Automation equipment for multi-step thickness metal plate machining

A technology of automation equipment and metal plates, applied in metal processing equipment, welding equipment, laser welding equipment, etc., can solve problems such as low efficiency, large investment in fixed assets, heavy metal pollution, etc., to achieve the effect of welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

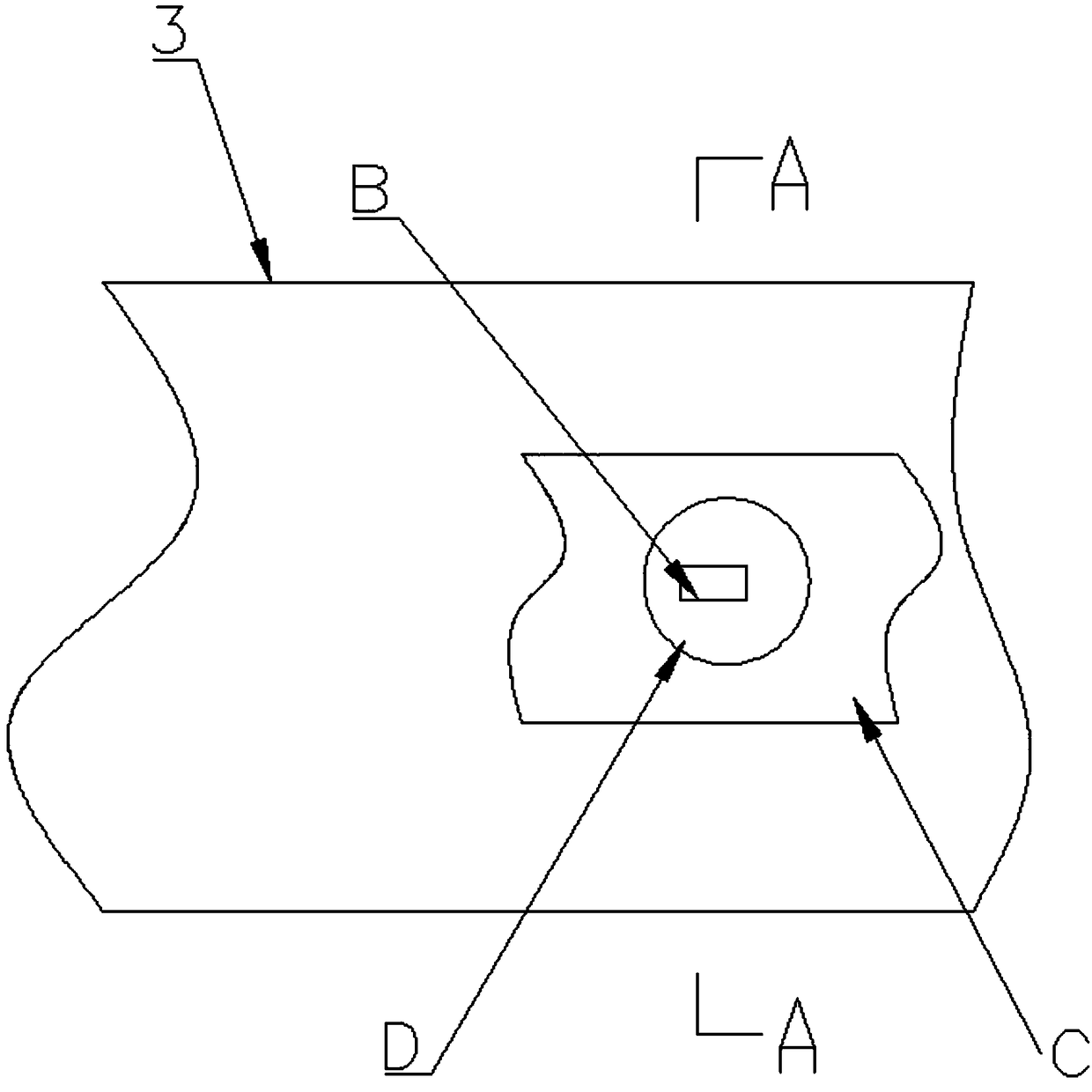

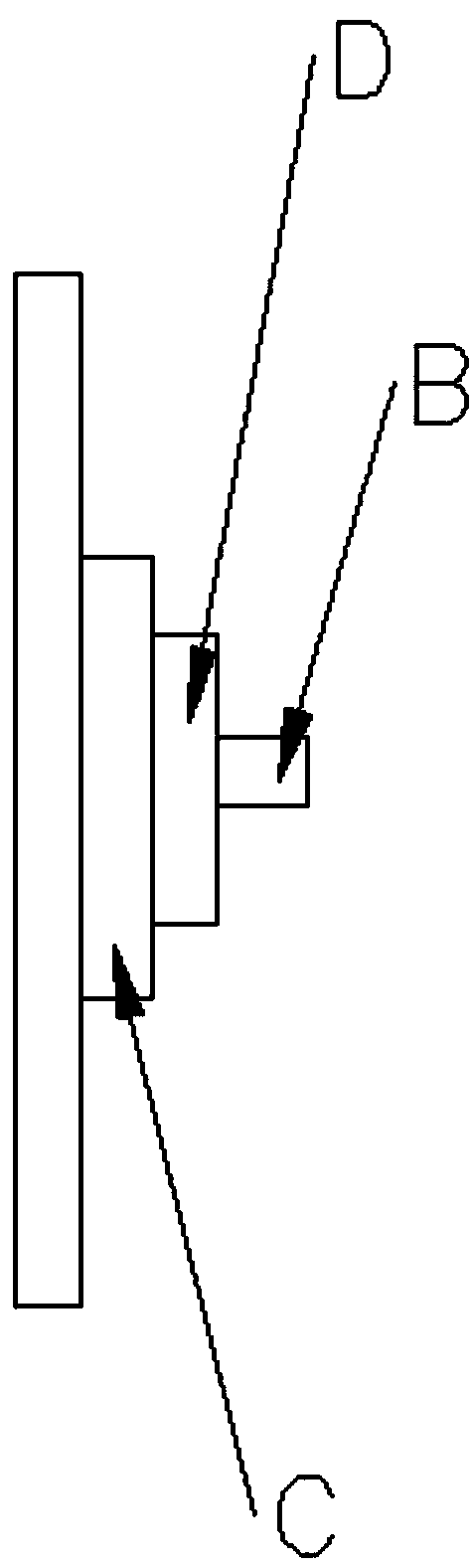

[0024] combine Figure 1 to Figure 2 Shown is an automatic equipment for processing multi-step thickness metal plates. In this embodiment, C is the metal plate substrate placed on the vacuum adsorption platform 3, and D is the first piece that needs to form steps and be welded on C. Cutting block, B is the second cutting block that needs to be welded on D.

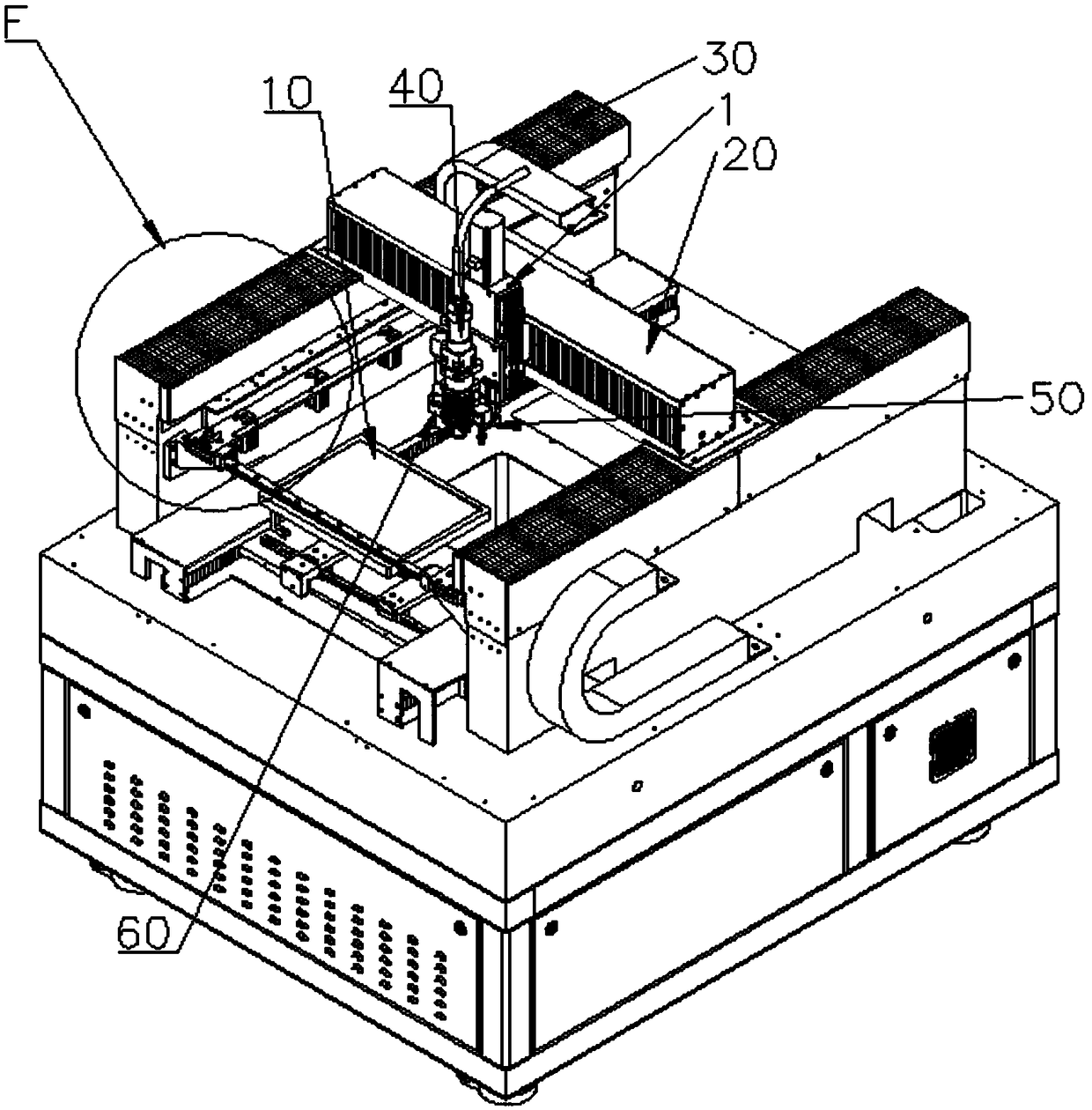

[0025] combine Figure 3 to Figure 10 The shown automatic equipment for multi-step thickness metal plate processing, in this embodiment, includes a control system, a product adsorption lifting jig 10 electrically connected to the control system, an X-axis transmission system 20, a Y-axis transmission System 30, laser welding and cutting head 40, product adsorption system 50 and CCD image acquisition module 60 arranged on both sides of laser welding and cutting head 40, product lifting fixture 10 is used to drive the metal plate to move back and forth along the Z-axis direction, and X-axis transmission The system 20 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com