Patents

Literature

33results about How to "Realize welding operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

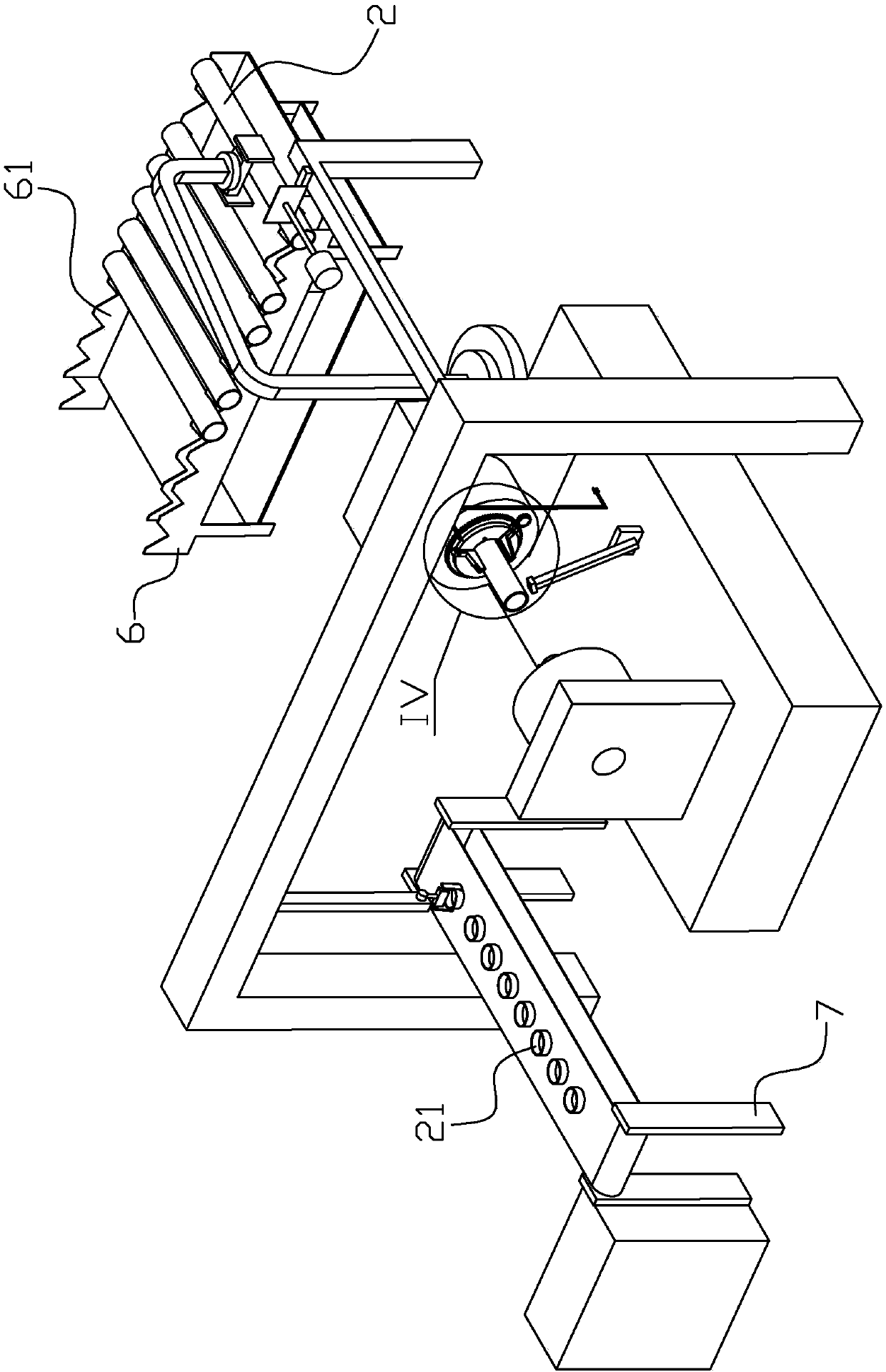

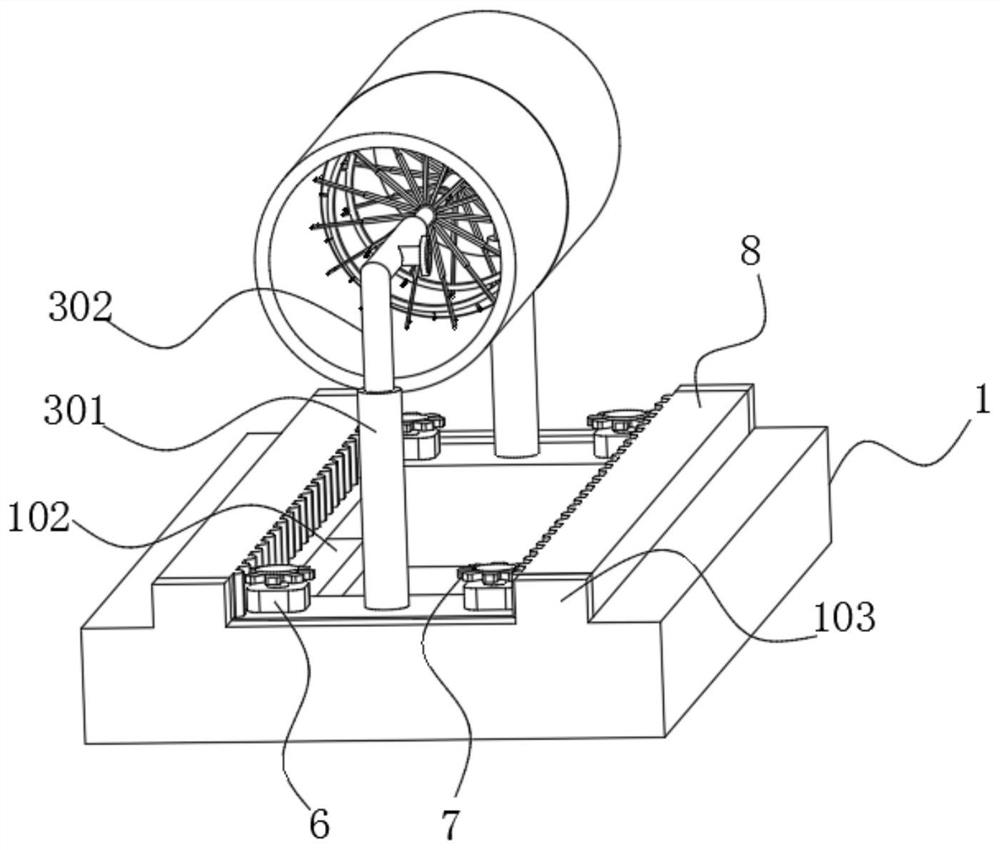

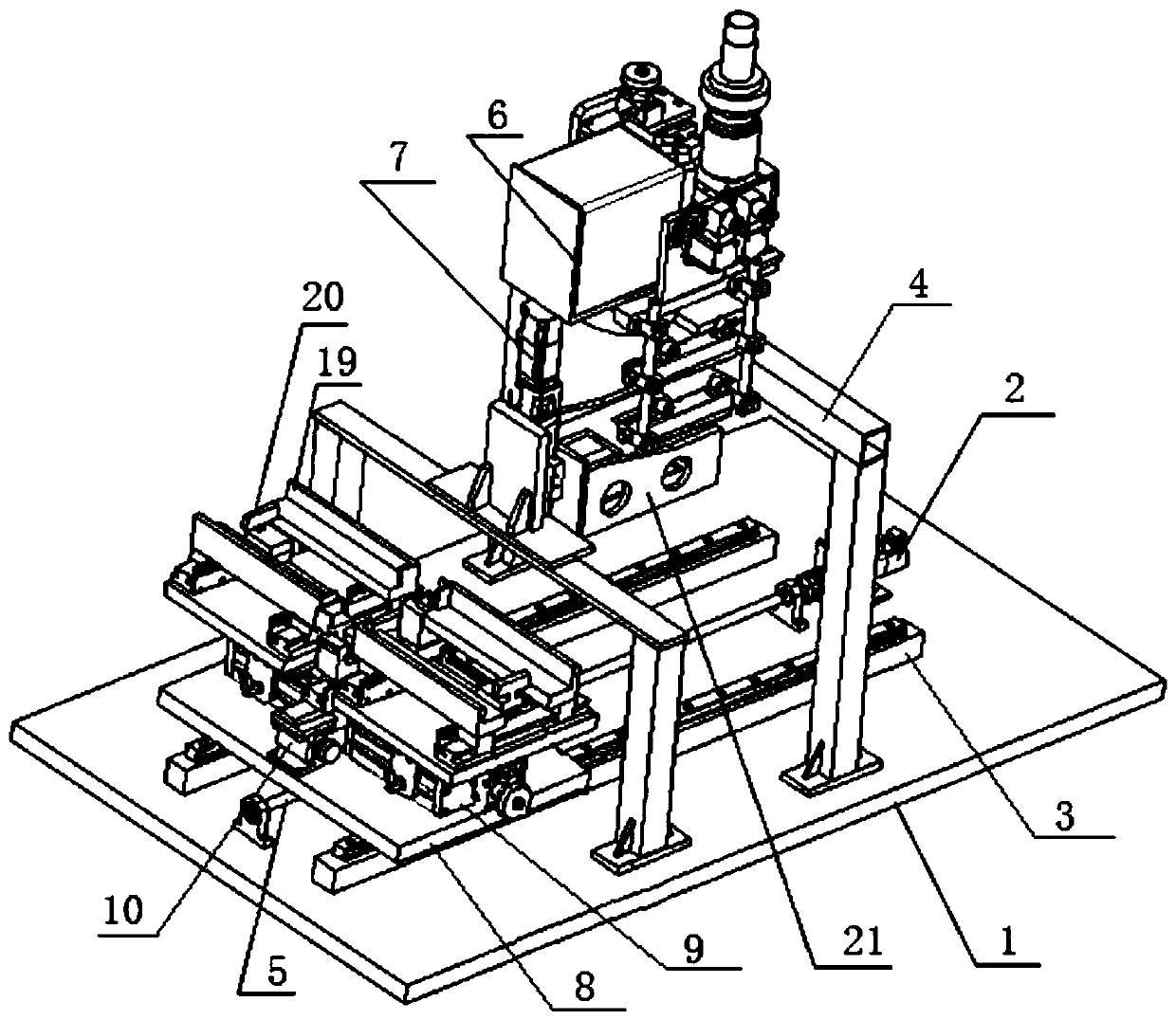

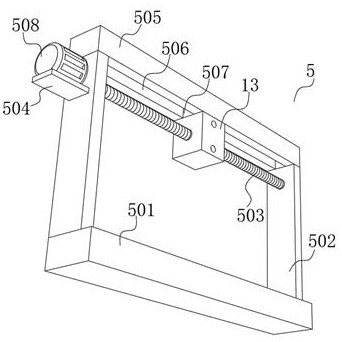

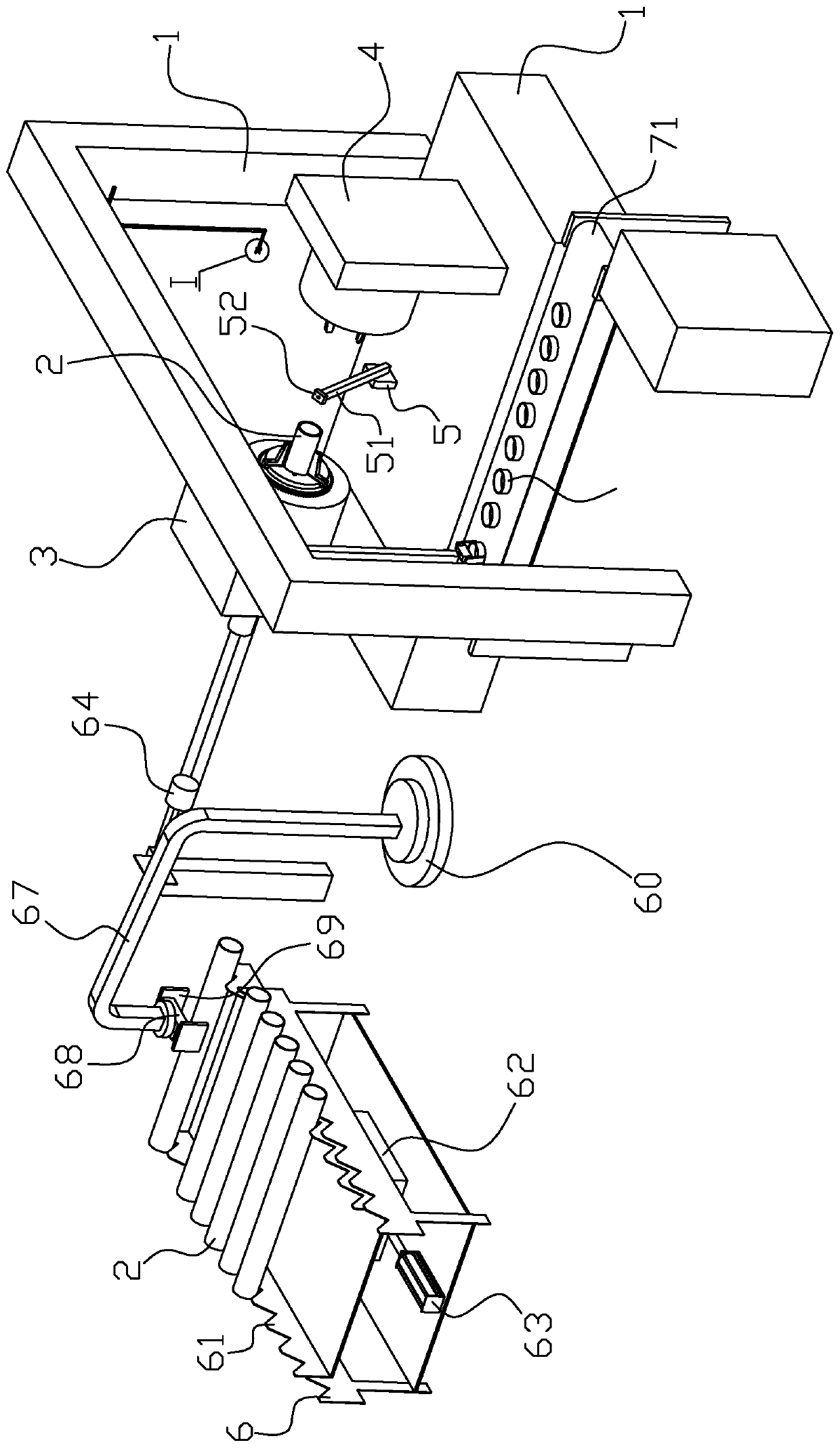

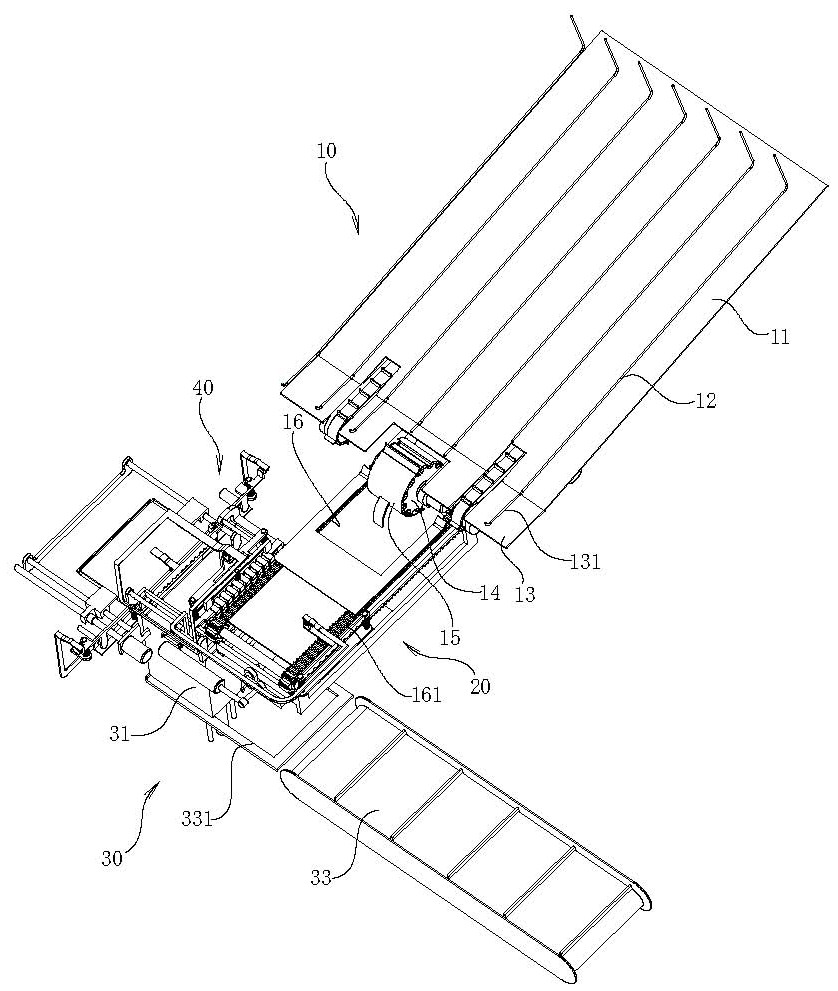

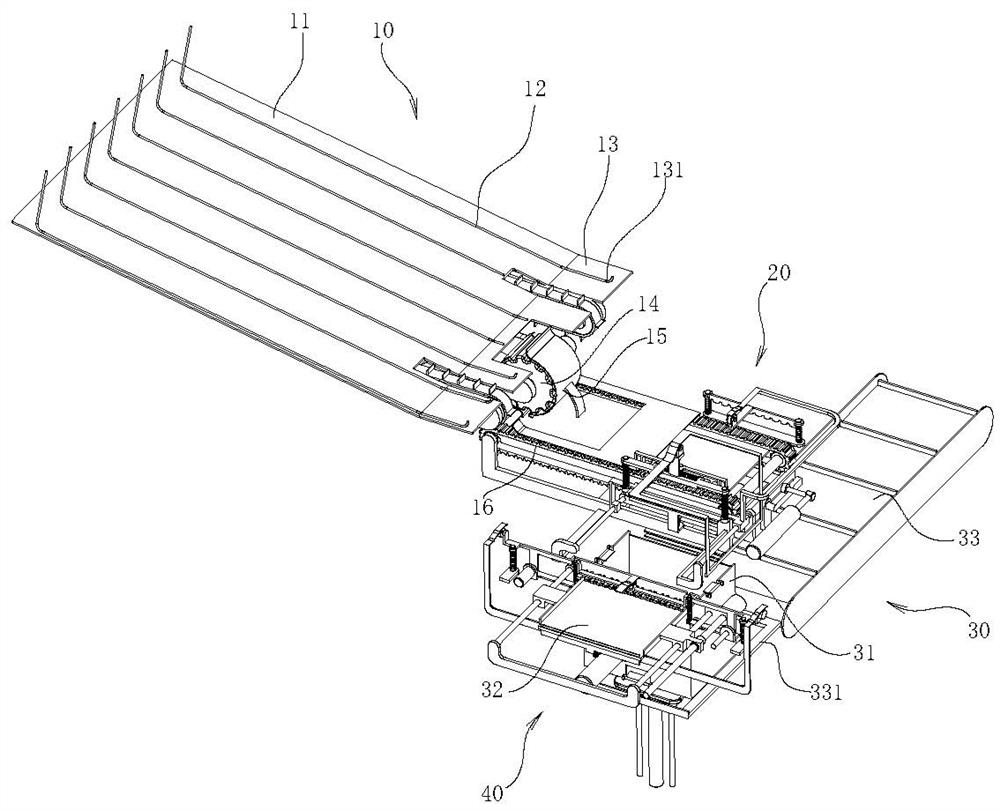

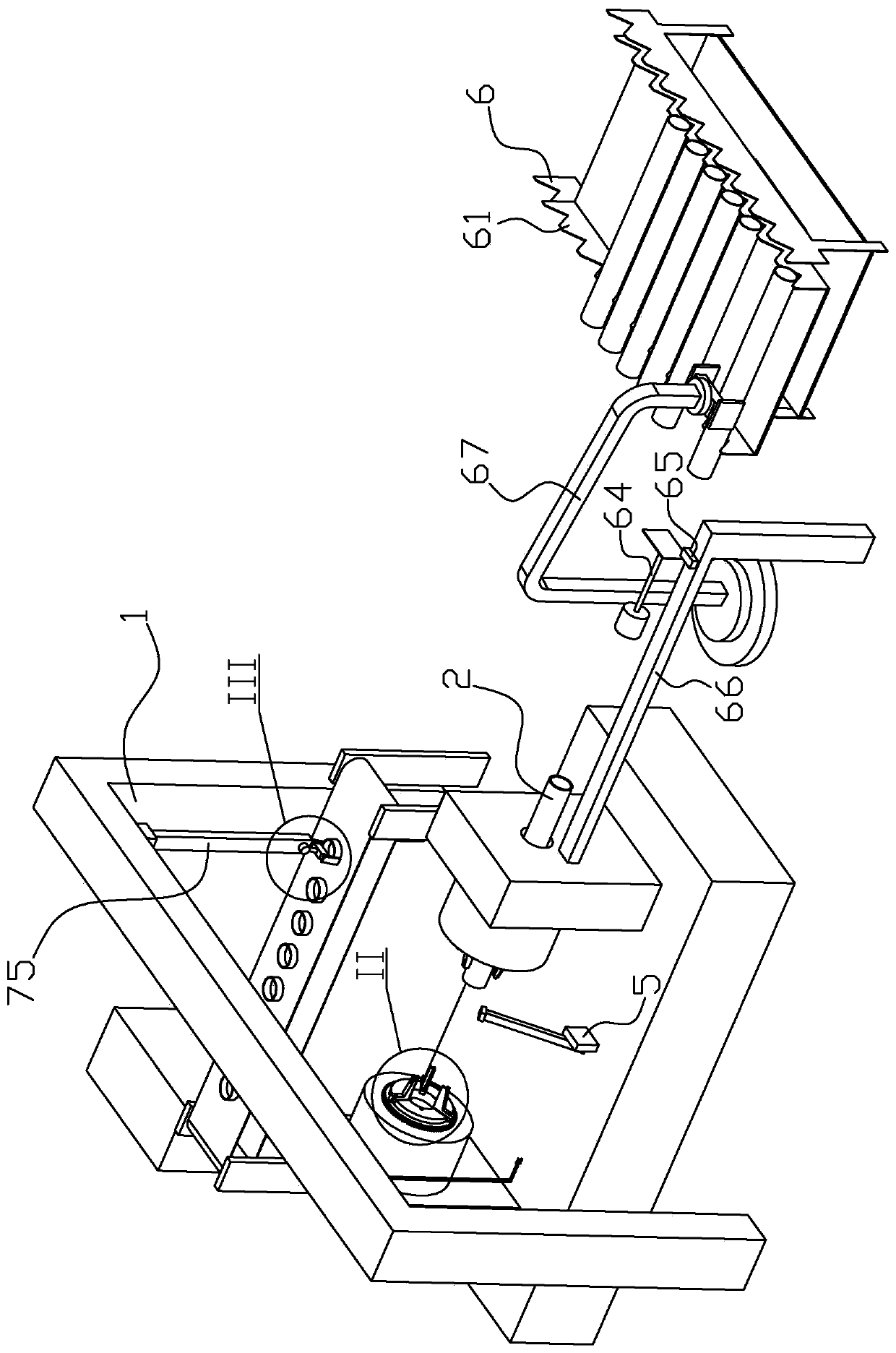

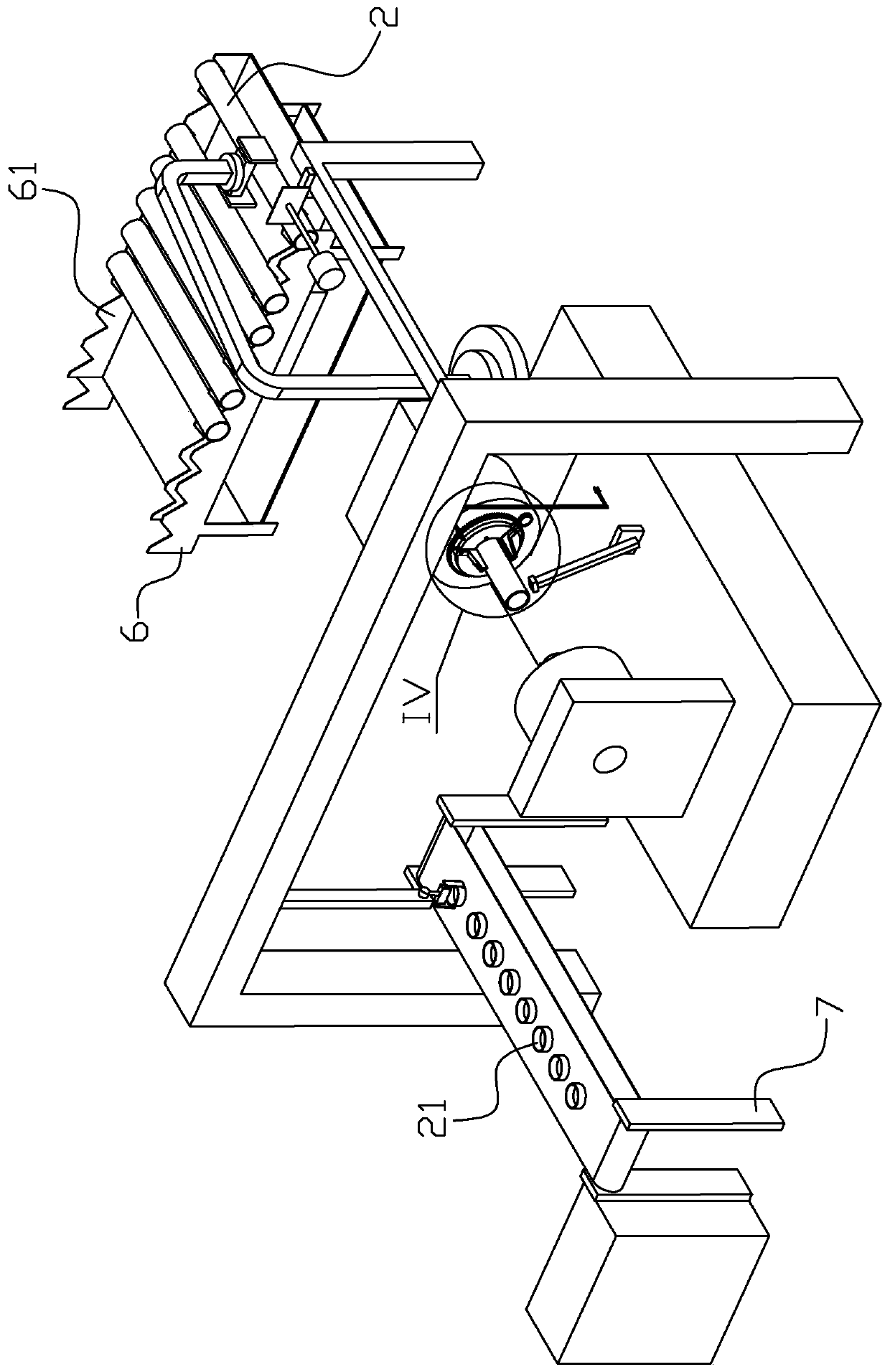

Automation equipment for multi-step thickness metal plate machining

InactiveCN109158754AAchieve fine-tuningRealize welding operationLaser beam welding apparatusControl systemElectrical connection

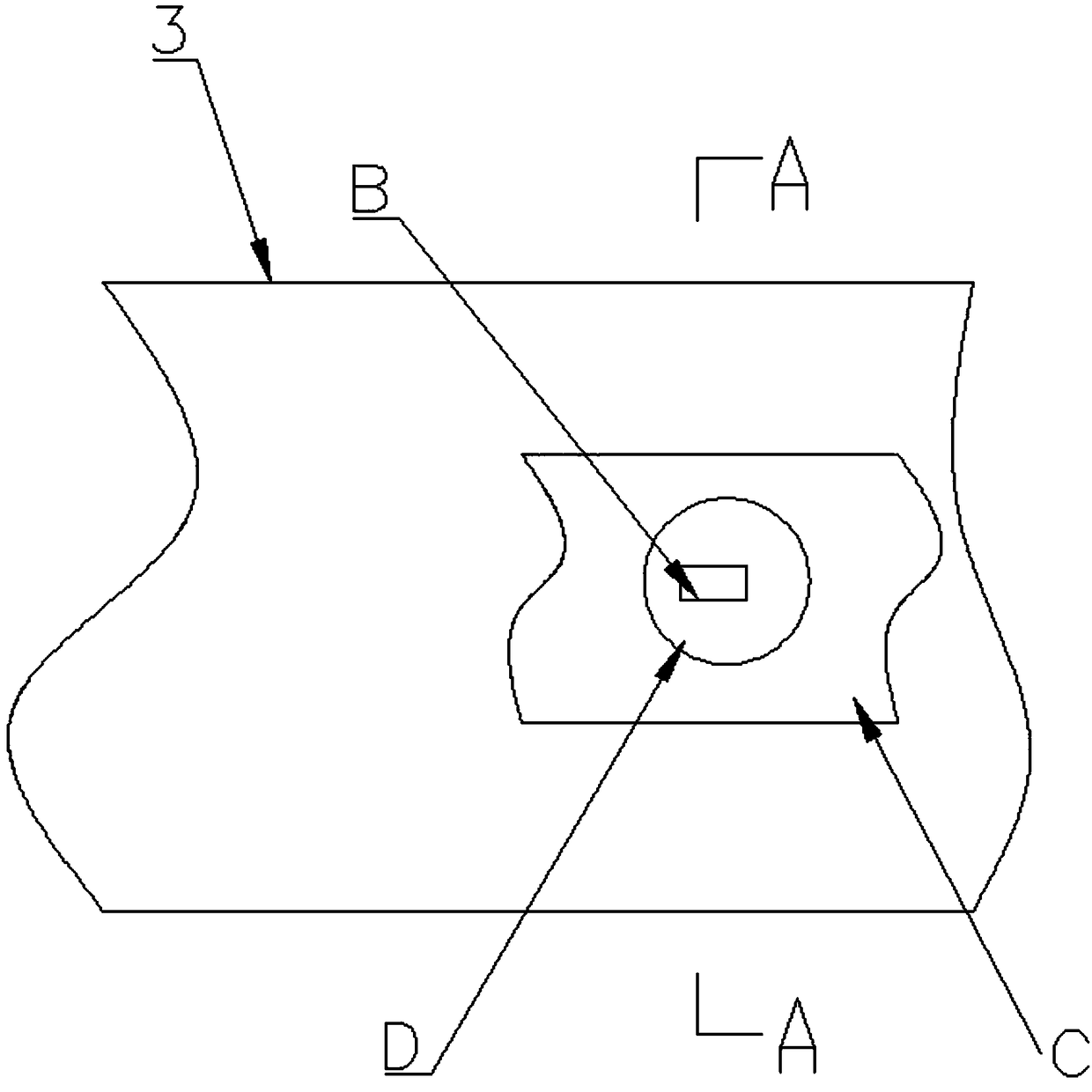

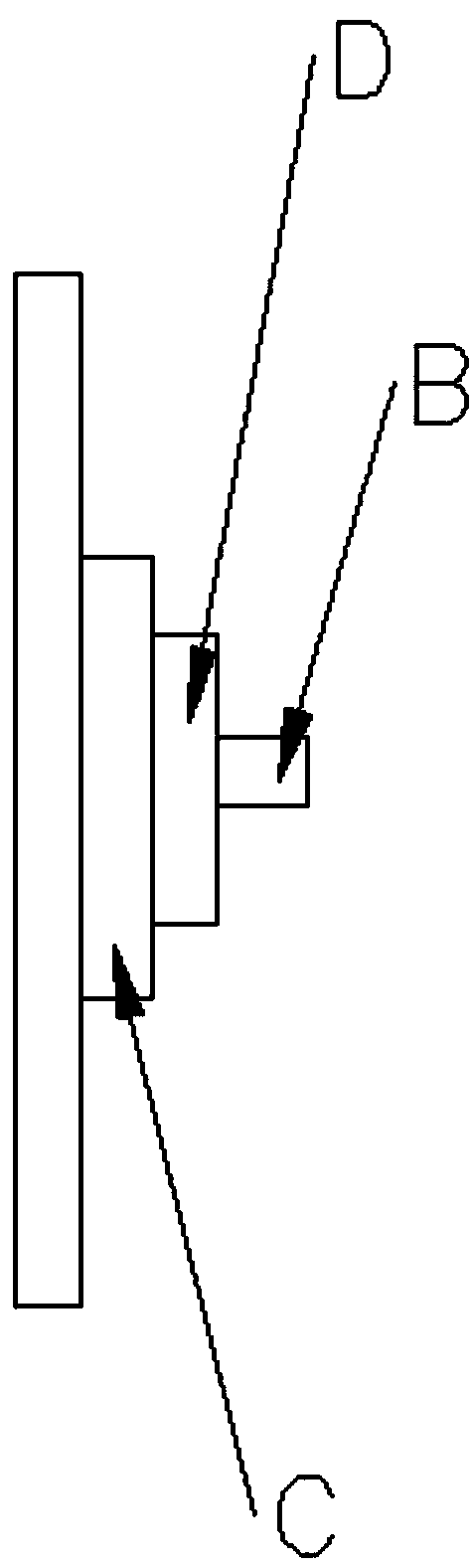

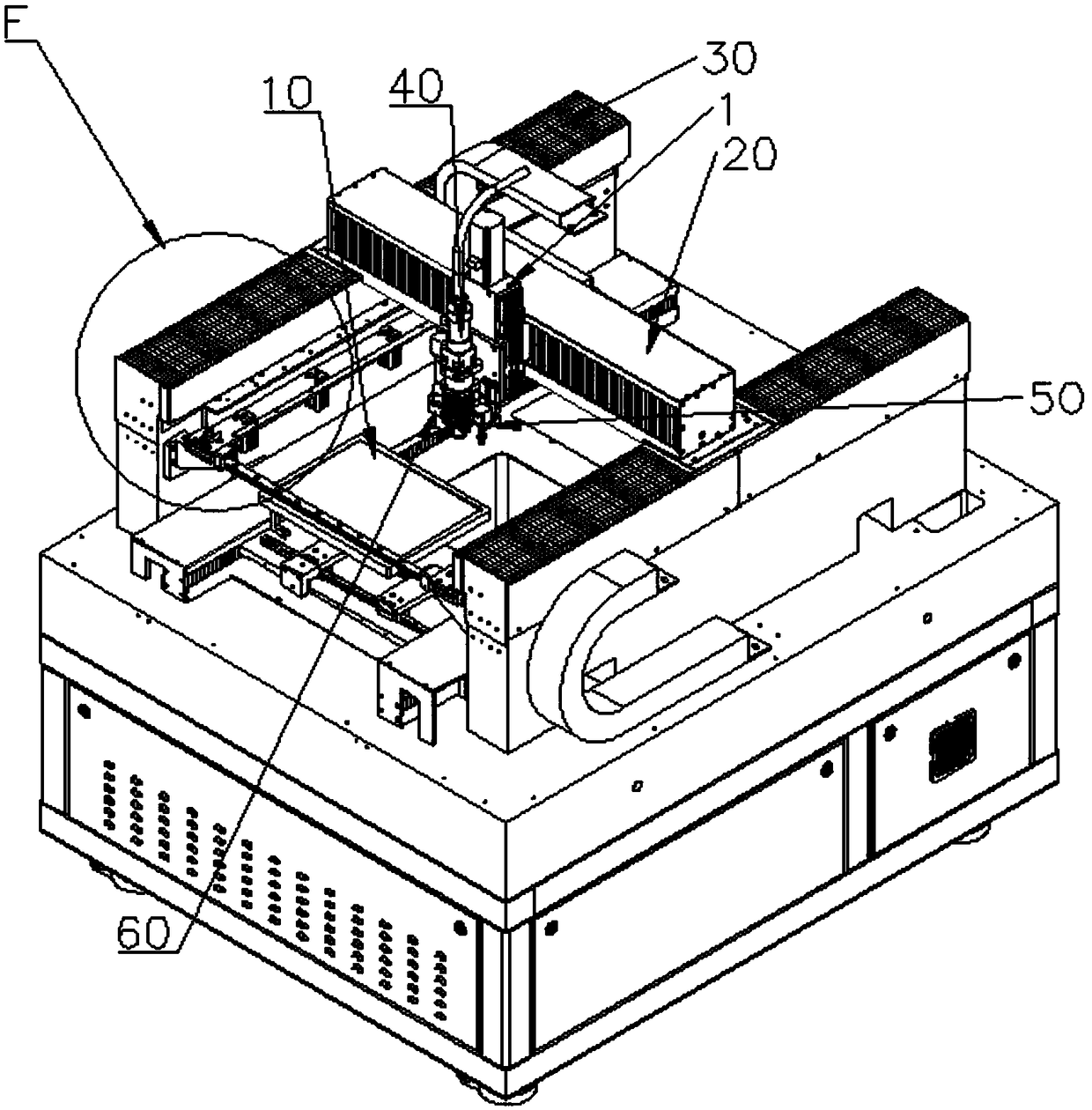

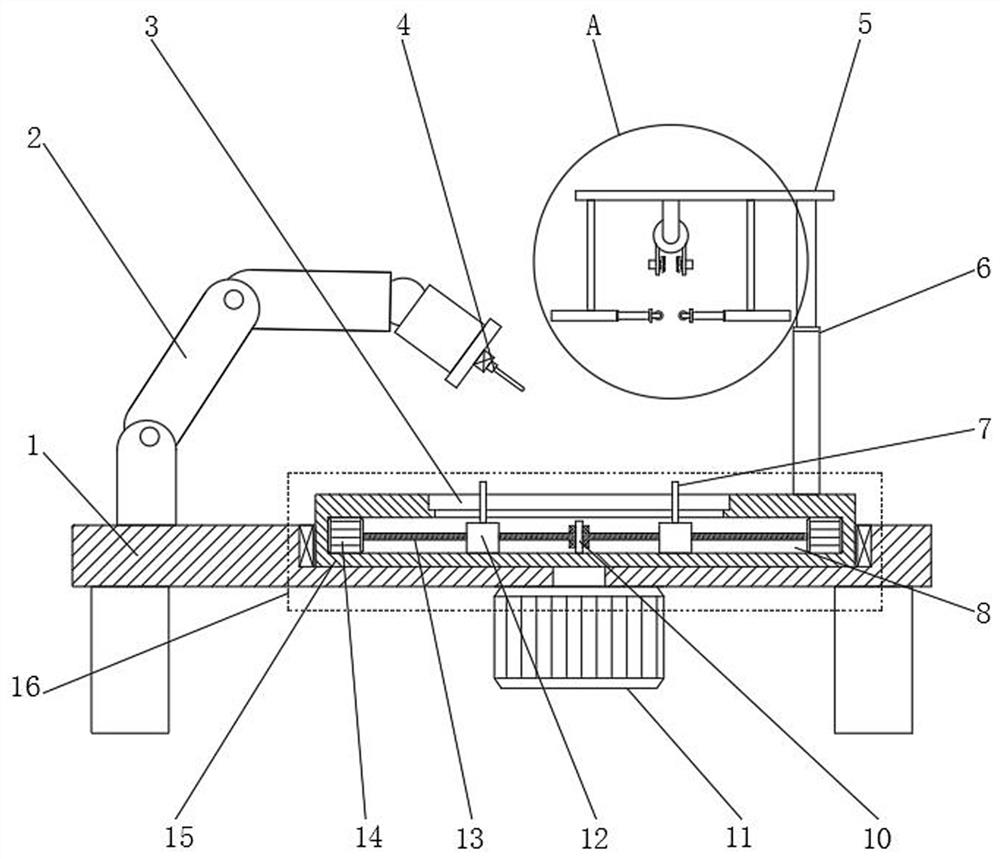

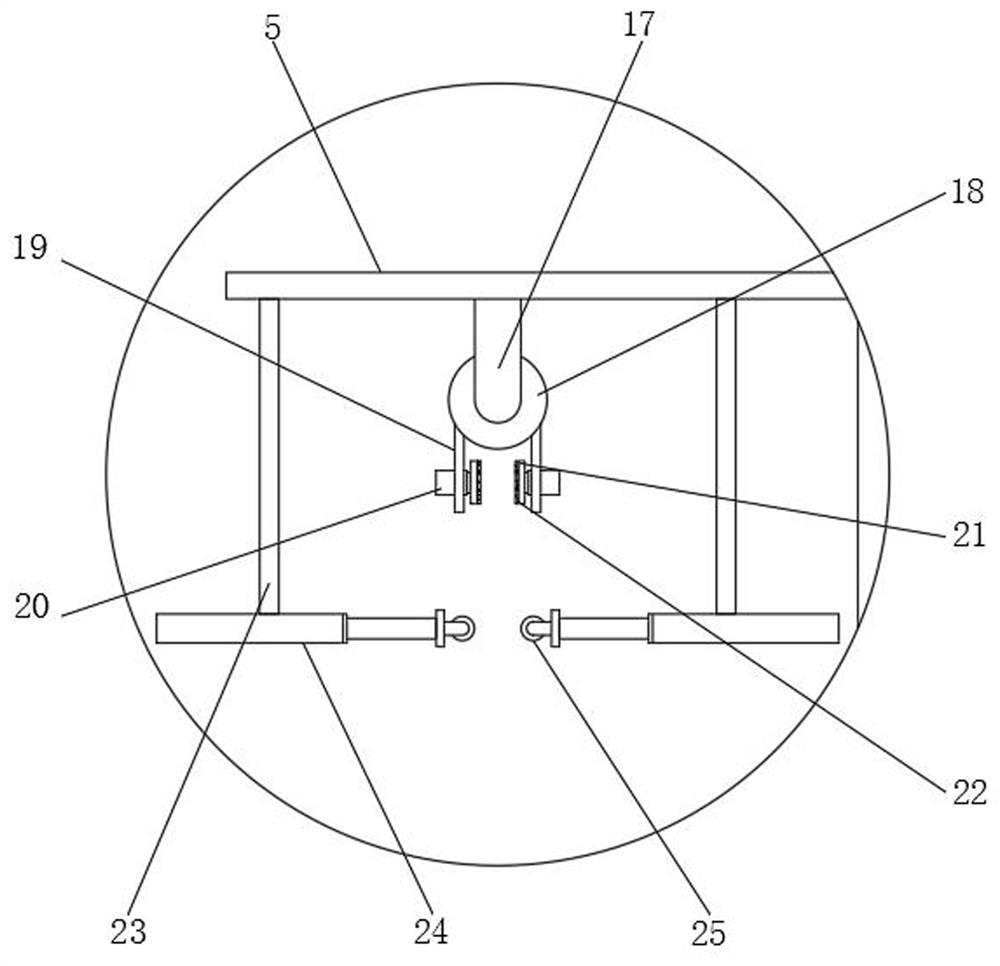

The invention provides automation equipment for multi-step thickness metal plate machining and belongs to the technical field of laser machining equipment. The automation equipment comprises a controlsystem, a product adsorbing lifting jig, an X-axis transmission system, a Y-axis transmission system, a laser welding cutting head, a product adsorbing system and a CCD image collection module, wherein the product adsorbing lifting jig, the X-axis transmission system, the Y-axis transmission system, the laser welding cutting head, the product adsorbing system and the CCD image collection module are in electrical connection with the control system, the product adsorbing system comprises a fixed bottom plate, an air cylinder, a motor fixing plate, a fine adjustment motor, a grabbing adsorbing head and a vacuum pump, and movement of the laser welding cutting head on the X-axis transmission system is realized through the fixed bottom plate, the air cylinder is fixed on the fixed bottom plate,the end portion of a piston rod of the air cylinder is connected with the motor fixing plate, the fine adjustment motor is fixed on the motor fixing plate, the end portion of a motor shaft of the fine adjustment motor is connected with the grabbing adsorbing head, and the grabbing adsorbing head is connected with the vacuum pump through a pipeline. The automation equipment is used for machining of multi-step thickness metal plates and is full-automatic equipment which integrates cutting, aligning and welding into a whole.

Owner:苏州迈克埃迩科技有限公司

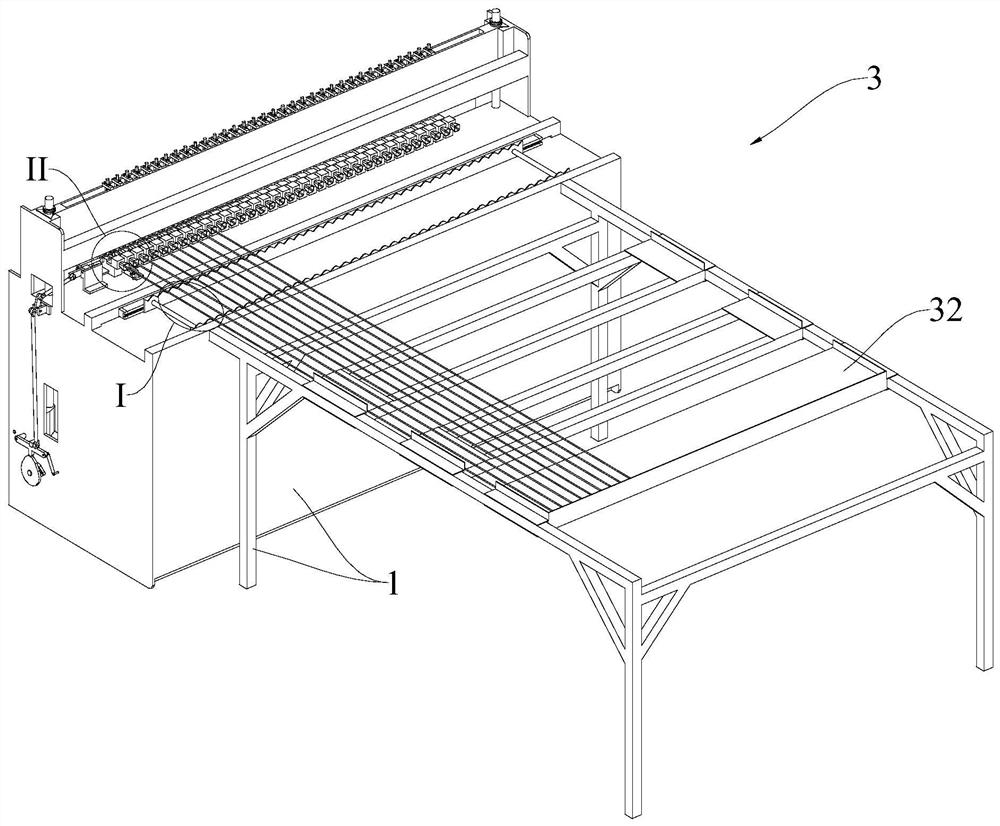

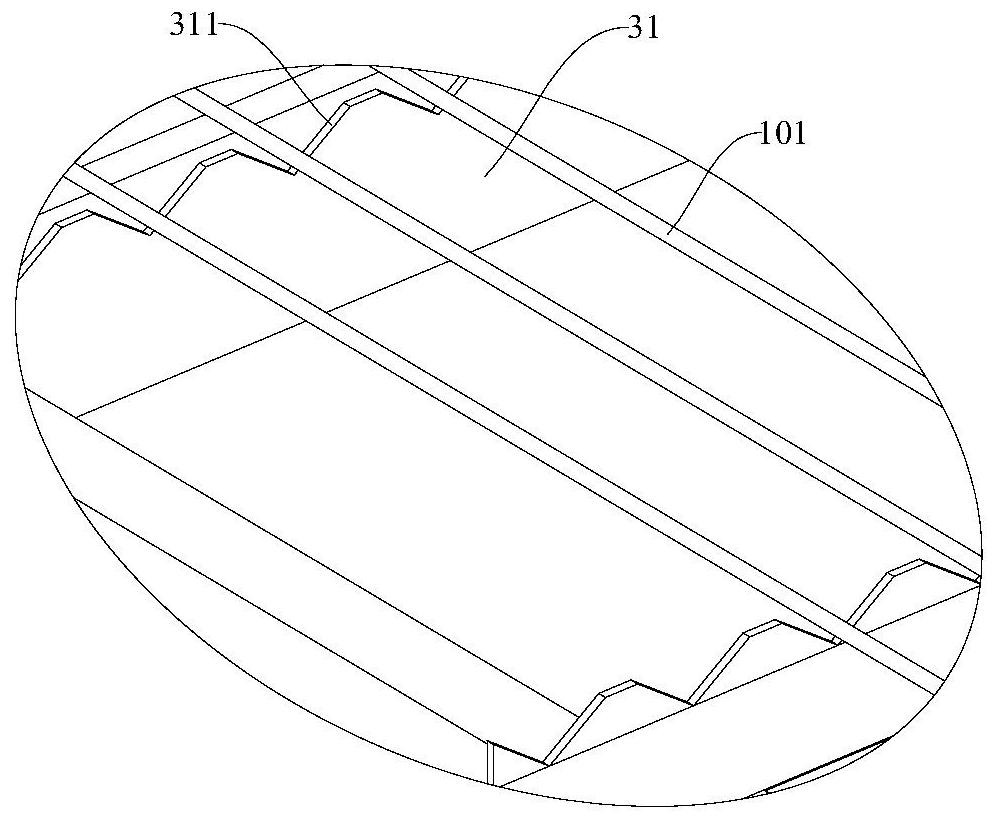

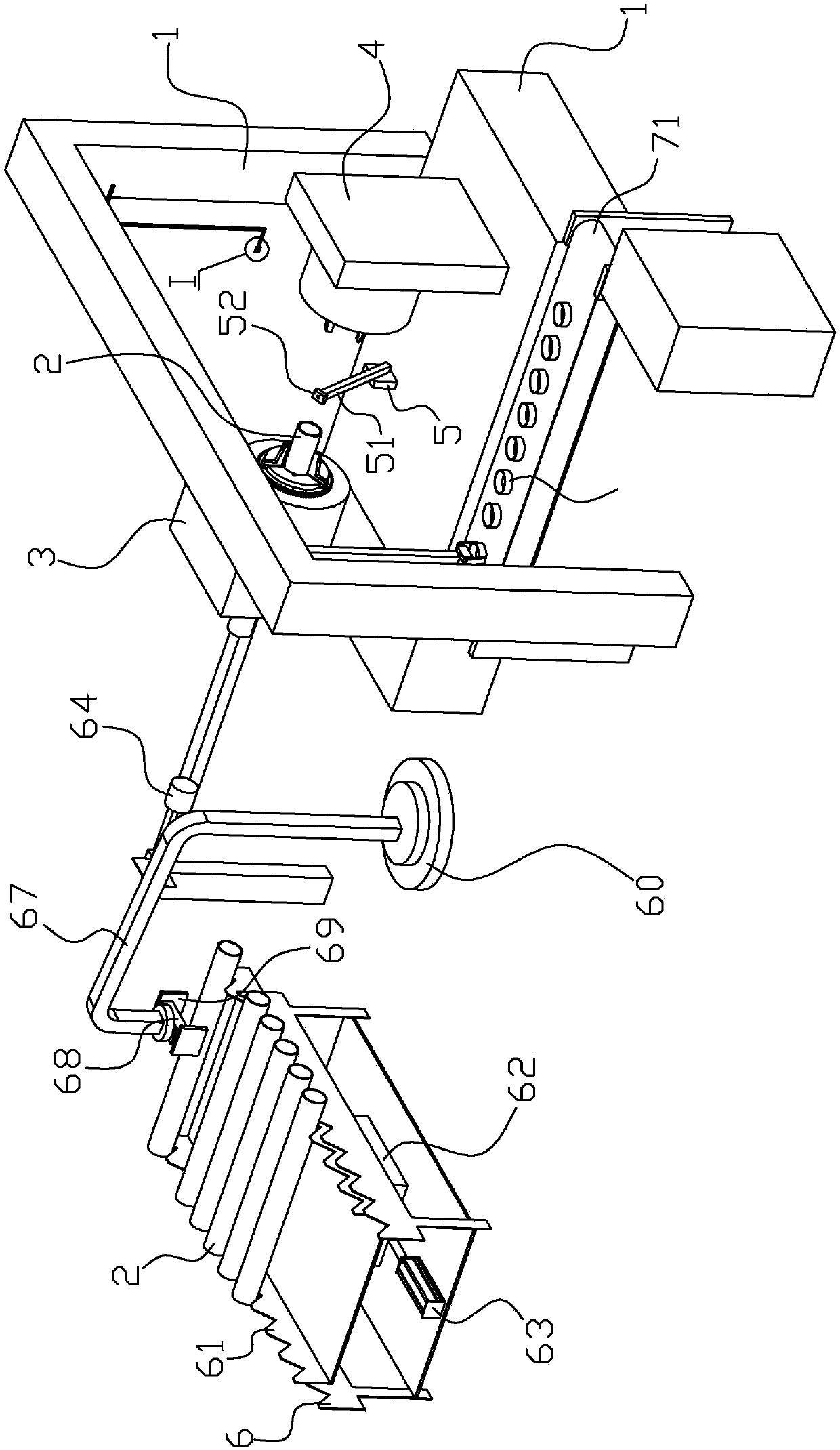

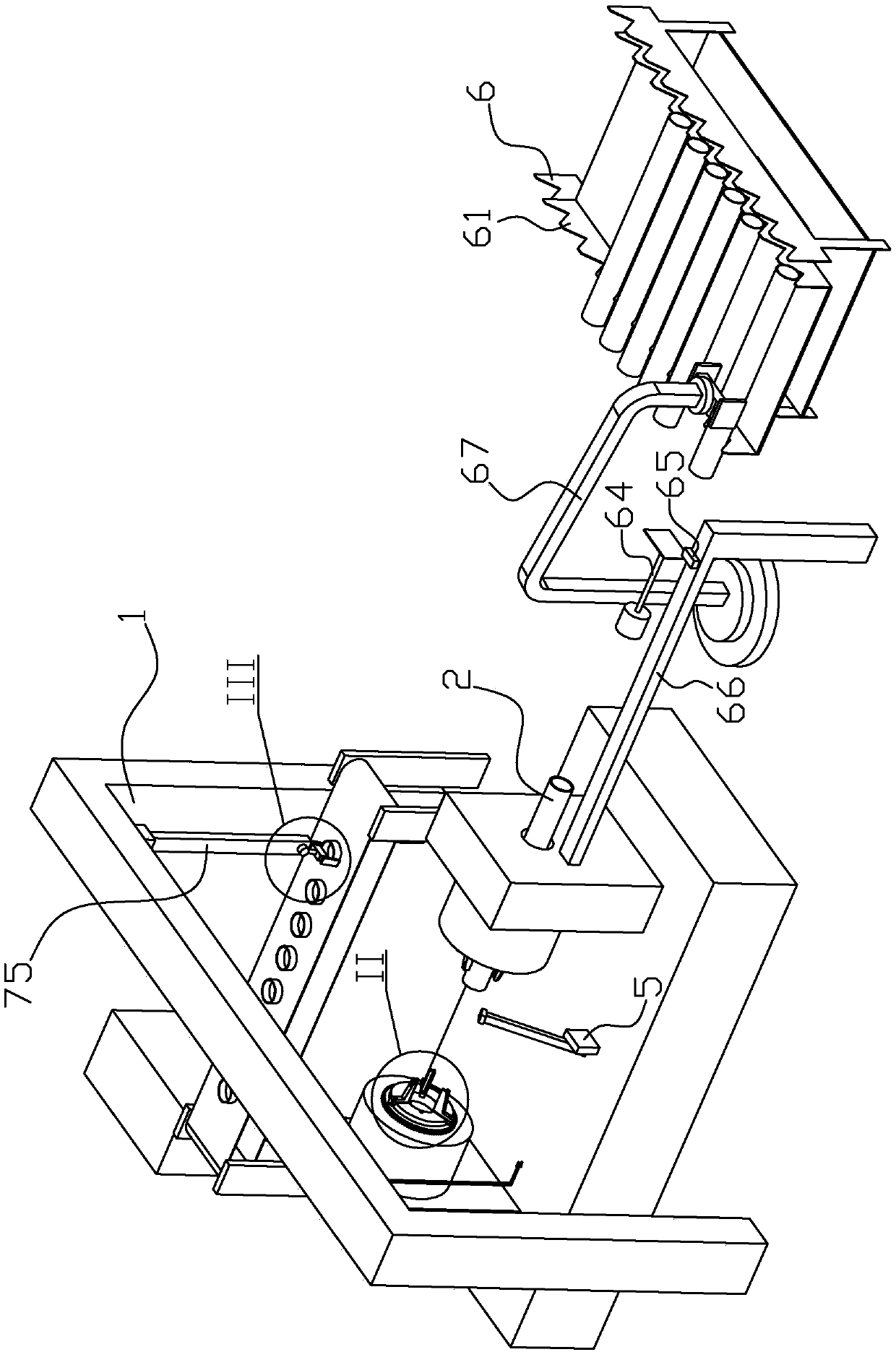

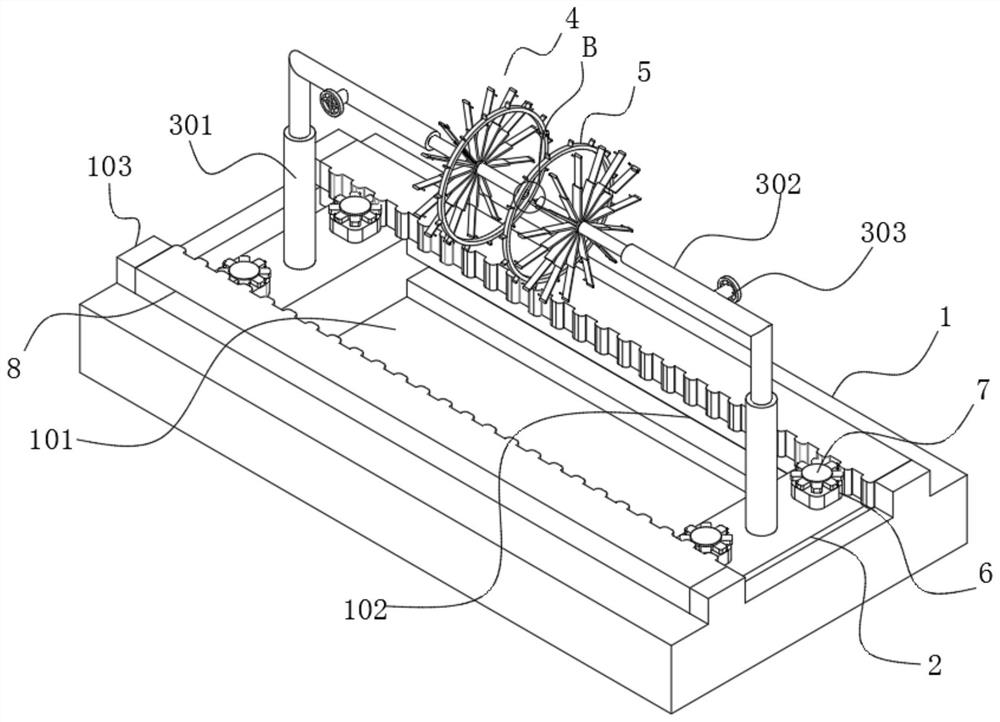

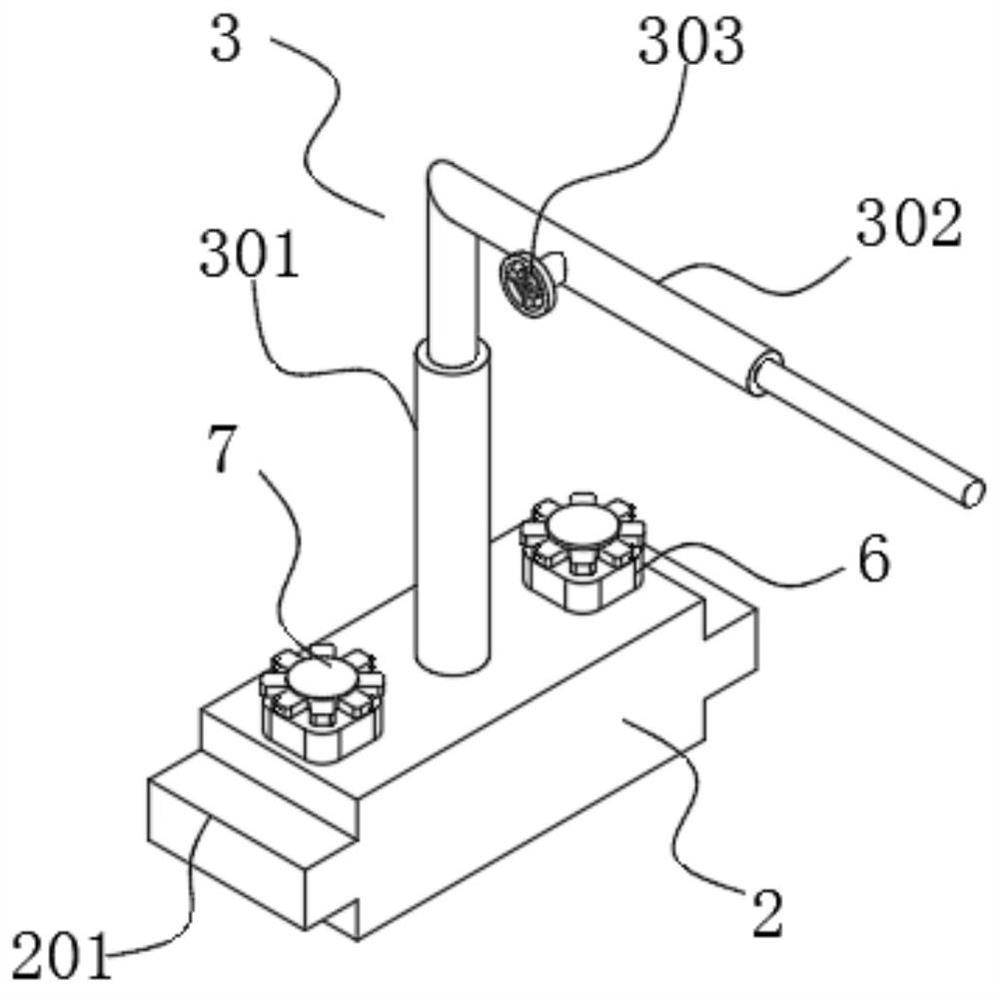

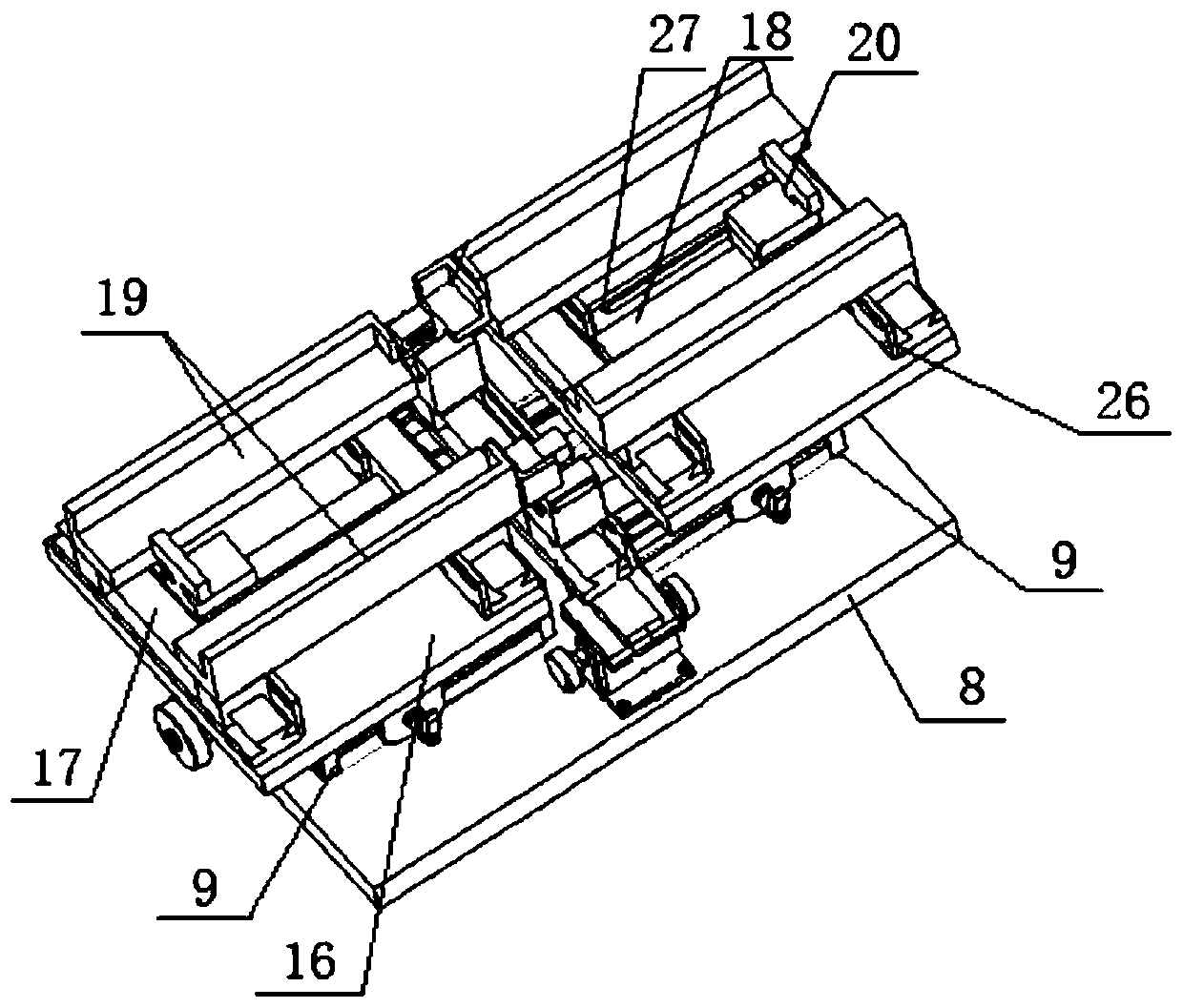

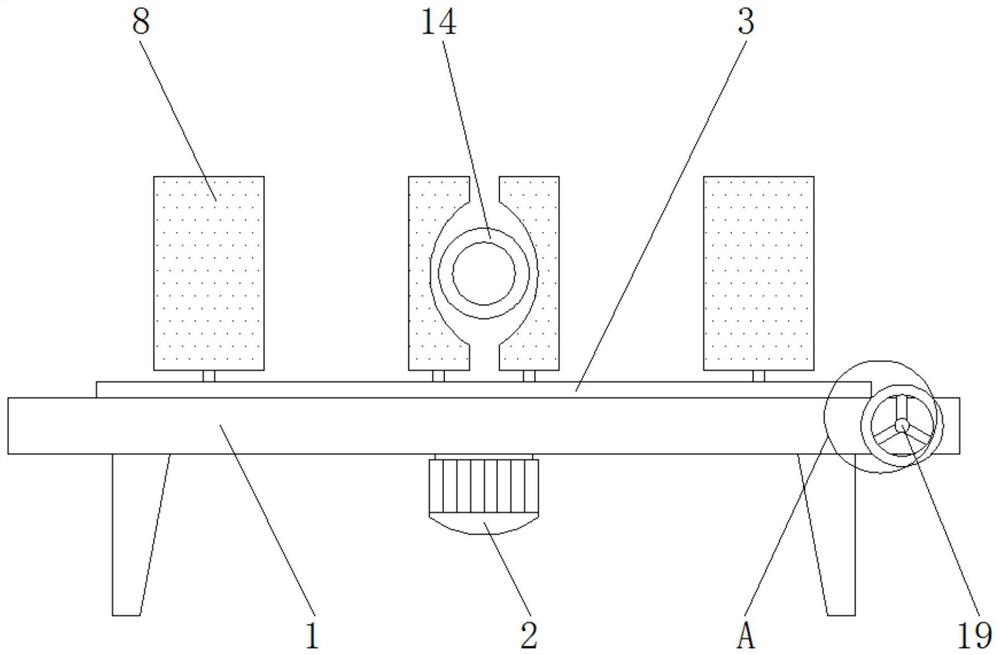

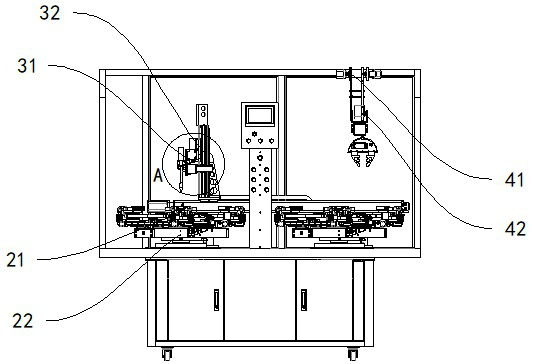

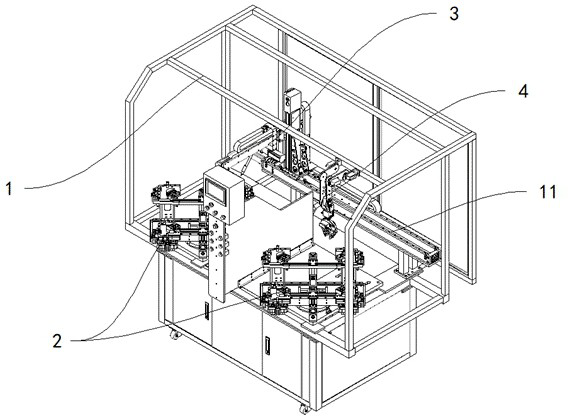

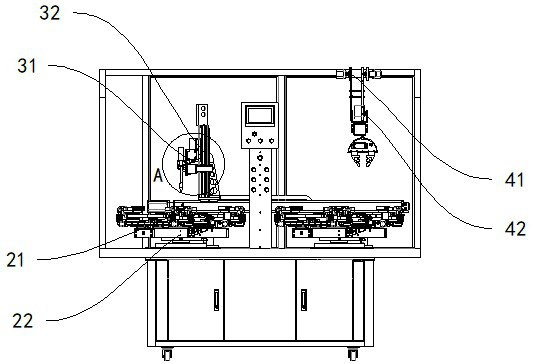

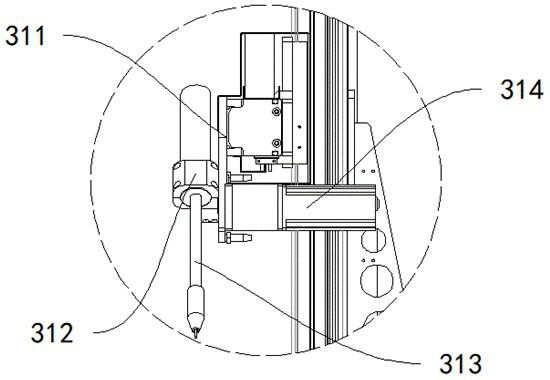

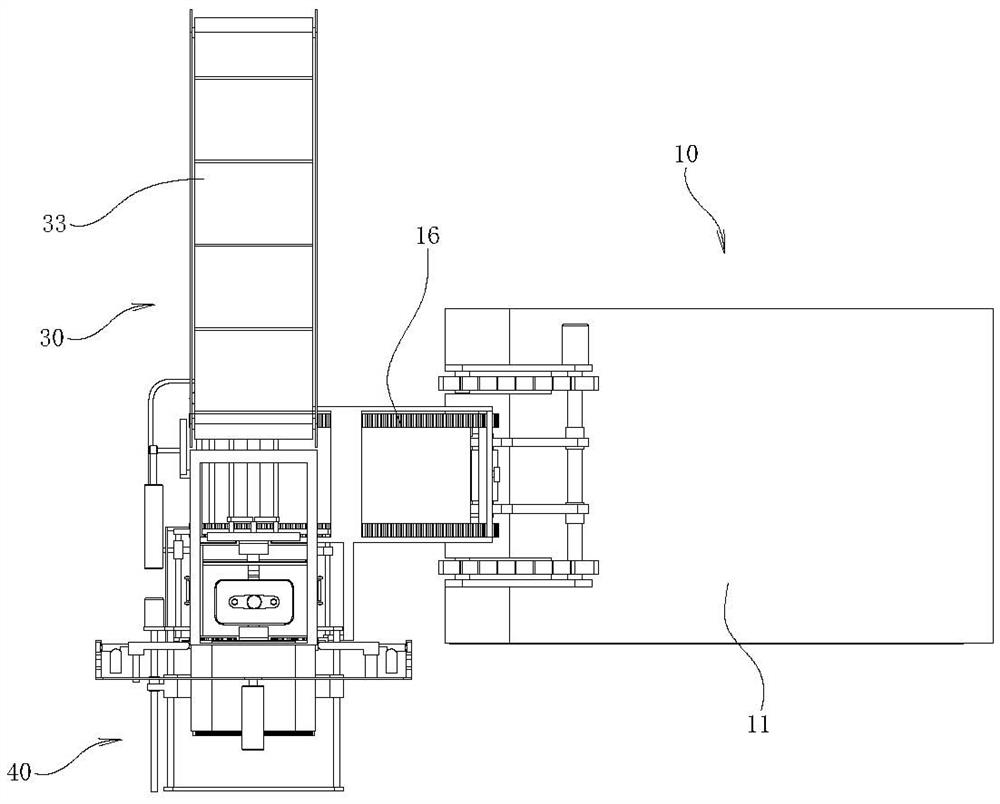

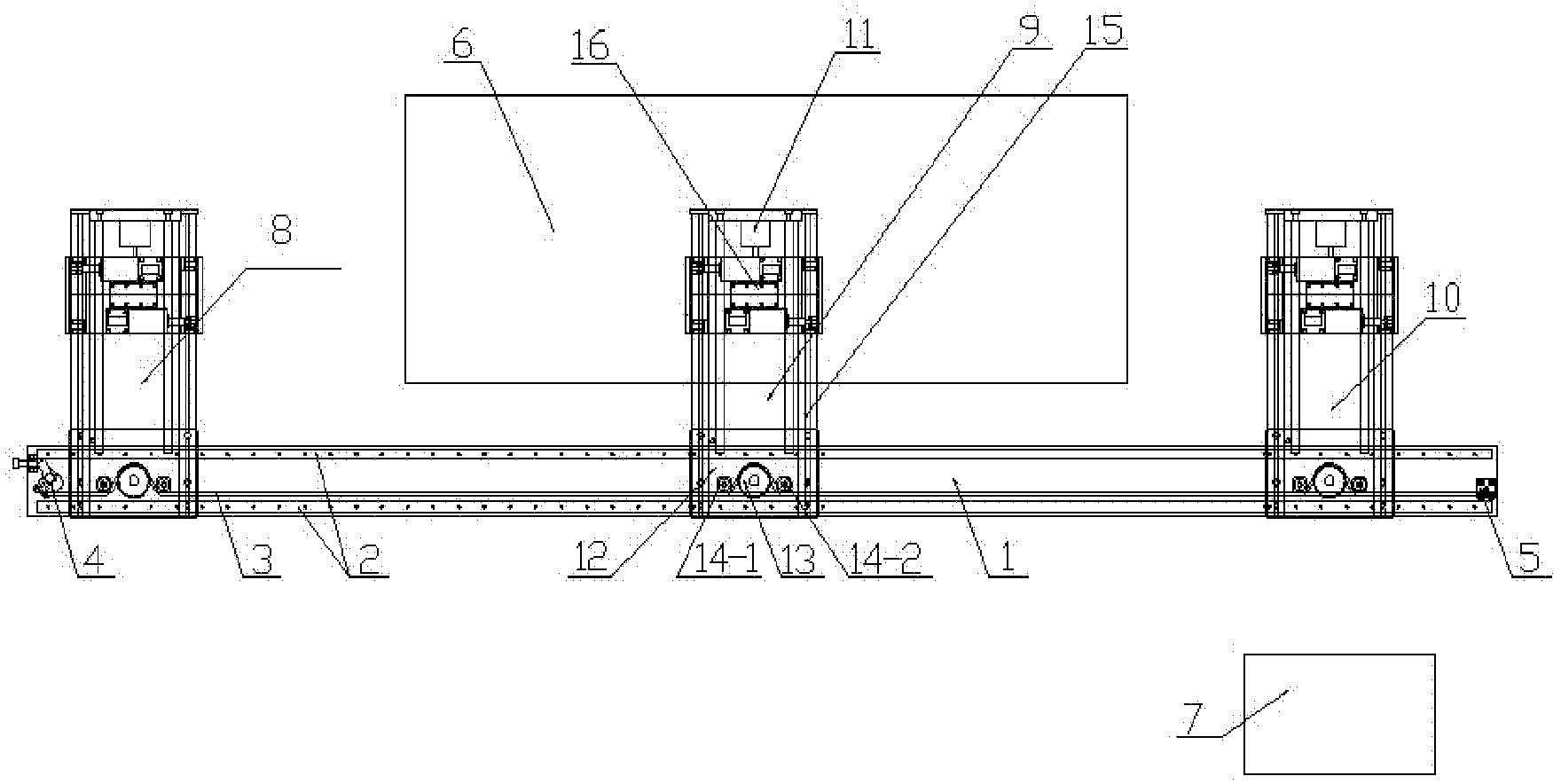

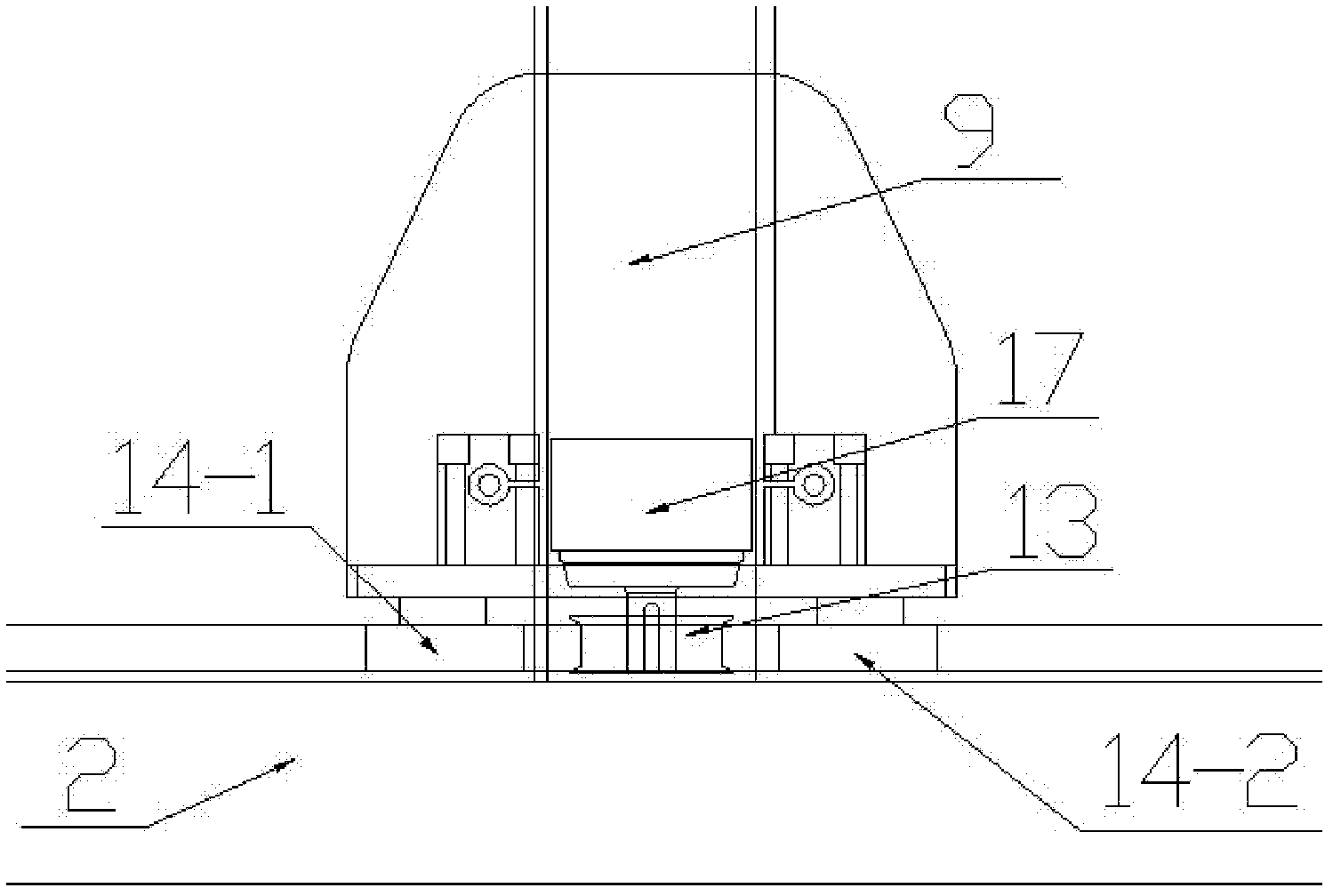

Automatic welding equipment

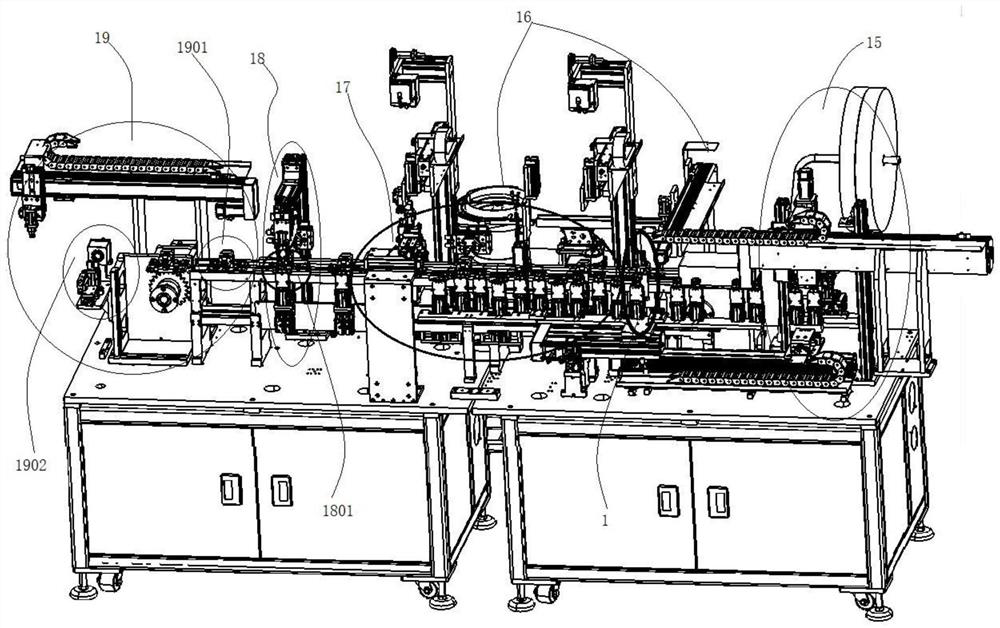

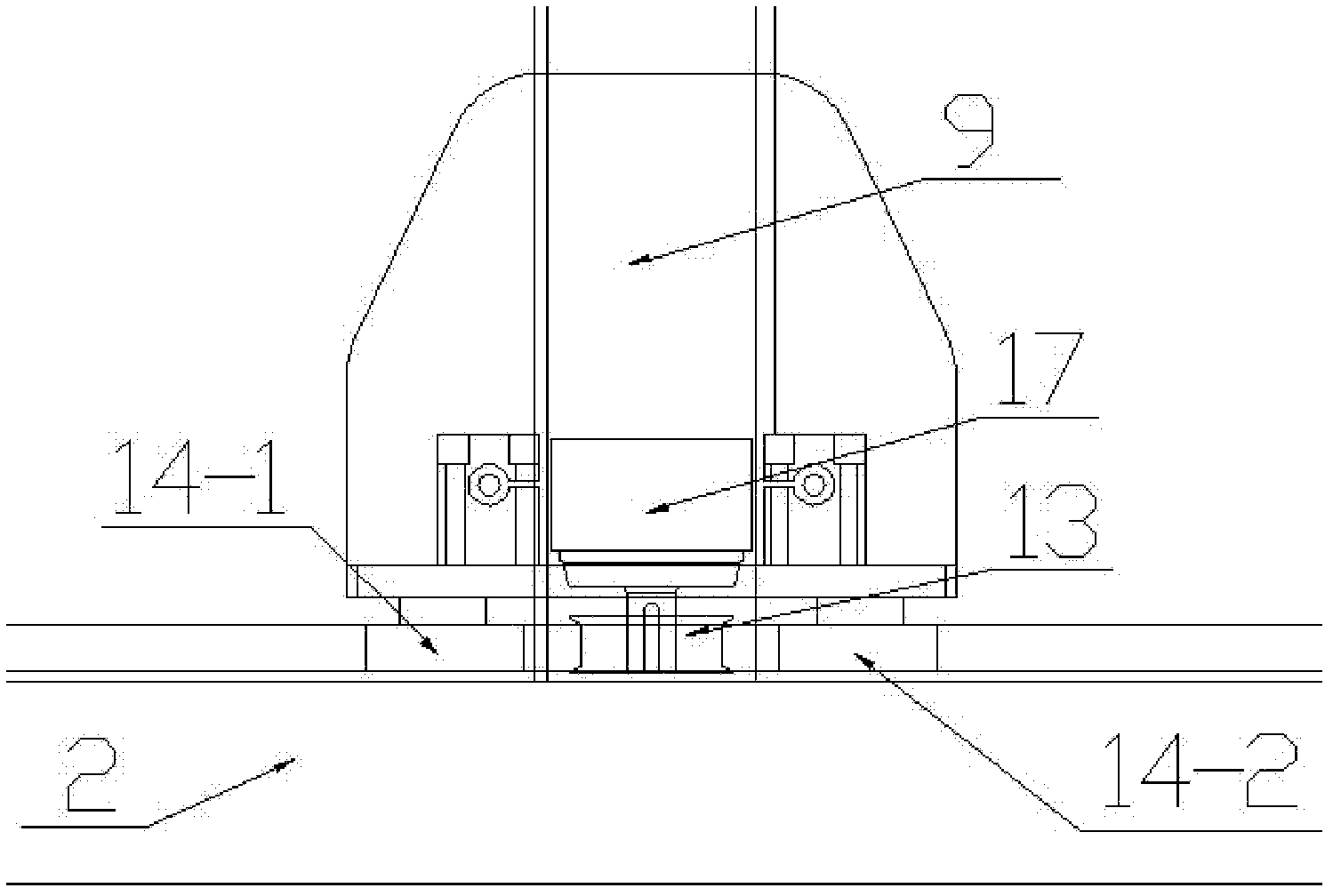

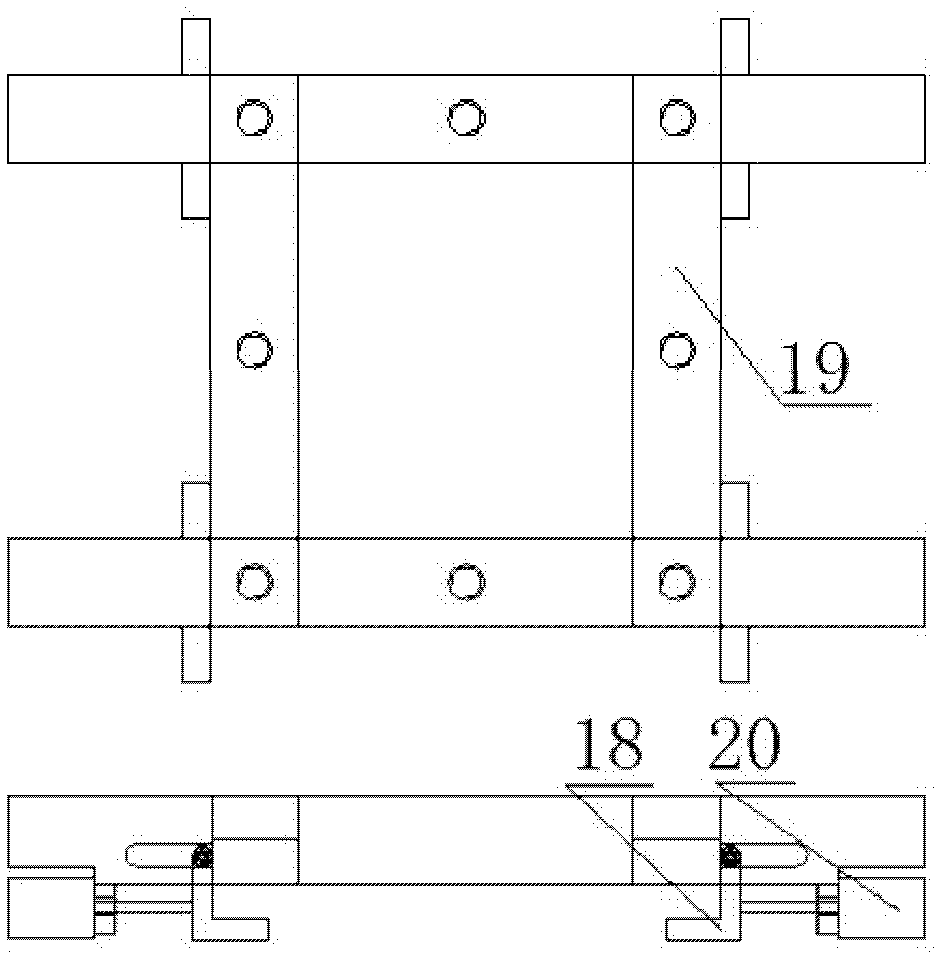

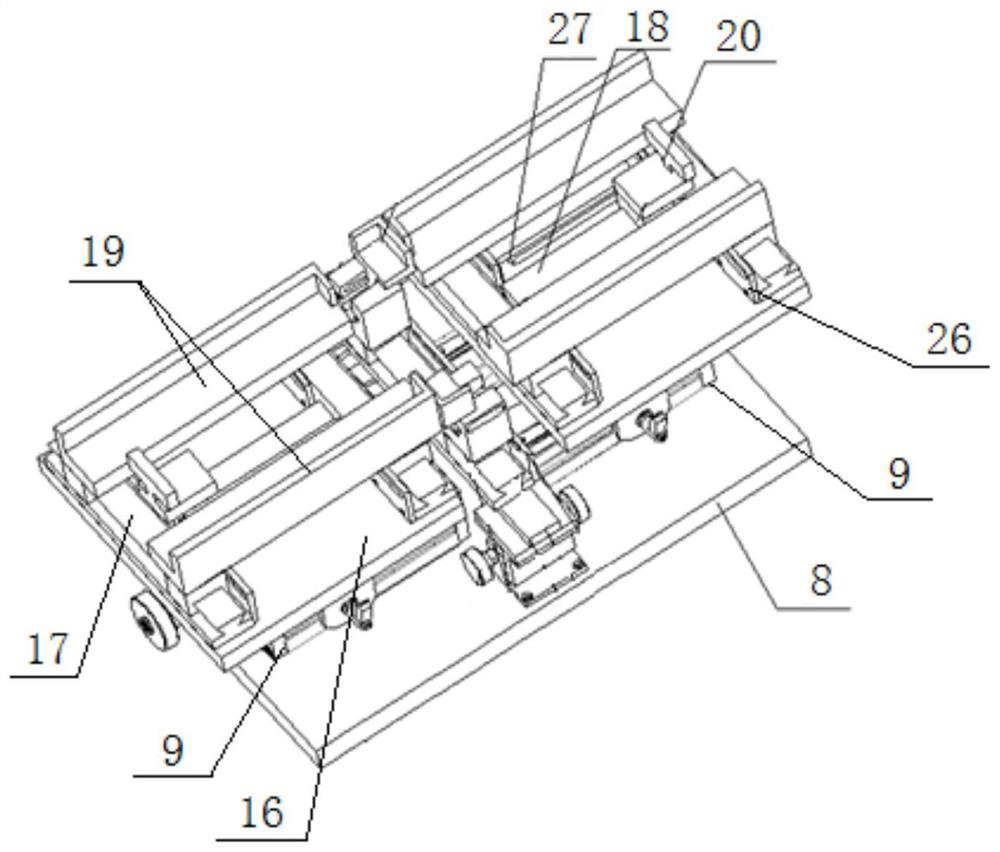

PendingCN112935156ARealize welding operationRealize automatic unloadingWire networkTraction frameEngineering

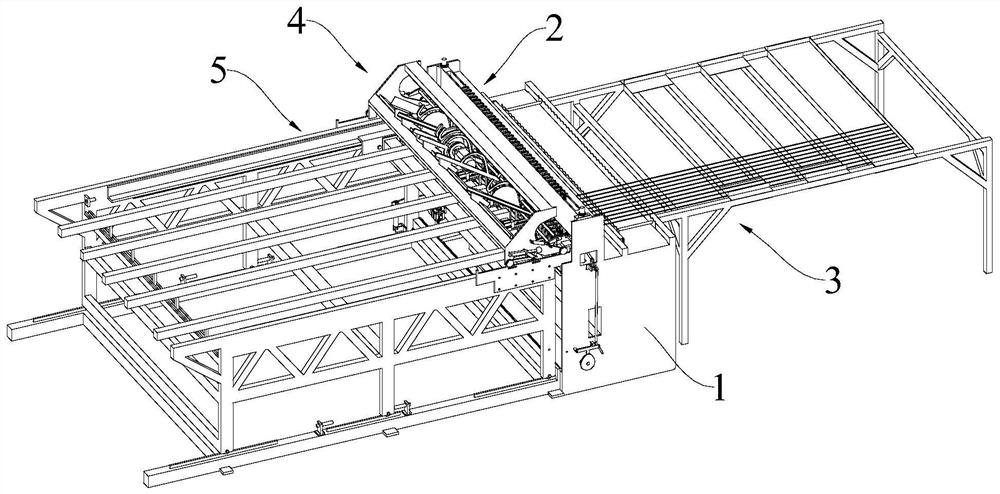

The invention discloses automatic welding equipment which comprises a rack, a welding mechanism, a first feeding mechanism, a second feeding mechanism, a traction mechanism, an automatic discharging mechanism and a storage area. The welding mechanism comprises multiple first welding bases and multiple second welding bases which are longitudinally arranged on the rack at intervals; the second welding bases are arranged over the first welding bases in a one-to-one correspondence mode and can move up and down; the first feeding mechanism is used for conveying multiple transverse ribs to the upper ends of the multiple first welding bases in a one-to-one correspondence mode; the second feeding mechanism is used for alternately conveying single longitudinal ribs to the upper ends of the multiple first welding bases at intervals; the traction mechanism comprises a moving track, a traction frame and a clamp; the traction frame can transversely slide on the moving track; the clamp is arranged on the traction frame and used for clamping the longitudinal ribs; and the automatic discharging mechanism is used for automatically conveying steel wire frameworks located on the moving track to the storage area. The automatic welding equipment is simple to operate, high in automation degree, high in production efficiency, low in labor demand and suitable for industrial production.

Owner:VICHNET COMM SCI & TECH

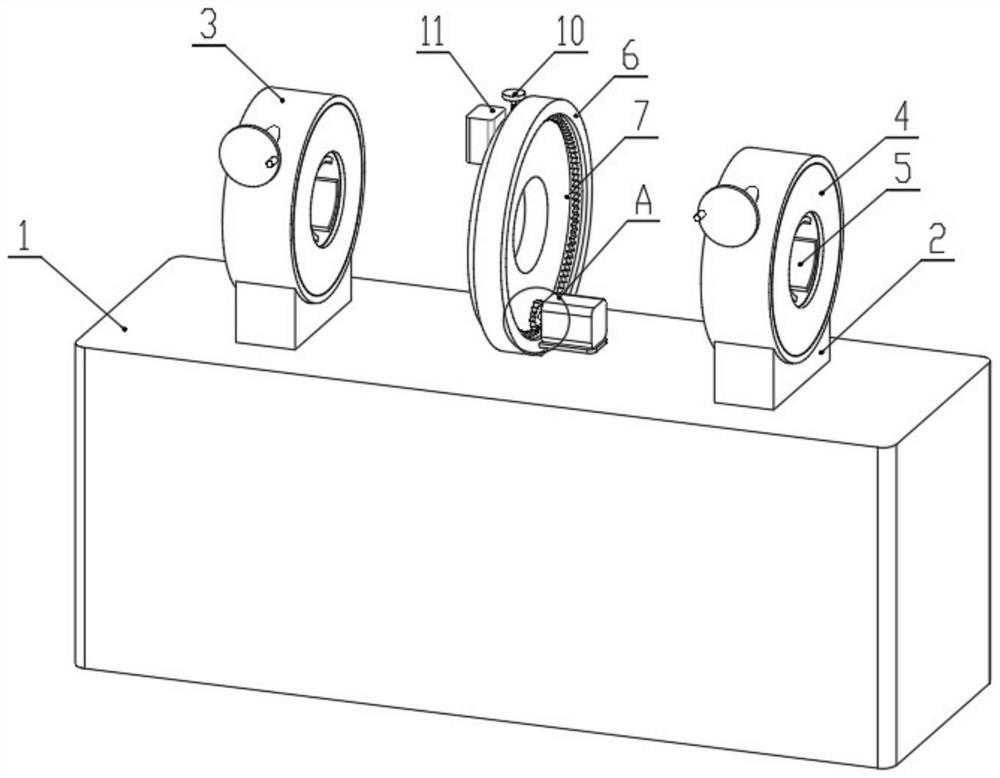

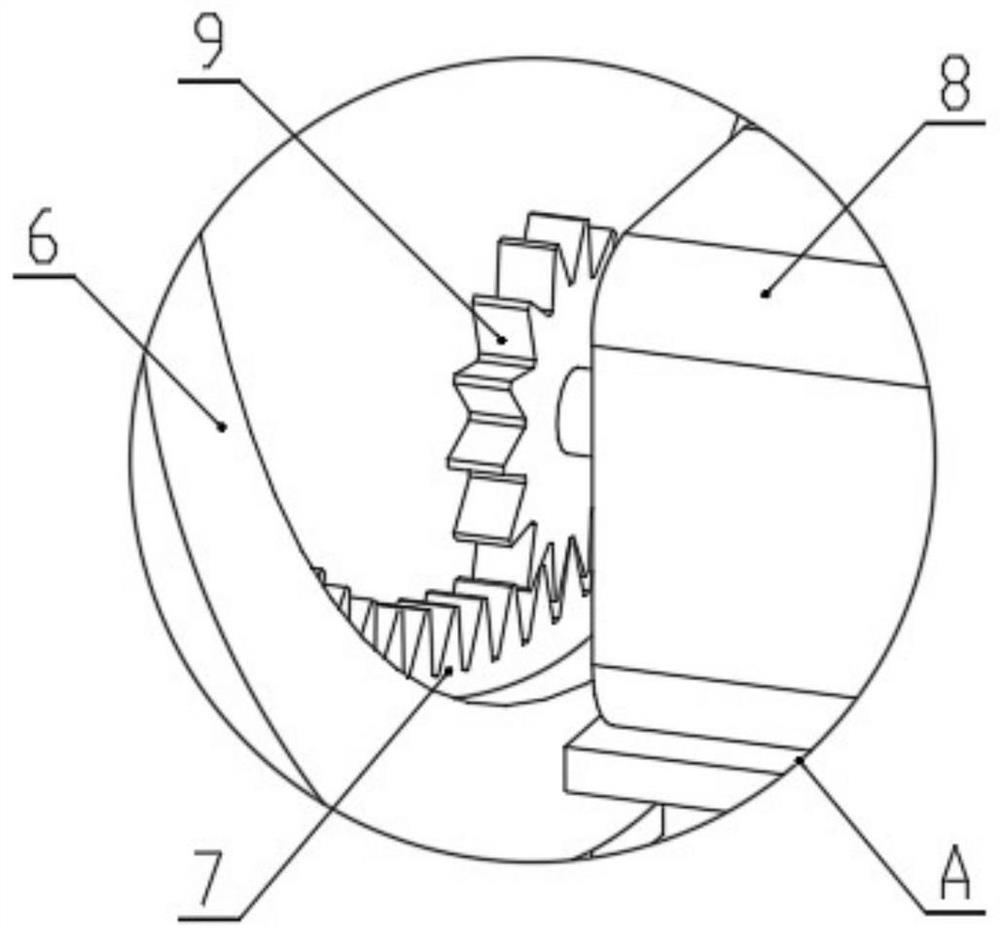

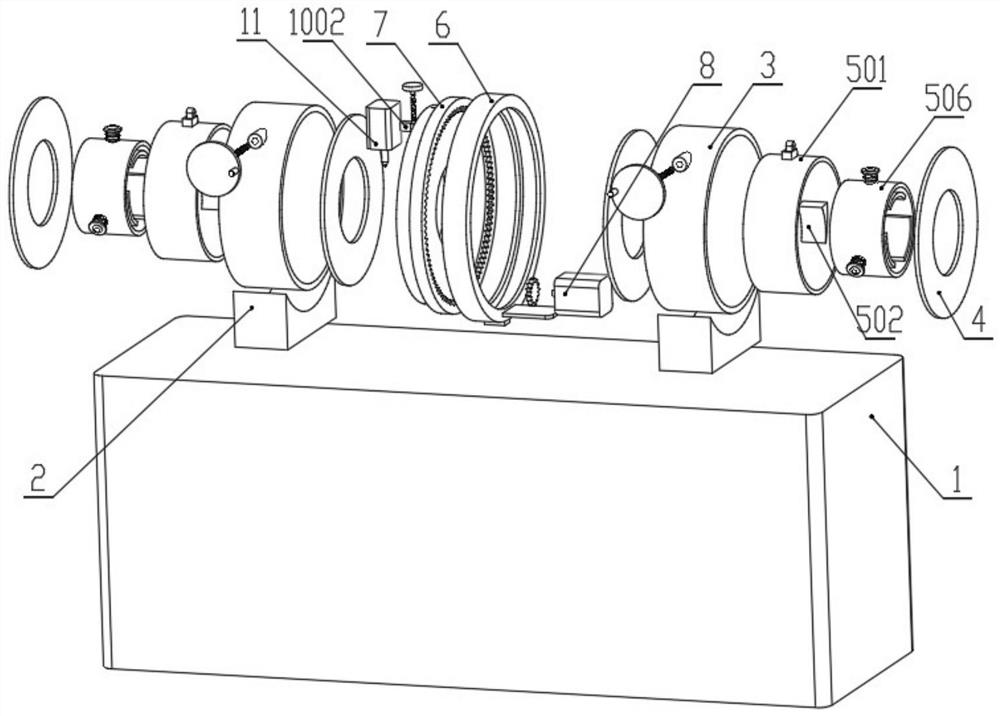

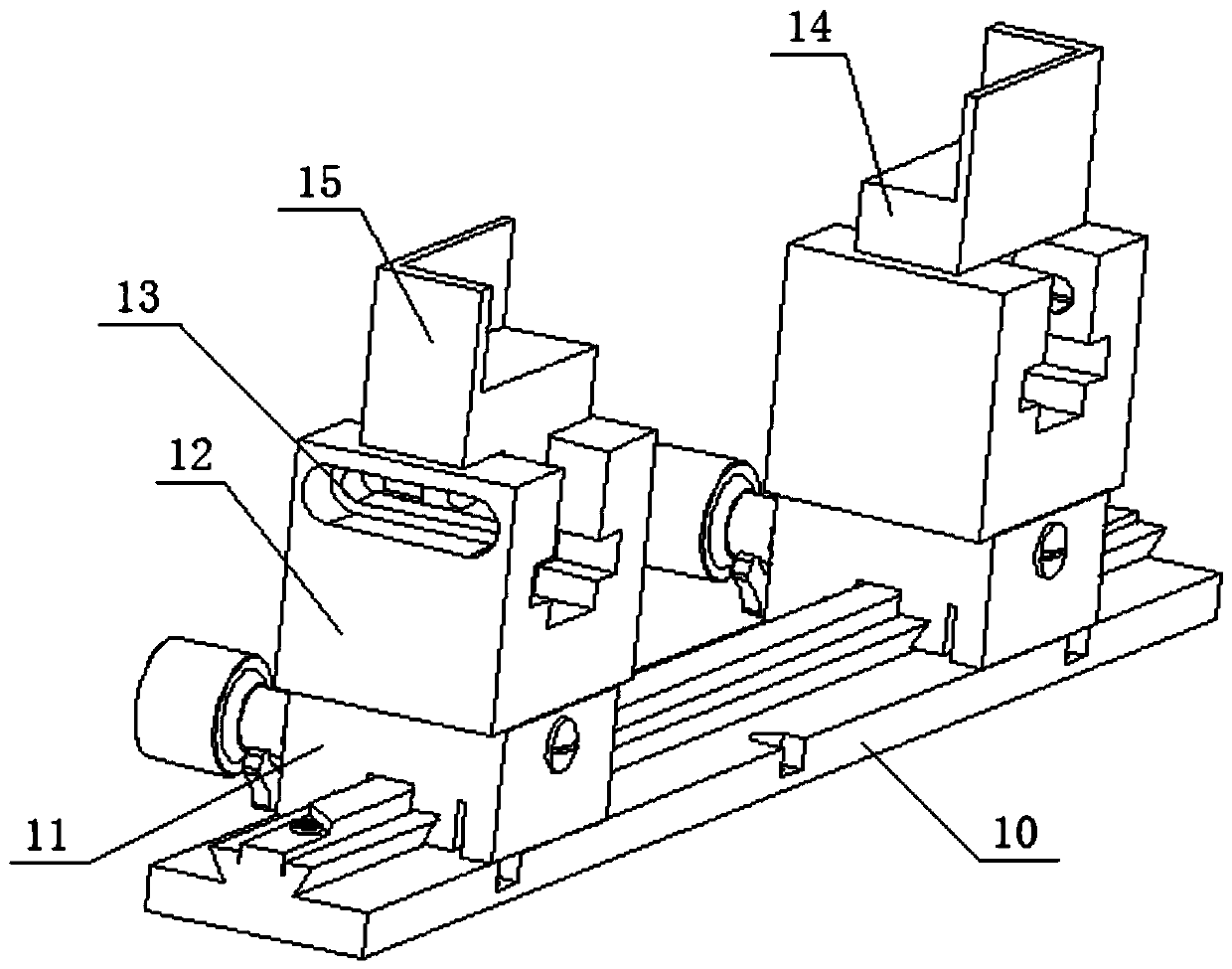

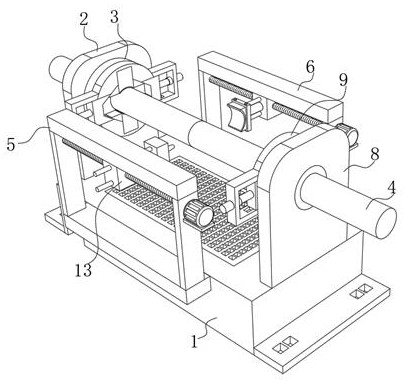

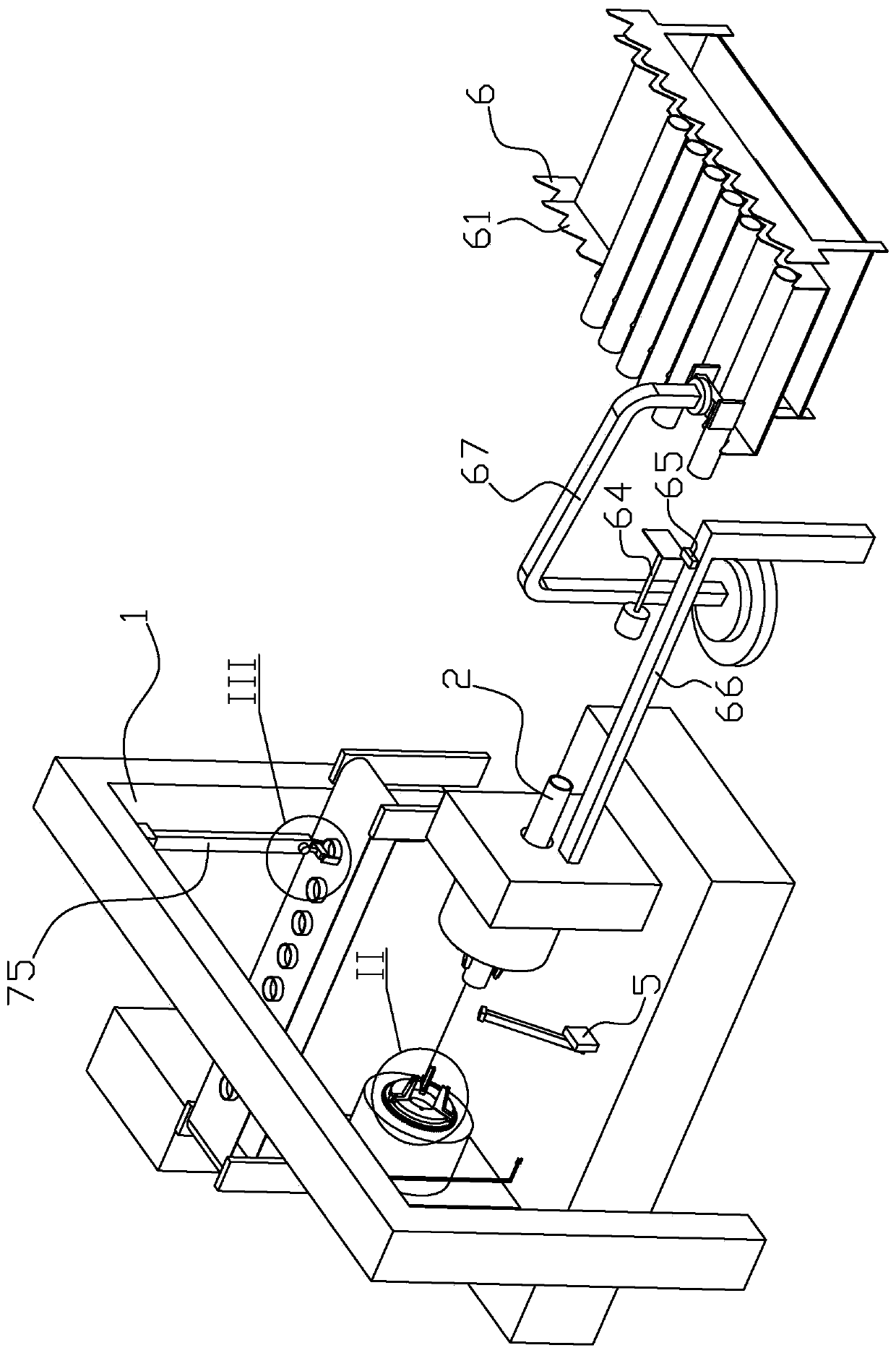

Glass pipe and metal pipe welding machine

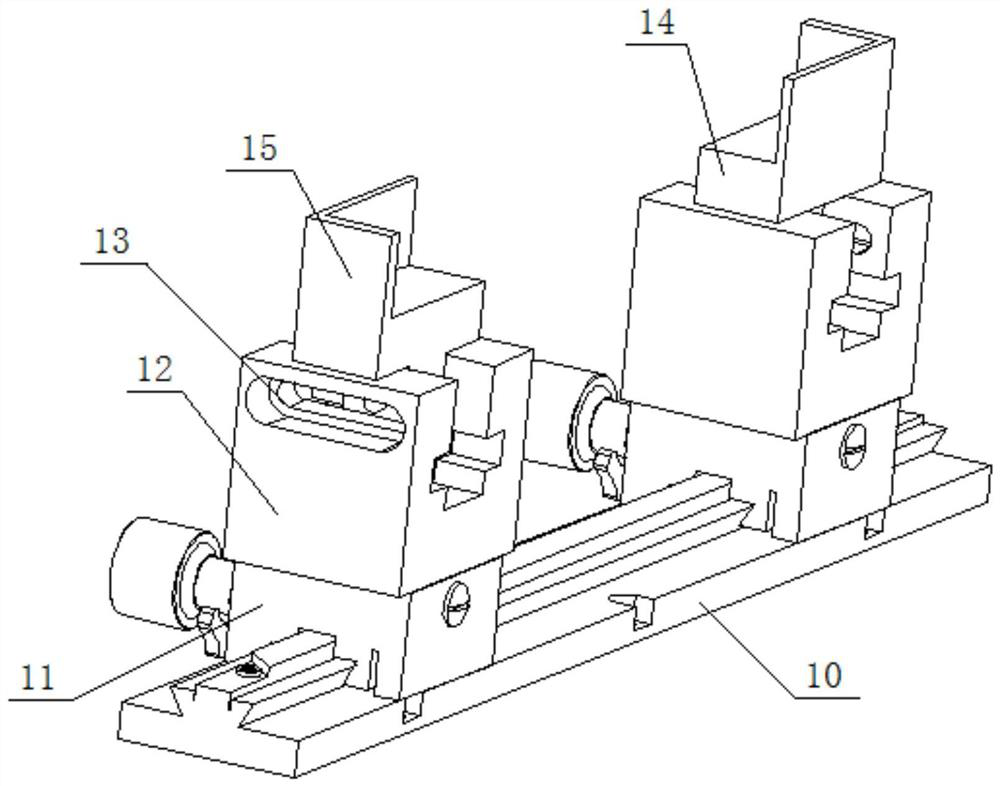

ActiveCN108031999ARealize welding operationHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringControl circuit

A glass pipe and metal pipe welding machine comprises a rack, a first clamping part, a second clamping part and a welding part. The welding part is arranged on the part, below the end portion of a glass pipe clamped by the first clamping part, of the rack, the first clamping part and the second clamping part are oppositely arranged and can be synchronously and rotationally arranged on the rack relative to the rack, and the second clamping part can move relative to the first clamping part so that a metal pipe can be connected to the end portion of the fused metal pipe in an inserted manner. Oneside of the rack is provided with a glass pipe conveying device for conveying the glass pipe to the first clamping part and a metal pipe conveying device for conveying the metal pipe to the second clamping part. The upper portion of the rack is provided with an extrusion part for extruding the end portion of the glass pipe when the glass pipe heated through the welding part rotates, and the firstclamping part, the second clamping part, the welding part, the glass pipe conveying device, the metal pipe conveying device and the extrusion part are connected with a control circuit through a line.The glass pipe and metal pipe welding machine has the beneficial effects that welding between the end portion of the glass pipe and the end portion of the metal pipe is achieved, the welding efficiency is high, and the welding effect is good.

Owner:宁波海曙洪德产品设计有限公司

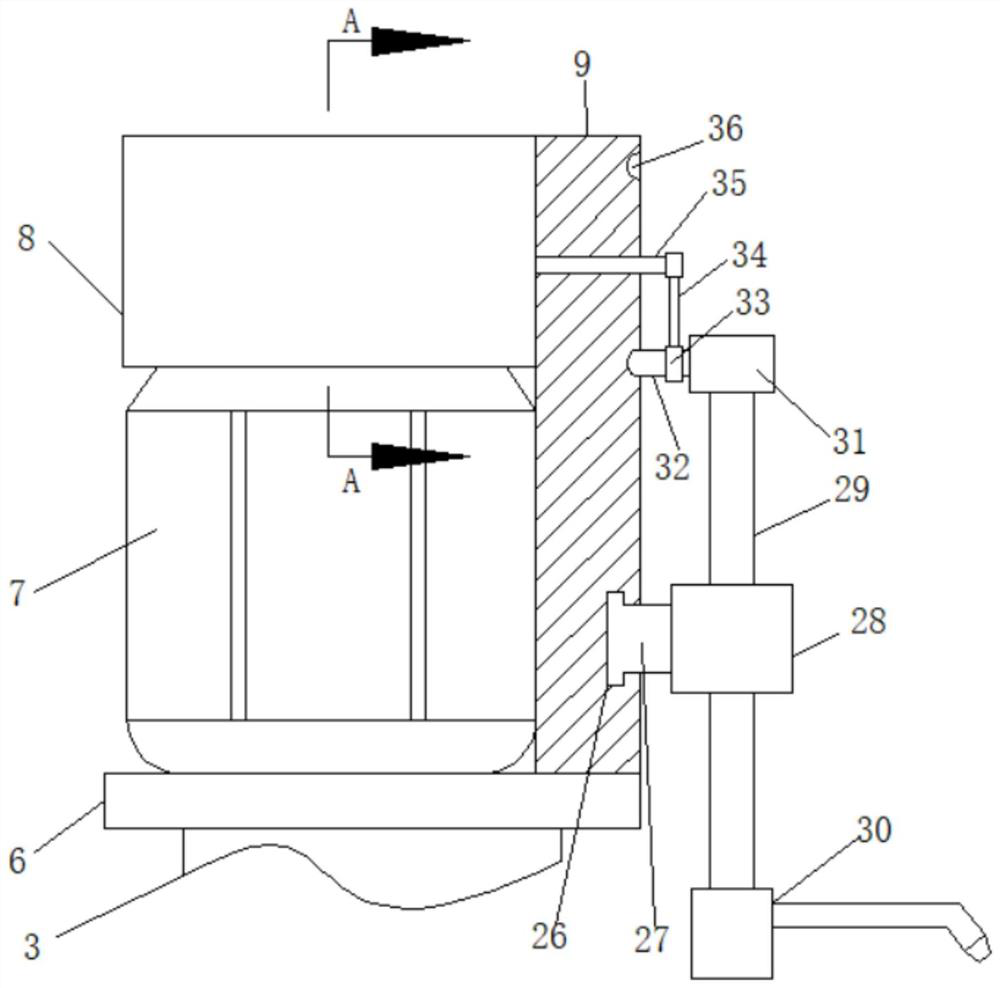

Automatic welding device and method for pipeline butt-joint machining

InactiveCN114029693AGuaranteed accuracy and stabilityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeManufacturing engineering

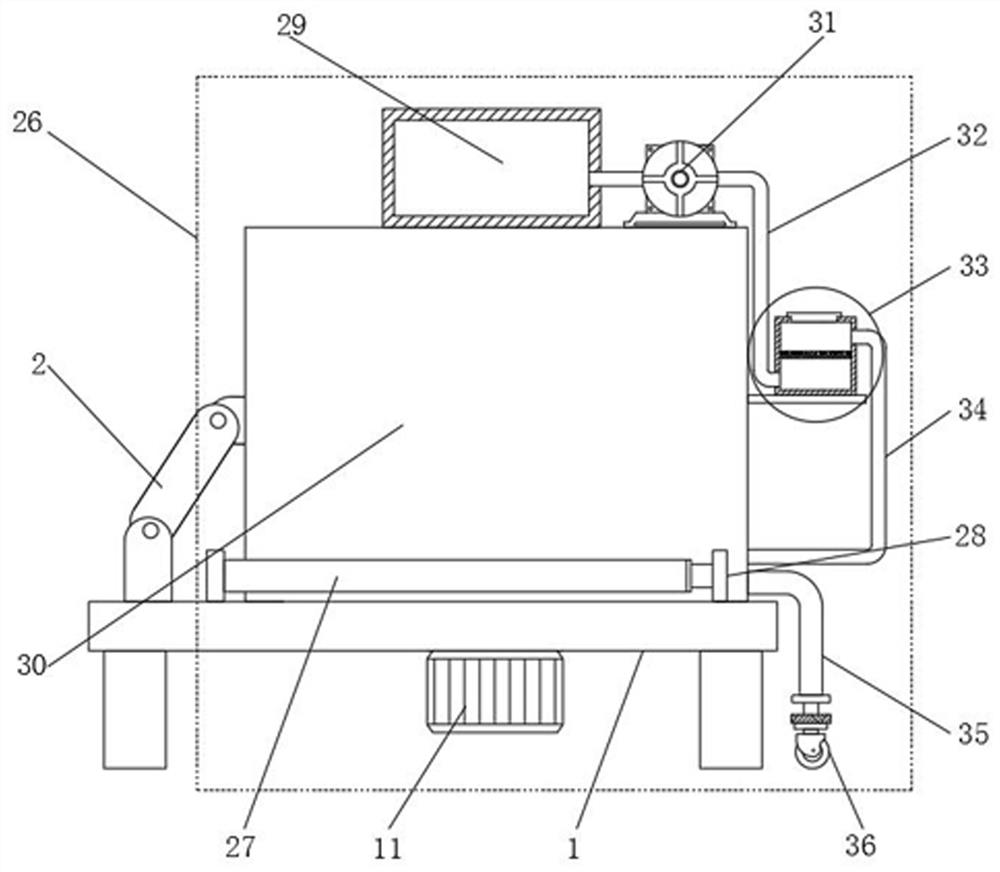

The invention discloses an automatic welding device and method for pipeline butt-joint machining. The automatic welding device comprises a workbench, fixing seats, clamping frame bodies, side cover plates and clamping adjusting mechanisms, wherein the fixing seats are connected to the left side and the right side of the upper end face of the workbench; the clamping frame body is fixedly connected to the position of the upper side of the fixing seat; the side cover plates are connected to the left side and the right side of the clamping frame body; and the clamping adjusting mechanism is arranged in the clamping frame body. According to the automatic welding device for pipeline butt-joint machining, steel pipes can be conveniently, rapidly and stably clamped and fixed, so that the butt-joint precision and stability of the steel pipes can be effectively guaranteed, the welding quality of the steel pipes is improved, the steel pipes can be conveniently, automatically and uniformly welded, the welding machining efficiency of the steel pipes is improved, the steel pipes with different diameters can be conveniently welded through adjustment of a distance adjusting mechanism, and the applicability of the welding device is improved.

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

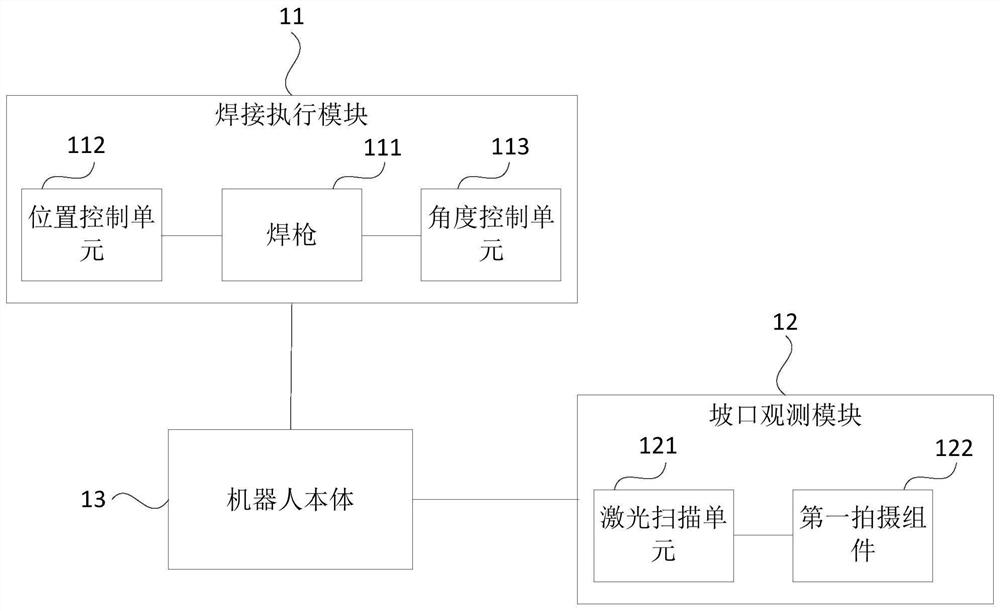

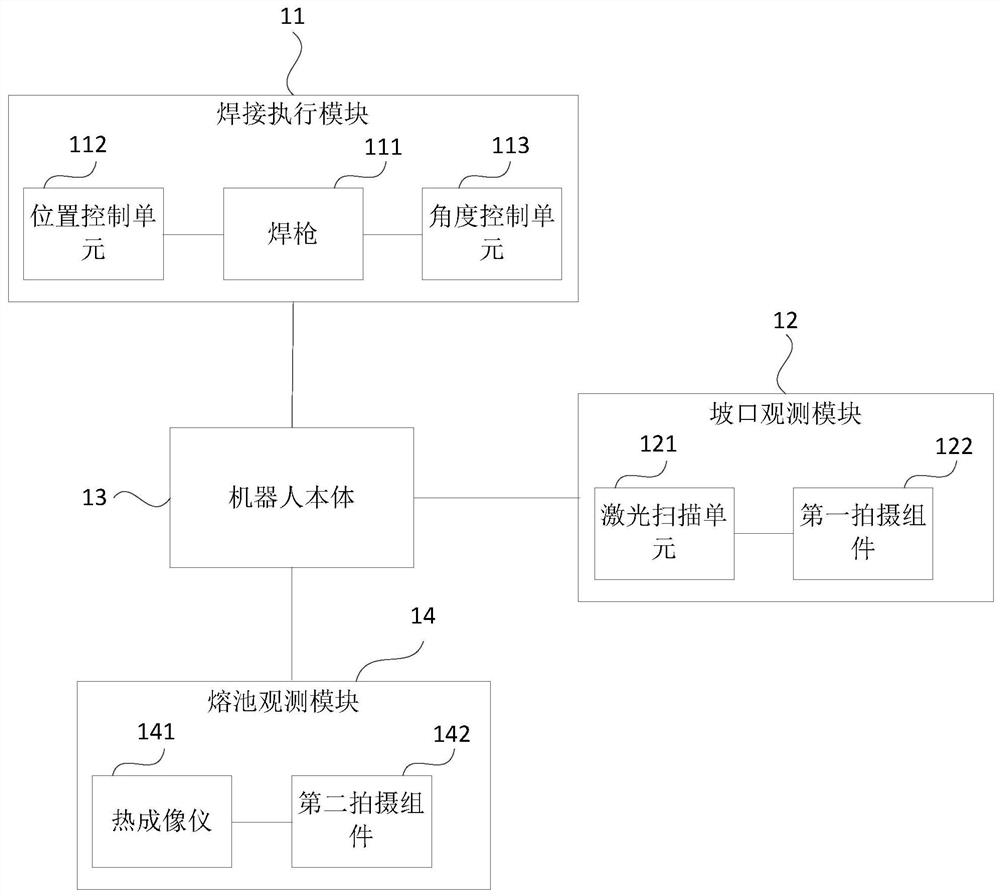

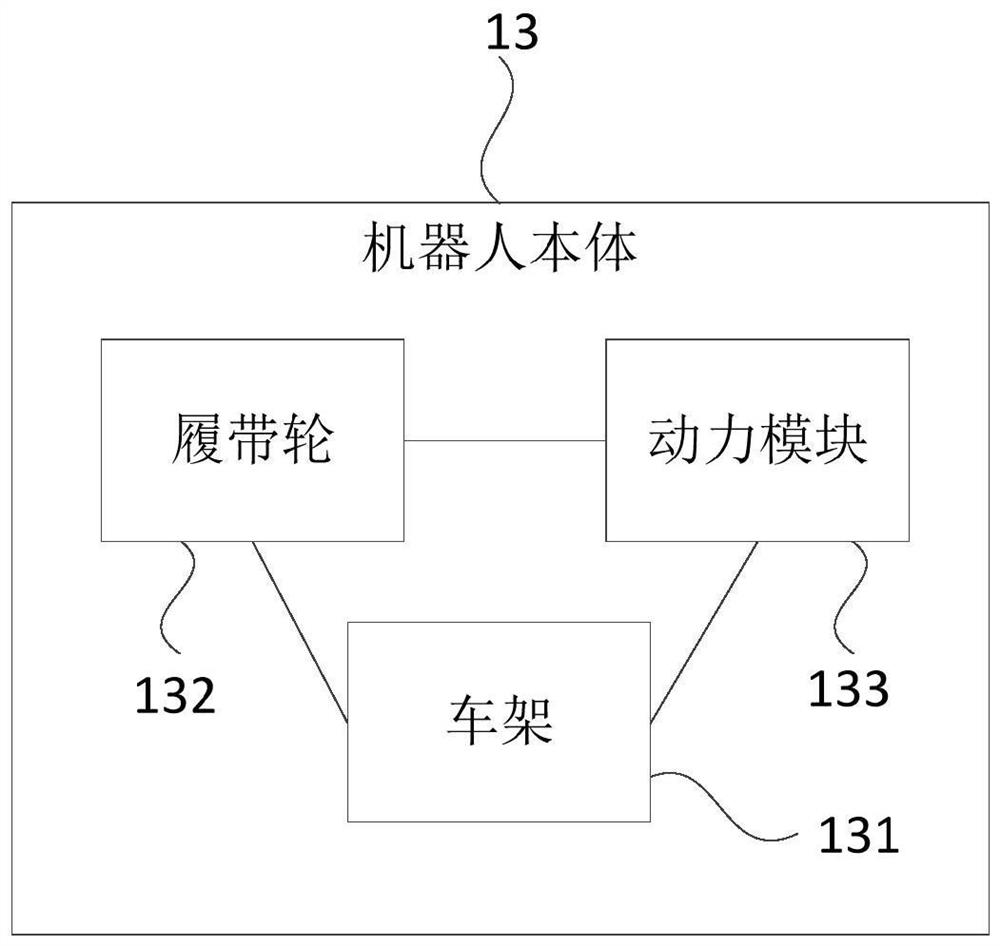

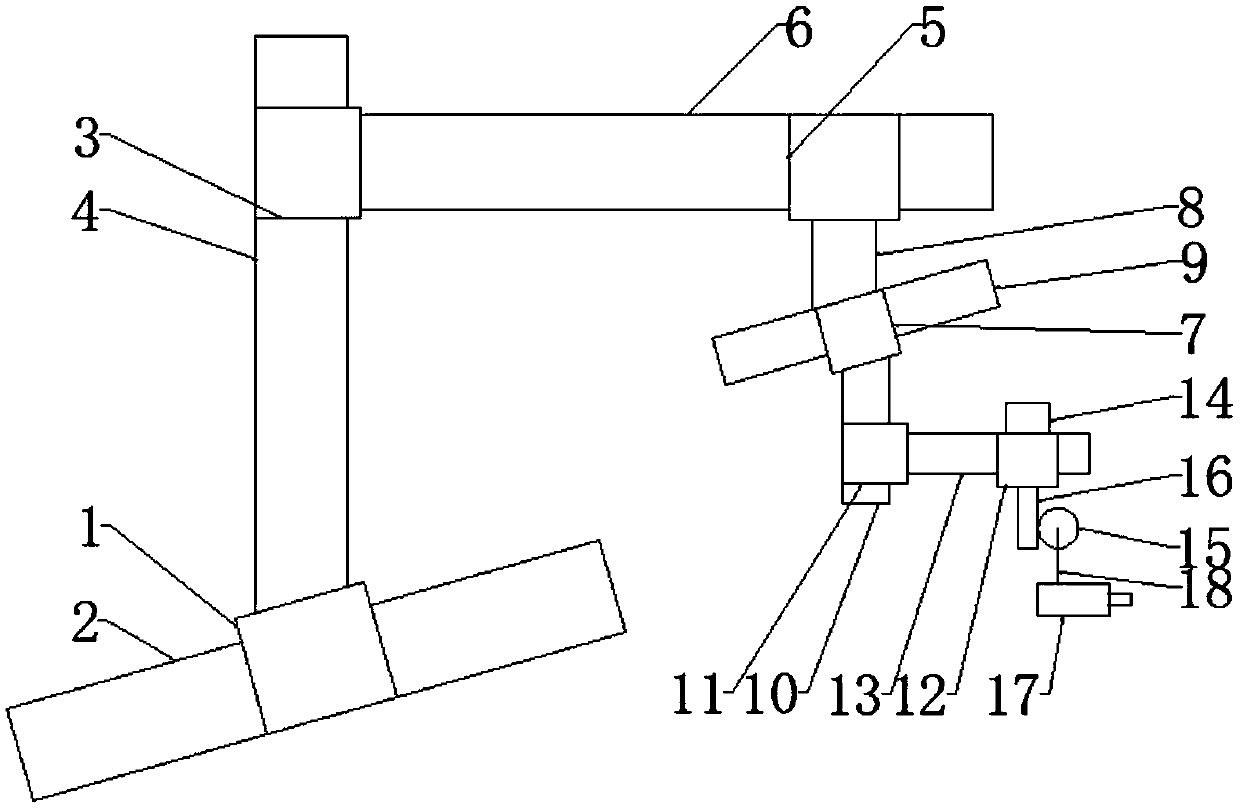

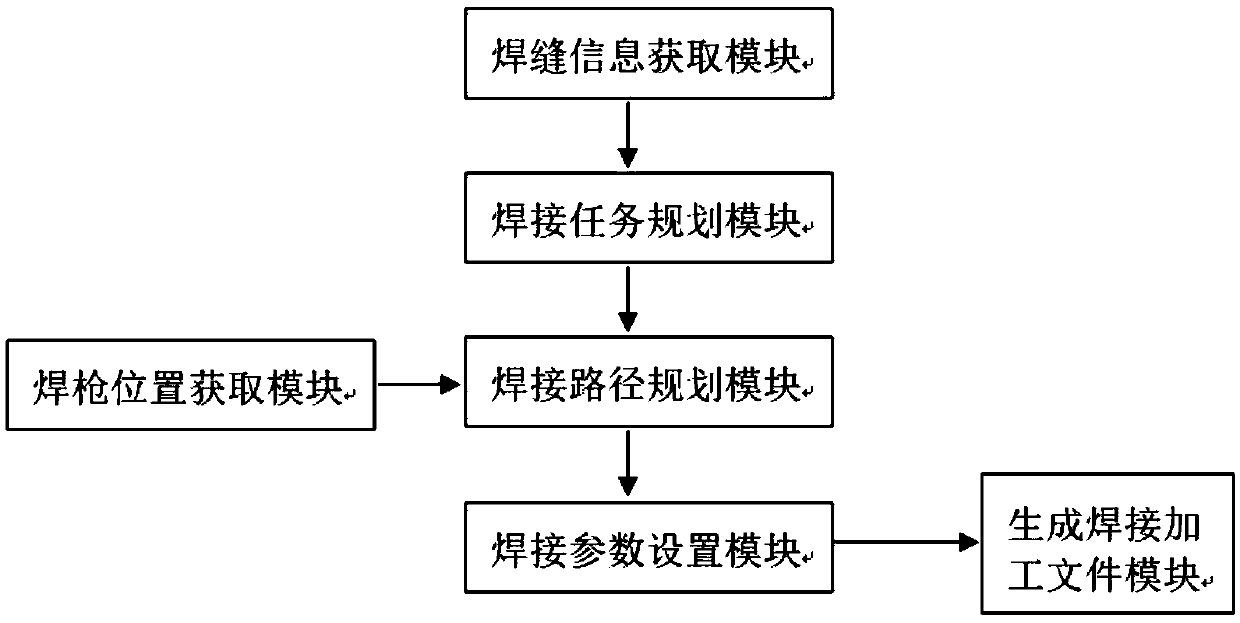

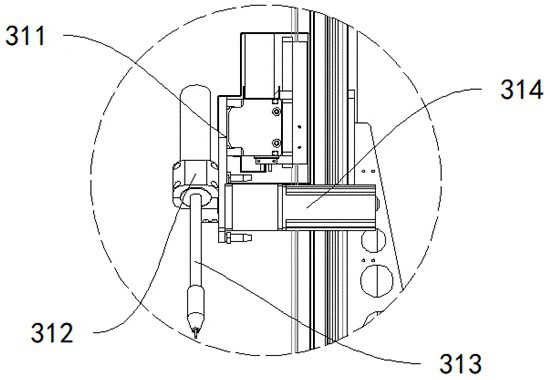

Welding robot and welding method

InactiveCN111761266ARealize welding operationImprove welding efficiencyProgramme-controlled manipulatorWelding/cutting auxillary devicesLaser scanningEngineering

The embodiment of the invention discloses a welding robot. The welding robot comprises a welding execution module, a groove observation module and a robot body, wherein the welding execution module and the groove observation module are located at the front end of a robot body; the welding execution module comprises a welding gun, a position control unit and an angle control unit; and a laser scanning unit in the groove observation module is used for acquiring the groove data information through laser scanning, and a first shooting assembly is used for acquiring an original image of a groove before welding and an welding seam image of the welded groove. According to the welding robot, the mechanical welding operation is realized, the groove image information before and after welding is obtained through the groove observation module, and the welding efficiency and the welding precision are improved; and meanwhile, the robot body has the capability of moving on the surface of an object tobe welded, and has excellent welding capability for a large structural device which is difficult to move, and the application range of the welding robot is enlarged.

Owner:BEIJING BO TSING TECH CO LTD

Auxiliary tool supporting device for welding of low-temperature container

InactiveCN112025193ARealize welding operationAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderGear wheel

The invention discloses an auxiliary tool supporting device for low-temperature container welding, and relates to the technical field of low-temperature container welding auxiliary tools. The auxiliary tool supporting device comprises a supporting platform, sliding blocks, adjusting rod assemblies, supporting adjusting frames and lug-ring-shaped rails; the sliding blocks are in sliding fit with the supporting platform; the adjusting rod assemblies are fixedly installed on the peripheral side faces of the adjusting rod assemblies; the supporting adjusting frames are in meshing transmission fitwith the lug-ring-shaped rails; the sliding rails are in sliding fit with sliding groove channels; rotating motors are symmetrically and fixedly mounted at the tops of the sliding blocks; the output end of each rotating motor is fixedly connected with a rotating gear; and the adjusting rod assembly comprises hydraulic cylinders. According to the auxiliary tool supporting device, by sliding of thetwo sliding blocks and adjustment between the adjusting rod assemblies, cylinders of different lengths and sizes can be welded at different heights; and seamless cutting-fit sleeves abut against the inner walls of the cylinders through the supporting adjusting frames and are fixed through annular lug chains, so that the situation that the cylinders are heated or deformed due to external force in the welding process is prevented.

Owner:JIUJIANG HAITIAN EQUIP MFG CO LTD

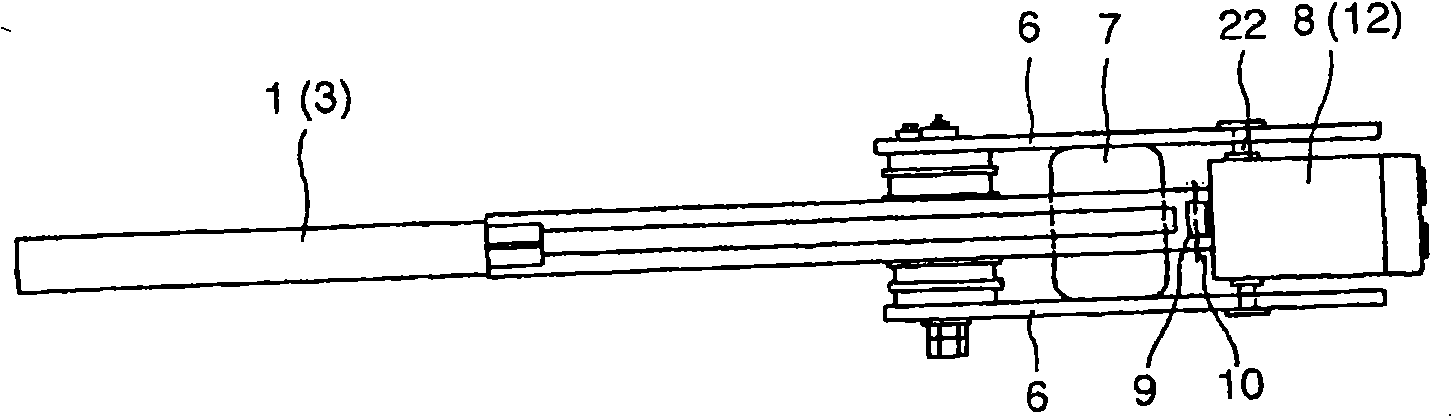

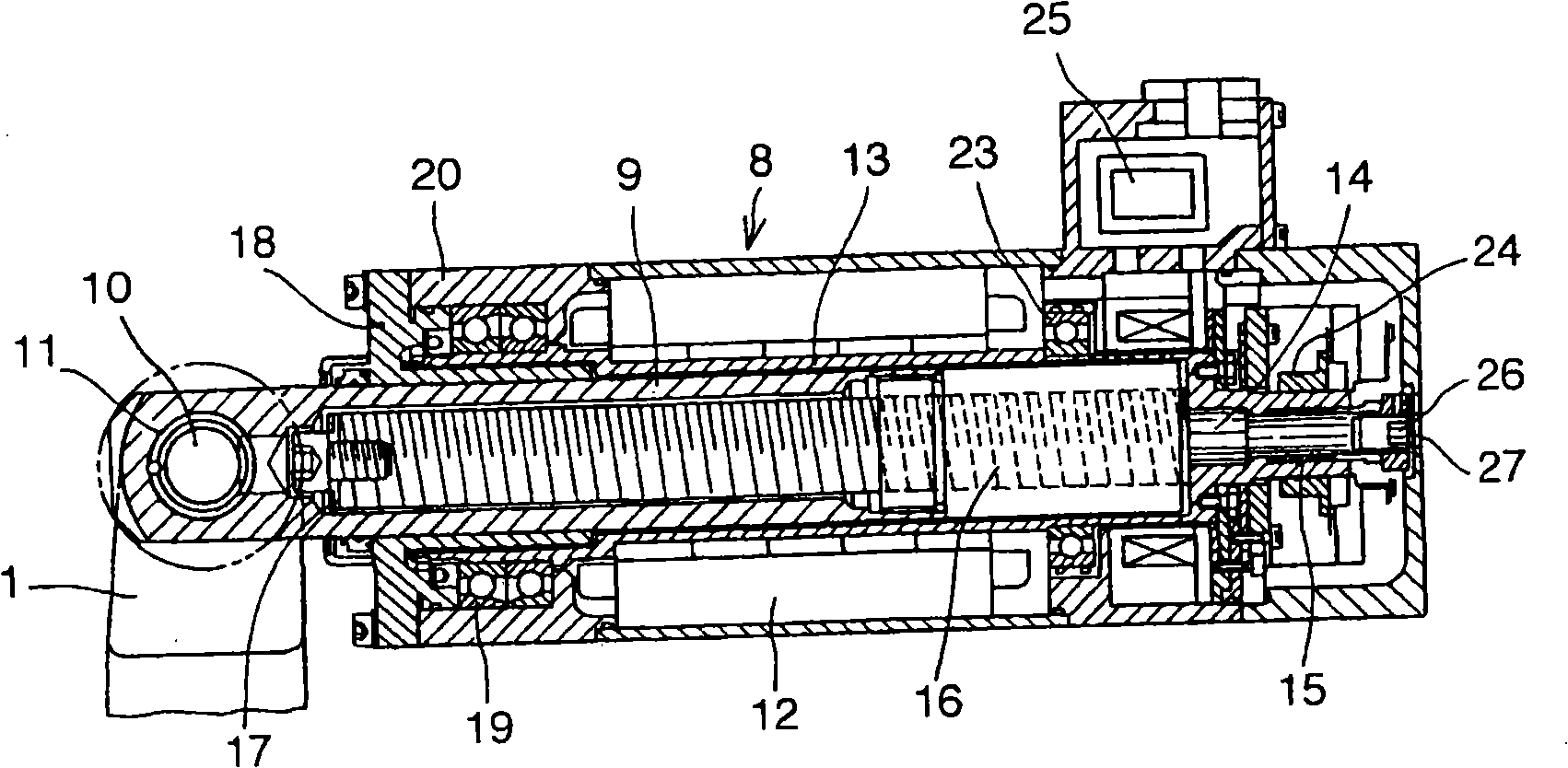

Electric drive unit for X type gun

InactiveCN101298113AKeep stableAchieve maintenanceWelding electric supplyElectricityElectric machinery

Owner:OHARA

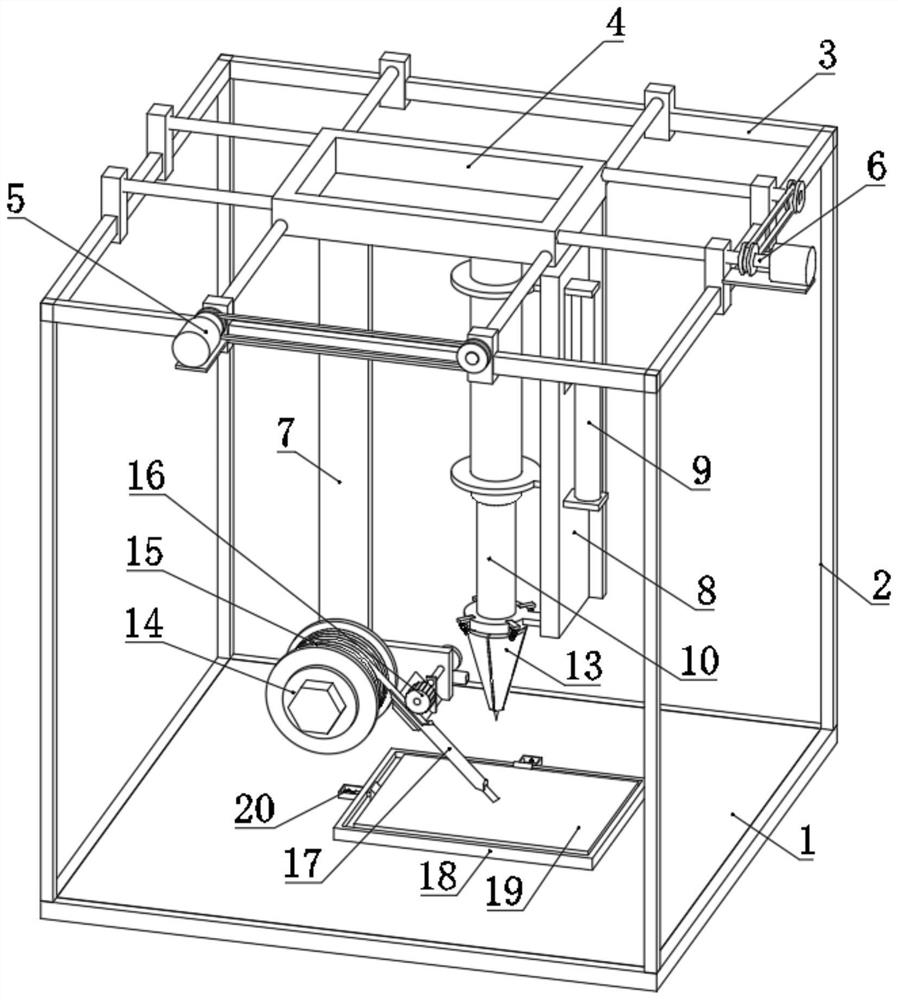

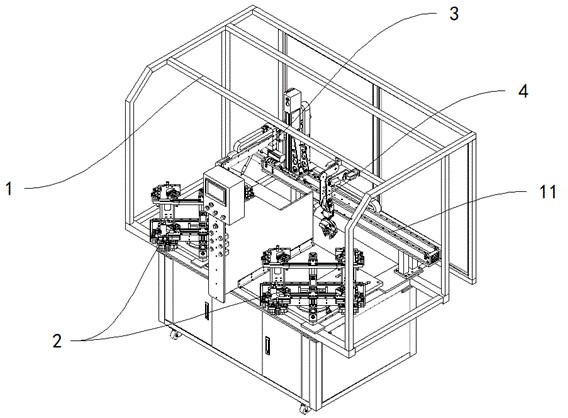

Automatic tin soldering equipment for electronic product

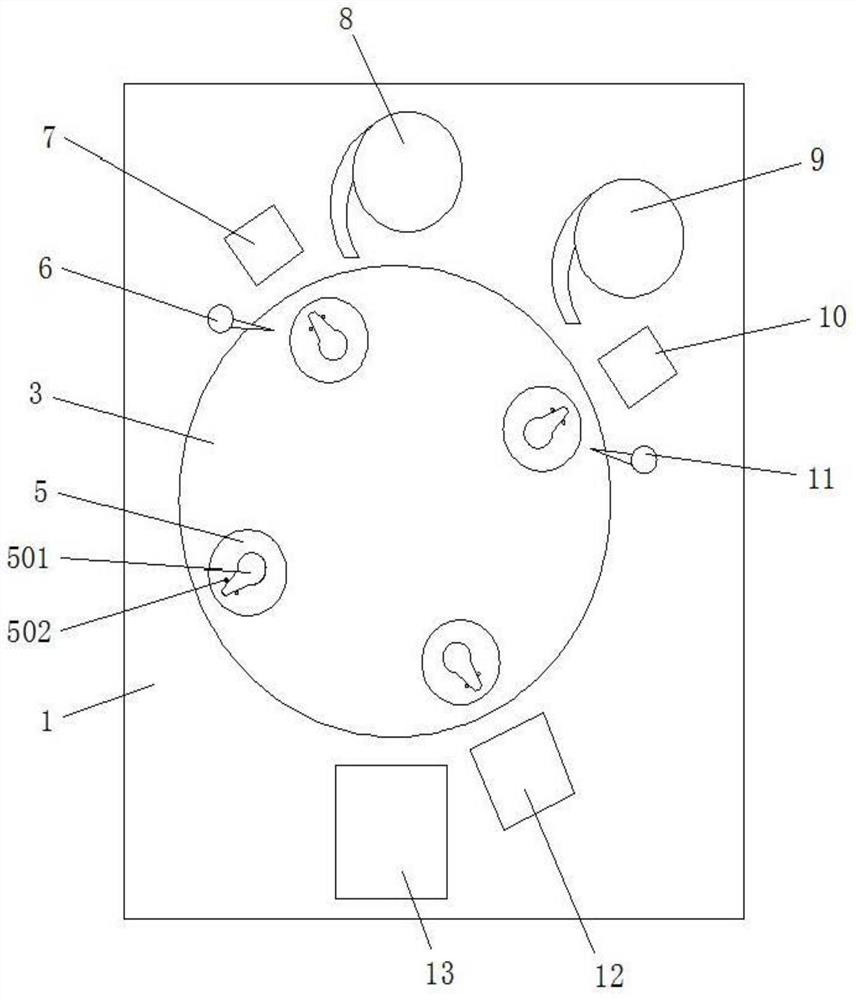

PendingCN113770473AHigh degree of automationReduce labor costsSoldering ironWelding/soldering/cutting articlesSlag (welding)Engineering

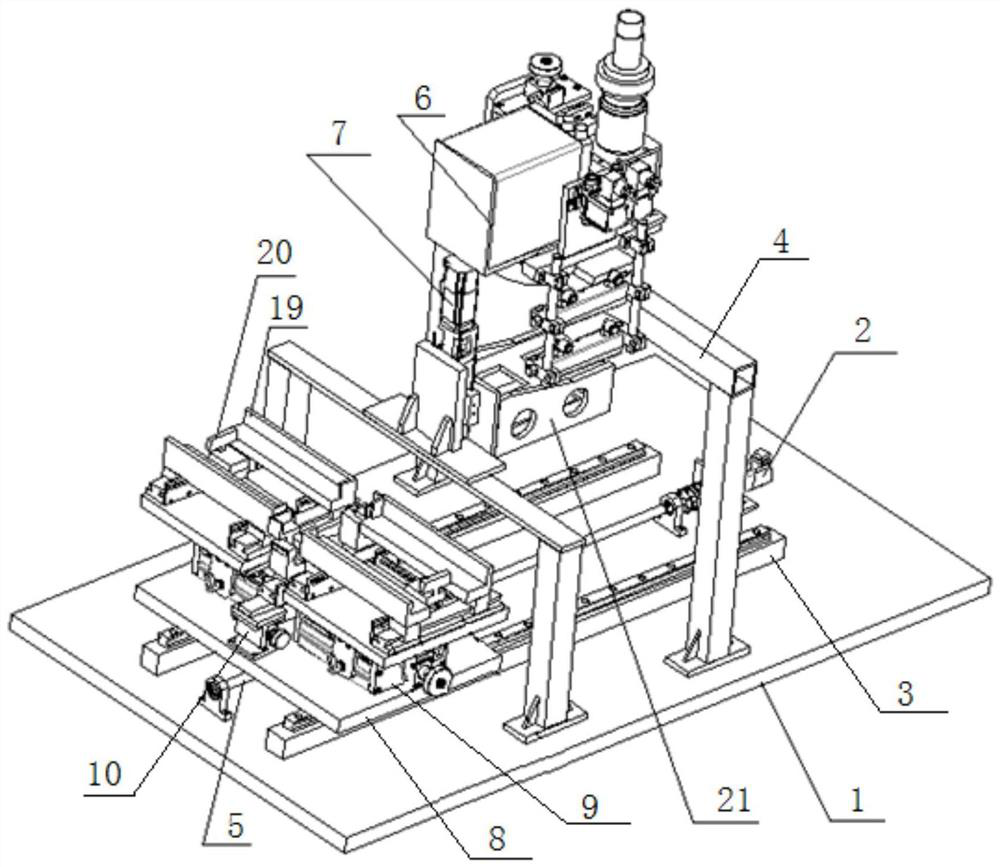

The invention discloses automatic tin soldering equipment for an electronic product, and belongs to the field of tin soldering of electronic products. The automatic tin soldering equipment comprises a bottom plate, wherein a frame is installed on the upper side of the bottom plate, a top frame is installed on the upper side of the frame, a first adjusting mechanism and a second adjusting mechanism are movably installed on the upper side of the top frame, a moving frame is arranged in the middle of the top frame, the moving frame is installed with the first adjusting mechanism and the second adjusting mechanism, and the moving frame is driven by the first adjusting mechanism and the second adjusting mechanism. According to the automatic tin soldering equipment, automatic welding of the electronic product can be realized, the operation process is simple, convenient and high in efficiency, welding slag adsorbed on a welding cone of an electric soldering iron can be scraped, normal use of the electric soldering iron is guaranteed, the electronic product can be effectively positioned, random movement during welding is avoided, generated smoke can be adsorbed during welding, and the health of personnel is prevented from being influenced.

Owner:XIAN TECHNOLOGICAL UNIV

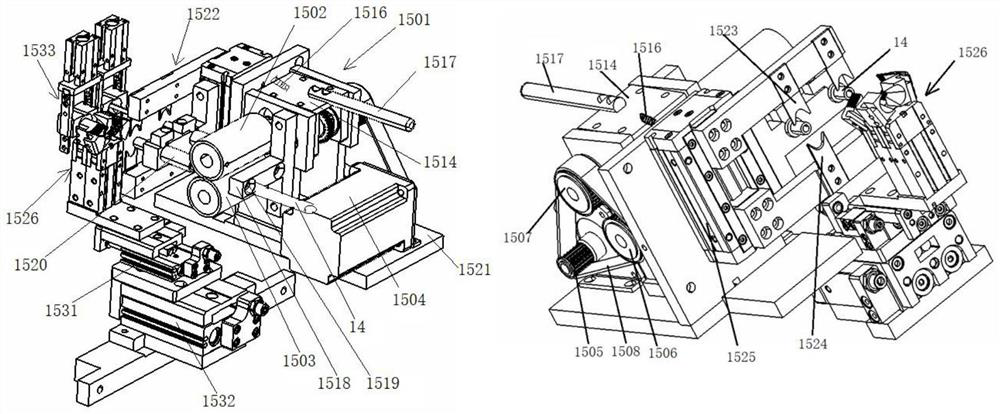

Portable lithium battery cover plate welding device

ActiveCN110434527APositioning mechanism, which can position and fix the two batteriesPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryEngineering

The invention discloses a portable lithium battery cover plate welding device. The portable lithium battery cover plate welding device comprises a bottom plate, horizontal movement guide rails, a support, a battery locating tool arranged on the horizontal movement guide rails in a sliding manner, a laser device welding assembly fixed to the support and a dust removal module, wherein the horizontalmovement guide rails and the support are fixed to the bottom plate. The battery locating tool comprises a transverse movement plate arranged on the horizontal movement guide rails in a sliding manner, two longitudinal movement guide rials fixed to the upper end face of the transverse movement plate and a cover plate locating guide rail. The cover plate locating guide rail is parallel to the horizontal movement guide rails. The two longitudinal movement guide rials are perpendicular to the horizontal movement guide rails. The cover plate locating guide rail is located between the two longitudinal movement guide rials. Corresponding cell locating mechanisms are in sliding connection to the two longitudinal movement guide rials. The portable lithium battery cover plate welding device is suitable for welding requirements of cover plate pole columns and soft connecting pieces of lithium batteries of multiple types, dust removal welding is adopted, and the percent of pass of welding is guaranteed.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

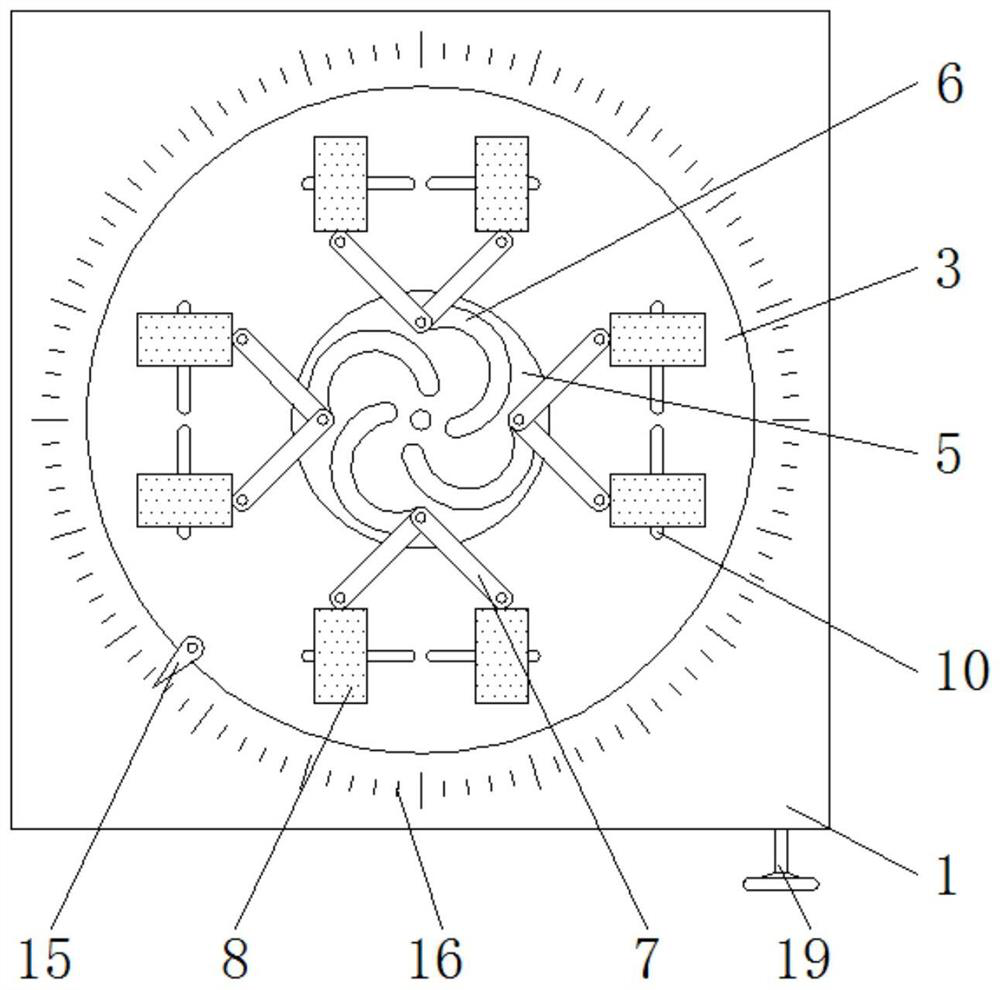

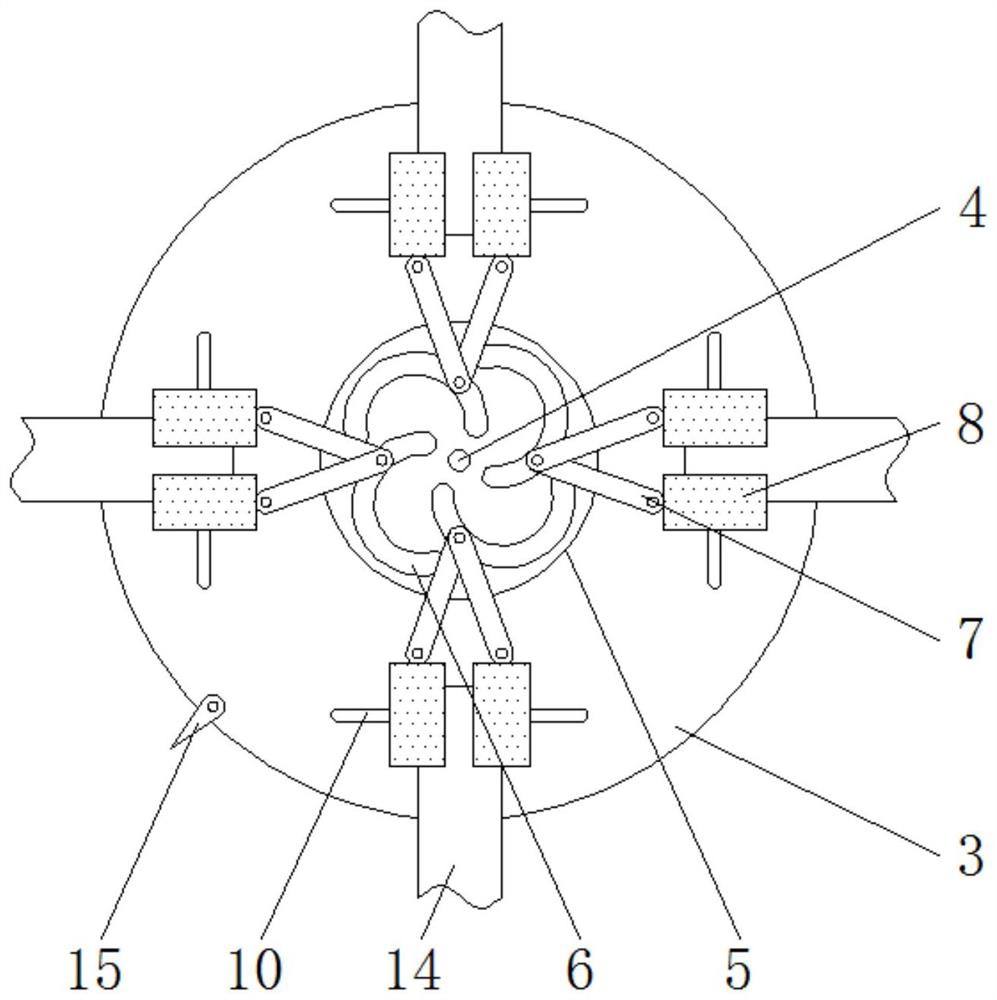

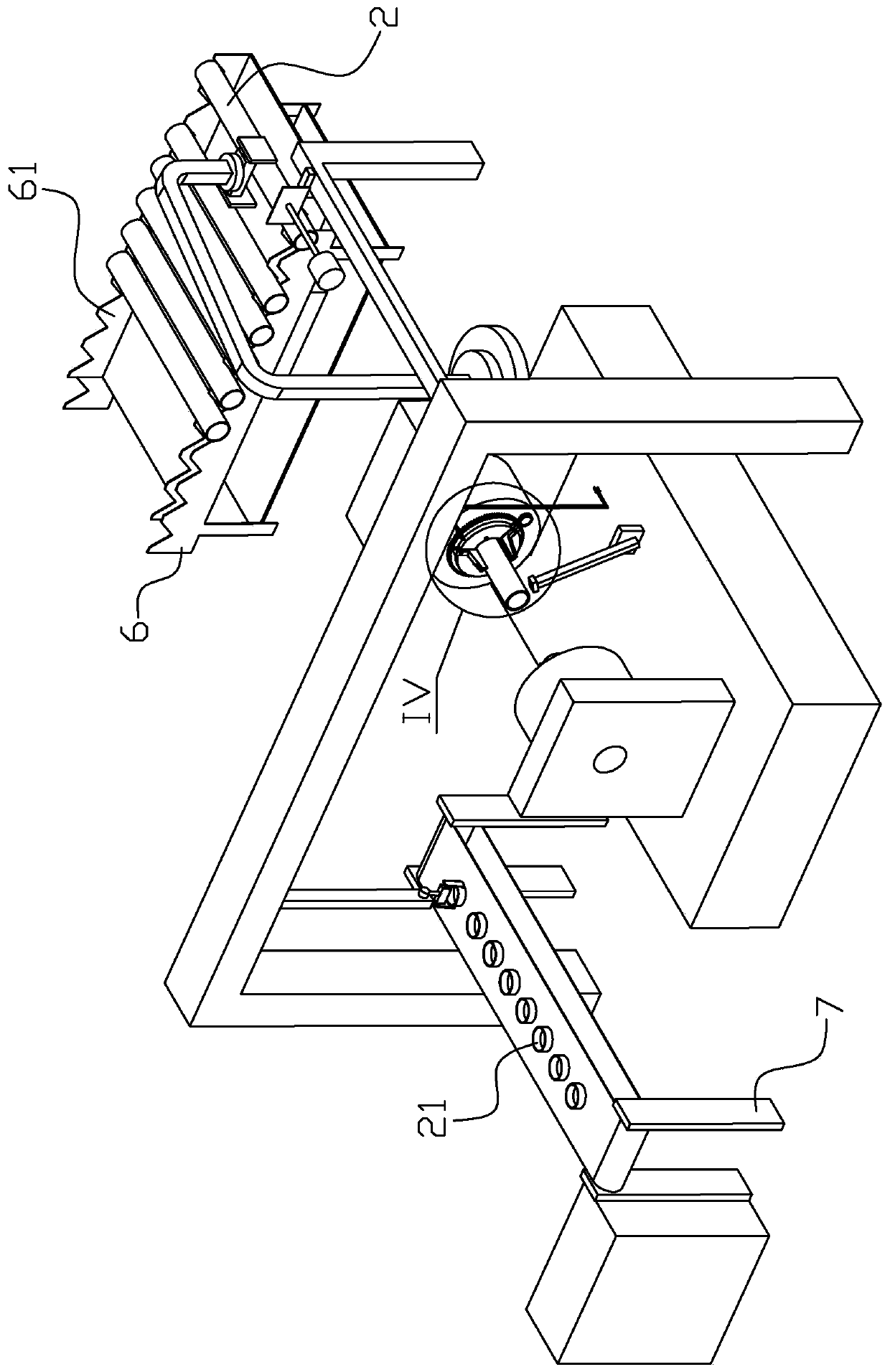

Tubular workpiece multi-direction synchronous positioning mechanism for robot welding

PendingCN112658545AAutomatic clampingAchieve synchronous clampingWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingElectric machinery

The invention discloses a tubular workpiece multi-direction synchronous positioning mechanism for robot welding. The mechanism comprises a machining table, a motor, a pipe fitting and an adjusting rod, a movable table is embedded in the upper end surface of the machining table, the top of the motor is rotationally connected with a motor shaft, a connecting plate is fixed to the top of the motor shaft, a movable groove is formed in the upper end surface of the connecting plate, a clamping block is movably installed at the other end of the guide rod, an air bag is pasted to the inner side of the clamping block, a connecting cavity is formed in the clamping block, an air outlet is reserved in the side surface of the clamping block, the pipe fitting is clamped by the inner side of the clamping block, a marking needle is arranged on the edge of the movable table, and the outer side of the movable table is sleeved with a worm gear. According to the tubular workpiece multi-direction synchronous positioning mechanism for robot welding, clamping of the pipe fitting can be automatically achieved, the phenomenon of deviation in the welding process can be avoided after clamping, meanwhile, synchronous clamping of multiple pipe fittings can be achieved through the same positioning mechanism, and then the machining efficiency is improved.

Owner:江苏欧朗汽车科技股份有限公司

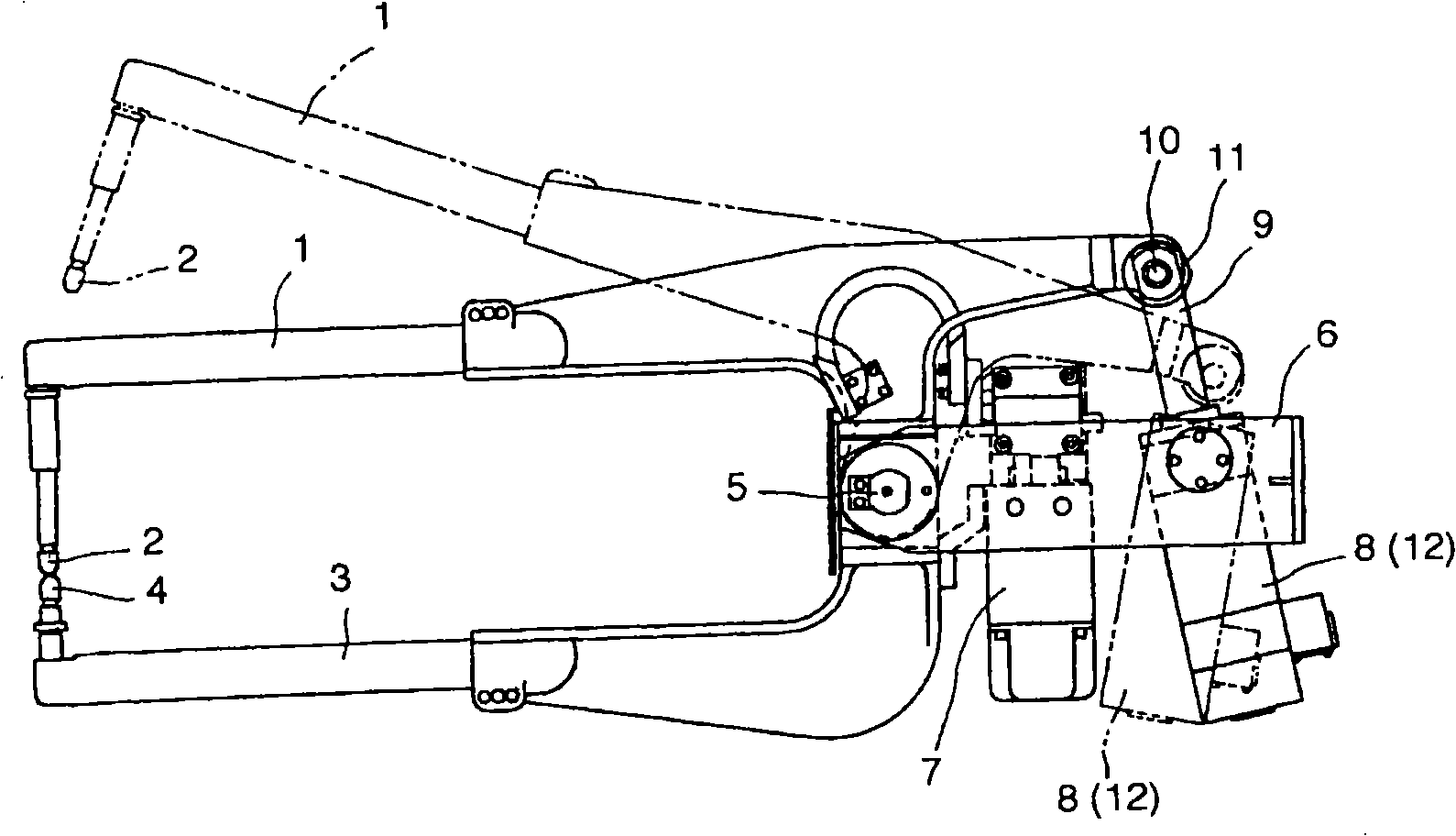

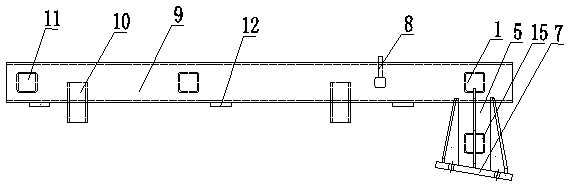

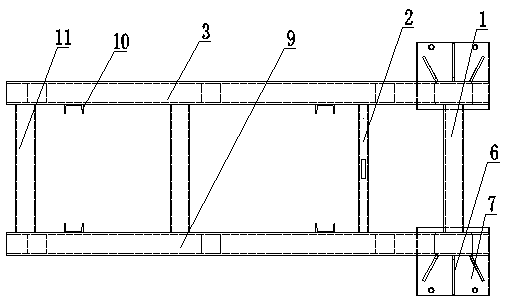

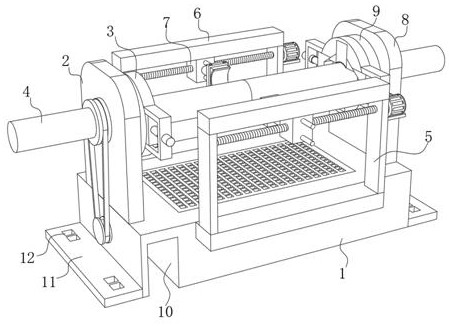

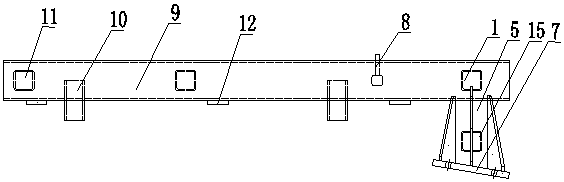

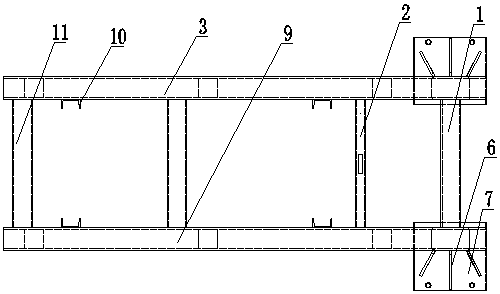

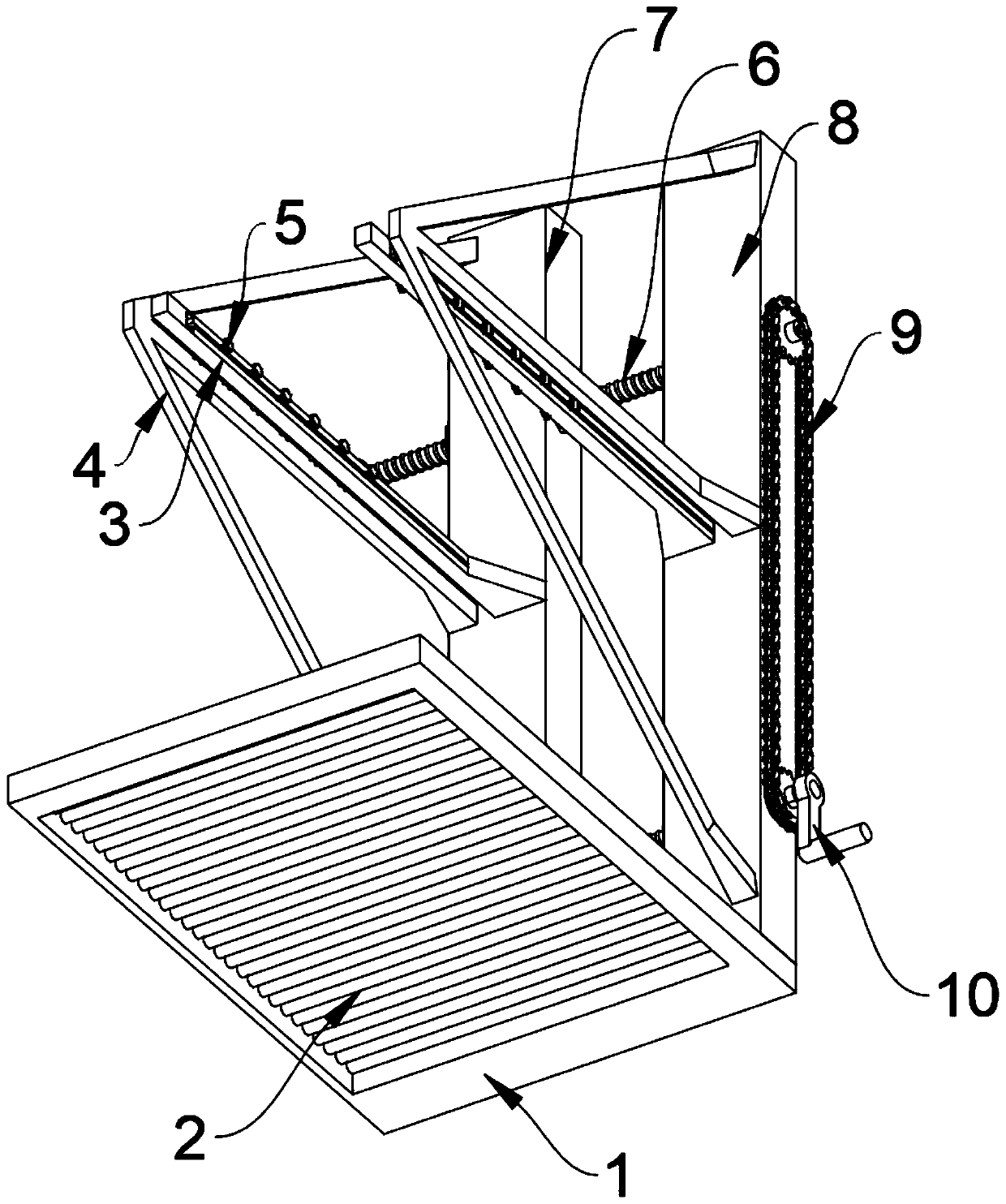

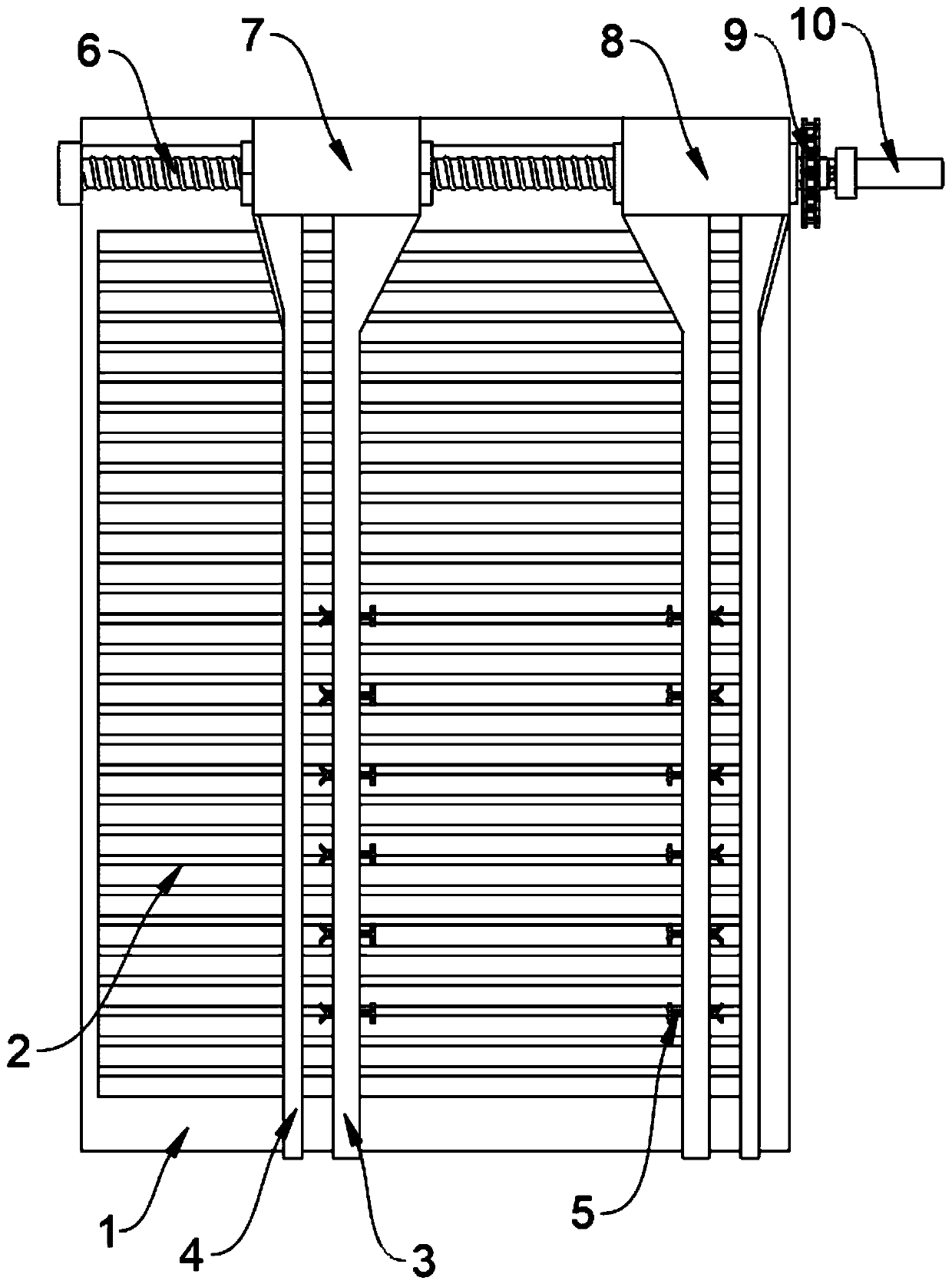

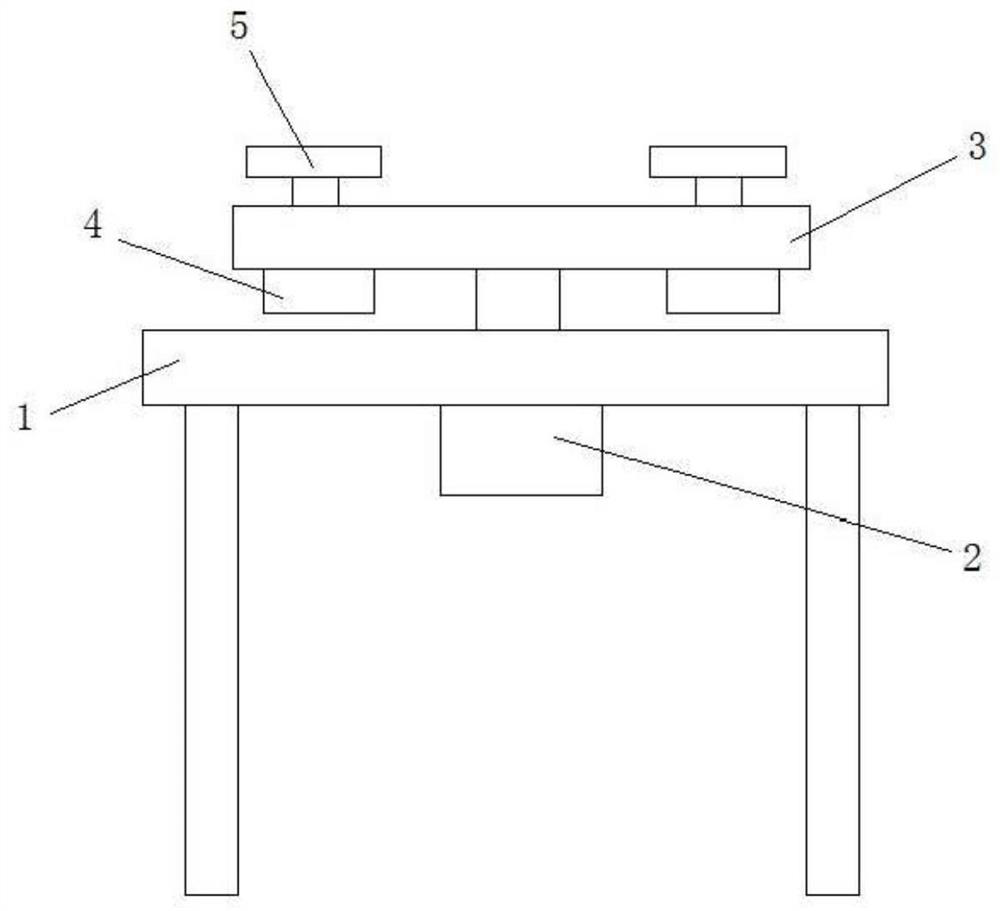

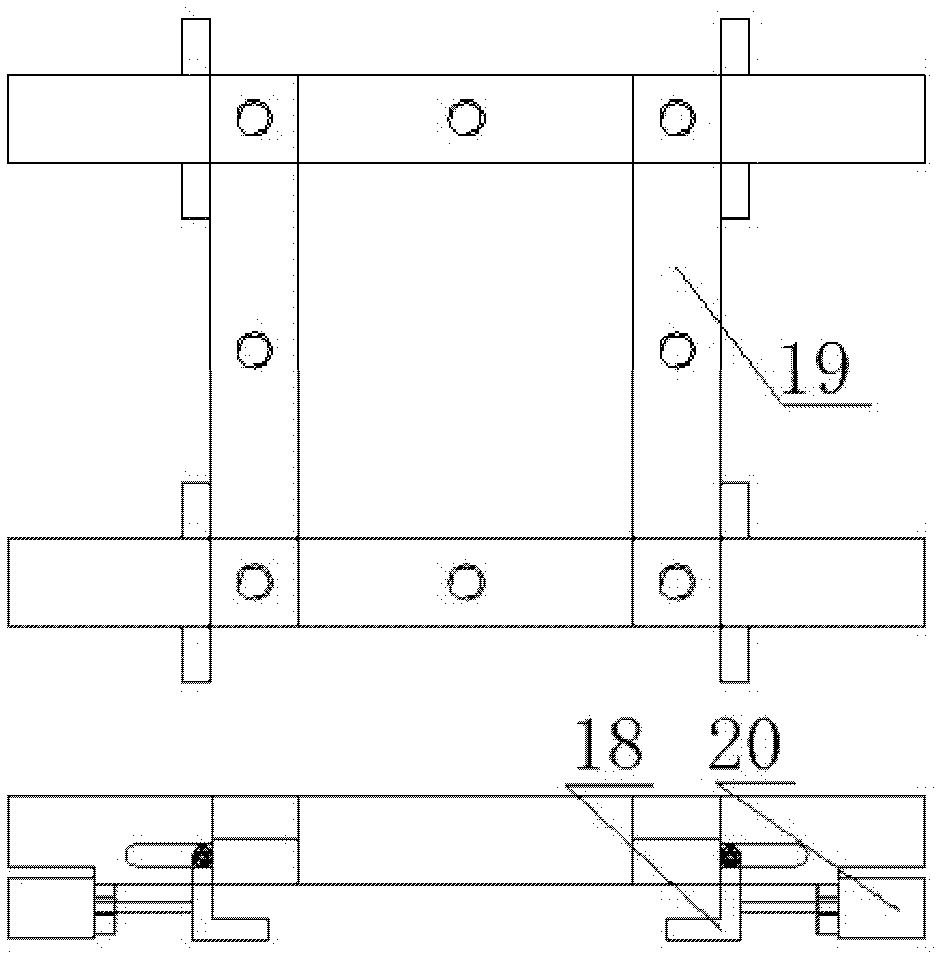

Hopper bracket welding and positioning tooling

ActiveCN103949826ARapid positioningAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

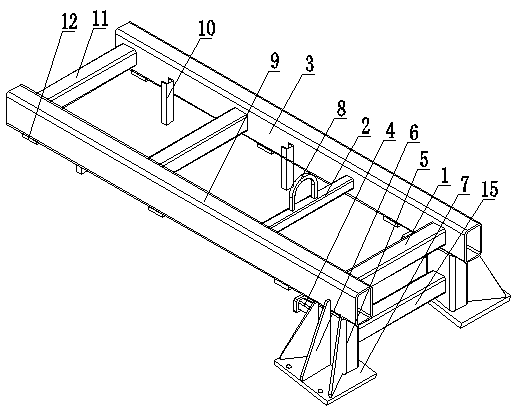

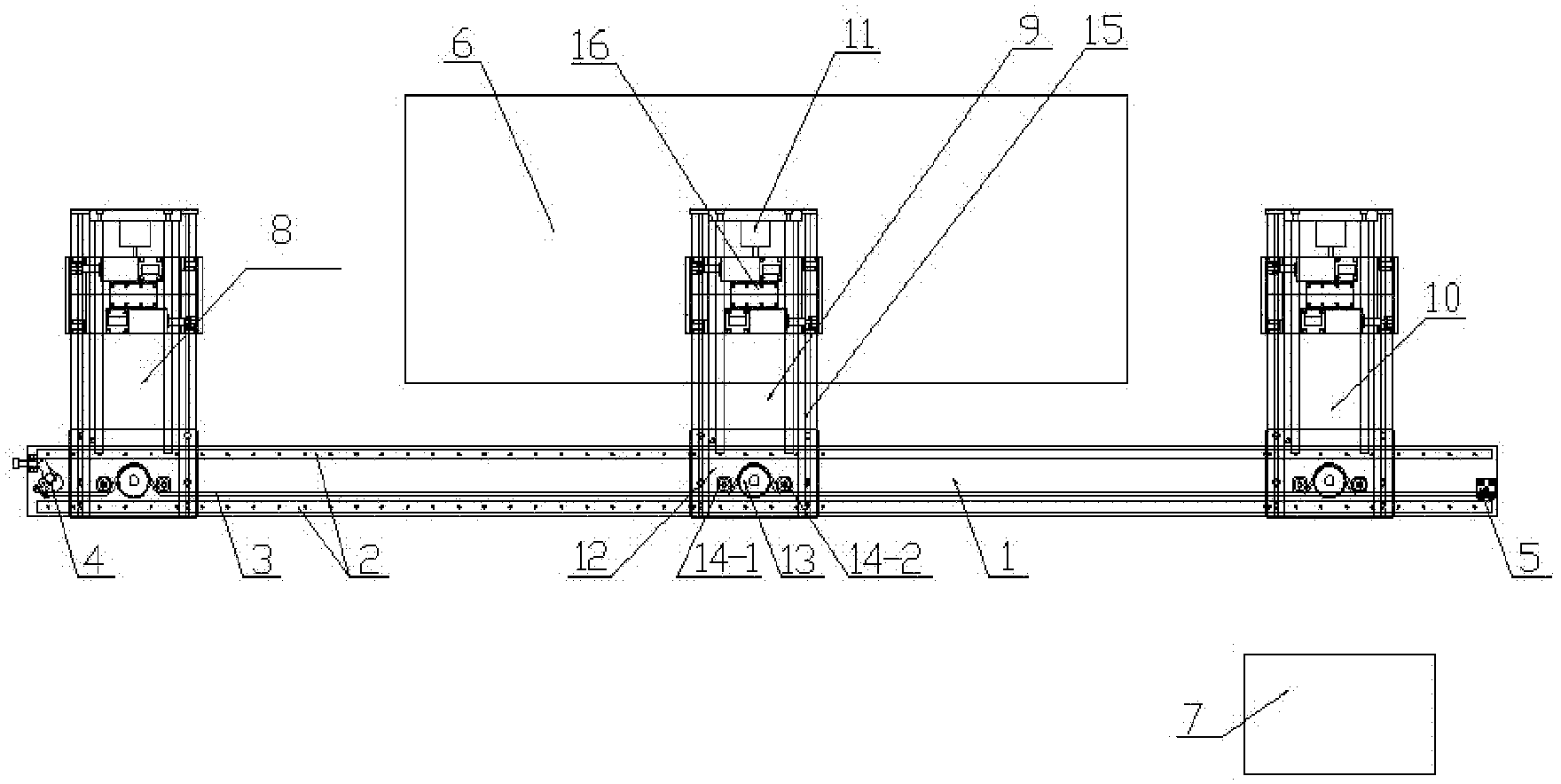

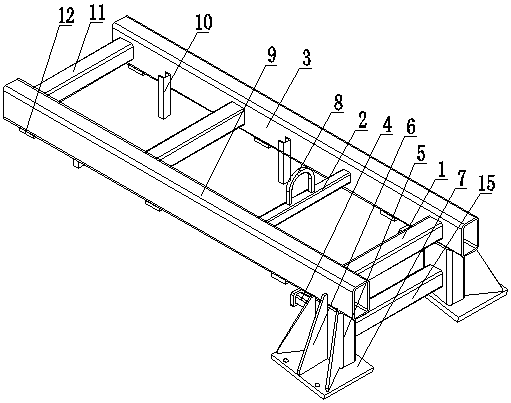

The invention relates to a hopper bracket welding and positioning tooling. The tooling is used for manufacturing a vehicle frame of a concrete pumper and is provided with a tooling first stringer (3), a tooling second stringer (9), at least two crossbeams (1 and 11) which are connected with the first stringer (3) and the second stringer (9), a first upright post, a second upright post (5), a first longitudinal positioning mechanism, a first bottom connecting plate, a second bottom connecting palate (7), a first transverse positioning mechanism (10) and a second transverse positioning mechanism, wherein the first upright post and the second upright post (5) are connected with the bottoms of the tooling stringers (3 and 9); the first longitudinal positioning mechanism is connected with one side of the first upright post; the first bottom connecting plate and the second bottom connecting plate (7) are connected with the bottoms of the upright posts; the first transverse positioning mechanism (10) and the second transverse positioning mechanism are fixed on the inner sides of the tooling first stringer (3) and the tooling second stringer (9); the inclination angles of the first bottom connecting plate and the second bottom connecting plate are matched with the welding angles of a hopper base, and the first bottom connecting plate and the second bottom connecting plate are respectively provided with at least two holes through which reamed hole bolts are mounted; the hopper bracket is connected with the bottoms of the first bottom connecting plate and the second bottom connecting plate in a positioning manner through the reamed hole bolts.

Owner:HUNAN HELI XINGBANG MACHINERY

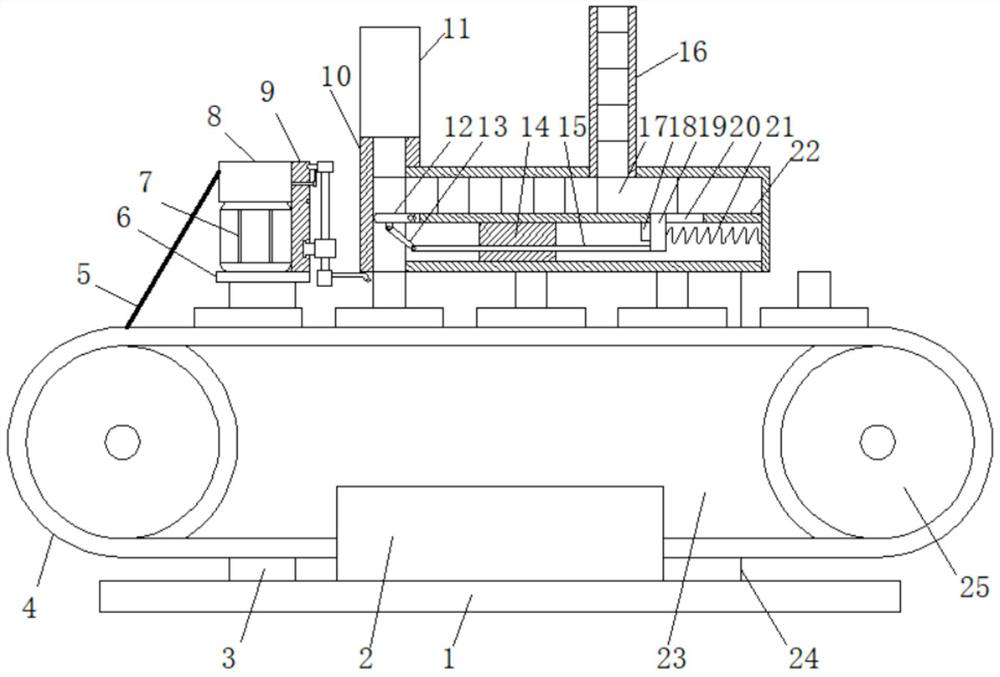

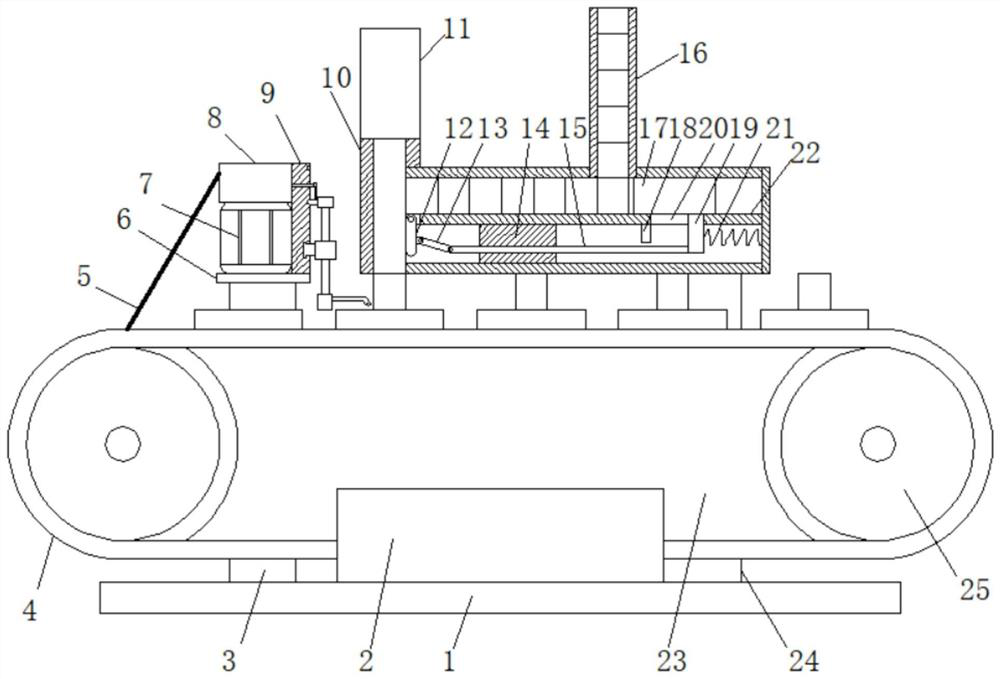

Tin soldering and drying all-in-one machine for connecting wire production

PendingCN113977030AAvoid safety hazardsIncrease productivityDrying machines with progressive movementsDrying solid materialsSolderingMaterials science

The invention relates to the technical field of connecting wire welding and drying, and discloses a tin soldering and drying all-in-one machine for connecting wire production, which comprises a circulating moving mechanism and a plurality of clamping jaw mechanisms, the clamping jaw mechanisms are arranged on the circulating moving mechanism at intervals, and a heat shrink tube sleeving device and a connector feeding device are arranged at the front end of the circulating moving mechanism. An initial station of the circulating moving mechanism is a connector feeding station, a continuous welding device and a heat shrink tube feeding device are further sequentially arranged on the circulating moving mechanism, and a heat shrink tube drying device is arranged at the tail end of the circulating moving mechanism. After the clamping jaw mechanisms clamp the connector, the clamping jaw mechanism and a wire sleeved through the heat shrink tube sleeving device sequentially pass through the continuous welding device, the heat shrink tube feeding device and the heat shrink tube drying device to be subjected to tin soldering, heat shrink tube feeding and heat shrink tube drying operation. Compared with the prior art, the connecting wire has the advantages that the connecting wire is produced in a streamlined manner after the original materials such as a connector and a wire are subjected to heat shrink tube sleeving, welding and heat drying, so that the working efficiency is improved, and the safety risk is reduced.

Owner:KUNSHAN ZILLION ELECTRONICS TECH

Welding method of tandem type solar silicon wafer group and special shelf thereof

InactiveCN102244148AFast and convenient operation speedReduce Fragmentation RateFinal product manufactureSemiconductor devicesEngineeringSilicon chip

The invention relates to a welding method of a tandem type solar silicon wafer group and a special shelf thereof. The shelf comprises a platy shelf; the shelf is provided with a plurality of raised spacer sets; and the spacer sets are arranged at intervals along the length direction of the shelf. The method for welding the solar silicon wafer group comprises the following steps: firstly overlaying silicon wafers with interconnected strips at the back side into a silicon wafer column, wherein the extending ends of all the interconnected strips are positioned at the same side of the silicon wafer column, the silicon wafer column is arranged above the shelf and moves from one end of the shelf to the other end, the moving direction is opposite to the extending direction of the interconnected strips, and in the moving process of the silicon wafer column, the silicon wafers at the most bottom layer are continuously and sequentially placed in different intervals on the shelf; then regulatingthe positions of the silicon wafers in the intervals so that the interconnected strips are overlapped with main grid lines on the adjacent silicon wafers; and finally welding the overlapped interconnected strips and the main grid lines together by utilizing a ferrochrome. The welding method is convenient and rapid, the operation efficiency is high, and the silicon wafers are not easy to crack in the welding process.

Owner:SOPRAY ENERGY

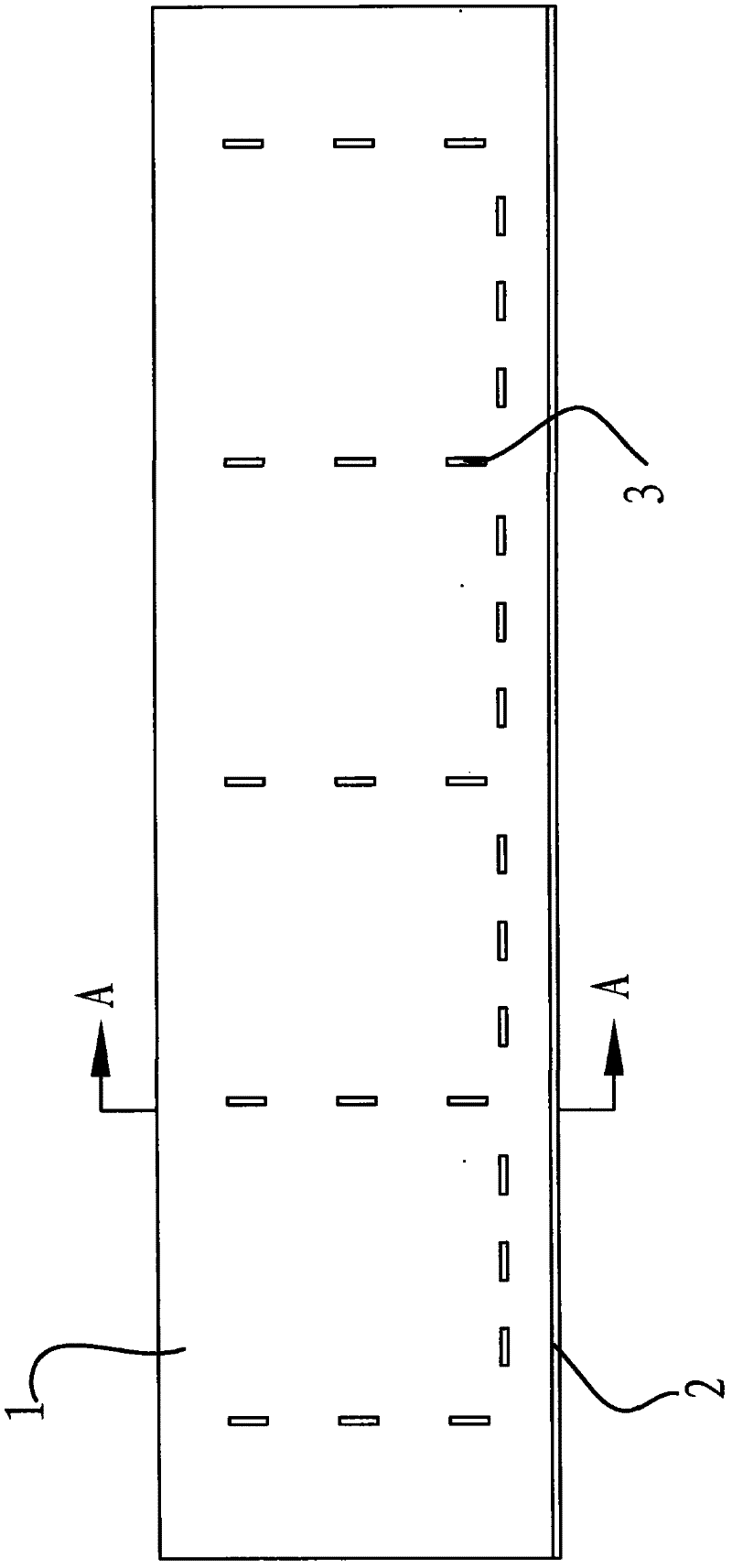

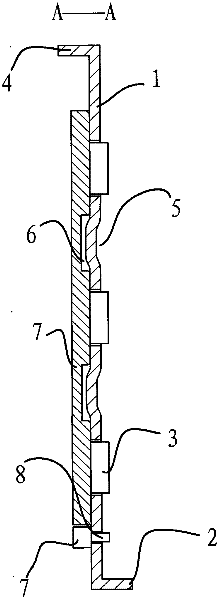

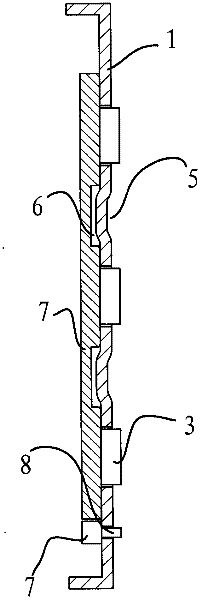

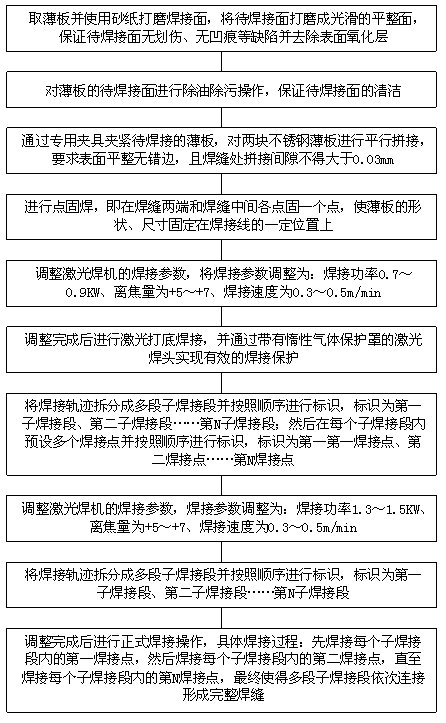

Welding process of high-power laser welding equipment for sheets

InactiveCN110744195ASimple welding processRealize welding operationMetal working apparatusLaser beam welding apparatusWeld lineEmery paper

The invention provides a welding process of high-power laser welding equipment for sheets. The welding process includes the specific steps that the sheets are taken, welding surfaces are polished through abrasive paper, and the to-be-welded surfaces are polished into smooth flat surfaces; the to-be-welded surfaces of the sheets are subjected to oil and dirt removal, and the to-be-welded surfaces are kept clean; a special clamp is used for clamping the to-be-welded sheets, and the two stainless steel sheets are spliced in parallel; tack welding is carried out, in other words, points are fixed to the two ends and the middle of a weld joint separately, and the shapes and the sizes of the sheets are fixed to certain positions of a welding line; welding parameters of a laser welding machine areadjusted, and laser backing welding is carried out; a welding track is split into multiple sub welding sections, the sub welding sections are identified in sequence, multiple welding points are preset in each sub welding section, and the welding points are identified in sequence; and the welding parameters of the laser welding machine are adjusted, and formal welding operation is carried out. Thesheet welding process is simplified, the operation is easy, the welding efficiency is high, the sheets can be welded, and the welding effect is extremely good.

Owner:WUHAN BAOHAN WELDING EQUIP

Three-dimensional welding robot

InactiveCN108673000ARealize welding operationPrecise Welding OperationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPower component

The invention discloses a three-dimensional welding robot. The three-dimensional welding robot comprises a welding unit, a movement unit and a control unit; the movement unit comprises a base, a firstX-axis slide rail component and a first X-axis sliding block, a first Z-axis slide rail component and a first Z-axis a sliding block, a first Y-axis slide rail component and a first Y-axis sliding block, a second X-axis slide rail component and a second X-axis sliding block, a second Z-axis slide rail component and a second Z-axis sliding block, a second Y-axis slide rail component and a second Y-axis sliding block, a power component, a worm gear and a worm rod; the first X-axis slide rail component is arranged on the base; and the second X-axis slide rail component is fixedly arranged on thebottom of the first Y-axis sliding block through a connection plate. The three-dimensional welding robot has the beneficial effects of being wide in application range and high in welding precision.

Owner:SHANGHAI ZHONGHONG ELECTRONICS TECH

Pipe repairing device for mechanical production

InactiveCN112658590AEasy to weldEasy to handleOther manufacturing equipments/toolsEngineeringPhysics

The invention discloses a pipe repairing device for mechanical production, and belongs to the technical field of mechanical production. The device comprises a bottom plate, a pipe, a first functional plate, a second functional plate, a first moving block and a second moving block, a first vertical plate and a second vertical plate are fixed to the upper surface of the bottom plate, a belt wheel is rotatably connected to the position, located right below the first vertical plate, of one side of the bottom plate, a first cylinder and a second cylinder are fixed to one end of the first functional plate and one end of the second functional plate respectively, the first cylinder and the second cylinder penetrate through the first vertical plate and the second vertical plate respectively and are rotationally connected with the first vertical plate and the second vertical plate respectively, and a first transmission assembly and a second transmission assembly are fixed to the two side faces of the bottom plate. According to the device, through the design of the first cylinder, the belt wheel, the second cylinder, the second functional plate and a second hollow plate, the pipe can be rapidly clamped and fixed, rotary welding and polishing treatment of the pipe is achieved, and the situation that dust generated in an operation process pollutes the environment and effects the operation of workers can be avoided.

Owner:王焯

Welding equipment

ActiveCN113369782AAchieve rotationEasy to installWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention relates to the technical field of machining, in particular to welding equipment. The welding equipment comprises a workbench, a clamping mechanism, a welding mechanism and a moving mechanism. A first guide rail is arranged on the workbench; the clamping mechanism comprises a mounting seat and a clamping device mounted on the mounting seat; the mounting seat is mounted on the workbench, the clamping device can rotate relative to the mounting seat, and the clamping device is used for clamping a profile; the welding mechanism comprises a connecting assembly, and a welding assembly slidably connected with the connecting assembly; the connecting assembly is installed on the first guide rail and can slide relative to the first guide rail; the welding assembly is located above the clamping device and used for welding the profile; and the moving mechanism is located above the clamping mechanism and used for conveying the profile to the clamping mechanism. The problem that traditional welding equipment is low in welding efficiency is solved, and the welding equipment has the advantages of being capable of rapidly fixing profiles and high in automation degree.

Owner:佛山市腾翱科技有限公司

Welding device for automobile seat framework

ActiveCN114535887AAdjust the tilt angleEasy to adjust the tilt angleWelding/cutting auxillary devicesAuxillary welding devicesCar seatManipulator

The invention relates to the technical field of automobile seat machining, in particular to a welding device for an automobile seat framework, which comprises a worktable, a manipulator is arranged on the outer wall of the worktable, a welding assembly is arranged at the end part of the manipulator, a mounting groove is formed in the outer wall of the worktable, and a turntable is rotationally arranged in the mounting groove; a first driving part is arranged on the outer wall of the other side of the workbench, the driving end of the first driving part is connected with the outer wall of the rotating disc, a first telescopic part is arranged on the outer wall of the rotating disc, a mounting plate is arranged at the telescopic end of the first telescopic part, a limiting rod is arranged on the outer wall of the mounting plate, and a rotating cylinder is rotationally arranged on the outer wall of the limiting rod; and a fixing plate is arranged on the outer wall of the rotary drum. According to the welding device, flexible splicing between the seat frameworks is effectively achieved, the welding angle is freely adjustable, further, flying chips can be prevented from splashing in the welding process through the chip blocking mechanism, and the safety performance of the device in use is effectively improved.

Owner:深圳市米里汽车电子有限公司

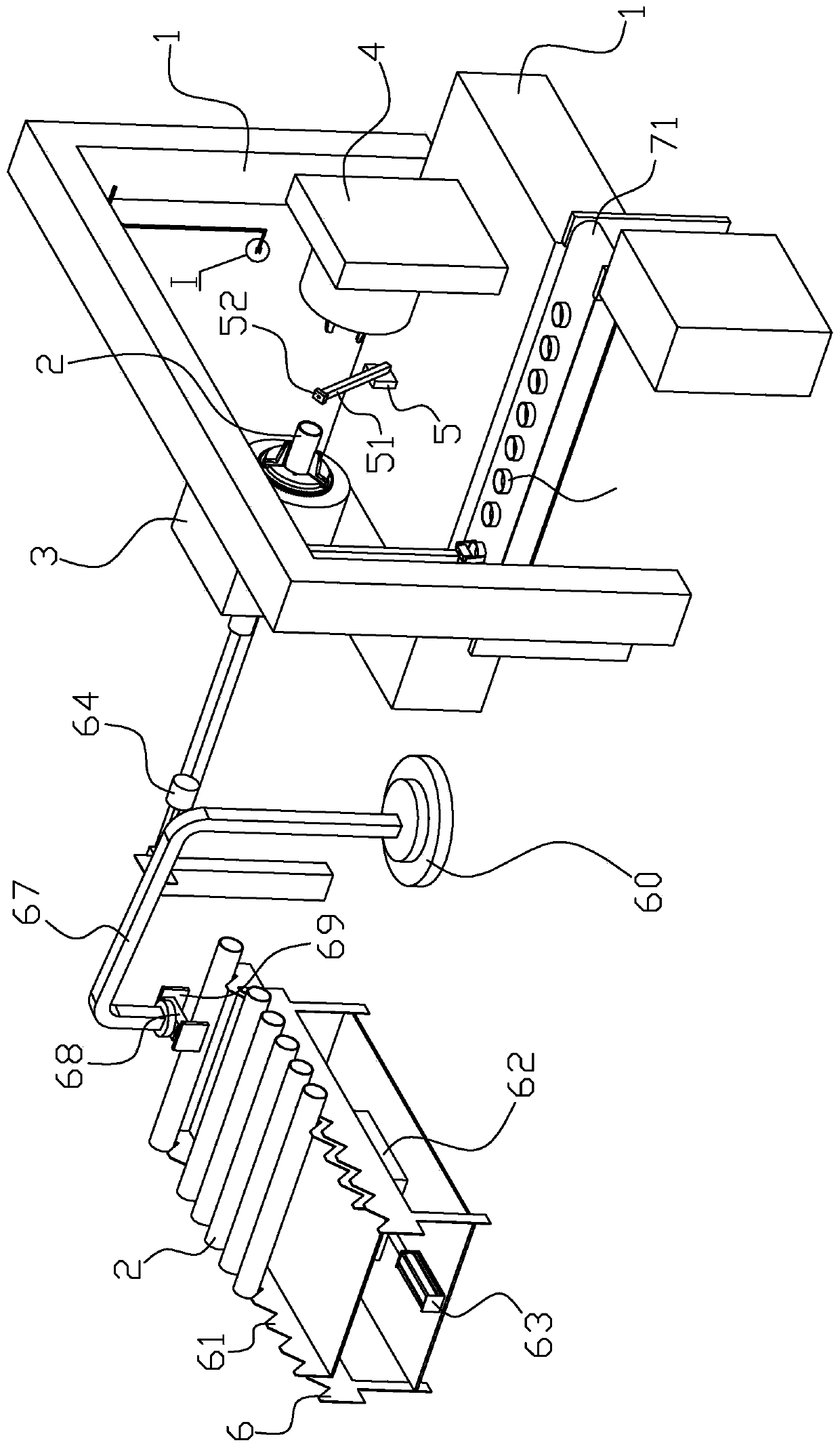

Industrial manipulator applicable to automatic arrangement and welding of solar photovoltaic cell

ActiveCN102528355ARealize fully automated handlingRealize arrangementProgramme-controlled manipulatorWelding/cutting auxillary devicesRobotic armEngineering

The invention discloses an industrial manipulator applicable to automatic arrangement and welding of a solar photovoltaic cell. The industrial manipulator comprises a pedestal, a sliding rail, a sliding platform, three mechanical arms, a servo motor, a synchronous pulley, a synchronous belt, a welding gun, a cylinder, a control cabinet, a fixture 1 and a fixture 2, wherein the sliding rail is arranged on the pedestal; the three manipulators are arranged on the sliding rail; the servo motor is arranged in each manipulator shell; a motor main shaft is connected with the synchronous pulley; the synchronous belt is engaged with the synchronous pulley, and the two ends of the belt are fixed inside the sliding rail and are tightened; the side face of a slide block is provided with a pulling device; and the pulling device is connected with one cylinder and is provided with the cylinder. The industrial manipulator has the advantages of simple structure, reliable control, accurate positioning and the like; the work of two workers for clamping and handling the photovoltaic cell during charging and discharging is substituted; the welding stability is guaranteed; the cost is greatly reduced; and the efficiency and the safety are improved.

Owner:宁波贝达新能源科技有限公司

Hopper bracket welding positioning tooling

ActiveCN103949826BRealize welding operationRapid positioningWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention relates to a hopper bracket welding and positioning tooling. The tooling is used for manufacturing a vehicle frame of a concrete pumper and is provided with a tooling first stringer (3), a tooling second stringer (9), at least two crossbeams (1 and 11) which are connected with the first stringer (3) and the second stringer (9), a first upright post, a second upright post (5), a first longitudinal positioning mechanism, a first bottom connecting plate, a second bottom connecting palate (7), a first transverse positioning mechanism (10) and a second transverse positioning mechanism, wherein the first upright post and the second upright post (5) are connected with the bottoms of the tooling stringers (3 and 9); the first longitudinal positioning mechanism is connected with one side of the first upright post; the first bottom connecting plate and the second bottom connecting plate (7) are connected with the bottoms of the upright posts; the first transverse positioning mechanism (10) and the second transverse positioning mechanism are fixed on the inner sides of the tooling first stringer (3) and the tooling second stringer (9); the inclination angles of the first bottom connecting plate and the second bottom connecting plate are matched with the welding angles of a hopper base, and the first bottom connecting plate and the second bottom connecting plate are respectively provided with at least two holes through which reamed hole bolts are mounted; the hopper bracket is connected with the bottoms of the first bottom connecting plate and the second bottom connecting plate in a positioning manner through the reamed hole bolts.

Owner:HUNAN HELI XINGBANG MACHINERY

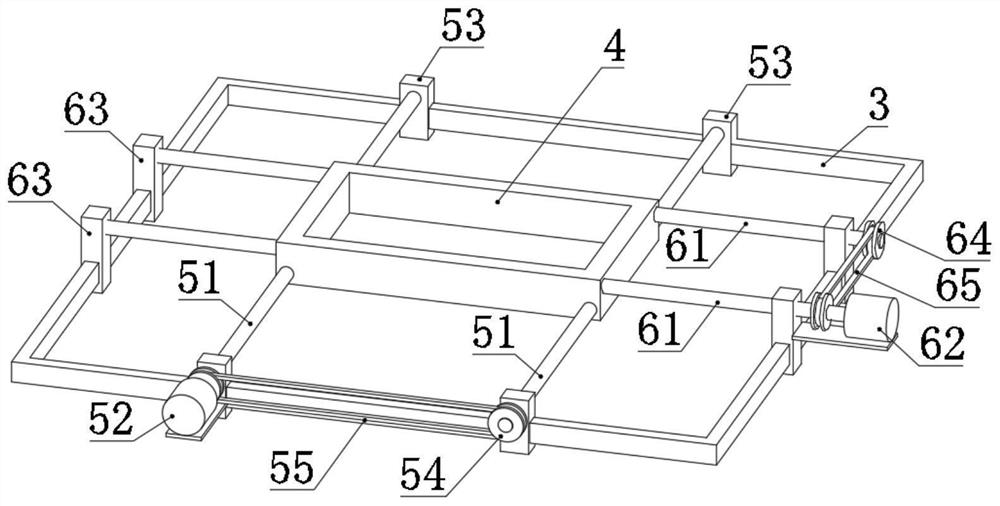

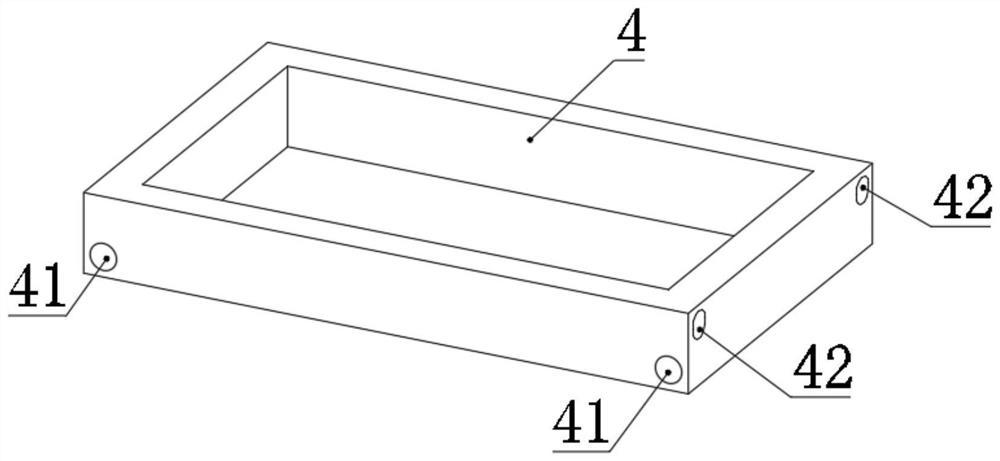

A portable lithium battery cover plate welding device

ActiveCN110434527BAchieve fixed positionPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesDust controlStructural engineering

The invention discloses a portable lithium battery cover plate welding device, which comprises a base plate, a horizontally moving guide rail and a bracket fixed on the base plate, a battery positioning tool slidably arranged on the horizontally moving guide rail, a laser welding assembly fixed on the bracket and The dust removal module, the battery positioning tooling includes a horizontal moving plate slidingly arranged on the horizontal moving guide rail, two longitudinal moving guide rails fixed on the upper surface of the horizontal moving plate and a cover plate positioning guide rail, the cover plate positioning guide rail is parallel to the horizontal moving guide rail , the two longitudinal moving guide rails are perpendicular to the horizontal moving guide rails, the cover plate positioning guide rail is located between the two longitudinal moving guide rails, and the corresponding cell positioning mechanisms are slidably connected to the two longitudinal moving guide rails. The invention is applicable to the welding requirements of the cover poles and soft connecting pieces of multiple types of lithium batteries, and adopts dust removal welding to ensure the qualified rate of welding.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of welding method of glass tube and metal tube

ActiveCN108161265BRealize welding operationHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesWeldingGlass tube

The invention discloses a welding method for glass tubes and metal tubes. The welding method includes the following steps that a glass tube conveying device conveys the glass tubes into an inner cavity of a first clamping part, and a first chuck clamps the glass tubes; a metal tube conveying device conveys the metal tubes onto a second chuck of a second clamping part, and the second chuck clamps the metal tubes; a first clamping disk drives the glass tubes to rotate, and a welding rod on a welding holder is rotated so that a welding head can heat the side walls of the ends of the glass tubes;a U-shaped cavity formed between squeezing stop rods of a squeezing part is arranged on the side walls of the ends of the glass tubes in a sleeving mode, a squeezing base squeezes the ends of the glass tubes so that the ends of the glass tubes can extend to the squeezing stop rods, and the tube wall thicknesses are increased; the second clamping part moves towards the first clamping part, the endsof the metal tubes are inserted into the ends of the glass tubes, and the welding head is used for heating the side walls of the glass tubes so that the metal tubes and the glass tubes can be weldedtogether; and the first chuck and the second chuck are loosened, and the welded glass tubes are stored for standby application. The welding method for the glass tubes and the metal tubes has the advantages that the ends of the glass tubes and the ends of the metal tubes can be welded, welding efficiency is high and the welding effect is good.

Owner:宁波海曙洪德产品设计有限公司

Positioning and welding integrated mechanism for building pouring frame

PendingCN111531306AImprove welding convenienceEasy to installWelding/cutting auxillary devicesAuxillary welding devicesRebarLocking plate

The invention discloses a positioning and welding integrated mechanism for a building pouring frame. The mechanism comprises a fixing base and a fixed support column, wherein the fixing base adopts arectangular frame type structural design, the fixed support column is fixedly welded and arranged at the corner of one end of the fixing base, a movable support column is arranged on the side, adjacent to the fixed support column, of the fixing base in a matched mode, two movable support column adjusting screw rods are arranged and rotatably mounted on the fixed support column, an adjusting handleis arranged at the outer side end of the movable support column adjusting screw rod on the lower side, and the fixed support column is connected with the movable support column through the movable support column adjusting screw rods. According to the positioning and welding integrated mechanism for the building pouring frame, the front side of an arranged screw rod is provided with a limiting locking plate in a welded mode, the limiting locking plate is in a vertical triangular iron structure, the angle iron structure design is beneficial to better use of steel bars with different outer wallshapes, and the steel bars can be more vertically fixed through the right angle structure.

Owner:周建平

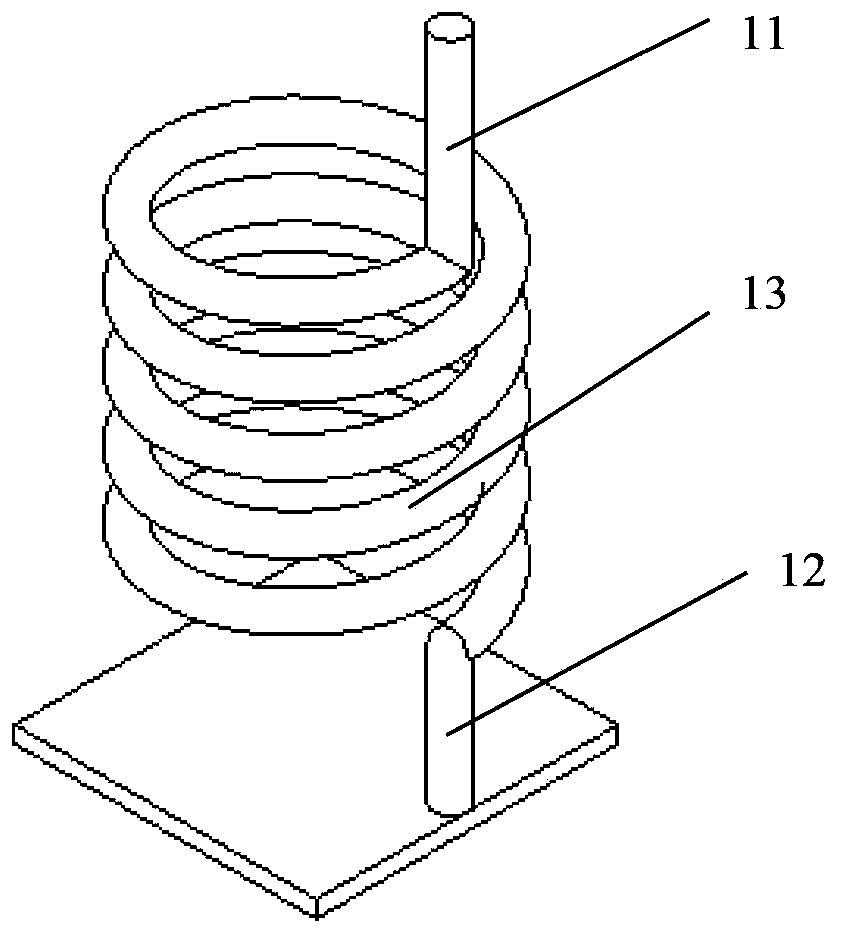

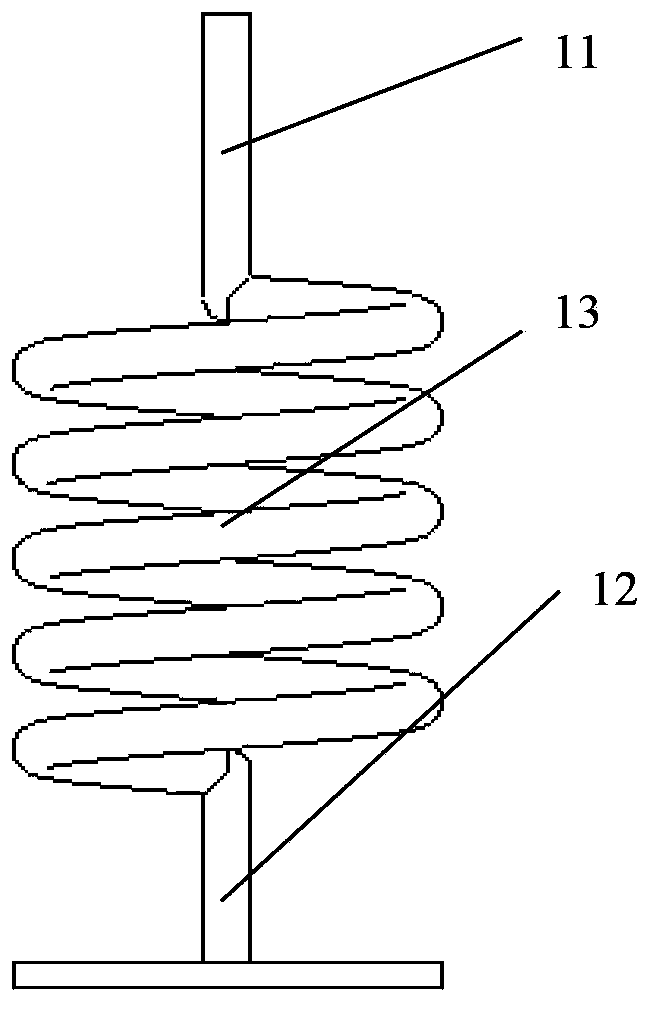

Sampling needle electrode and welded IGBT module unit

InactiveCN103681567ALarge activity marginImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

The invention discloses a sampling needle electrode. The sampling needle electrode includes a first connecting electrode and a second connecting electrode, and adopts a spiral needle structure made of gold-plated copper. The welding quality of the sampling needle electrode is improved, so as to improve the product quality and reliability, and further achieve a higher productivity; meanwhile, the sampling needle electrode has a larger movement allowance, so as to prevent welding points from dropping during the application of a module due to thermal expansion and contraction. The structural design facilitates pulling and other operations in subsequent procedures, so as to achieve easy operations.

Owner:XIAN YONGDIAN ELECTRIC

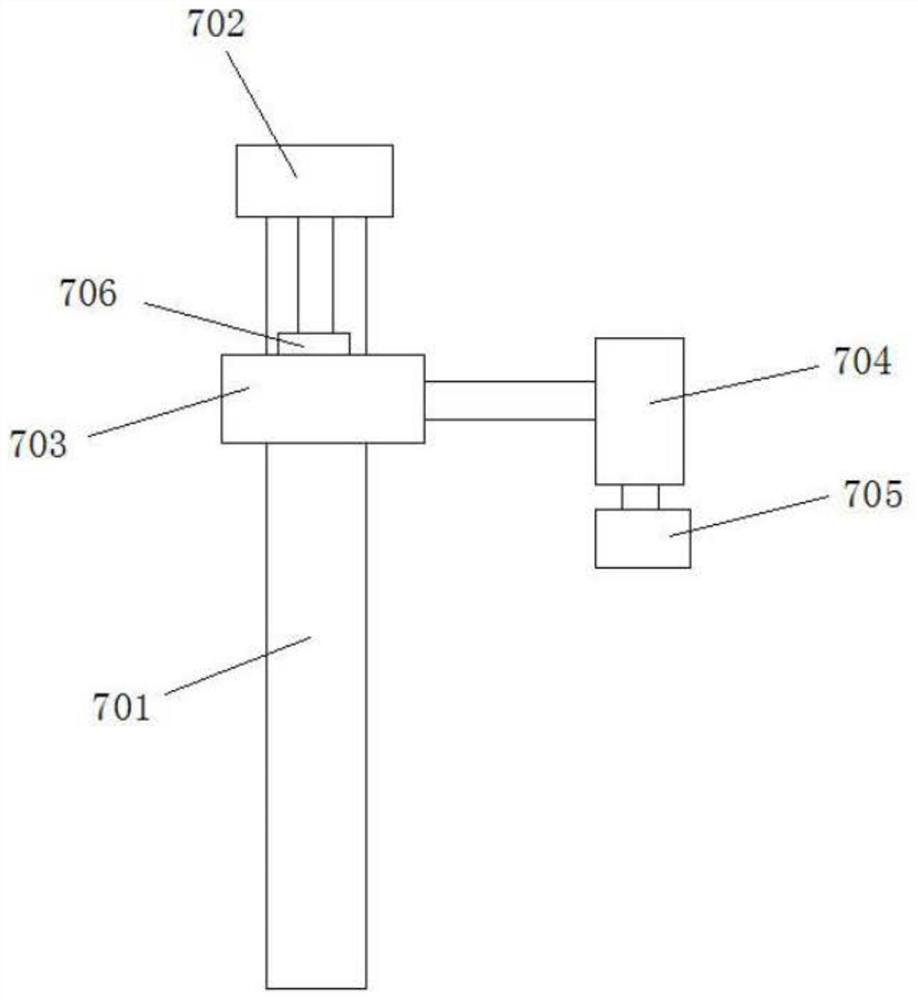

Faucet handle welding equipment and working method thereof

PendingCN112171060AOperation steps save time and effortSimple production operationLaser beam welding apparatusElectric machineryEngineering

The invention discloses faucet handle welding equipment and a working method thereof. The faucet handle welding equipment comprises a workbench, a rotary motor and a rotary table. The rotary motor isconnected to the workbench, an output shaft of the rotary motor is connected with the rotary table, and four station assemblies are arranged on the rotary table. A first machining assembly, a second machining assembly and a material receiving assembly are arranged on the outer side of the rotary table. The working method comprises the following steps: S1, a handle plate is manually placed in a placing groove; S2, a placing table is controlled to rotate to the position of the first machining assembly; S3, a first clamping mechanism takes a handle core and places the handle core on the handle plate; S4, a first laser welding machine carries out welding operation; S5, the placing table is rotated to the position of the second machining assembly; S6, a second clamping mechanism takes a handlering and places the handle ring on the handle plate; S7, a second laser welding machine performs welding operation; S8, the placing table is rotated to the position of the material receiving assembly;and S9, a third clamping mechanism takes out a faucet finished product.

Owner:鹤山市正鑫卫浴科技有限公司

a welding device

ActiveCN113369782BAchieve rotationEasy to installWelding/cutting auxillary devicesAuxillary welding devicesMachiningWorkbench

The present invention relates to the technical field of mechanical processing, in particular to a welding device, which includes a workbench, a clamping mechanism, a welding mechanism and a moving mechanism; the workbench is provided with a first guide rail; the clamping mechanism includes a mounting seat and a clamping device mounted on the mounting base; the mounting base is mounted on the workbench, the clamping device can rotate relative to the mounting base, and the clamping device is used for clamping profile; the welding mechanism includes a connection assembly and a welding assembly slidingly connected with the connection assembly; the connection assembly is installed on the first guide rail and can slide relative to the first guide rail, and the welding assembly is located on the clamp The upper part of the holding device is used for welding the profile; the moving mechanism is located above the clamping mechanism and is used for delivering the profile to the clamping mechanism. The invention solves the problem of low welding efficiency of traditional welding equipment, and has the advantages of fast fixing profiles and high degree of automation.

Owner:佛山市腾翱科技有限公司

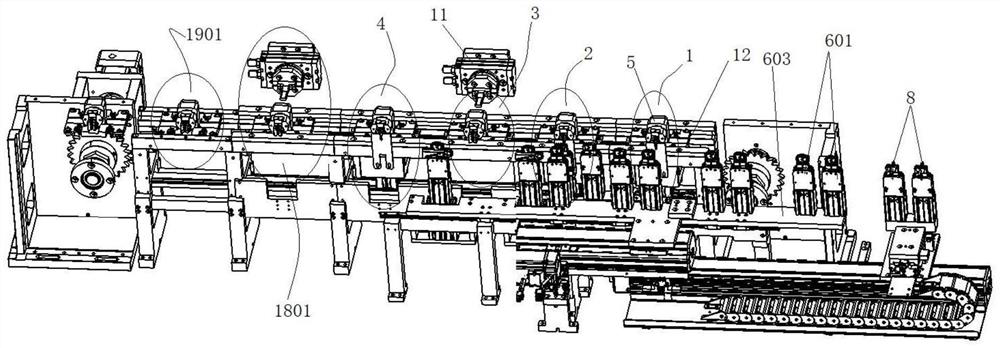

Pin guiding, conveying and crimping device

The invention relates to a pin guiding, conveying and crimping device. A pin welding device is arranged beside the pin guiding, conveying and crimping device; the pin welding device is used for welding wire pins to wiring terminals of the array type LED lamp beads. The pin guiding, conveying and crimping device comprises a crimping head arranged above a translation table of the feeding device of the array type LED lamp beads; the crimping head is provided with a clamping comb plate used for clamping two pins of a wire harness. The clamping comb plate moves horizontally and straightens the twopins of the wire harness. Before the two wiring pins are welded with the wiring terminals of the LED lamp bead on the translation table, the clamping comb plate on the crimping head is in contact withthe two connecting wires; and the clamping comb plate is driven to move horizontally, so that the positions of the two wiring pins are further limited, the two pins of the wiring harness are just located over the wiring terminals of the LED lamp beads, the pin welding device is started, and welding operation of the two pins and the wiring terminals of the LED lamp beads is implemented.

Owner:ANHUI LANRUI ELECTRONICS TECH

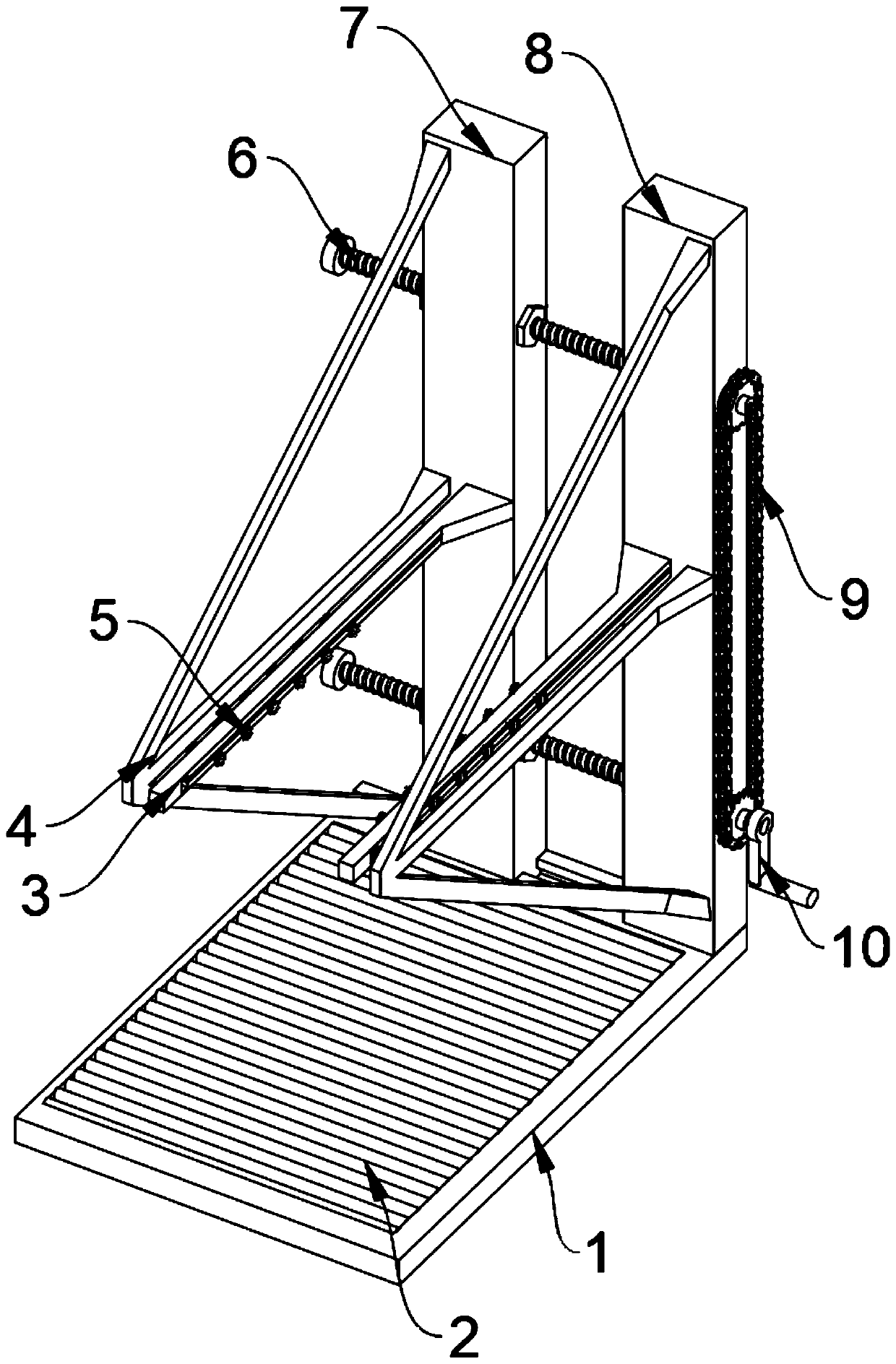

Welding tool for aerial work platform bottom plate production and using method thereof

InactiveCN112139694AShorten the timeReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesManufacturing engineeringAerial work platform

The invention relates to the field of aerial work equipment, in particular to a welding tool for aerial work platform bottom plate production and a using method thereof. The welding tool comprises a base, a first support is fixed to the base, a first conveying mechanism is arranged at the upper end of the first support, a second support is fixed to the base, and a welding mechanism used for welding a beam body and a bottom plate is arranged at the upper end of the second support; a welding gun is arranged on the welding mechanism, the welding mechanism can be in transmission connection with afirst material conveying mechanism, a third support is fixed to the base, a second material conveying mechanism is arranged at the upper end of the third support, and the second material conveying mechanism can convey the beam body and press and fix the beam body to the corresponding bottom plate on the first material conveying mechanism; and according to the welding tool for aerial work platformbottom plate production and the using method of the welding tool, an external fixing tool does not need to be used for fixing the beam body and the bottom plate, time is saved, two-way automatic feeding of the bottom plate and the beam body is achieved, manpower participation is not needed, the labor intensity is reduced, and the production efficiency is improved.

Owner:潘治霖

Industrial manipulator applicable to automatic arrangement and welding of solar photovoltaic cell

ActiveCN102528355BRealize fully automated handlingRealize arrangementProgramme-controlled manipulatorWelding/cutting auxillary devicesRobotic armEngineering

The invention discloses an industrial manipulator applicable to automatic arrangement and welding of a solar photovoltaic cell. The industrial manipulator comprises a pedestal, a sliding rail, a sliding platform, three mechanical arms, a servo motor, a synchronous pulley, a synchronous belt, a welding gun, a cylinder, a control cabinet, a fixture 1 and a fixture 2, wherein the sliding rail is arranged on the pedestal; the three manipulators are arranged on the sliding rail; the servo motor is arranged in each manipulator shell; a motor main shaft is connected with the synchronous pulley; the synchronous belt is engaged with the synchronous pulley, and the two ends of the belt are fixed inside the sliding rail and are tightened; the side face of a slide block is provided with a pulling device; and the pulling device is connected with one cylinder and is provided with the cylinder. The industrial manipulator has the advantages of simple structure, reliable control, accurate positioning and the like; the work of two workers for clamping and handling the photovoltaic cell during charging and discharging is substituted; the welding stability is guaranteed; the cost is greatly reduced; and the efficiency and the safety are improved.

Owner:宁波贝达新能源科技有限公司

Welding machine for glass tube and metal tube

ActiveCN108031999BRealize welding operationHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesPipeControl circuit

A glass pipe and metal pipe welding machine comprises a rack, a first clamping part, a second clamping part and a welding part. The welding part is arranged on the part, below the end portion of a glass pipe clamped by the first clamping part, of the rack, the first clamping part and the second clamping part are oppositely arranged and can be synchronously and rotationally arranged on the rack relative to the rack, and the second clamping part can move relative to the first clamping part so that a metal pipe can be connected to the end portion of the fused metal pipe in an inserted manner. Oneside of the rack is provided with a glass pipe conveying device for conveying the glass pipe to the first clamping part and a metal pipe conveying device for conveying the metal pipe to the second clamping part. The upper portion of the rack is provided with an extrusion part for extruding the end portion of the glass pipe when the glass pipe heated through the welding part rotates, and the firstclamping part, the second clamping part, the welding part, the glass pipe conveying device, the metal pipe conveying device and the extrusion part are connected with a control circuit through a line.The glass pipe and metal pipe welding machine has the beneficial effects that welding between the end portion of the glass pipe and the end portion of the metal pipe is achieved, the welding efficiency is high, and the welding effect is good.

Owner:宁波海曙洪德产品设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com