Method and device for detecting loading process and attenuation law of laser shock wave

A loading process, laser shock technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of complex operation, difficult adjustment, expensive equipment, etc., to achieve the effect of simple equipment structure, clear measurement principle, and convenient operation

Inactive Publication Date: 2014-05-28

JIANGSU UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The salient features of laser-induced plasma shock wave pressure are high pressure (GPa level), short action time (ns level), and fast decay, which brings great difficulties to the experimental measurement of the shock wave attenuation law. Currently, the measurement of laser plasma shock wave The method of attenuation law can be divided into contact detection method and non-contact detection method; contact detection method includes broadband loudspeaker, PVDF or PZT transducer, quartz sensor, sapphire sensor, manganese copper wire piezoresistive sensor and based on dual Optical fiber sensors based on refraction theory, etc. The disadvantages of these measurement methods are that the shock wave pressure range and temperature field changes have a great influence on the measurement results, the frequency response of the equipment is limited, the measurement data is unstable, and the randomness is large; the non-contact detection method includes beam deflection method, beam detection method, high-speed photography method, phase measurement method, optical scattering method, ultrafast microscopic imaging interferometer, ultrafast time-resolved imaging interferometer, ultrafast time-resolved frequency-domain interferometer, etc., these measurement methods The disadvantages are that the equipment is expensive, the operation is complicated, the adjustment is difficult, and the measurement results are greatly affected by the environment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

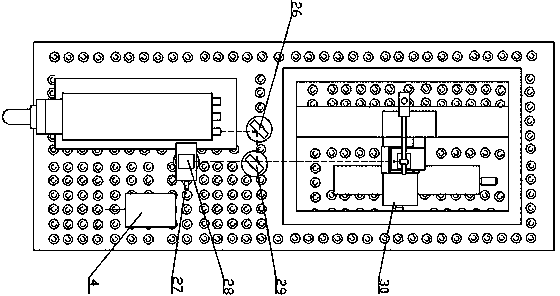

[0035] The dynamic strain curves measured by a single impact on 2024 aluminum alloys with three different thicknesses (1.3mm, 1.7mm, 2.1mm) using the principle and device of the present invention are as follows: Figure 4 shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

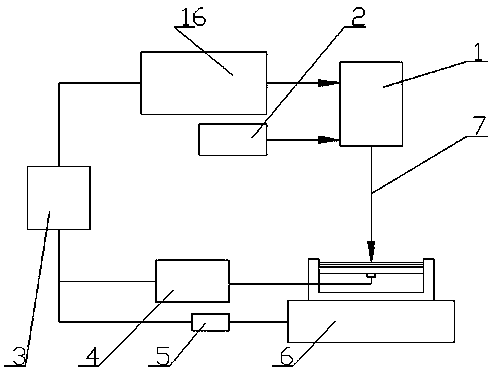

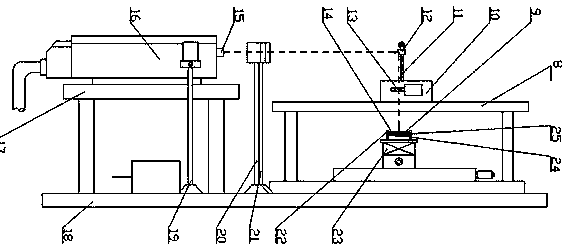

The invention relates to the technical field of laser shock wave measurement, in particular to a method and a device for detecting loading process and an attenuation law of laser shock wave based on strain gauge technology, which utilize a strain gauge to detect a dynamic strain curve at the backs of target materials with different thickness, the target materials are shocked by laser, and the loading process and the attenuation law of the laser shock wave are analyzed according to a collected dynamic strain curve. The method and the device for detecting the loading process and the attenuation law of the laser shock wave are clear in measurement principle, simple in device structure, convenient to operate and low in cost, and the measurement result cannot be influenced by environment.

Description

technical field [0001] The present invention relates to the technical field of laser shock wave measurement, in particular to a method and device for detecting the loading process and attenuation law of laser shock wave based on strain gauge technology. The collected dynamic strain curves are used to analyze the loading process and attenuation law of the laser shock wave. Background technique [0002] In the early 1960s, Askaryon and Morez discovered the laser-induced plasma shock wave phenomenon for the first time, and then scholars from various countries conducted a large number of theoretical modeling and experimental research, and gradually applied it in industry, developing into the most popular laser shock strengthening technology. It has the characteristics of strain-affected layer depth, controllable impact area and pressure, well maintained surface roughness and dimensional accuracy of the strengthening position, and easy automation; the laser shock strengthening pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01D21/00

Inventor 冯爱新聂贵锋曹宇鹏周鹏程王俊伟卢轶

Owner JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com