Method for producing a wiper blade, device for carrying out the method and wiper blade produced according to the method

A technology of wiper blades and wiper strips, which is applied in vehicle cleaning, transportation and packaging, and vehicle maintenance. It can solve the problems of being easily disturbed, complicated in mass production, and difficult to achieve accurate cooperation. It achieves simple insertion, process-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

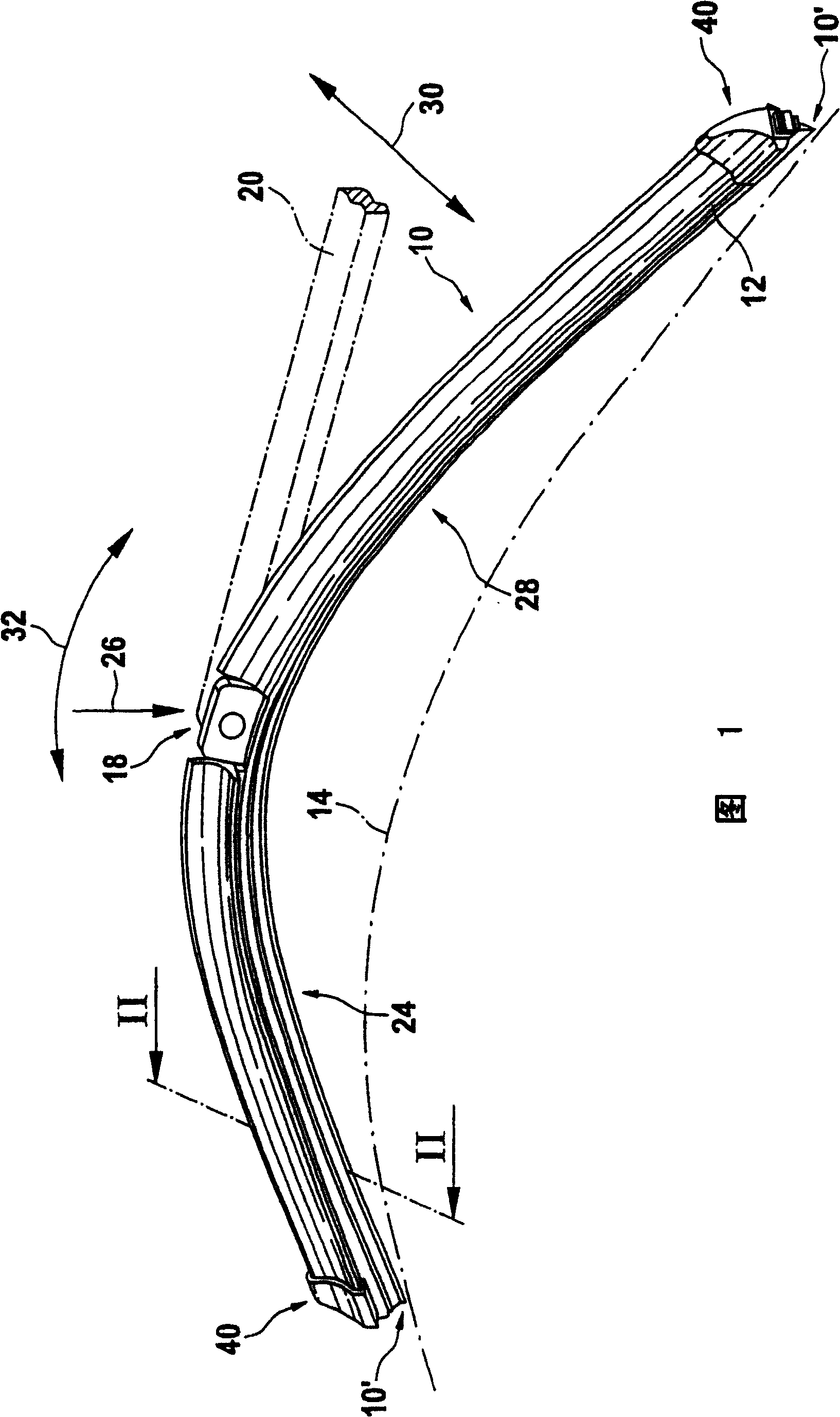

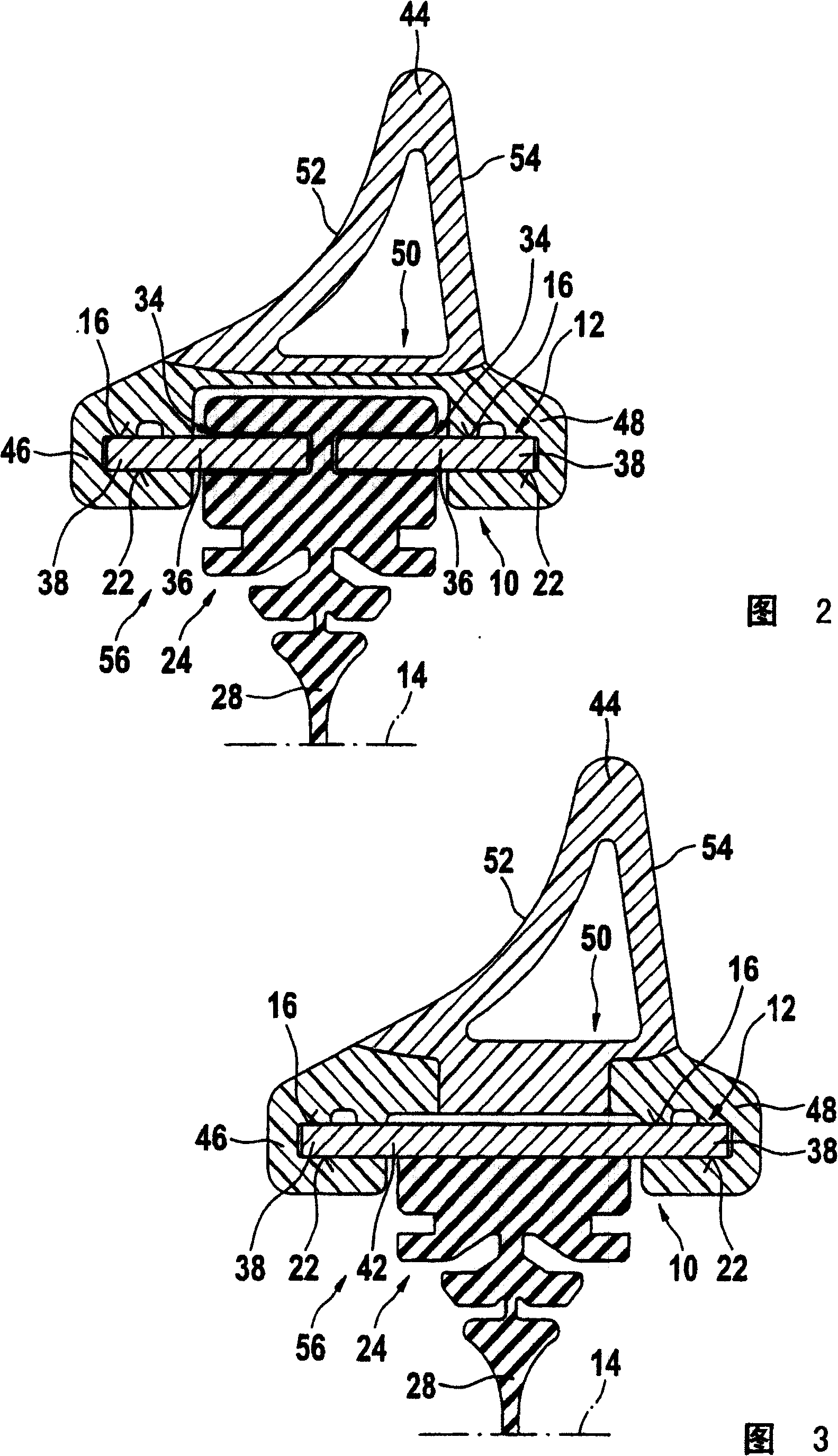

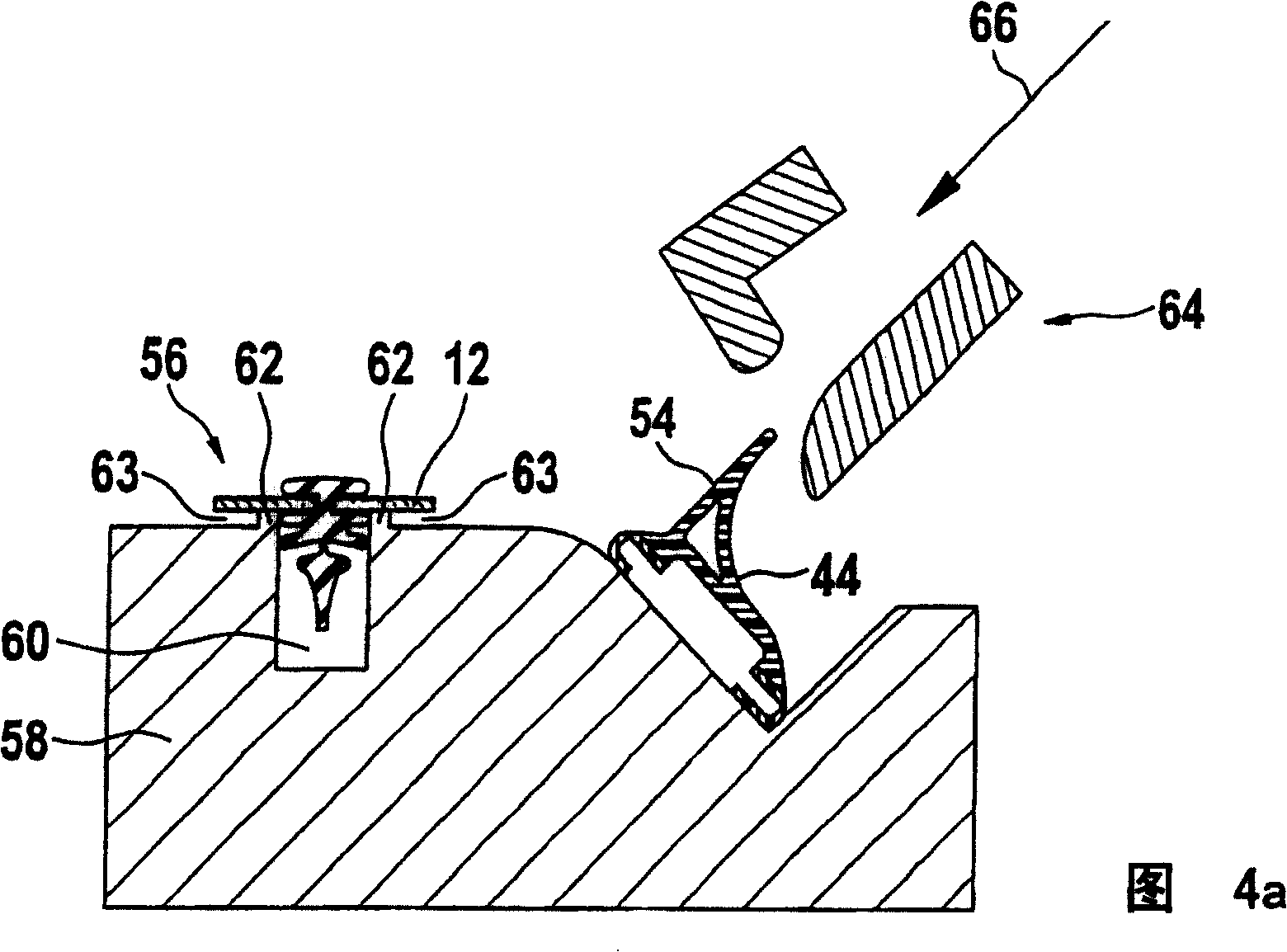

[0029] The wiper blade 10 shown in FIG. 1 has a strip-shaped, elongated, spring-elastic one-piece or multi-part support component 12 which is bent in the longitudinal direction in the unloaded state. On the raised upper or outer surface 16 of the support member 12 facing away from the glass pane 14 to be wiped ( FIGS. 1 and 2 ), on the middle section of the support member is arranged a for example flat against said upper or A connecting device 18 on the outer web 16, by means of which the wiper blade 10 can be releasably connected to a driven wiper arm 20 which is guided and moved on the vehicle body. A long rubber-elastic wiper strip 24 is arranged on the concave lower or inner web or edge 22 of the curved carrier element 12 facing the glass pane, the longitudinal axis of which is parallel to the carrier element. On the free end of the wiper arm there is an opposing connecting device, not shown in detail, which cooperates in a hinged manner with the connecting device 18 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com