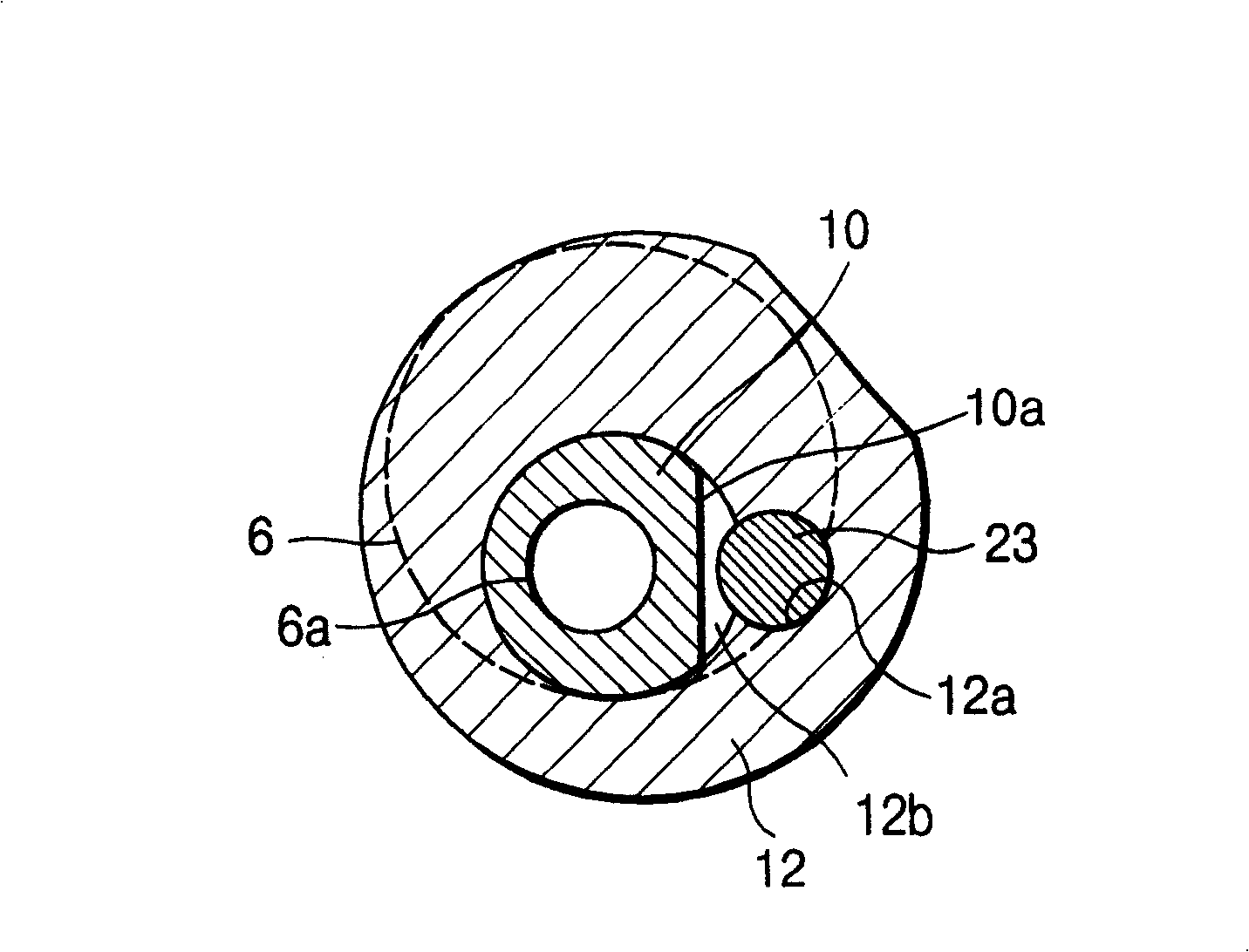

[0045]Generally, the eccentric bushing 12 is provided with a crankpin coupling hole 12b and a brake coupling hole 12a, and is rotatably coupled to the crankpin coupling hole 12b with the crankpin 10 arranged on the upper end surface of the crankshaft 6, one side of the crankpin 10 The upper part is formed with a brake hook surface 10a in a vertical section, and when the brake 23 is inserted into the brake coupling hole 12a of the eccentric bush 12 to rotate the eccentric bush 12, the brake 23 contacts the brake hook surface 10a to limit the movement of the eccentric bush 12. amount of rotation.

[0046] In the eccentric bushing brake of the scroll compressor, there is a device that compresses the eccentric bushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com