Bottom sealing device for can processing

A sealing device and canning technology, applied in applications, closures, household appliances, etc., can solve the problems of high labor cost and labor, and achieve the effect of eliminating the need to manually place the bottom of the can

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

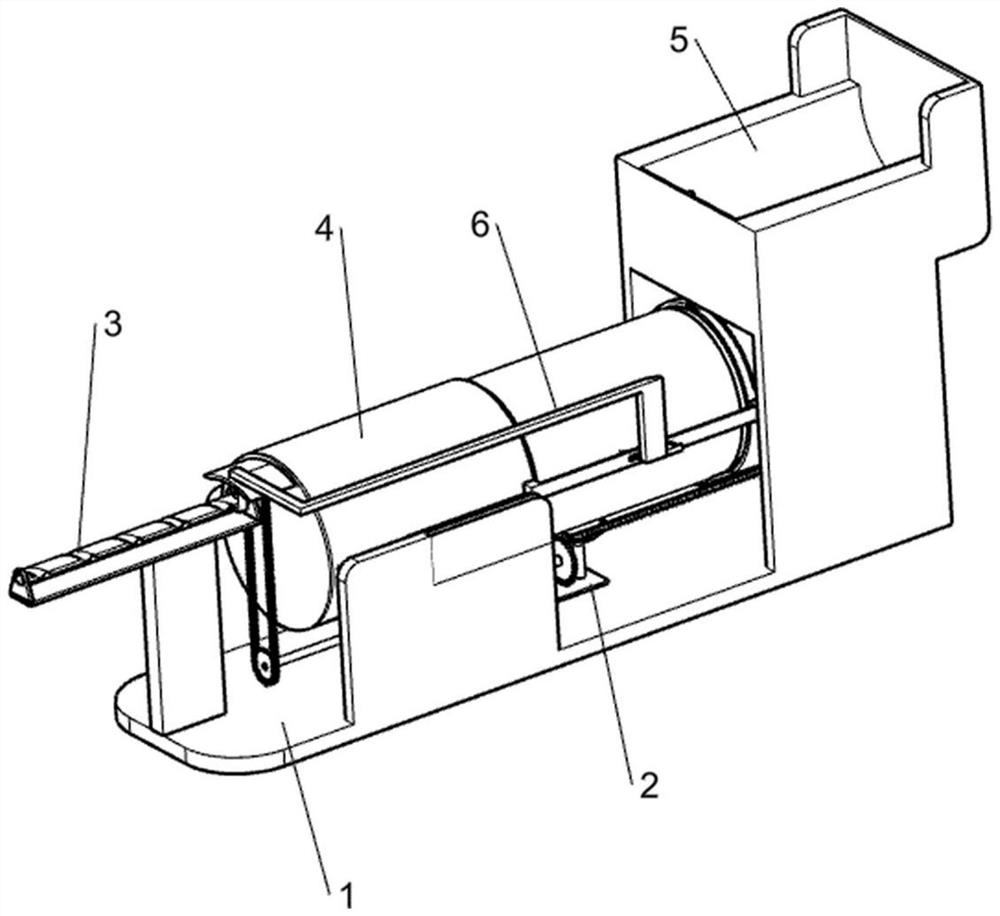

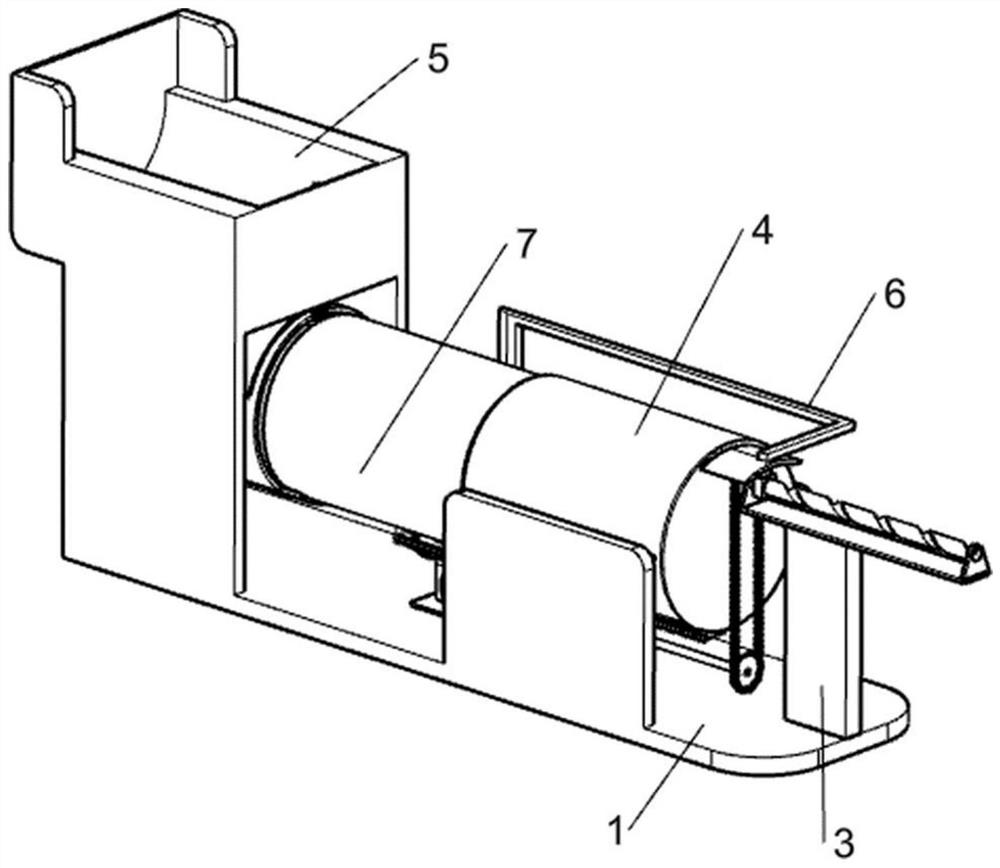

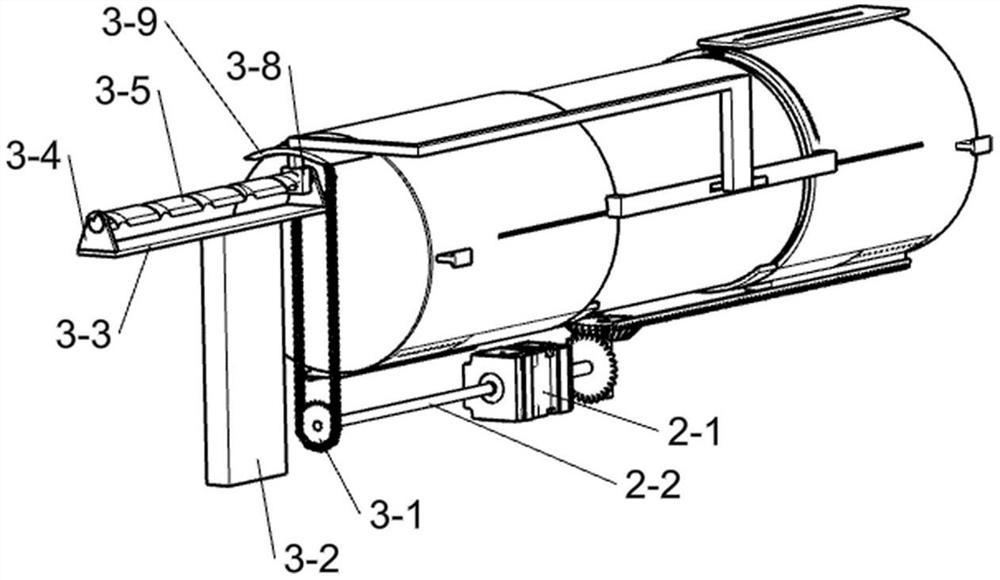

[0028] A bottom sealing device for can processing, such as Figure 1-10 As shown, it includes a bottom plate support 1, a driving mechanism 2, a pushing mechanism 3, an extrusion mechanism 4, a blanking mechanism 5, and a forming and pushing mechanism 6. The driving mechanism 2 is installed on the top of the bottom plate support 1, and the driving mechanism 2 is used to drive the device. Operation, the pushing mechanism 3 is arranged on one side of the floor support 1, and the pushing mechanism 3 is used to push out the cans with the bottom installed so as to separate them from the shell 4-5. The pressing mechanism 4 is used to install the bottom material of the can on the can that needs to be installed with the bottom. The blanking mechanism 5 is arranged on the extruding mechanism 4. The blanking mechanism 5 is used to place the bottom material of the can, and the forming ejection mechanism 6 is arranged on the extruding mechanism. 4 on one side, the forming push-out mechani...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 6 Shown, also include supporting plate 7-1 and back-moving spring three 7-2, supporting plate 7-1 is respectively slidable and is located in two shells 4-5, and supporting plate 7-1 needs to install the can of bottom and installed For the can at the bottom, the supporting plate 7-1 is positioned between the bottoms of the two shells 4-5 and the two cylinders 4-7, and a pair of return springs 3 7-2 are connected between the supporting plate 7-1 and the shell 4-5. Three 7-2 are used to drive supporting plate 7-1 to reset.

[0037] When the two shells 4-5 approached each other, the supporting plate 7-1 would move in a direction away from each other as the two shells 4-5 approached and squeezed each other, and the back-moving spring 3 7-2 was compressed thereupon, when the two shells When 4-5 are far away from each other, the compressed return spring 3 7-2 will reset accordingly, and drive the two pallets 7-1 to reset, and the pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com