Method for manufacturing seamless plastered, watertight and down penetration resistant down garment

A production method and anti-drilling velvet technology, applied to sewing tools, clothing, clothing, etc., can solve the problems of reduced windproof performance, affecting the overall appearance, and not easy to dry, so as to achieve convenient movement and movement, and avoid needle seams Better leakage and heat retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

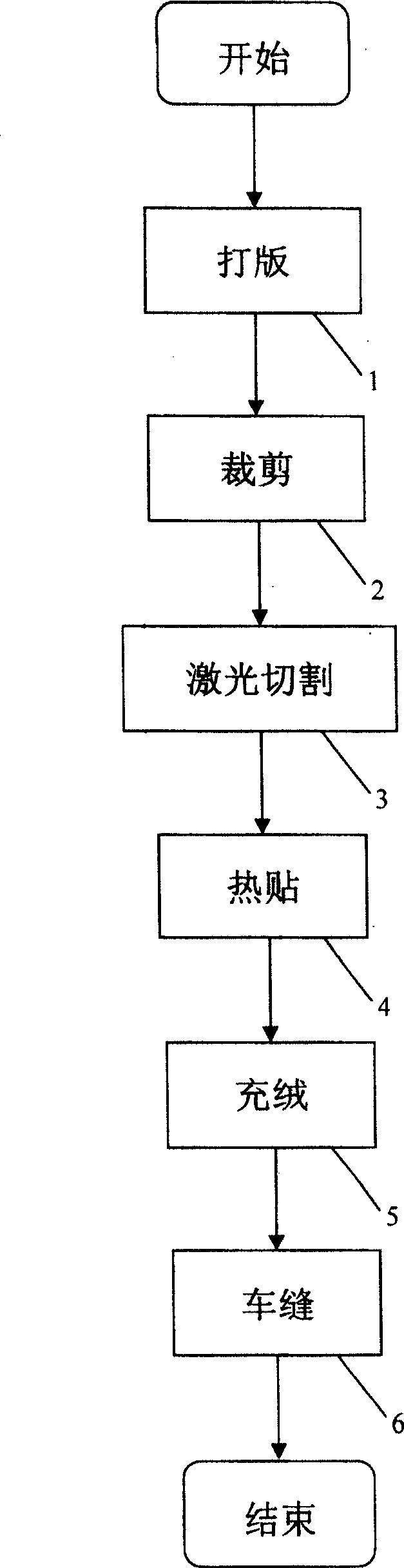

[0015] figure 1 It is a flow chart of a method for making a seamlessly fitted waterproof and anti-drilling down jacket. Including the following steps:

[0016] Pattern making 1: According to the designed style diagram, pattern making is carried out according to the size requirements;

[0017] Cutting 2: Cutting according to the pattern provided by the pattern making;

[0018] Laser cutting 3: Use the drawing software to set the pattern to be laser cut on the computer, set the energy and speed of the laser cutting machine, and transfer the pattern to the laser cutting machine for cutting. The production process of traditional down jackets does not have this step. During the fabric production process, the outermost layer of the fabric is treated with an extremely thin layer of durable water-extracting agent PU film, which will promote the formation of water beads and improve runoff through a seamless smoother garment surface. , so that the formed water droplets slide down qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com