Honeycomb-type grating filler automatic filling device

A filling and honeycomb technology, which is applied in a device field of medical tumor radiotherapy equipment, can solve the problems of intensity-modulated conformal field performance and quality discount, poor treatment efficiency, and low image follow-up rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

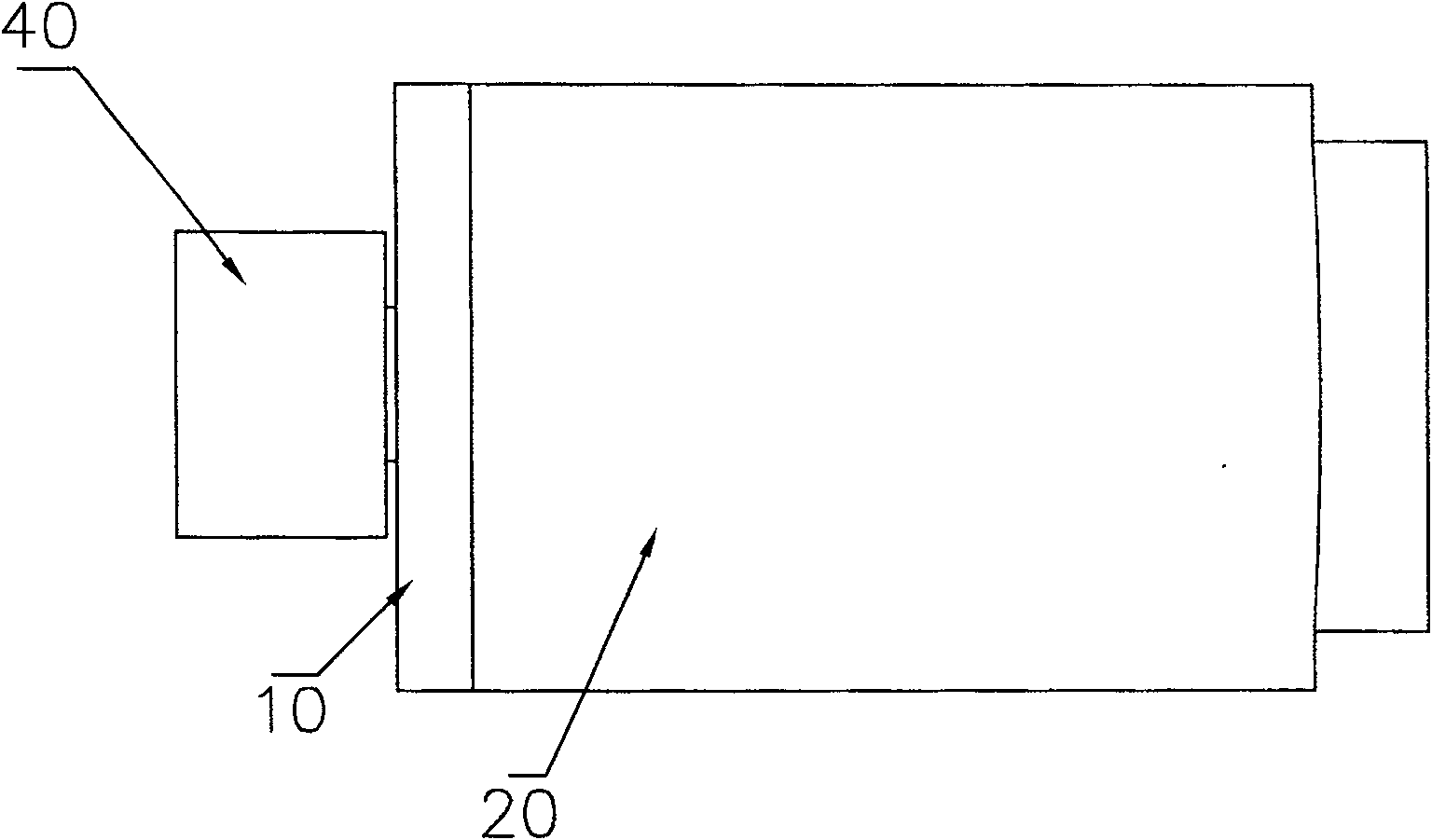

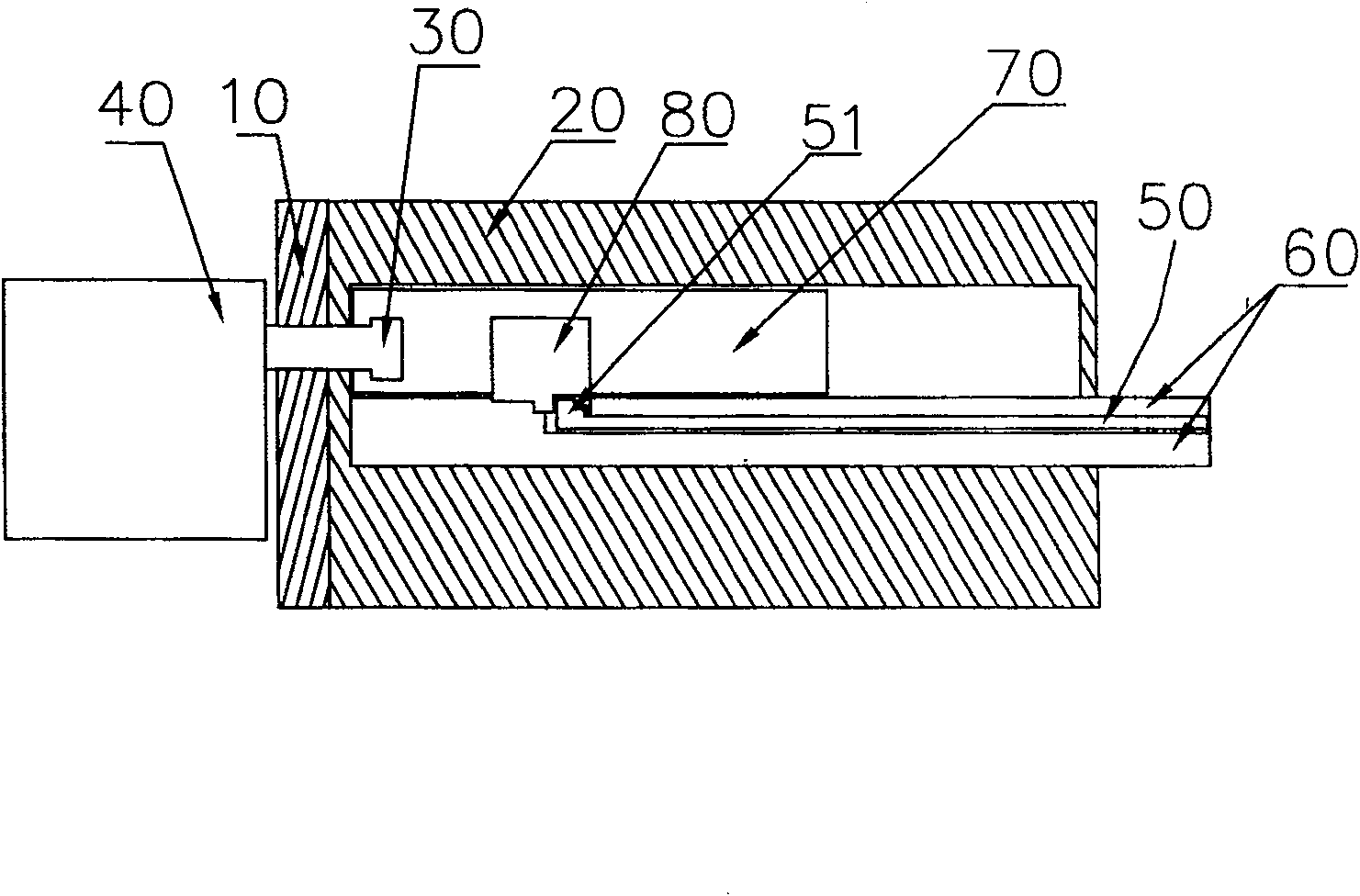

[0019] The present invention provides the first embodiment, refer below in conjunction with figure 1 , figure 2 , image 3 and Figure 4 The first embodiment will be described in detail.

[0020] Such as figure 1 and figure 2 As shown, the honeycomb grating filling automatic installation device provided by the first embodiment includes a support 10 , a housing 20 , a push rod assembly, a driving rod 30 and a cylinder 40 . Wherein, the housing 20 is arranged on the support 10, and the housing 20 has a receiving cavity inside, and the receiving cavity communicates with the outside world. The push rod assembly is accommodated in the housing cavity of the housing 20 , and the push rod assembly includes a push rod protection and guide mechanism 60 , a push rod 50 , a clutch control mechanism 80 and a sliding guide mechanism 70 . The push rod guarding mechanism 60 is fixed in the receiving cavity of the housing 20 , the push rod 50 is slidably stored on the push rod guarding...

no. 2 example

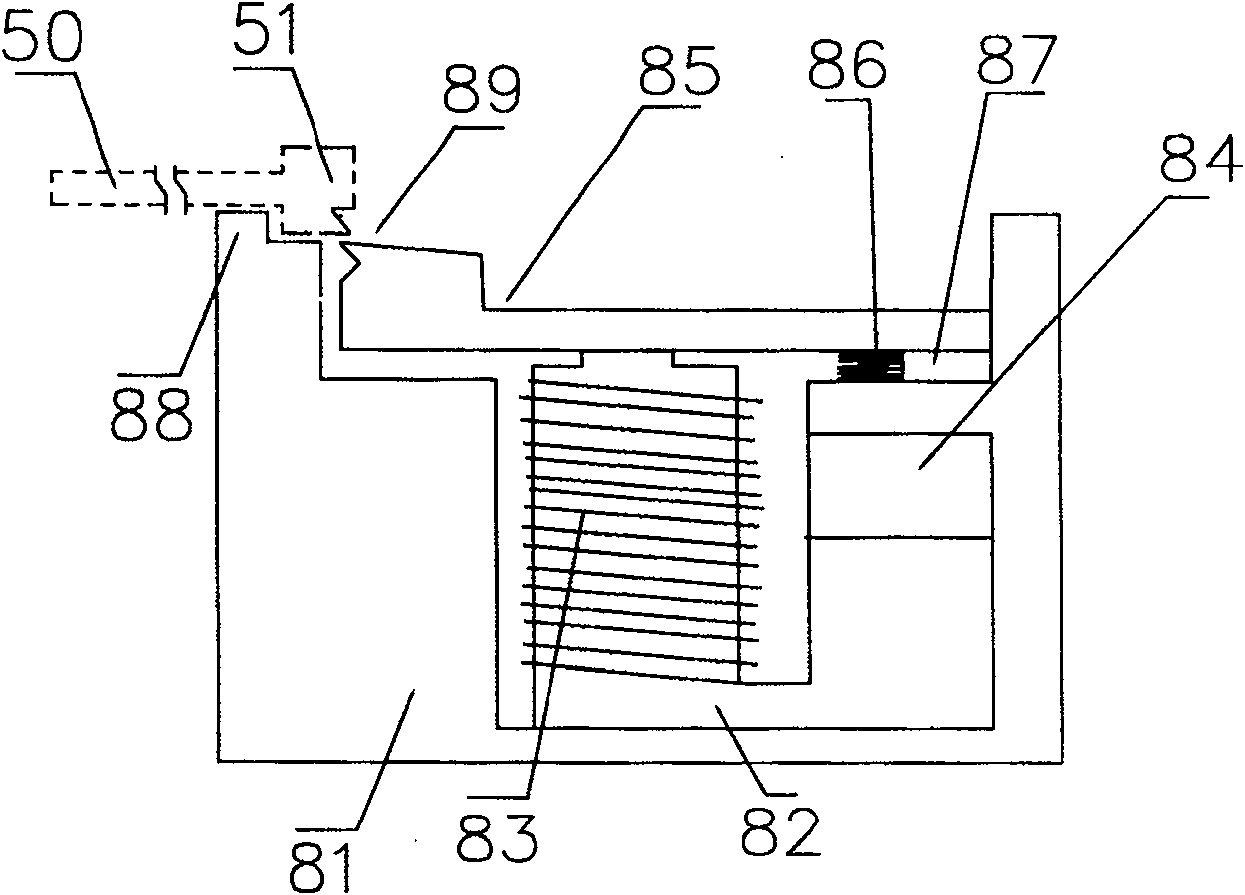

[0023] The present invention provides a second embodiment, which is combined below Figure 5 , Figure 6 and Figure 7 Describe in detail.

[0024] The automatic installation device for honeycomb grating filler provided by the second embodiment includes two sets of push pin assemblies, and also includes a partition 90 . Each push pin assembly includes a push rod protection guide mechanism 60 , a plurality of push rods 50 , a sliding guide mechanism 70 and a plurality of clutch control mechanisms 80 . Such as Figure 5 As shown, the partition 90 is arranged in the center of the housing cavity 20, and the two sets of push pin assemblies are independently and symmetrically arranged on both sides of the partition 90, and the sliding guide mechanism 70 of each push rod assembly is in line with the described The drive rod 30 is connected. Please combine Figure 6 As shown, in the second embodiment, a plurality of clutch control mechanisms 80 are included, and these clutch cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com