New-generation sweet sorghum coat removing machine for intelligent agriculture

A new-generation technology for sweet sorghum, applied in the field of sorghum coat removal machines, which can solve the problems of time-consuming, affecting the efficiency of sweet sorghum, and easily scratching hands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

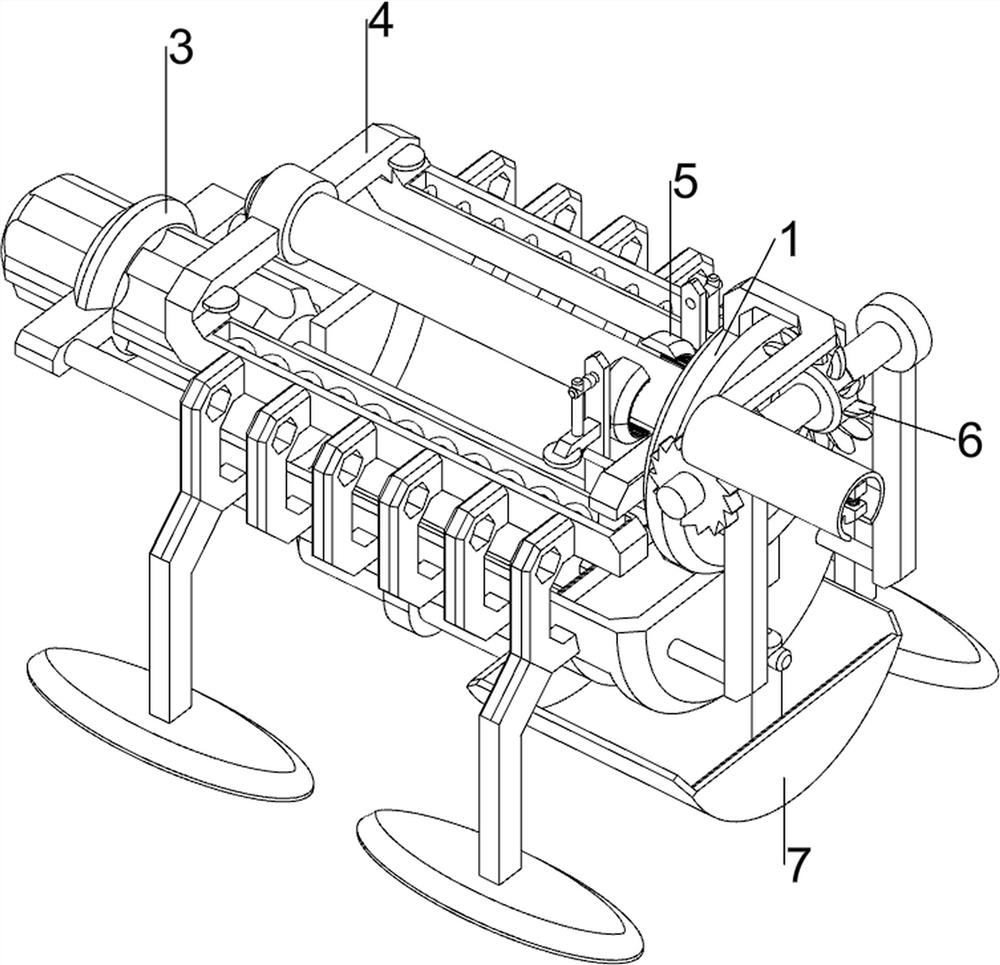

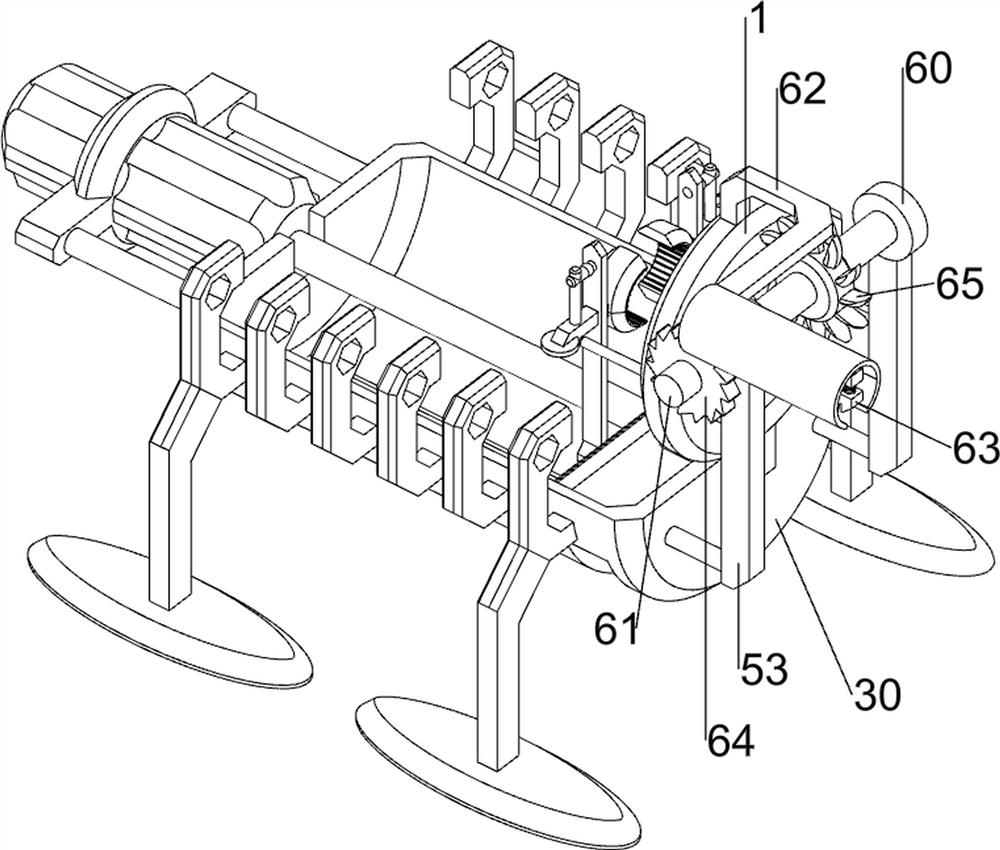

[0028] A new generation of intelligent agricultural sweet sorghum coat removal machine, such as Figure 1-5 As shown, it includes a mounting plate 1, a scraper 2, a propulsion mechanism 3 and a limit mechanism 4. The right side of the propulsion mechanism 3 components is provided with a mounting plate 1, and the inner wall of the mounting plate 1 is uniformly equipped with a scraper 2 along the circumferential direction, and the propulsion mechanism 3 A limit mechanism 4 is provided on it.

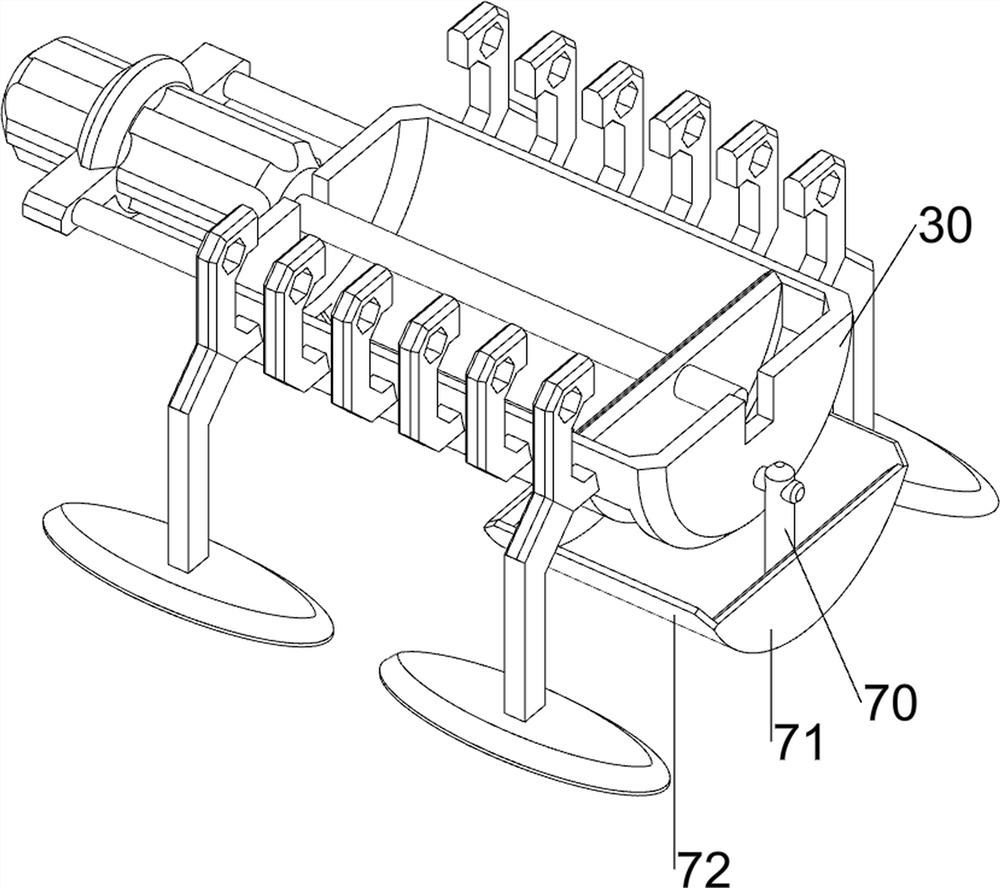

[0029] The propulsion mechanism 3 comprises arc box 30, supporting pin 31, fixed frame 32, cylinder 33 and advancing plate 34, and arc box 30 bottom, front, rear, left and right four sides are all provided with supporting pin 31, and arc box 30 left side is provided with fixed frame 32 , fixed frame 32 is provided with cylinder 33, and the right side of cylinder 33 telescopic rods is provided with advancing plate 34, and cylinder 33 telescopic rods right-hand ends are connected with mounti...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 6-10 As shown, clamping mechanism 5 is also included, and clamping mechanism 5 includes mounting plate 50, moving disc 51, clamping device 52, extruding rod 53, rubber pinball 54 and installation arc plate 55, and advancing plate 34 left Mounting plates 50 are connected to the front and rear sides of the head, and the upper part of the mounting plate 50 is slidably connected to a moving plate 51. The inner side of the moving plate 51 is provided with a clamp 52, and the top of the moving plate 51 is provided with a rubber ball 54. Both front and rear sides of the right part of 43 are connected with installation arc-shaped plates 55, both sides of the right part of the arc box 30 are connected with extruding rods 53, and the left side of the extruding rod 53 passes through the mounting disc 1 and the sliding disc 42.

[0034] The forward plate 34 moves to the left to drive the mounting plate 50 to move to the left, and the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com