Discontinuous grinding mill for ceramic materials

A grinder and raw material technology, applied in the production of ceramic materials, grain processing, etc., to achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

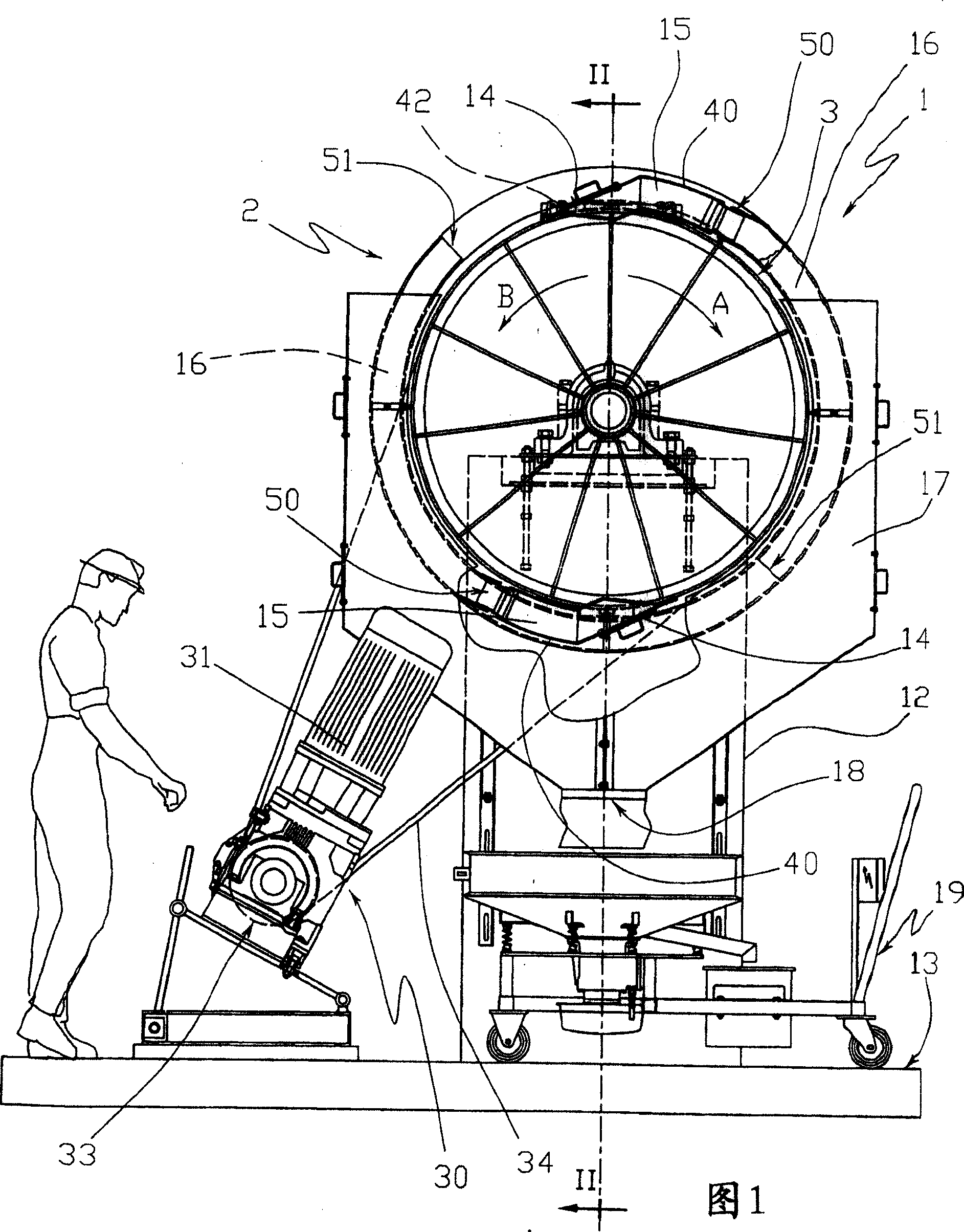

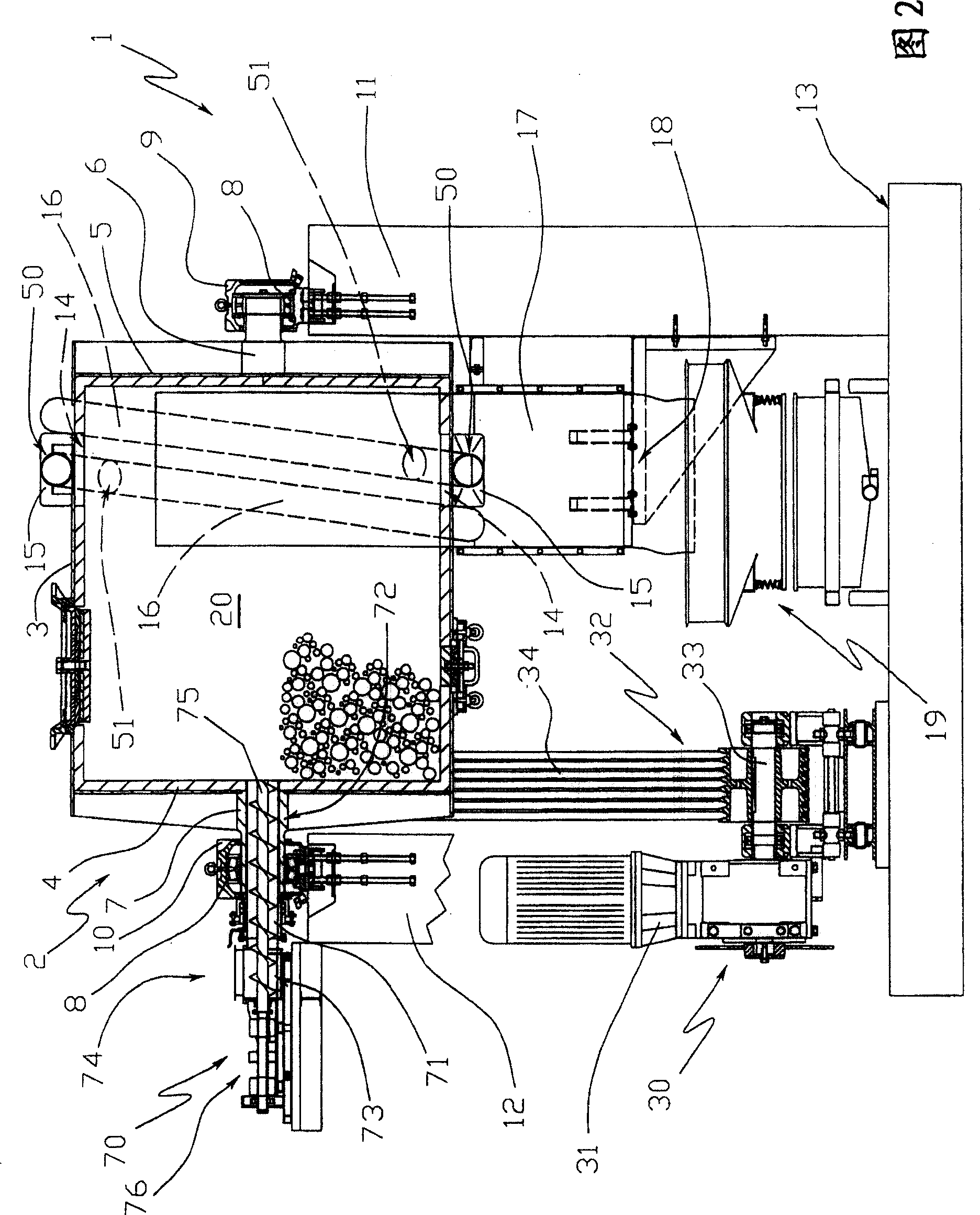

[0030] As can be seen from Figures 1 and 2, a discontinuous mill 1 is used to process coarse-grained raw materials to obtain a slurry with a certain particle size.

[0031] The discontinuous mill 1 comprises a cylindrical drum 2 having a horizontal axis, and the drum also comprises a housing 3, a top base 4 and a bottom base 5, the top base 4 and the bottom base 5 The housing 3 is closed on both sides and defines an internal cavity 20 into which grinding bodies of suitable size are introduced.

[0032] A protruding shaft 6 arranged coaxially with the housing 3 is connected to the bottom base plate 5 (see Figure 2), while a hollow cylindrical sleeve 7 also protrudes from the housing 3 and is mounted coaxially with the housing 3 , which is suitable as an opening to communicate the internal cavity 20 with the outside world, and is connected with the top bottom plate 4 .

[0033] The protruding shaft 6 and the hollow cylindrical sleeve 7 are connected together via bearings 8 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com