Method for converting standard process layout to system-level mode in micro-electromechanical system

A technology of micro-electromechanical system and conversion method, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that the overlapping parts of each component of the process layout cannot be solved automatically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

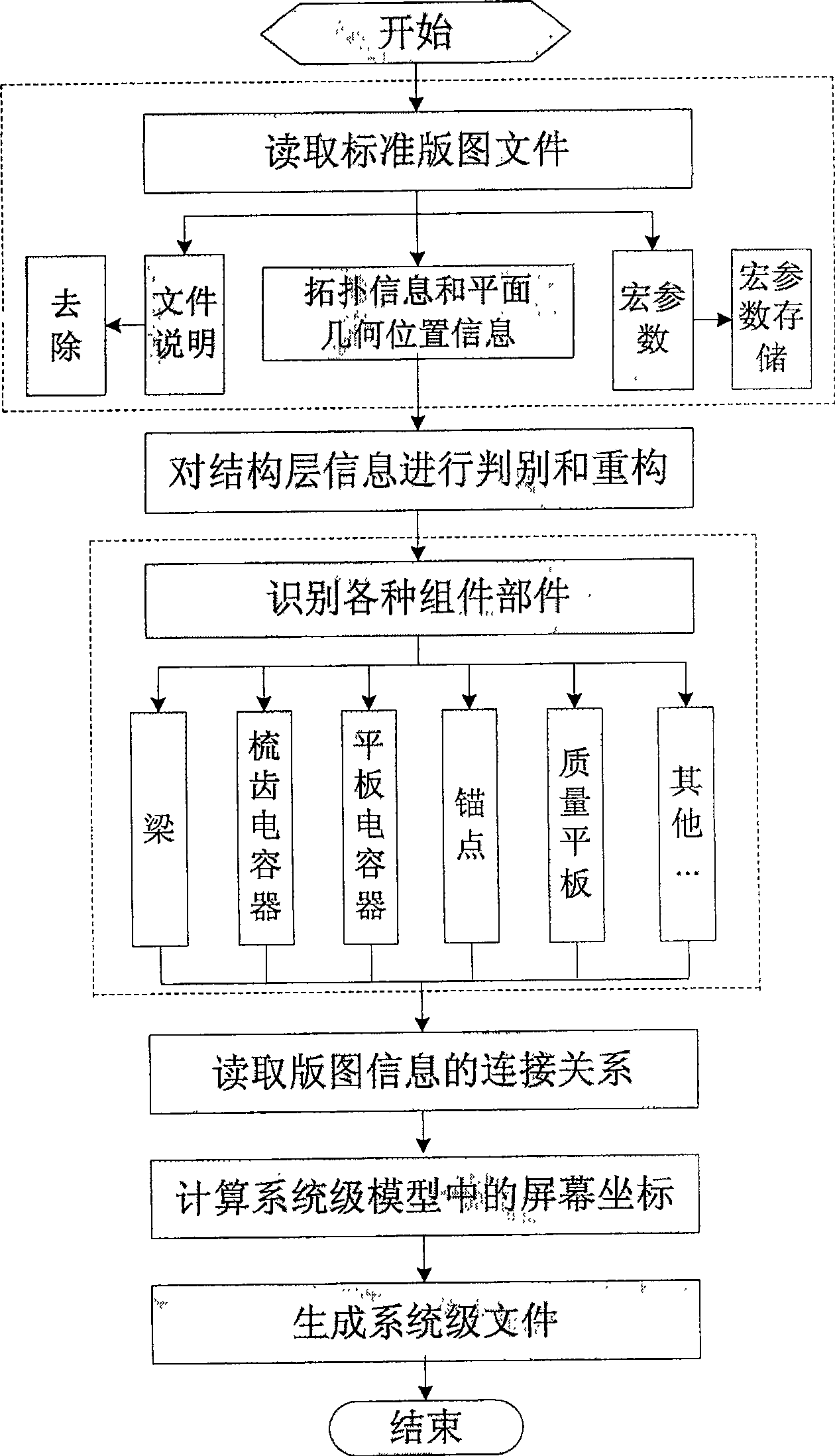

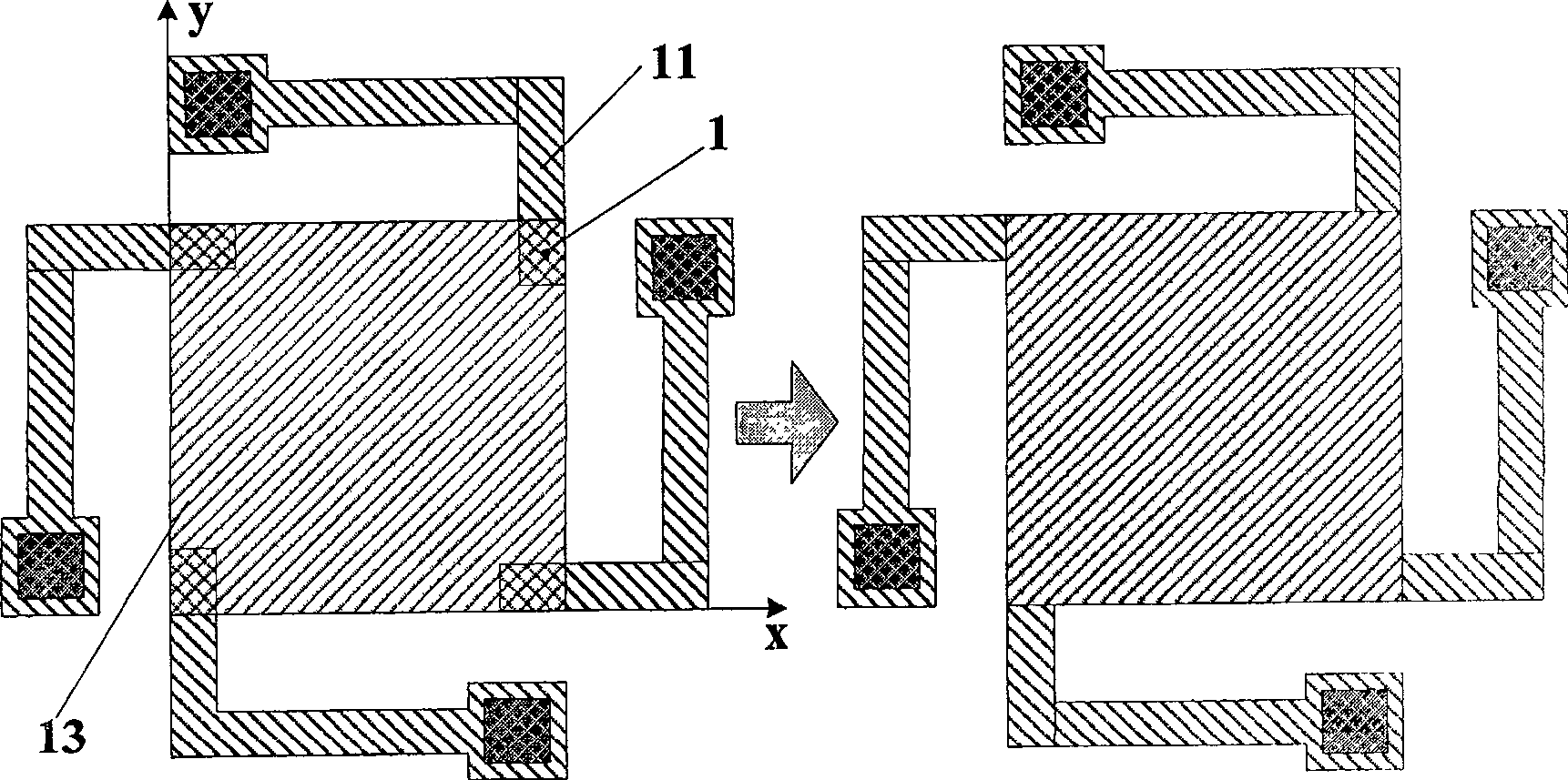

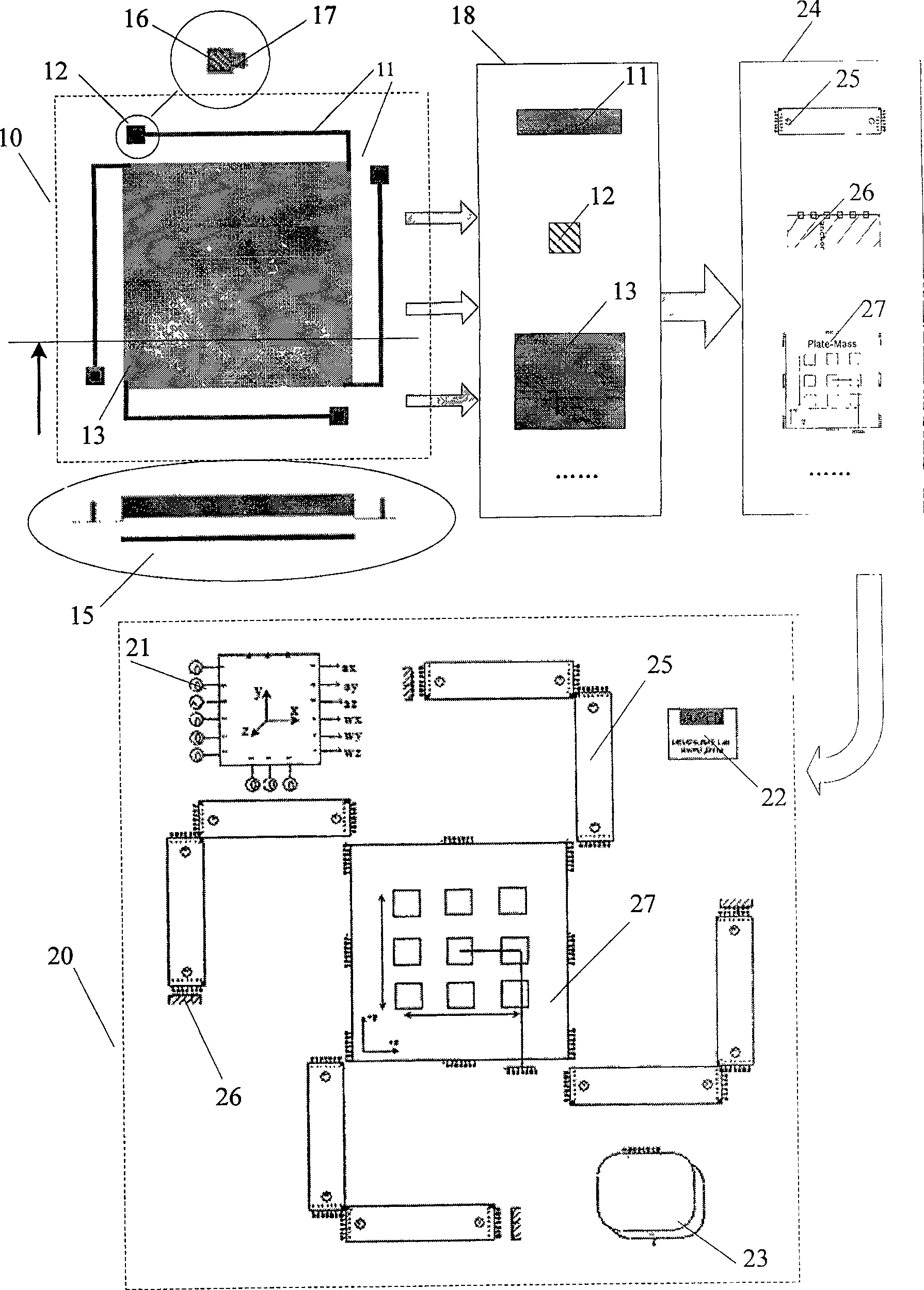

[0020] see figure 2 , the present invention takes a single-mass flat-plate Z-axis micro-accelerometer as an example to illustrate the conversion method from a standard process layout to a system-level model.

[0021] image 3 Middle 10 is the technological layout of a single-mass flat plate Z-axis micro-accelerometer. The structure includes eight beam components 11, four anchor point components 12, and a quality flat plate component 13; first, extract the geometric information of the structure from the standard layout file and Topological information, after judging, classifying and calculating the extracted information, the layout components are classified into units in the component library, including beam components 11, anchor point components 12, mass plate capacitor components 13, plate capacitor components 15, etc., and then the layout Component library 18 conversion corresponds to the MEMS component library 24 in the system level, including beam components 25, anchor p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com