Fabric drying-disinfecting machine

A technology for sterilizing machines and fabrics, which is used in household dryers, textiles, papermaking, washing devices, etc., to achieve the effects of rapid heating, uniform heating, sterilization and drying, and reduction of microwave leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

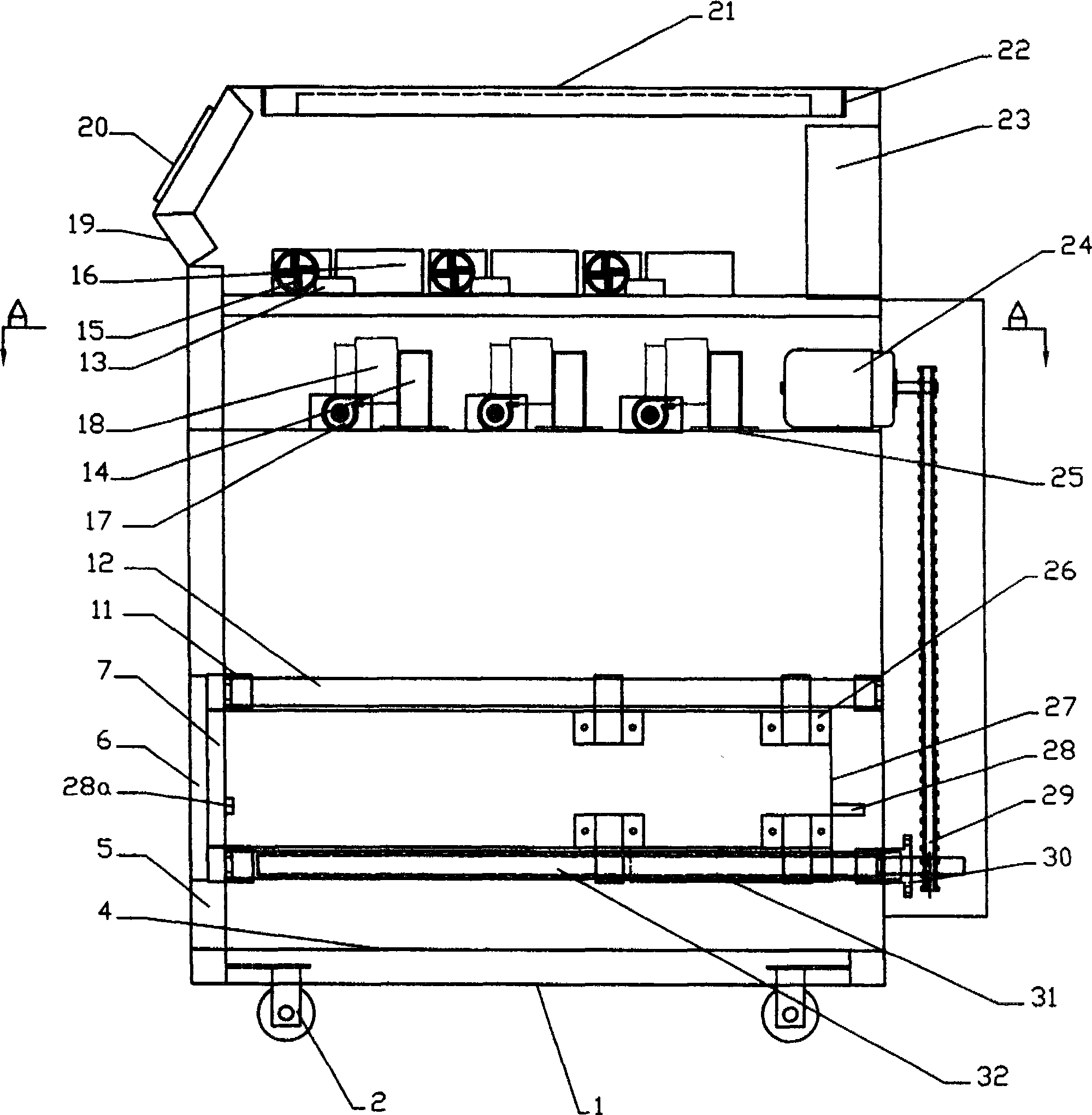

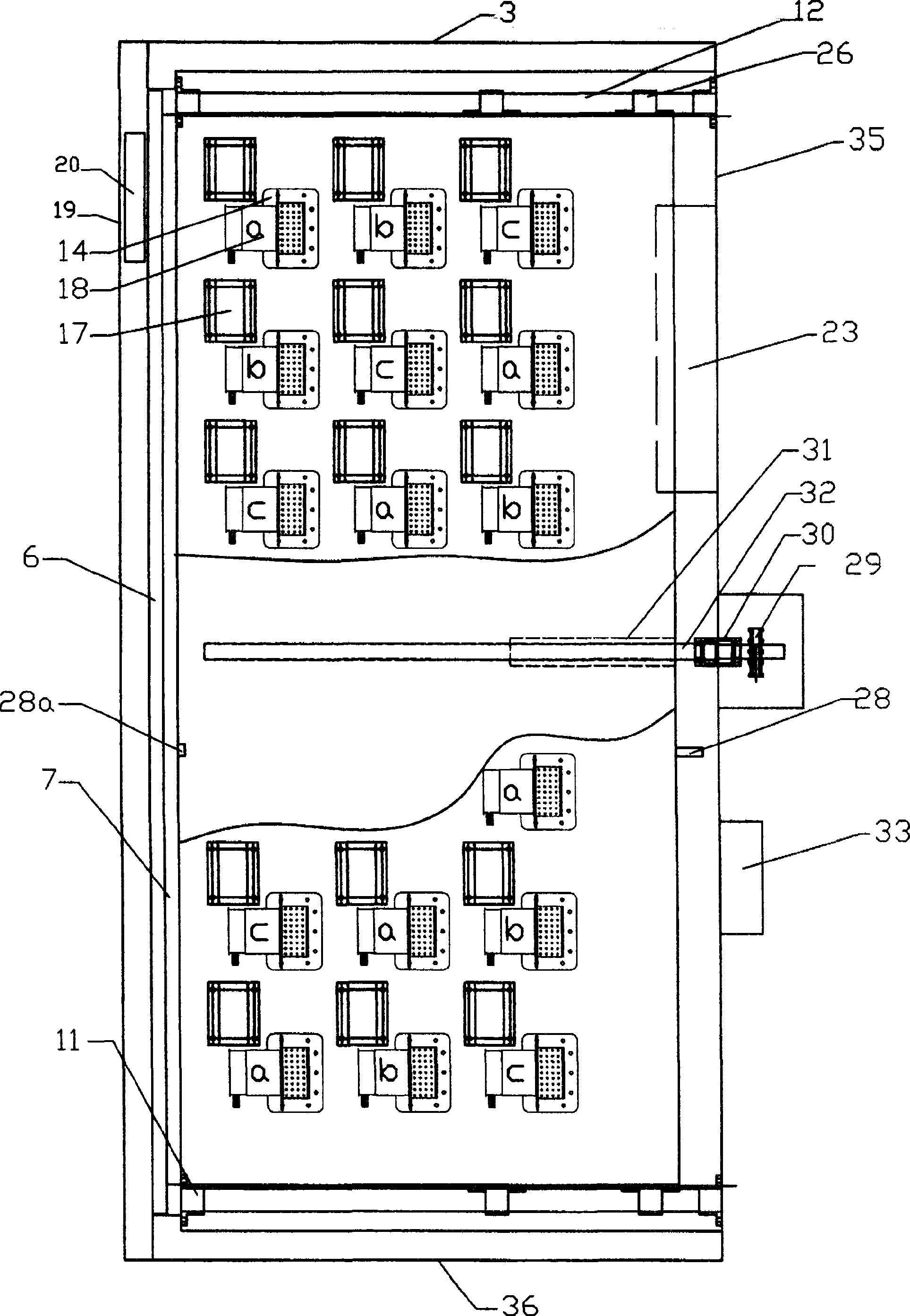

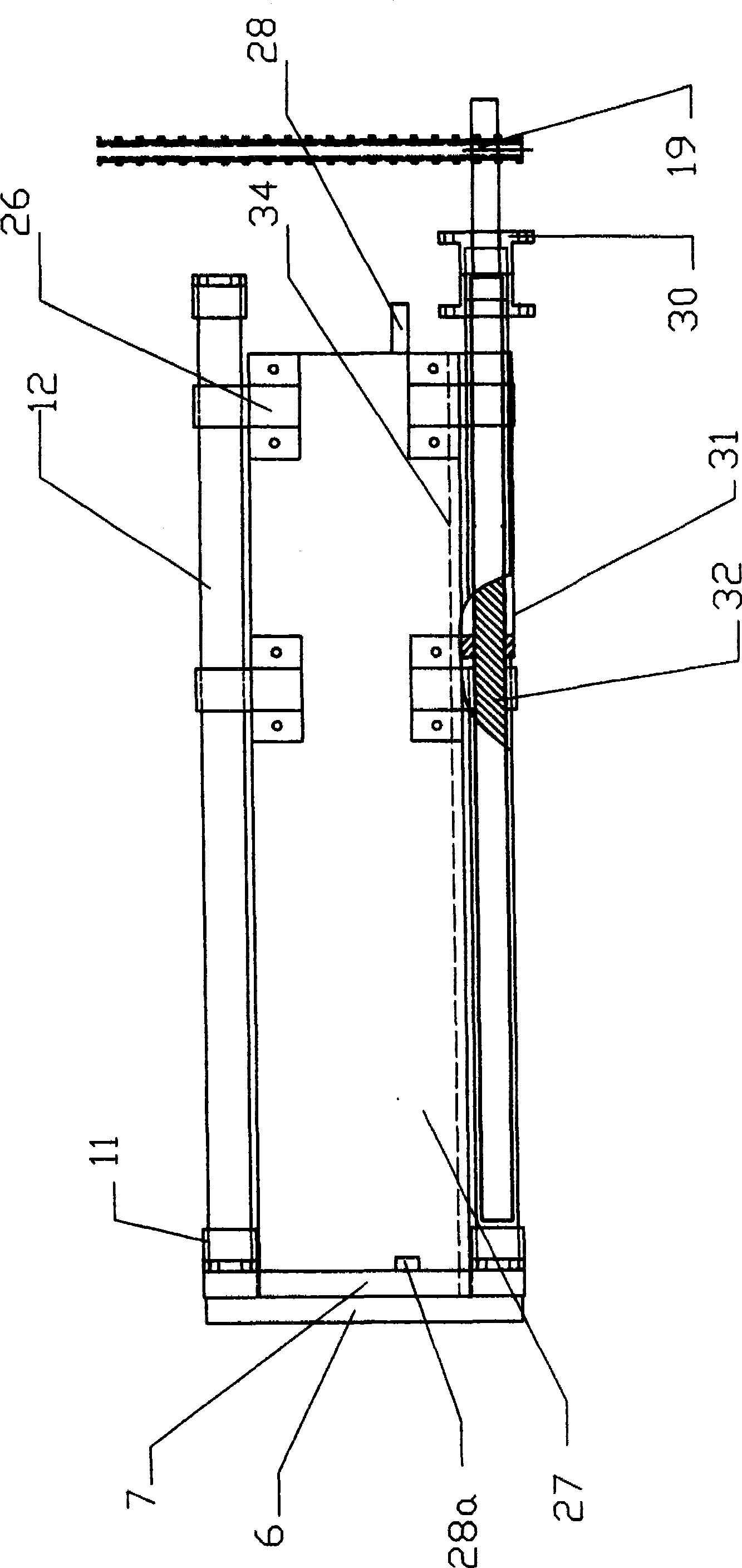

[0033] Embodiment 1. The structure of the fabric drying and sterilizing machine of this embodiment can be obtained from figure 1 , figure 2 and image 3As seen in the figure, it includes chassis 1, wheels 2, left side panel 3, right side panel 36, rear side panel 35, front side panel 19, lower side panel 5, bottom panel 4, middle panel 25, inspection cover frame 22, maintenance Cover plate 21, dehumidification cavity 33, glass 34, magnetron 18, waveguide 14, axial flow fan 15, transformer 16, centrifugal fan 17, capacitor 13, control cabinet 23, control panel 20, motor 24, photoelectric switch 28 , drawer 27 and its transmission parts, that is, drawer door 6, drawer door stopper frame 7, drawer shaft seat 11, track round pipe 12, drawer shaft sleeve 26, sprocket chain 29, screw shaft seat 30, screw rod outer tube 31, screw mandrel 32. Its characteristic is that a circle of magnetic powder wrapped by temperature-resistant cloth is placed on the joint surface of the drawer d...

Embodiment 2

[0037] Embodiment 2. The structure of the fabric drying and sterilizing machine of this embodiment can be obtained from Figure 6 Seen in, it is different from embodiment 1 in that it does not have sprocket chain 29, screw shaft seat 30, screw mandrel outer square pipe 31, screw mandrel 32, and adorn a pair of rotating parts (cards) at both ends of the drawer door Axle 37, back-up ring 38, connecting rod 39, bolt 40, rivet 41, spring 42), realize the manual opening of drawer 27, now drawer door is separated from drawer, drawer door can be directly opened by hand, then drawer from machine Zips inside to place or remove fabric. The clamping shaft a and the drawer door 6 are fixed, the clamping shaft b is put into the round hole of the connecting rod 39, the retaining ring 38 and the right side plate 36 and the left side plate 3 are fixed, the clamping shaft b is inserted therein, the rivets 41 and the connecting rod 39 The other end is fixed, one end of the spring 42 hooks the ...

Embodiment 3

[0038] Embodiment 3. The structure of the fabric drying and sterilizing machine of this embodiment can be obtained from Figure 7 , Figure 8 and Figure 9 Seen in, it differs from Embodiment 1 in that there are no drawers and transmission parts thereof, except that it includes chassis 1, wheels 2, left side panels 3, bottom panels 4, right side panels 36, rear side panels 35, and front side panels 19 , middle plate 25, maintenance cover plate 21, dehumidification cavity 33, glass 34, magnetron 18, waveguide 14, capacitor 13, axial flow fan 15, transformer 16, centrifugal fan 17, control cabinet 23, control panel 20, Motor 24, light curtain 43, cover plate 44 and transmission parts thereof are also arranged outside photoelectric switch 28, i.e. cover plate frame 45, cover plate rotating shaft 46, cover plate rotating shaft shaft seat 47, worm gear 48, worm screw 49, it is characterized in that cover plate A circle of magnetic powder wrapped by temperature-resistant cloth is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com