Industrial manipulator applicable to automatic arrangement and welding of solar photovoltaic cell

A technology of industrial manipulators and photovoltaic cells, applied in manipulators, program-controlled manipulators, welding equipment, etc., can solve the problems of lack of handling aids, low position accuracy, poor welding quality, etc., achieve simple structure, reduce costs, and reduce accidents The effect of incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

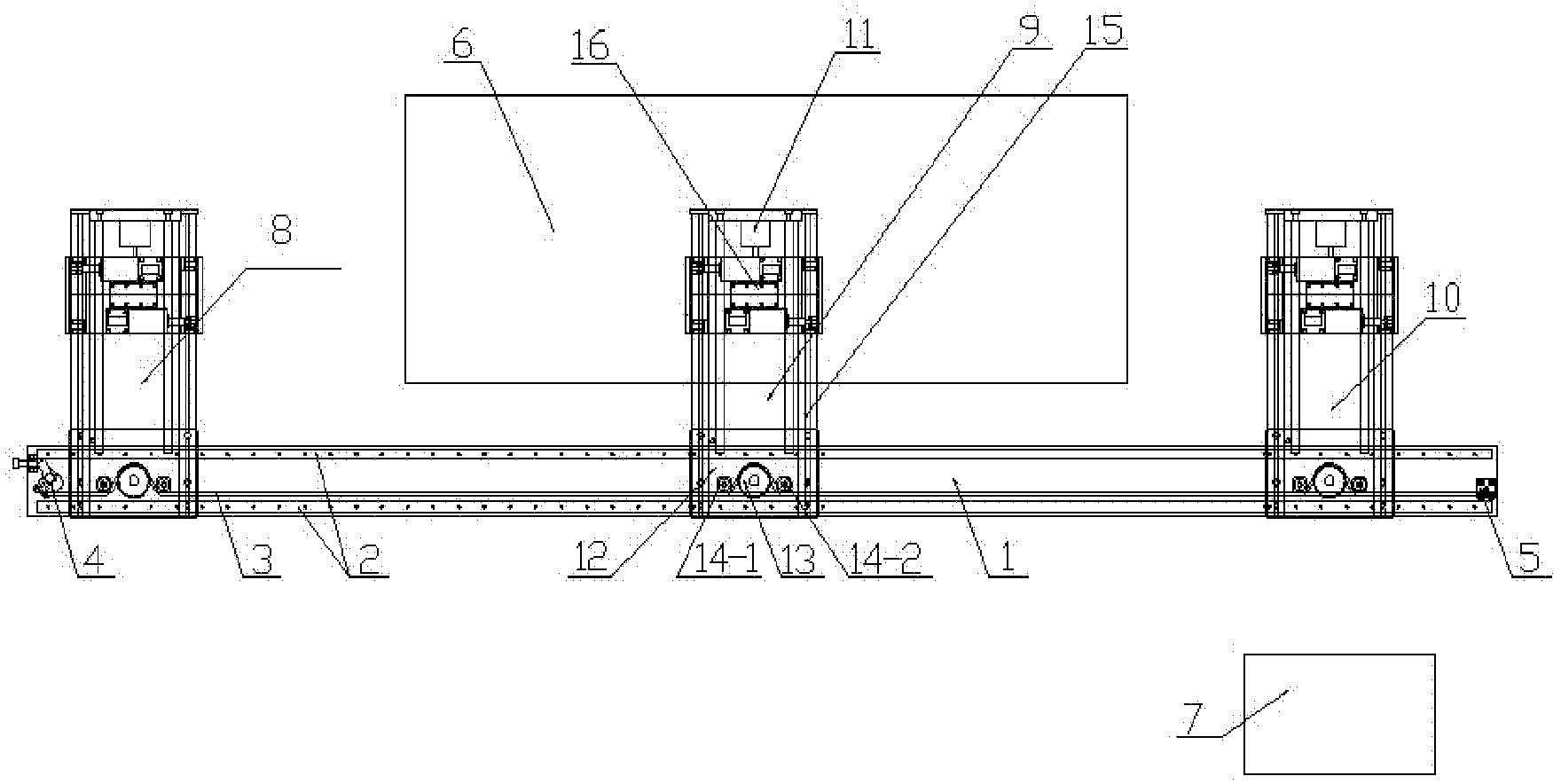

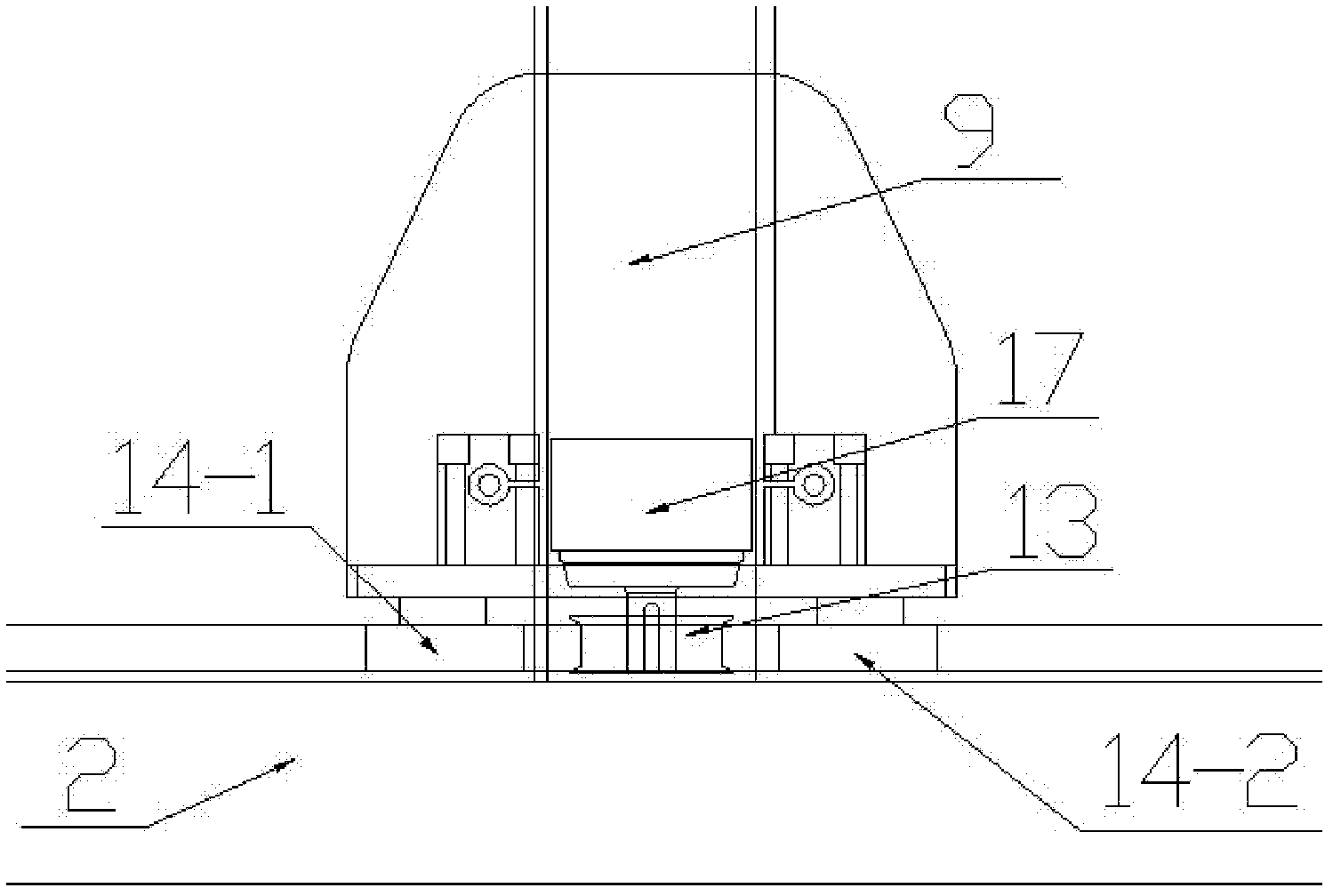

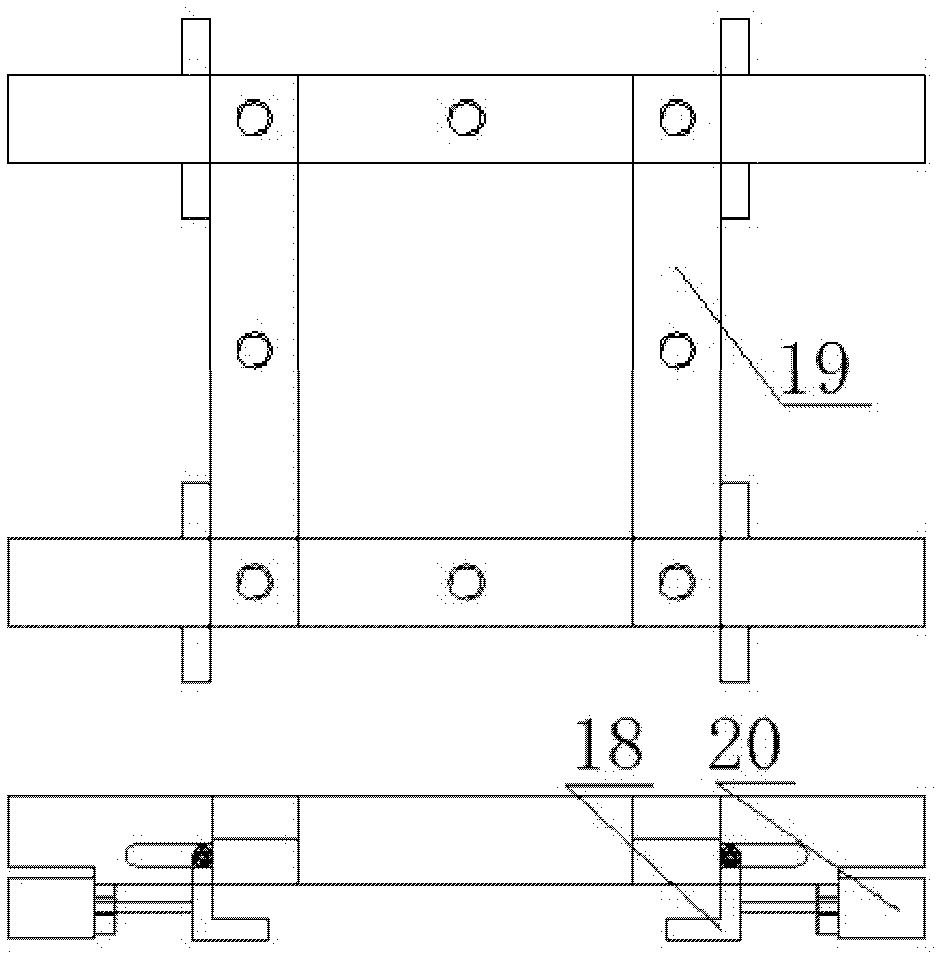

[0019] like figure 1 , figure 2 As shown, the present invention includes a base 1, a slide rail 2, a timing belt 3, a timing belt adjusting device 4, a timing belt fixing device 5, a welding stand 6, a first manipulator 8, a second manipulator 9, a third manipulator 10, a control Cabinet 7, fixture one 19 and fixture two 22. The base 1 is a Π-shaped structure, two slide rails 2 are installed on the top of the base 1 in parallel, and the first manipulator 8, the second manipulator 9 and the third manipulator 10 are respectively installed on the slide rail 2 from left to right. The welding stand 6 is arranged directly behind the base 1 . One end of the synchronous belt 3 is fixed to the synchronous belt adjusting device 4 , and the other end is fixed to the synchronous belt fixing device 5 . The timing belt adjusting device 4 is fixed on the left end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com