Air expansion shaft transferring mechanism, air expansion shaft circulating mechanism and full-automatic winding machine

A transfer mechanism and inflatable shaft technology, applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve the problems of low work efficiency, high safety hazards, easy to be interrupted, etc., to improve production efficiency, reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

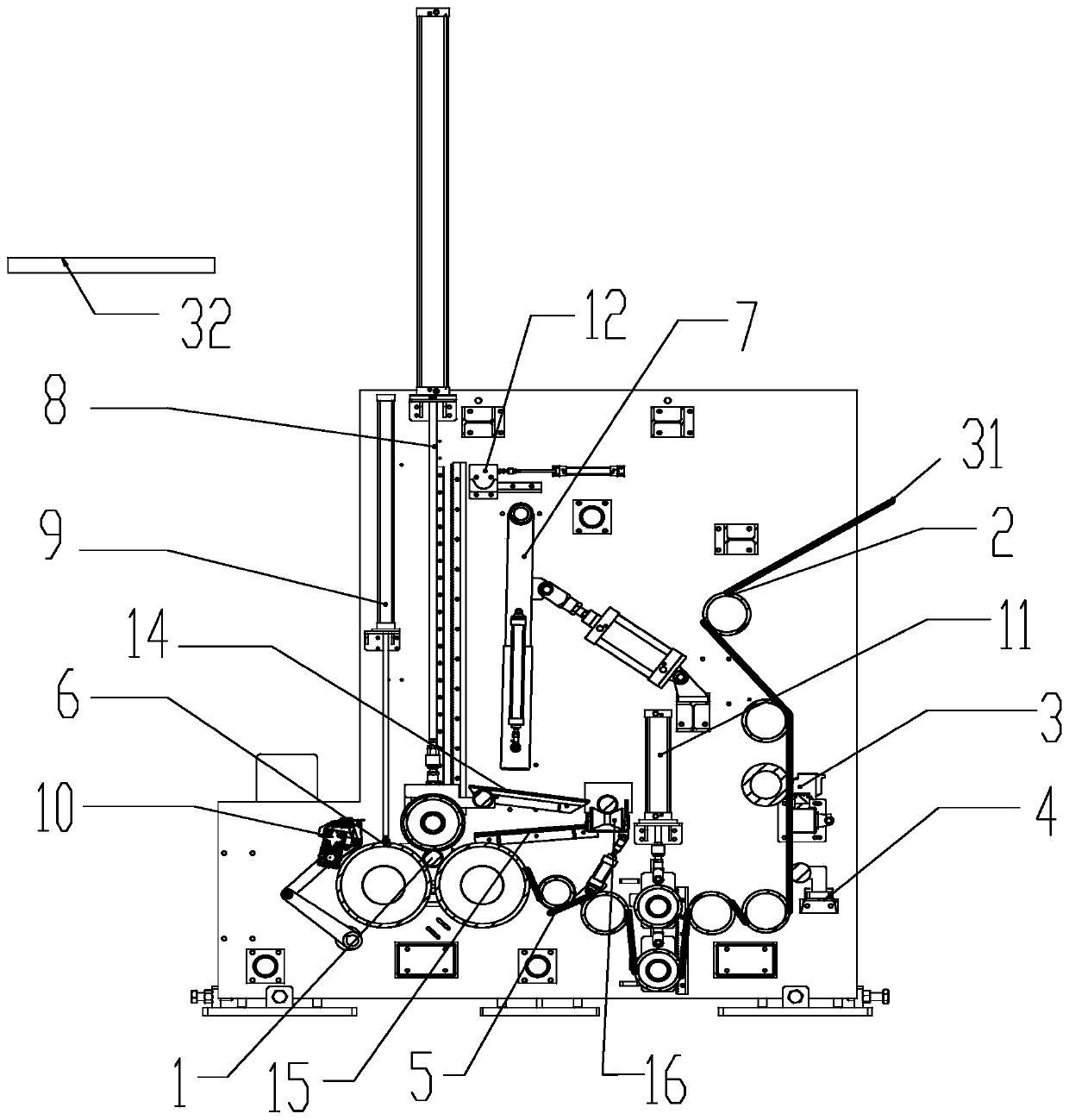

[0032] Reference figure 1 , the fully automatic winding machine in the present embodiment comprises cloth guide roller 2, cloth cutting device 3, distribution roll device 4, spoke expanding device 5, cloth pressing roll device 8, cloth supporting roller device 6, cloth roll device 7 And the side wall (not labeled in the figure), also includes the air shaft transmission mechanism, the air shaft transmission mechanism is used to transfer the air shaft 1 to the carrier roller device 6. The main structures and functions of each device are introduced respectively below, and in order to avoid redundant description, only a brief introduction is made to the prior art known in the technical field.

[0033] Cloth guide roller 2: Allow the cloth roll 31 to be diverted from the external equipment to the cutter roller through the cloth guide roller 2, so as to prepare for the next step of automatic pressing and slitting.

[0034] Cloth cutting device 3: The pneumatic cutter presses the pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com