Household fabric drying sterilizer

A technology for sterilizing machines and fabrics, which is applied to household clothes dryers, household appliances, applications, etc., and can solve the problems of long sterilization and drying time, large equipment footprint or space, and high total investment costs, achieving The effect of reducing microwave leakage damage, small equipment footprint, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

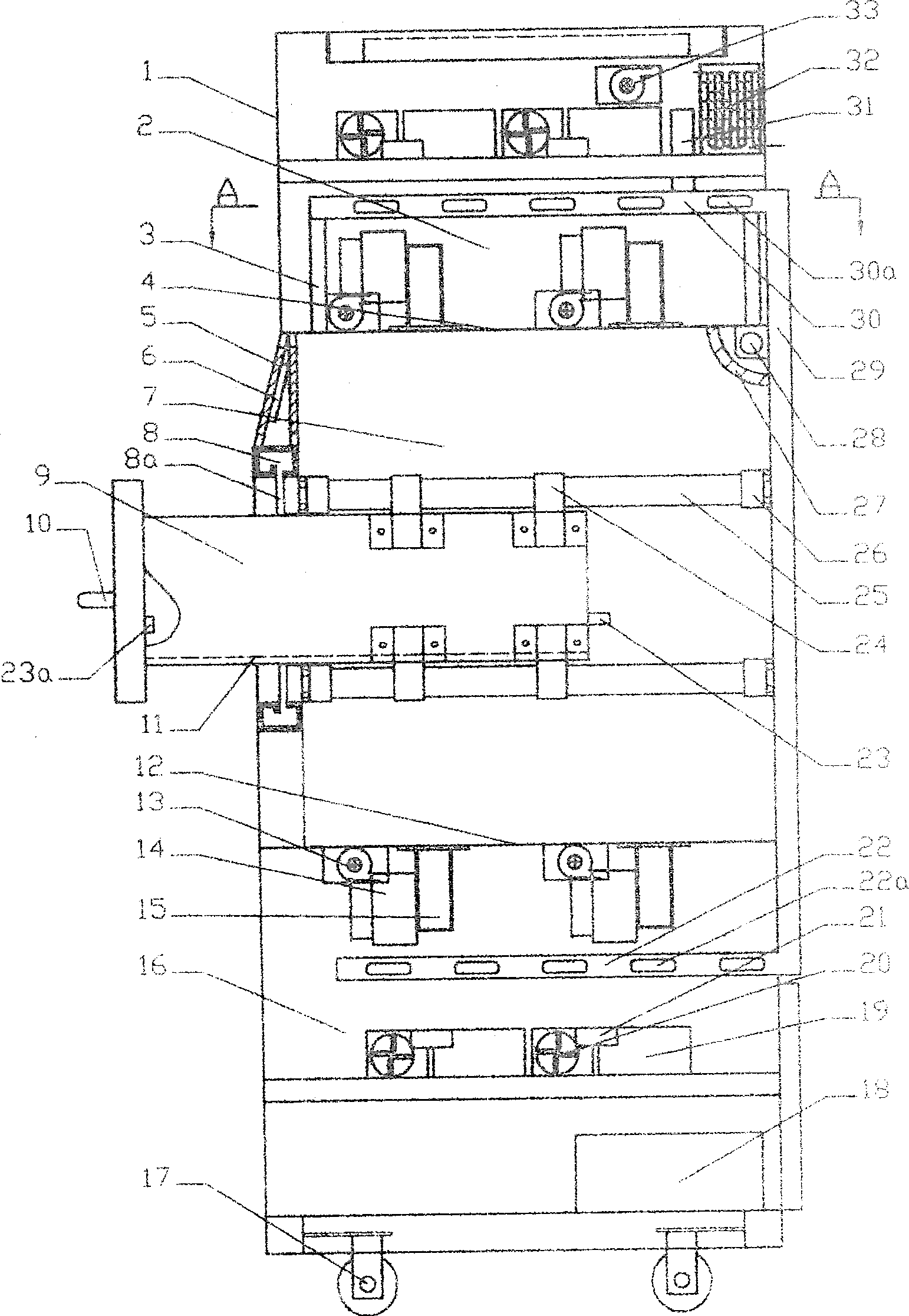

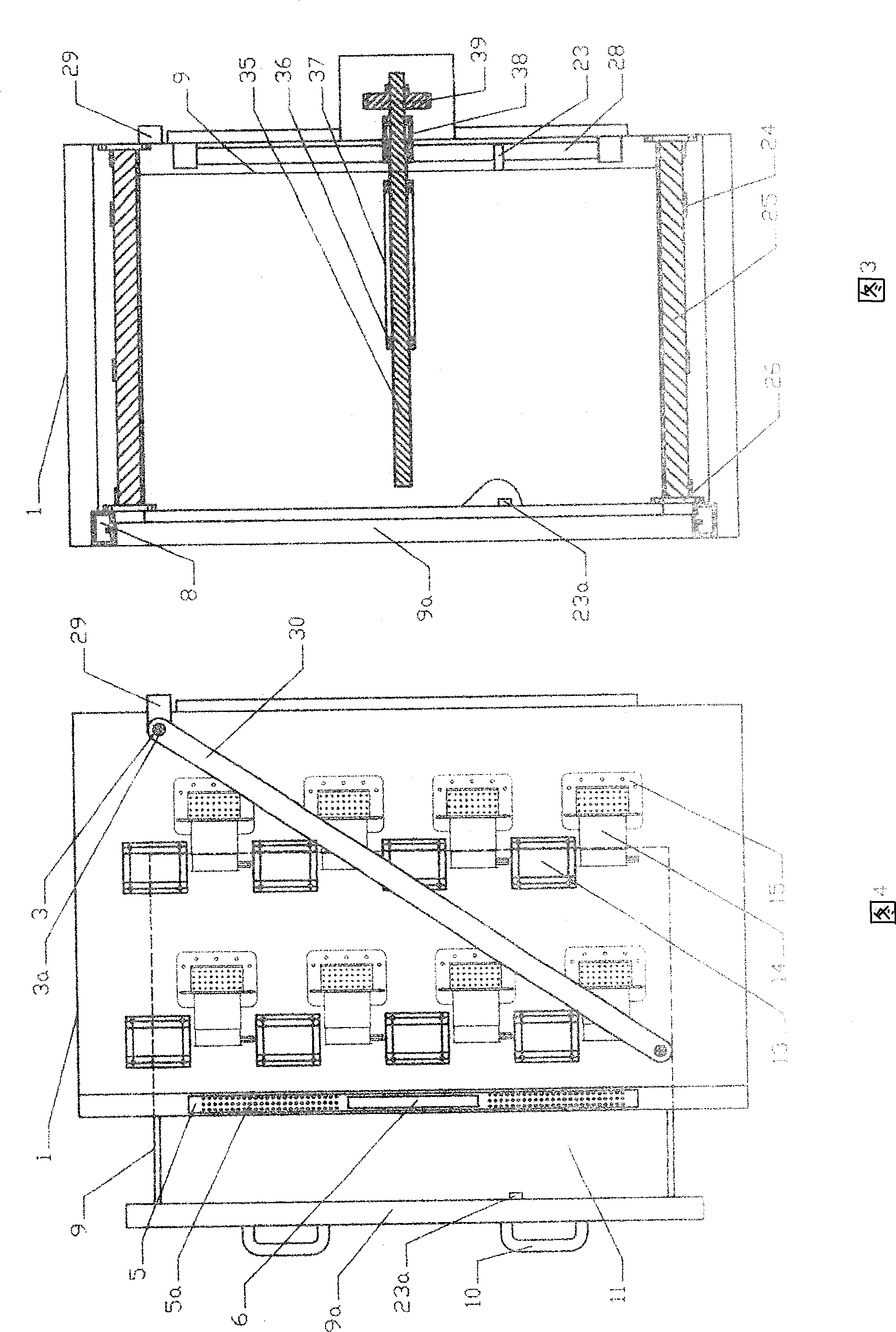

[0020] Embodiment 1. The structure of the household fabric drying and sterilizing machine of this embodiment can be obtained from figure 1 And see among Fig. 3, it contains wheel 17, cabinet 1, control panel 6, in cabinet 1 by upper and lower two dividing plates 4,12 it is separated into three cavities, wherein two dividing plates 4,12 The cavity is a microwave heater 7, and a drawer 9 with a bottom plate of glass 11 is installed in the opening in the middle of the front side of the microwave heater 7; , respectively install 8 groups of microwave working units that emit microwaves to the microwave heater 7, namely magnetron 14, waveguide 15, axial flow fan 20, transformer 19, centrifugal fan 13 and capacitor 21; there is an exhaust pipe outside the cabinet 1 29 protrudes a moisture-discharging heat pipe 30 with a heat dissipation hole 30a on the two component working chambers 2 and 16 respectively.

[0021] Two axle sleeves 24 are respectively adorned on the both sides of the...

Embodiment 2

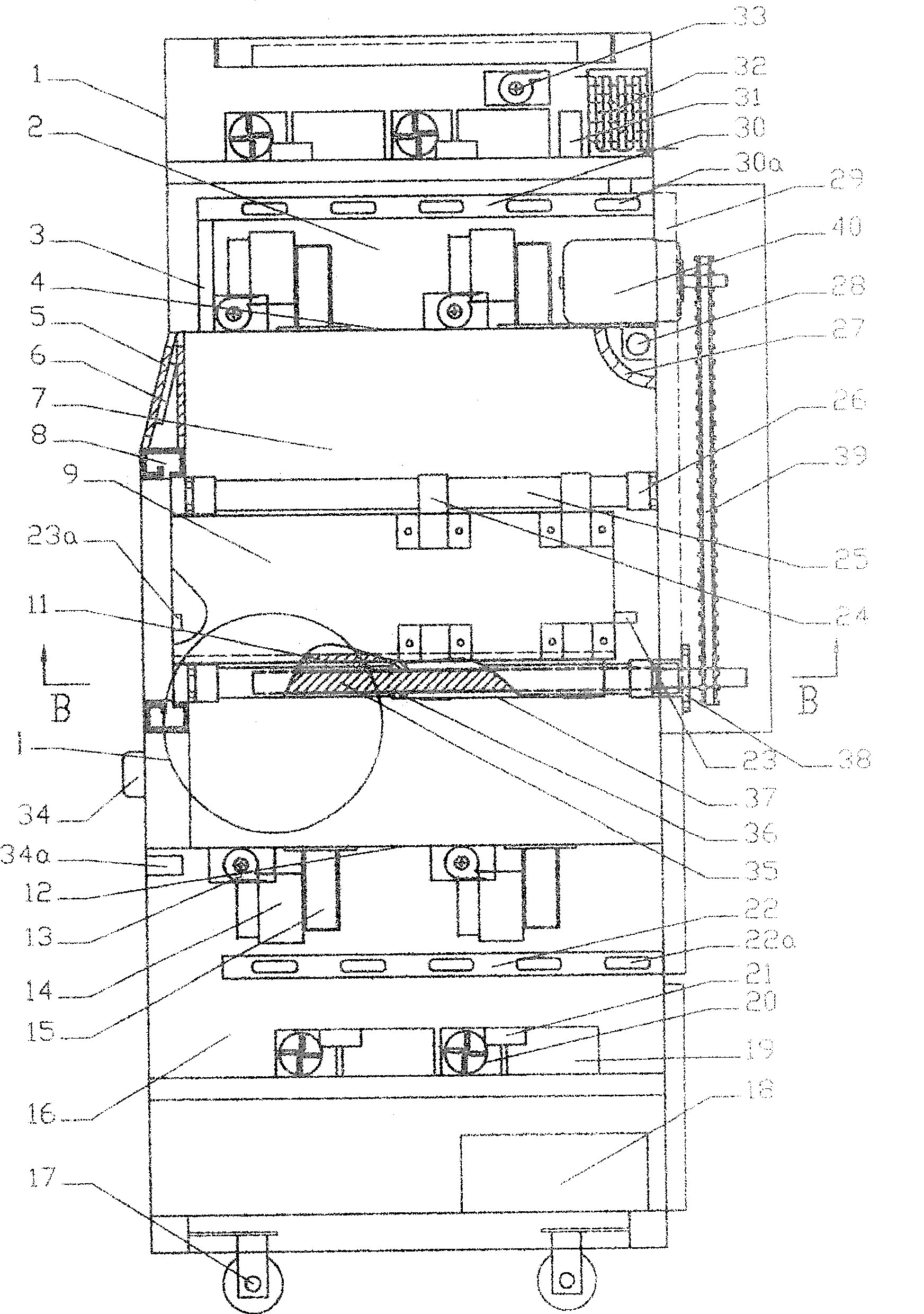

[0028] Embodiment 2. The structure of the household fabric drying and sterilizing machine of this embodiment can be obtained from figure 2 See among Fig. 4, it is different from embodiment 1, a square pipe 37 is adorned under the drawer 9, and each fixed one at the inner two ends Female 36 is engaged with the screw mandrel 35 that is fixed on the rear side of the cabinet 1 by two shaft seats 38 inside and outside. There is a motor 40 at one end, and a near voice prompt alarm 34 and 4 to 6 proximity switches 34a are adorned on the front side of the cabinet 1.

[0029] When the equipment of this embodiment was working, after the quilt and the quilt had been dried and sterilized, the drawer 9 could be automatically controlled by the motor 40 through the sprocket mechanism 39 to move in and out along the orbital tube 25, making the operation easier. More convenient and labor-saving. When someone is close to the equipment in operation, the proximity switch 34a installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com