Plastic pipe used water dividing device and its diversion method

A water separator and a practical technology, applied in the direction of pipes, pipe components, branch pipelines, etc., can solve the problems of complex structure, inconvenient use, high production cost, etc., and achieve the effect of convenient operation, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

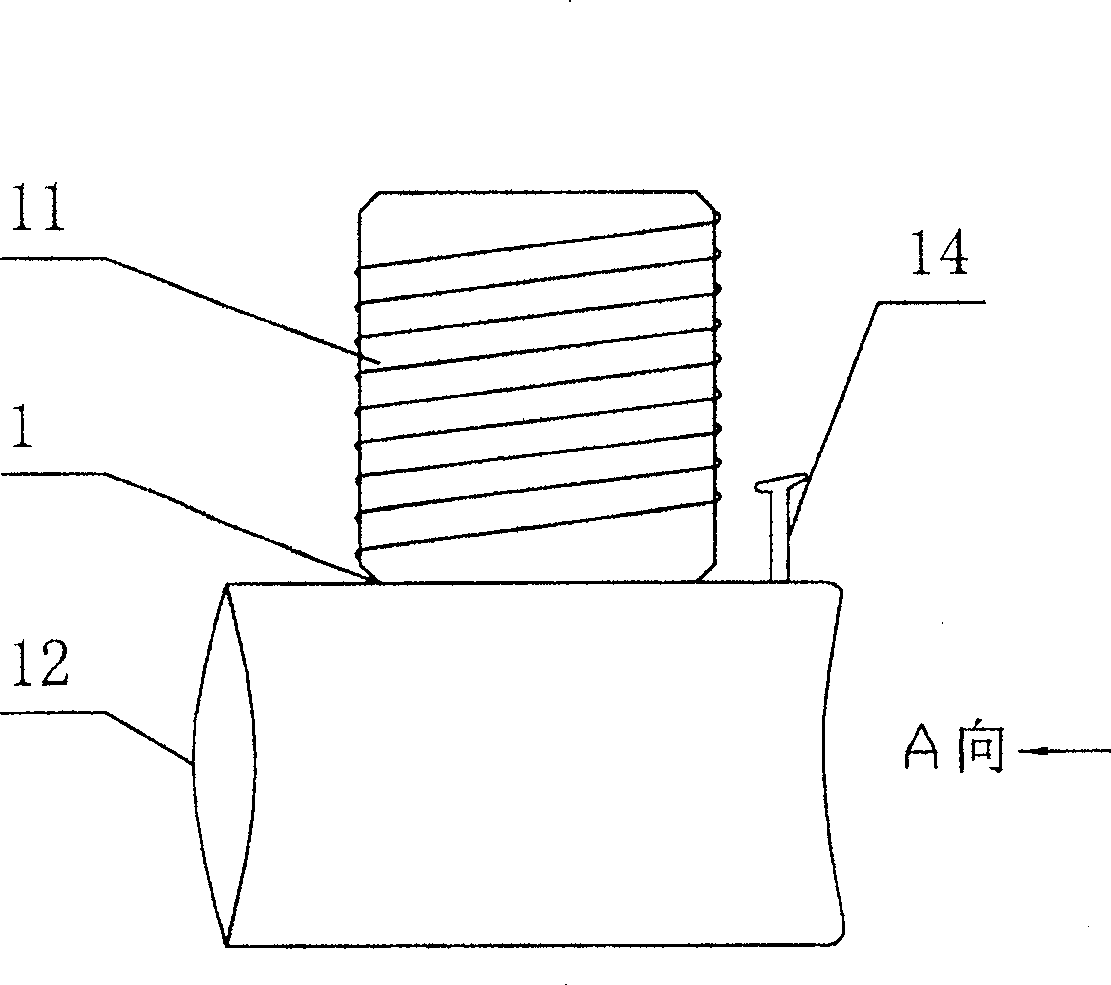

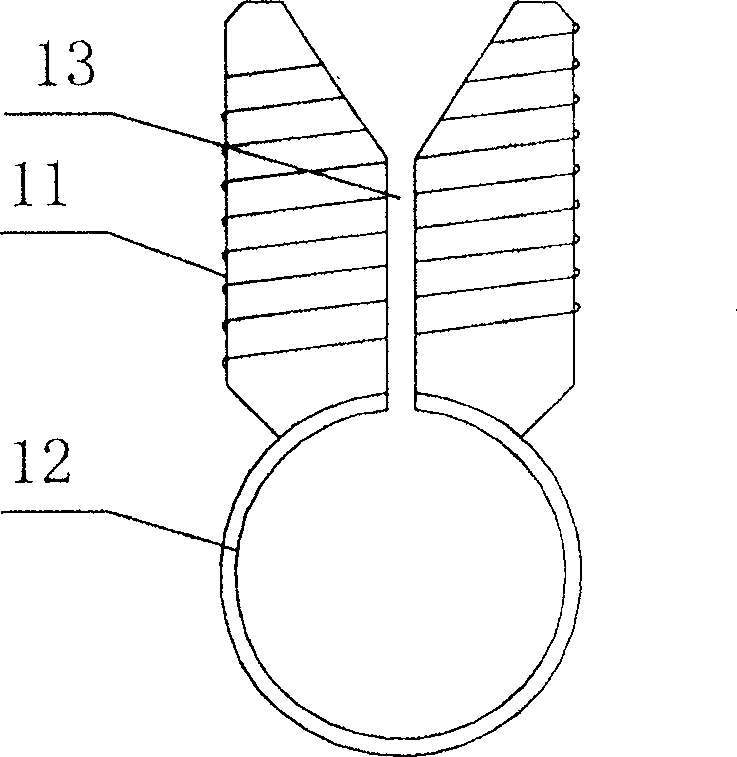

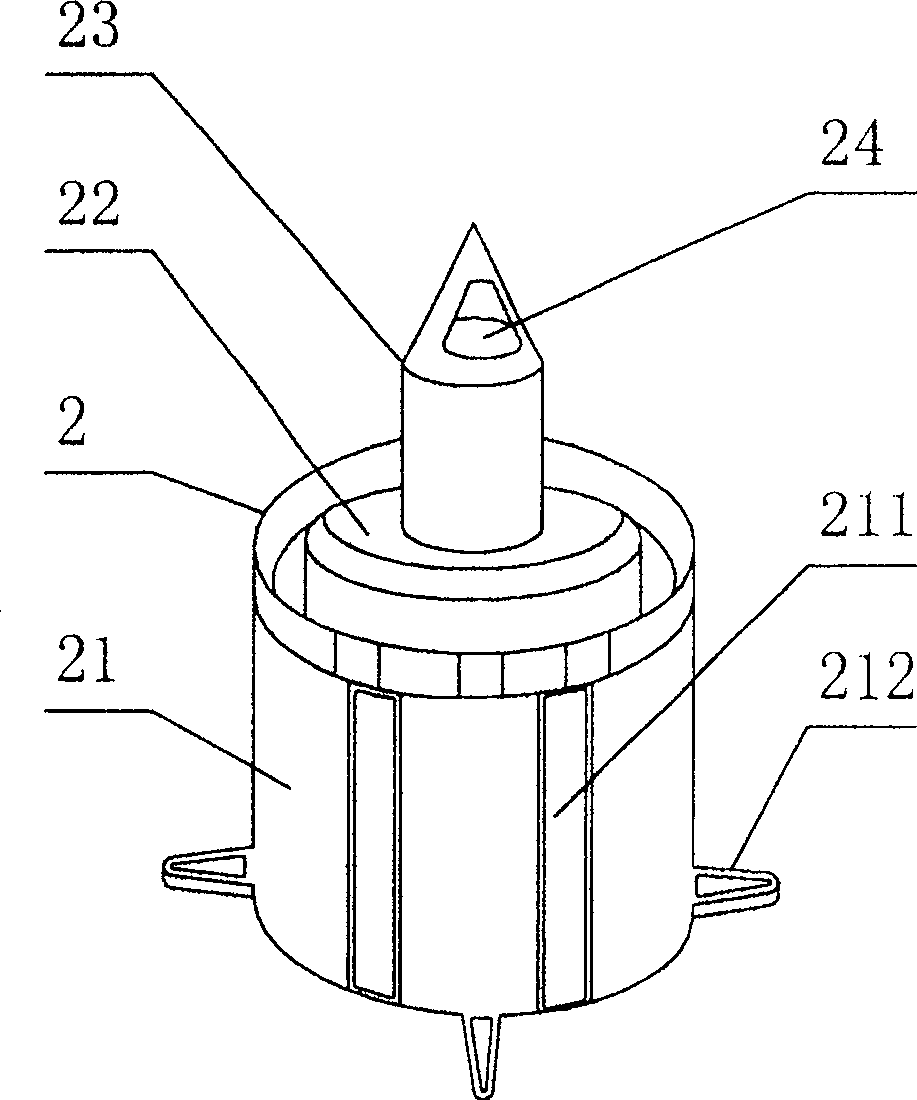

[0018] Figure 1 to Figure 4 A water separator for plastic pipes according to the present invention is shown, including a pipe collar 1 and a joint 2 sleeved on the outer wall of the pipe collar 1, wherein the pipe collar 1 includes a longitudinal sleeve 11 and a joint 2 sleeved together. The horizontal casing 12 used to socket the water pipe 3, the longitudinal casing 11 and the horizontal casing 12 are arranged in a "⊥" shape, and the middle part of the longitudinal casing 11 is provided with an open groove 13 parallel to its axis, and the open groove 13 can also be In order to pass through the central axis of the longitudinal casing 11 of the pipe collar 1 and be parallel to the axial direction of the horizontal casing 12, and also make a "V"-shaped notch on its upper part, the setting of the opening groove 13 facilitates the water pipe to be packed into the horizontal casing. The joint 2 includes an outer sleeve 21 sleeved on the outside of the longitudinal sleeve 11 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com