Mounting device for transfusion filter assembling machine

A filter group and assembly device technology, applied in the field of machinery, can solve assembly problems and achieve the effects of simple structure, high speed and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

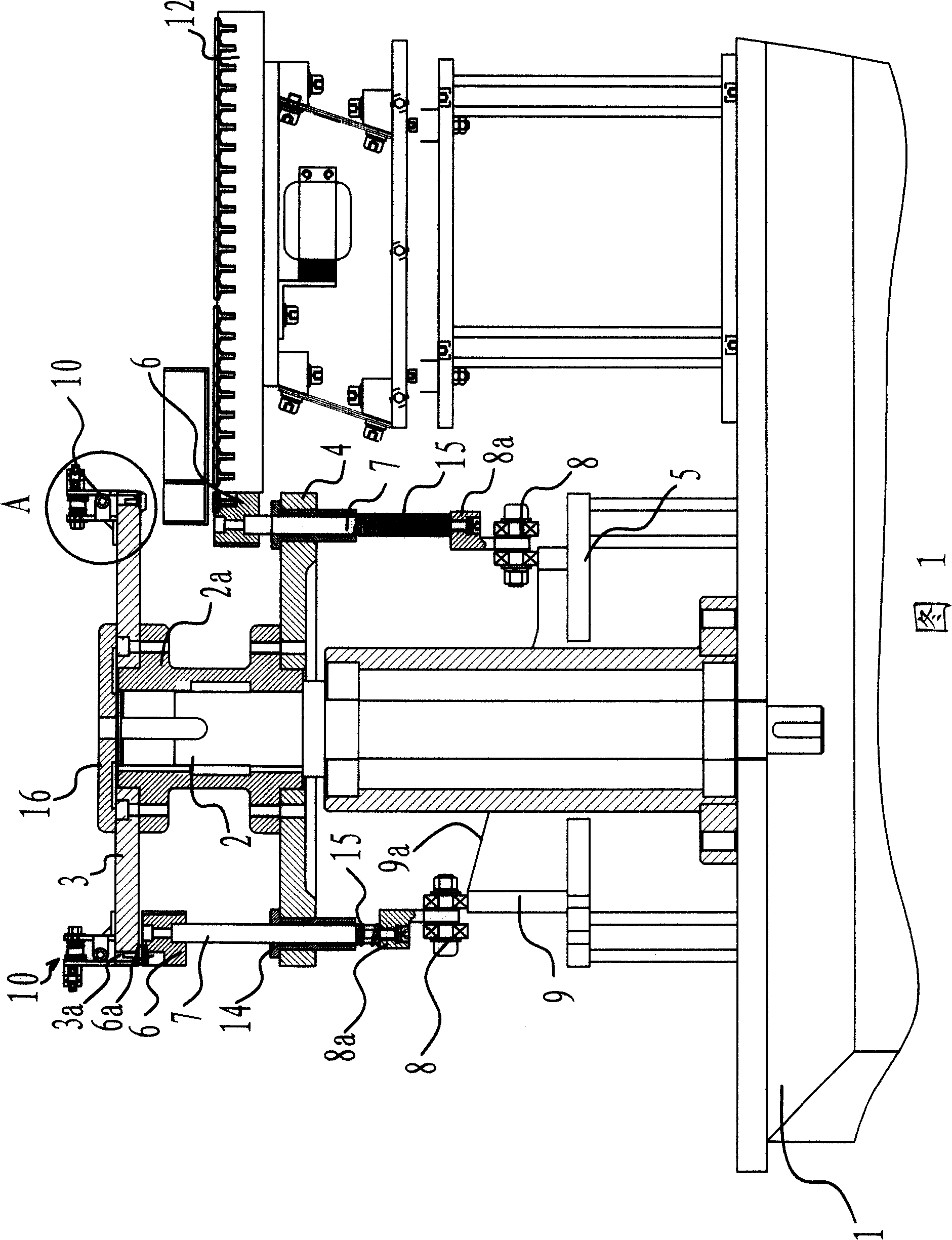

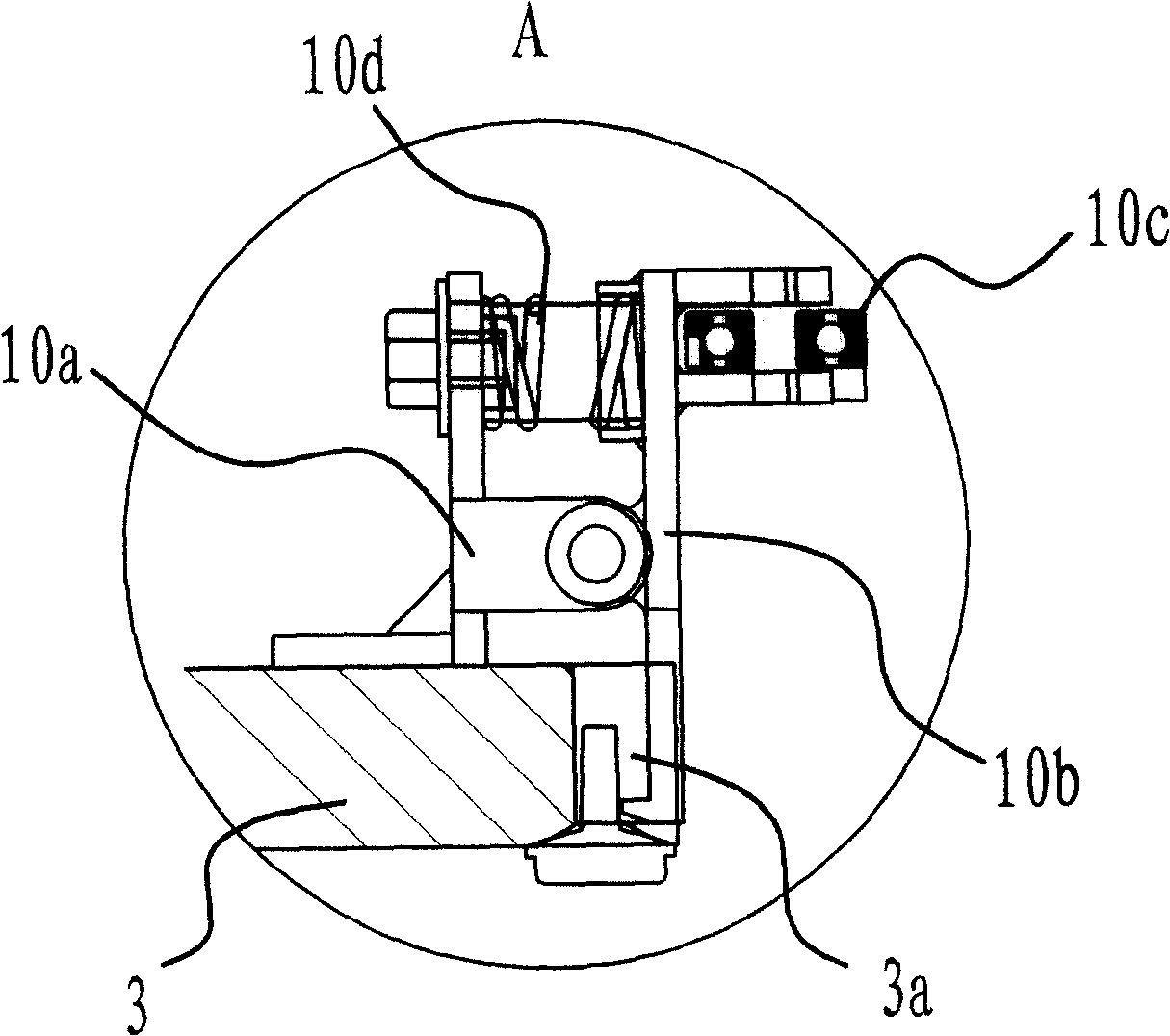

[0028] As shown in Figure 1 and Figure 2, the assembly device of the infusion filter assembly machine is set on the frame 1 of the infusion filter assembly machine. It comprises parts such as rotating shaft 2, upper turntable 3, lower turntable 4, base 5, slide block 6, push rod 7, pulley 8, upper shell fixing device 10.

[0029] As shown in Figure 1, two upper turntables 3 and lower turntables 4 that can rotate together with the turntable 2 are fixed on the rotating shaft 2, and a fixed base 5 is arranged at the bottom of the lower turntable 4. There are 12 evenly distributed sliders 6 between them, and the sliders 6 are connected with the corresponding pulleys 8 through the push rods 7 passing through the lower turntable 4 . A projection 9 with an inclined surface 9a is also fixed on the top of the base 5 along the sliding route of the pulley 8 .

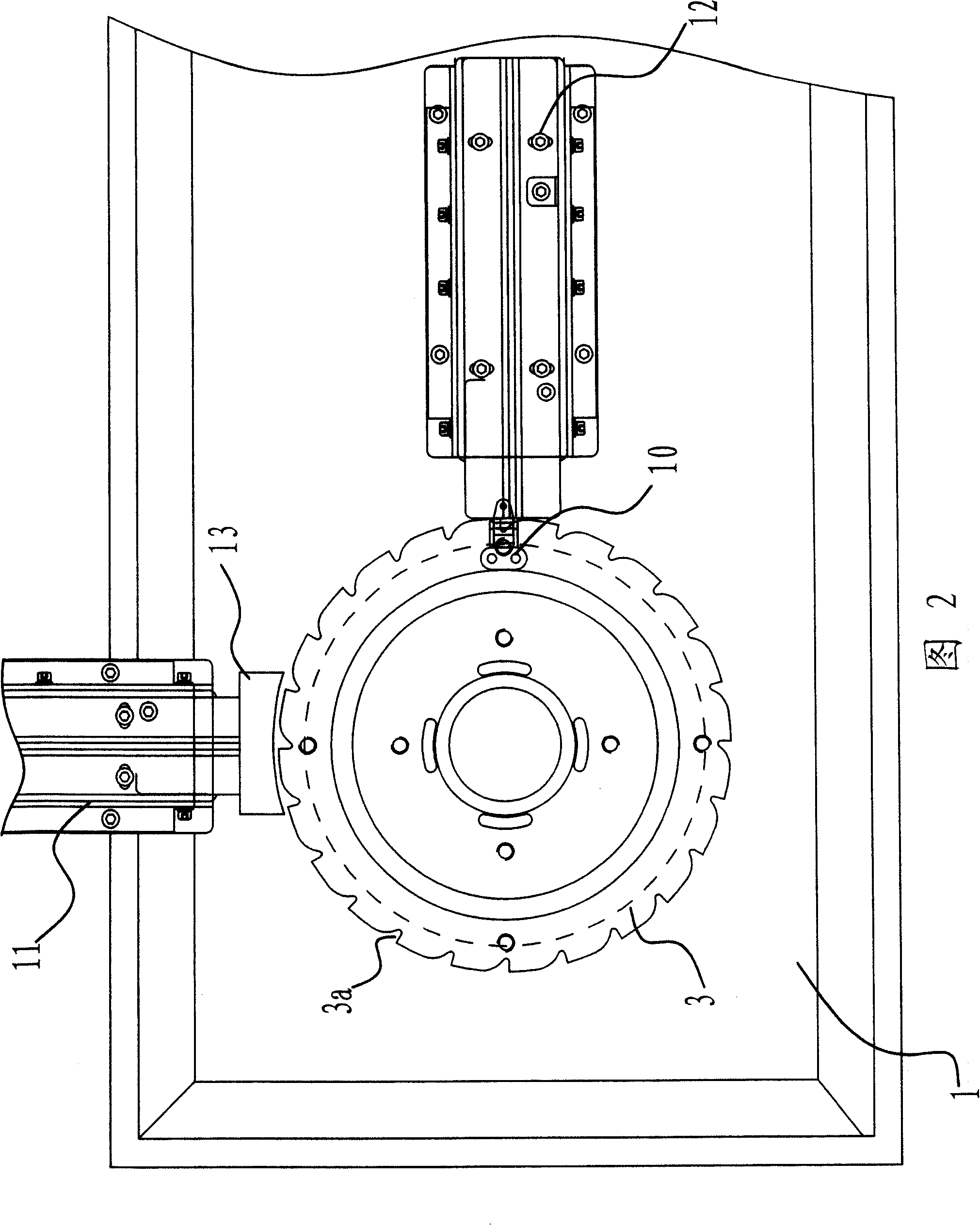

[0030] As shown in FIG. 2 , an upper shell horizontal feed slot 11 for conveying the upper shell is provided on one side of the...

Embodiment 2

[0037] In this embodiment, a torsion spring is provided at the hinge joint between the clip 10b and the frame 10a, and the two legs of the torsion spring respectively act on the clip 10b and the frame 10a. The rest are the same as in Example 1, and will not be described in detail herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com