Method of raising response frequency of high pressure servo system in rolling machine

A technology of servo system and response frequency, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of restricting the response frequency of the rolling mill servo system, and achieve the effect of increasing the response frequency and increasing the frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

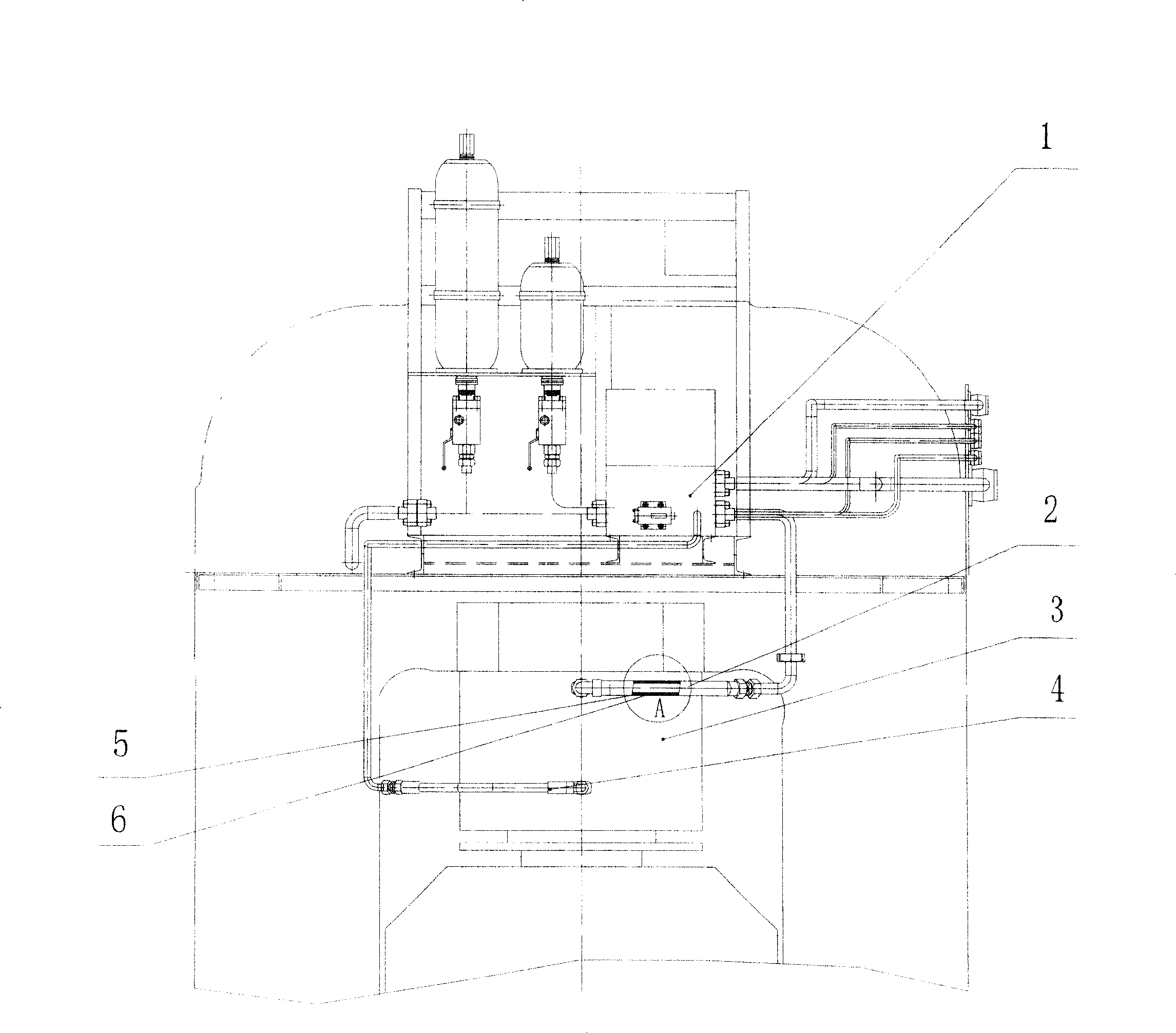

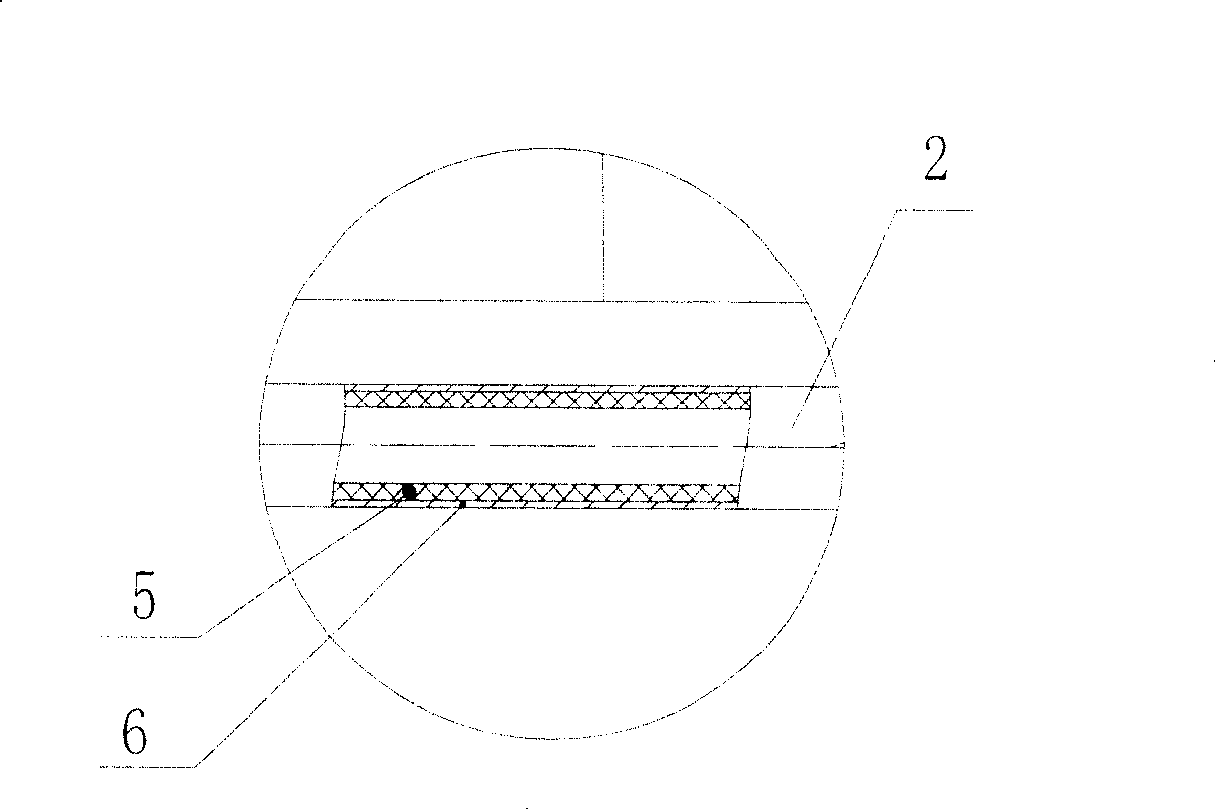

[0012] Such as figure 1 , figure 2 As shown, a method for improving the response frequency of the high-pressure servo system of the rolling mill, in the high-pressure servo system of the high-speed tandem cold rolling mill, a steel pipe 6 is added to the high-pressure hose 5 connecting the pressing cylinder valve table 1 and the pressing cylinder 3, Steel pipe thickness 3mm. The high-voltage servo system of the high-speed tandem cold rolling mill referred to in the present invention is a known technology.

Embodiment 2

[0014] Such as figure 1 , figure 2 As shown, a method for improving the response frequency of the high-pressure servo system of the rolling mill, in the high-pressure servo system of the high-speed tandem cold rolling mill, a steel pipe 6 is added to the high-pressure hose 5 connecting the pressing cylinder valve table 1 and the pressing cylinder 3, Steel pipe thickness 4mm.

Embodiment 3

[0016] Such as figure 1 , figure 2 As shown, a method for improving the response frequency of the high-pressure servo system of the rolling mill, in the high-pressure servo system of the high-speed tandem cold rolling mill, a steel pipe 6 is added to the high-pressure hose 5 connecting the pressing cylinder valve table 1 and the pressing cylinder 3, Steel pipe thickness 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com