Detection device and method for fault of engine fuel system

A fuel system and detection device technology, which is applied in the direction of engine testing, measuring devices, machine/structural component testing, etc. It can solve the problem of weak ability to explain the cause of failure, weak guidance for troubleshooting, and inability to judge the fuel supply angle. Size and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be further described in detail below in conjunction with the drawings and specific examples.

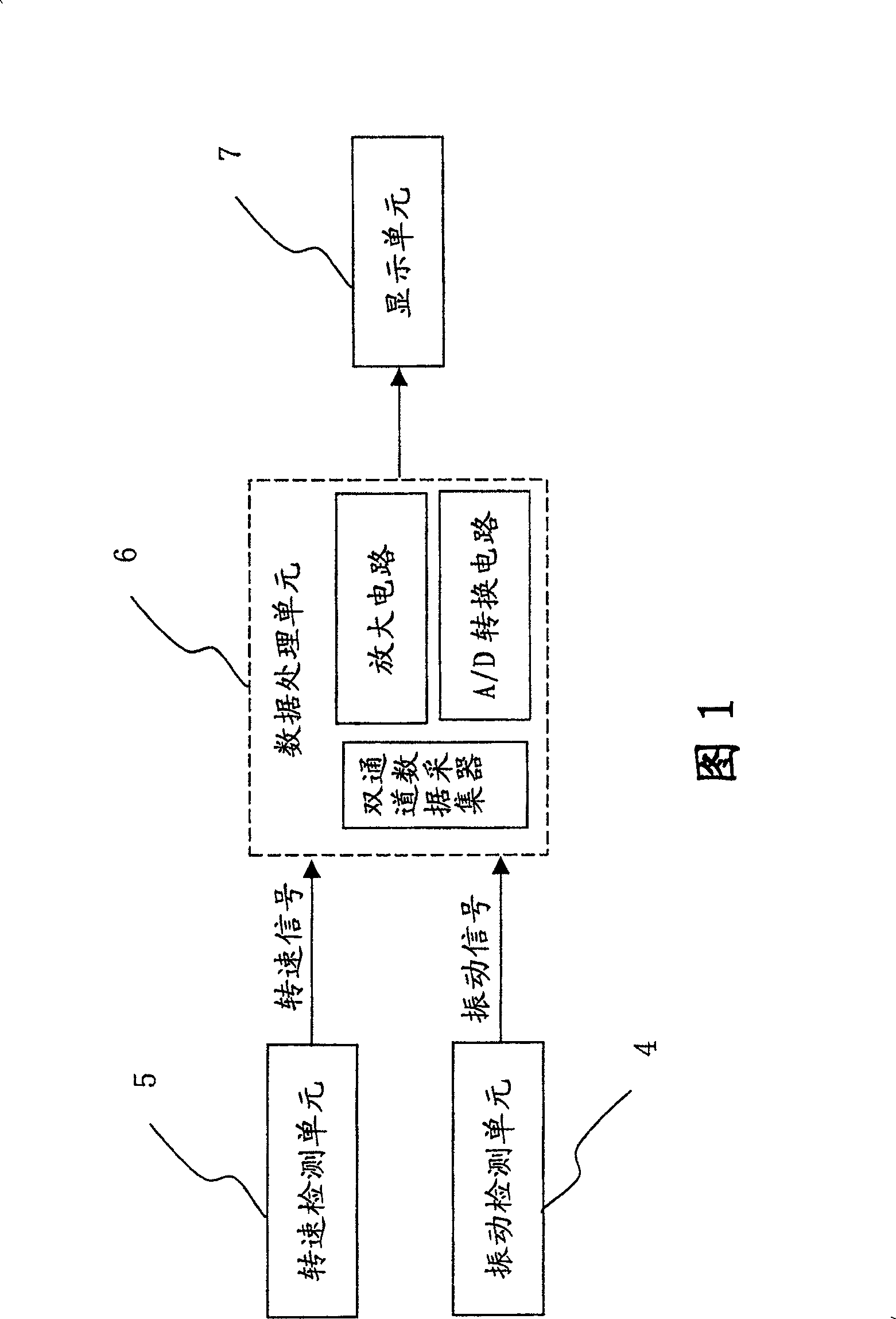

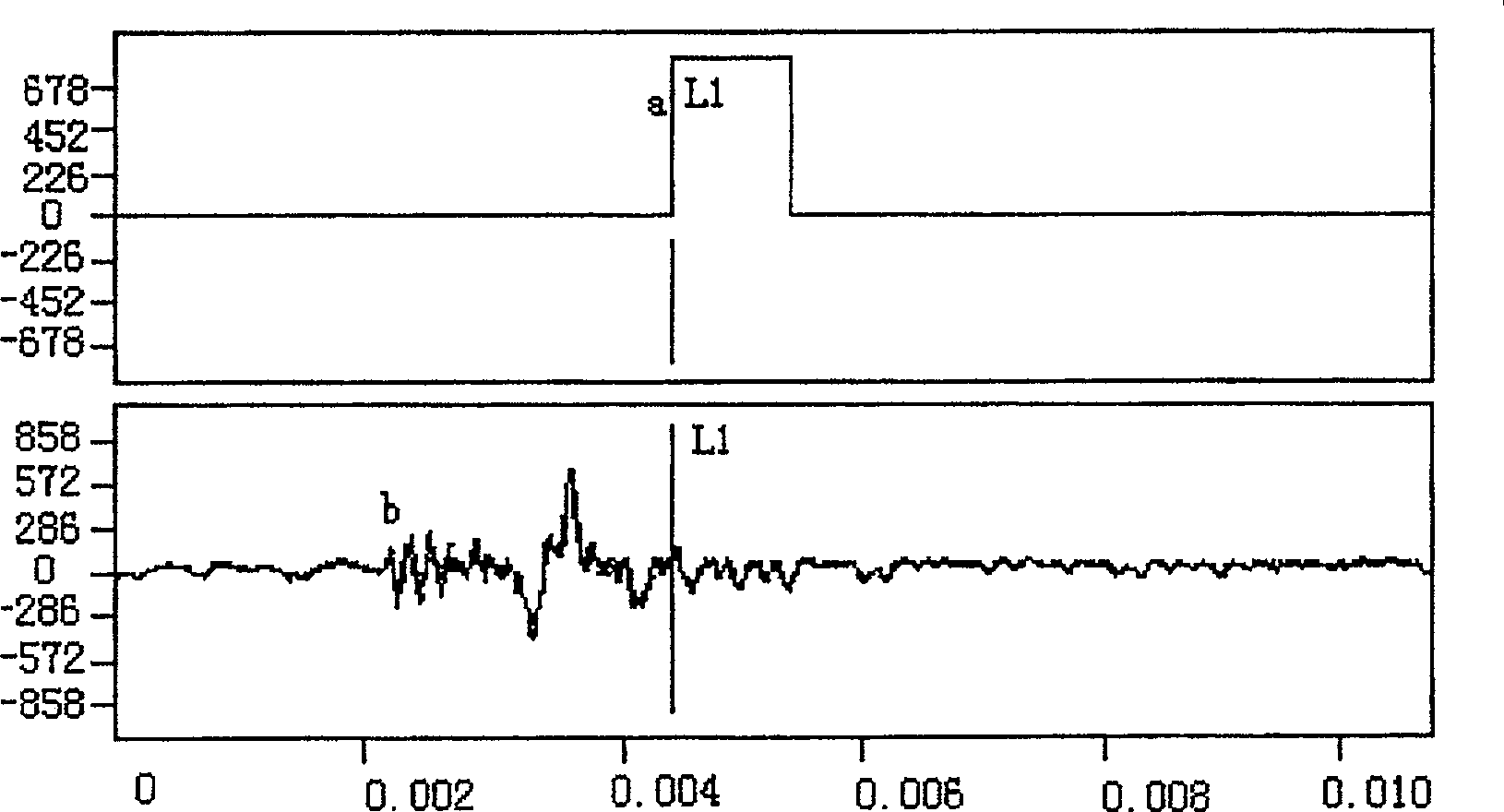

[0027] As shown in Fig. 1, the detection device of the engine fuel system failure of the present invention includes a rotational speed detection unit 5, a vibration detection unit 4 and a data processing unit 6, wherein the data processing unit 6 receives the speed detected by the rotational speed detection unit 5 The rotation speed signal and the combustion vibration signal obtained by the vibration detection unit 4 are amplified by the amplifier circuit and the A / D conversion circuit, and the analog / digital conversion is performed on the above-mentioned signal, and the pulse waveform of the rotation speed and the combustion vibration waveform are compared and analyzed to determine the Oil advance angle and combustion conditions.

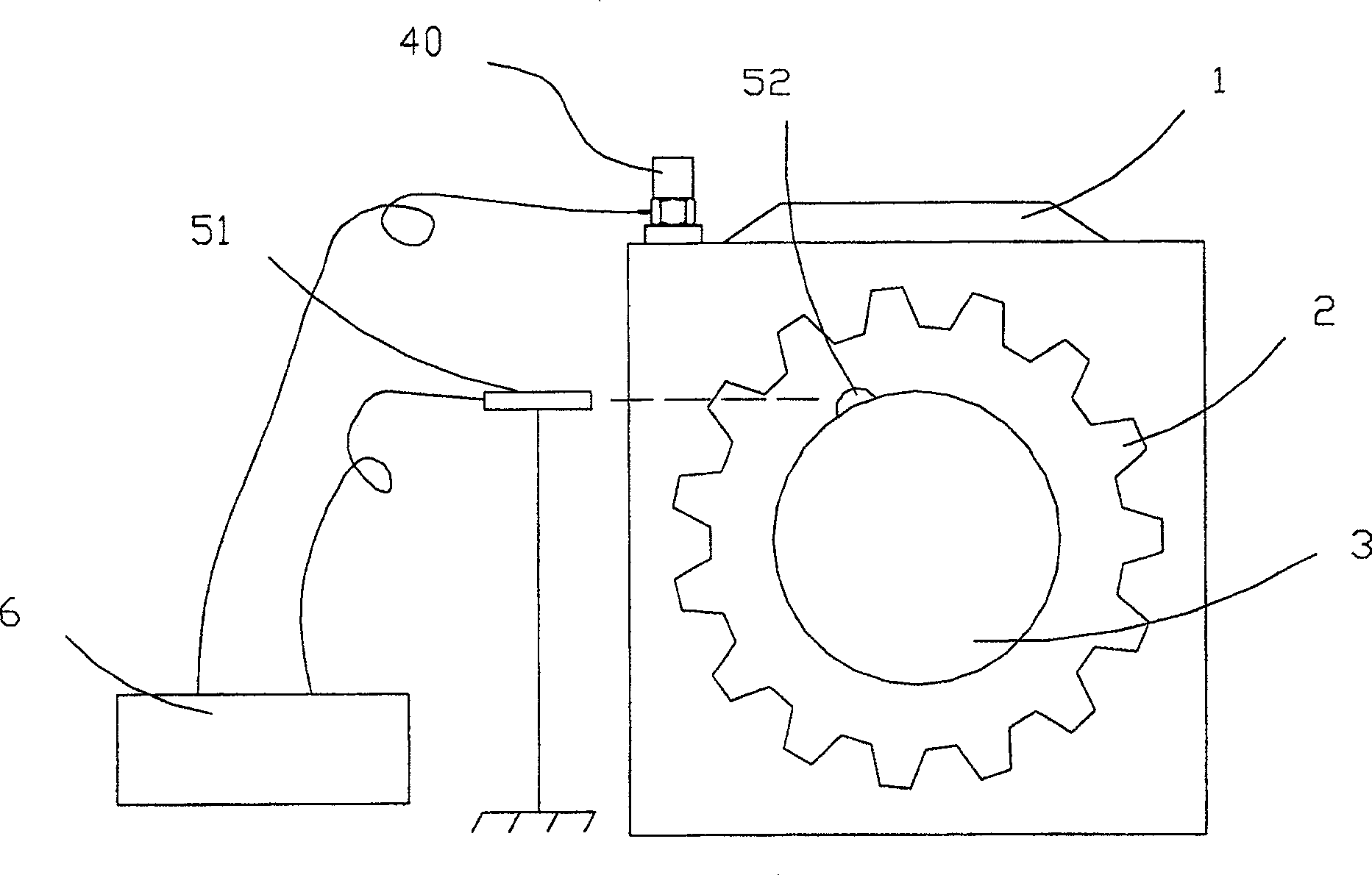

[0028] to combine figure 2 As shown, the rotational speed detection unit 5 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com