A method for applying ethanol-humidified air or natural gas to blend-burning ethanol fuel of IC engines

A technology of alcohol fuel and natural gas, which is applied to gaseous engine fuel, internal combustion piston engine, combustion engine, etc., can solve the problems of difficult to mix evenly, two phases are difficult to mix evenly, mixed combustion, etc., and achieves simple implementation, wide application range, improved economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

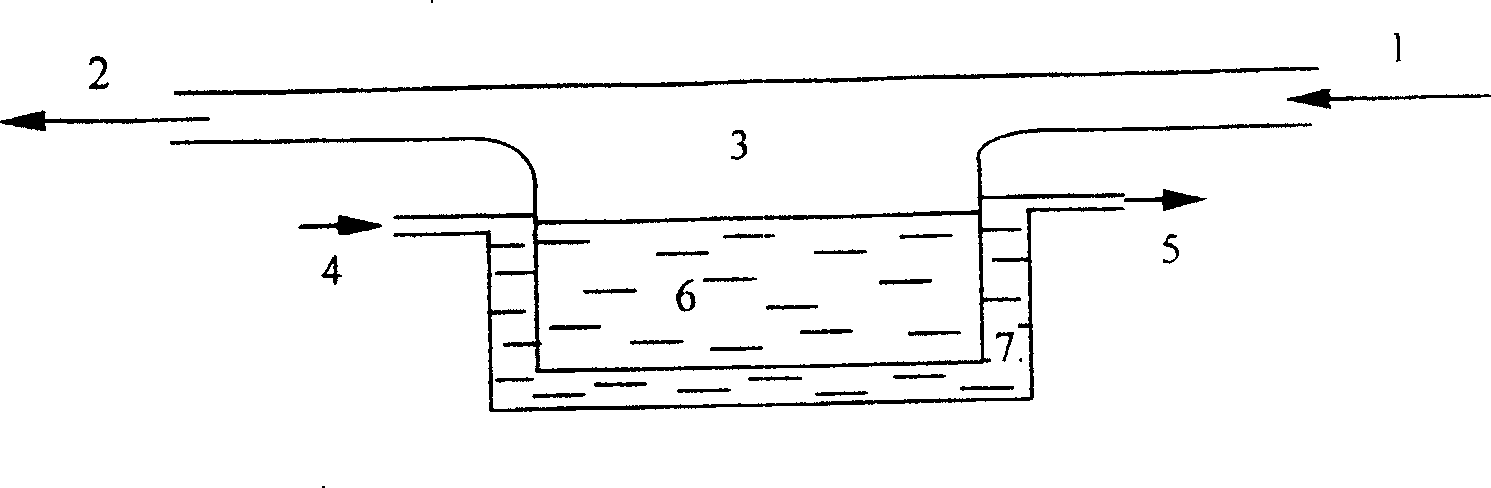

Method used

Image

Examples

example 1

[0013] At room temperature 20°C, the contact area of the alcohol liquid surface and phase is 11cm 2 , use alcohol fuel to humidify air or natural gas to form a mixed gas of alcohol and air or natural gas, and measure the relationship between air or natural gas flow rate (Q) and alcohol volume content (V) in alcohol mixed gas. The data are shown in attached table 1. Alcohol fuels include methanol, absolute ethanol and 95% ethanol, the same below.

example 2

[0015] The flow rate of air or natural gas is 2.4L / min, and the contact area of alcohol liquid surface is 11cm 2 , use alcohol fuel to humidify air or natural gas to form a mixed gas of alcohol and air or natural gas, and measure the relationship between the alcohol fuel temperature (T) and the alcohol volume content (V) in the alcohol mixed gas. The data are shown in Table 2.

example 3

[0017] The flow rate of air or natural gas is 3.0L / min. Use alcohol fuel to humidify the air or natural gas to form a mixed gas of alcohol and air or natural gas. The temperature of alcohol fuel is 30°C and 50°C. For the volume content (V) relationship of alcohol in the gas mixture, please see attached table 3 for the data.

[0018] Table 1 Air ① (or natural gas ② ) The relationship between the flow rate Q and the alcohol volume content in the alcohol mixture

[0019] Q, L / min 1.2 1.6 2.4 3.0 3.6 V MeOH ,% ① 14.5 15.0 15.1 14.9 15.2 V MeOH ,% ② 16.2 15.9 16.0 15.7 16.1 V EtOH ,% ① 12.8 12.9 13.1 13.0 13.3 V 95%EtOH ,% ① 10.5 11.0 11.1 10.8 10.9 V EtOH ,% ② 13.2 12.9 13.0 13.3 12.8 V 95%EtOH ,% ② 11.5 11.3 11.4 11.6 11.6

[0020] Table 2 Relationship between alcohol fuel temperature T and alcohol volume content in alcohol mixture gas

[0021] T,℃ 20 30 40 50 60 V MeOH ,% ① 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com