Positioning and welding integrated mechanism for building pouring frame

A positioning welding and frame technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the frame structure is not easy to move, affect the welding work and quality, and the steel bars are dumped, so as to improve the convenience of fixing and the Scope of application, the effect of improving the convenience of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

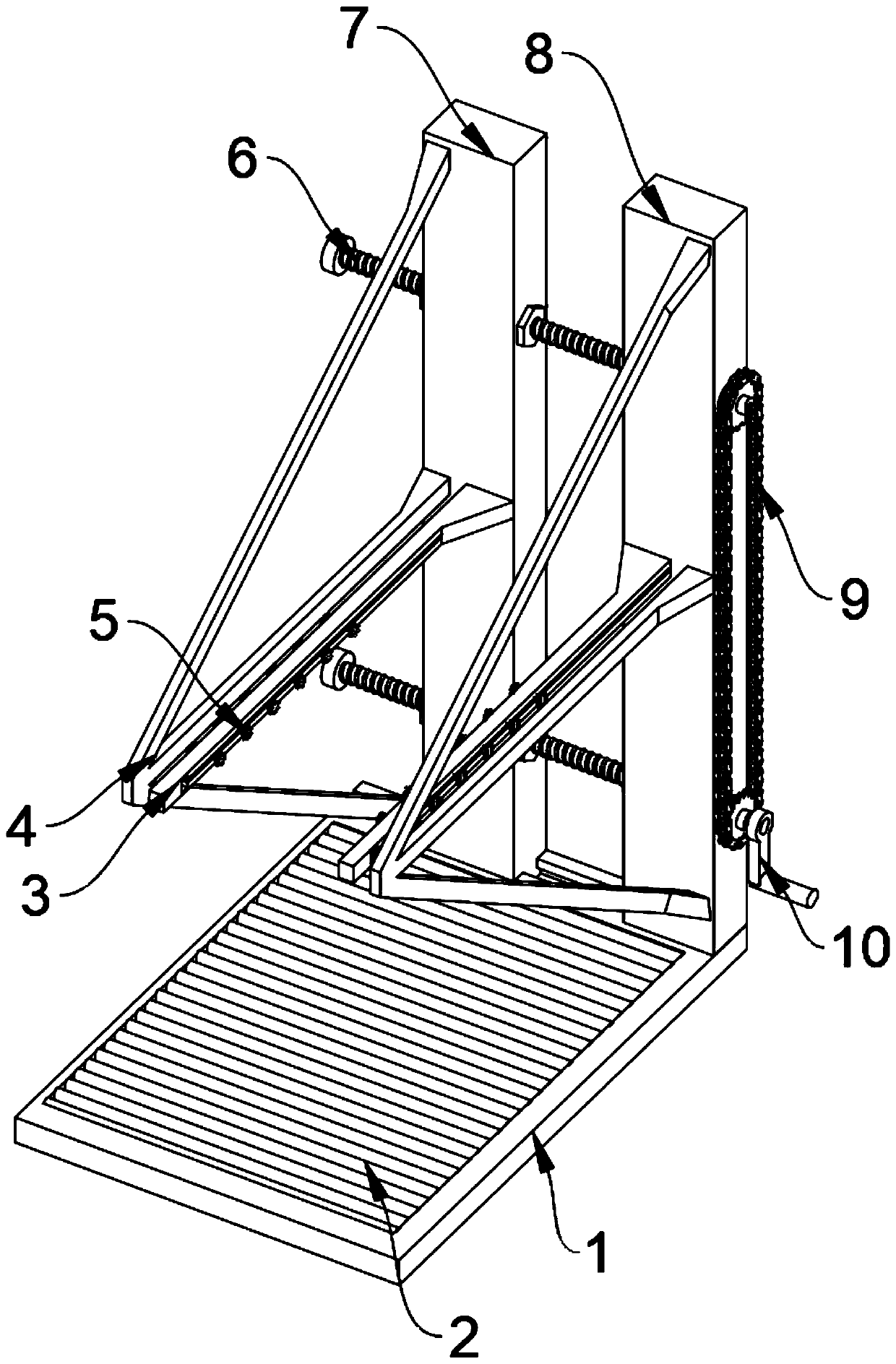

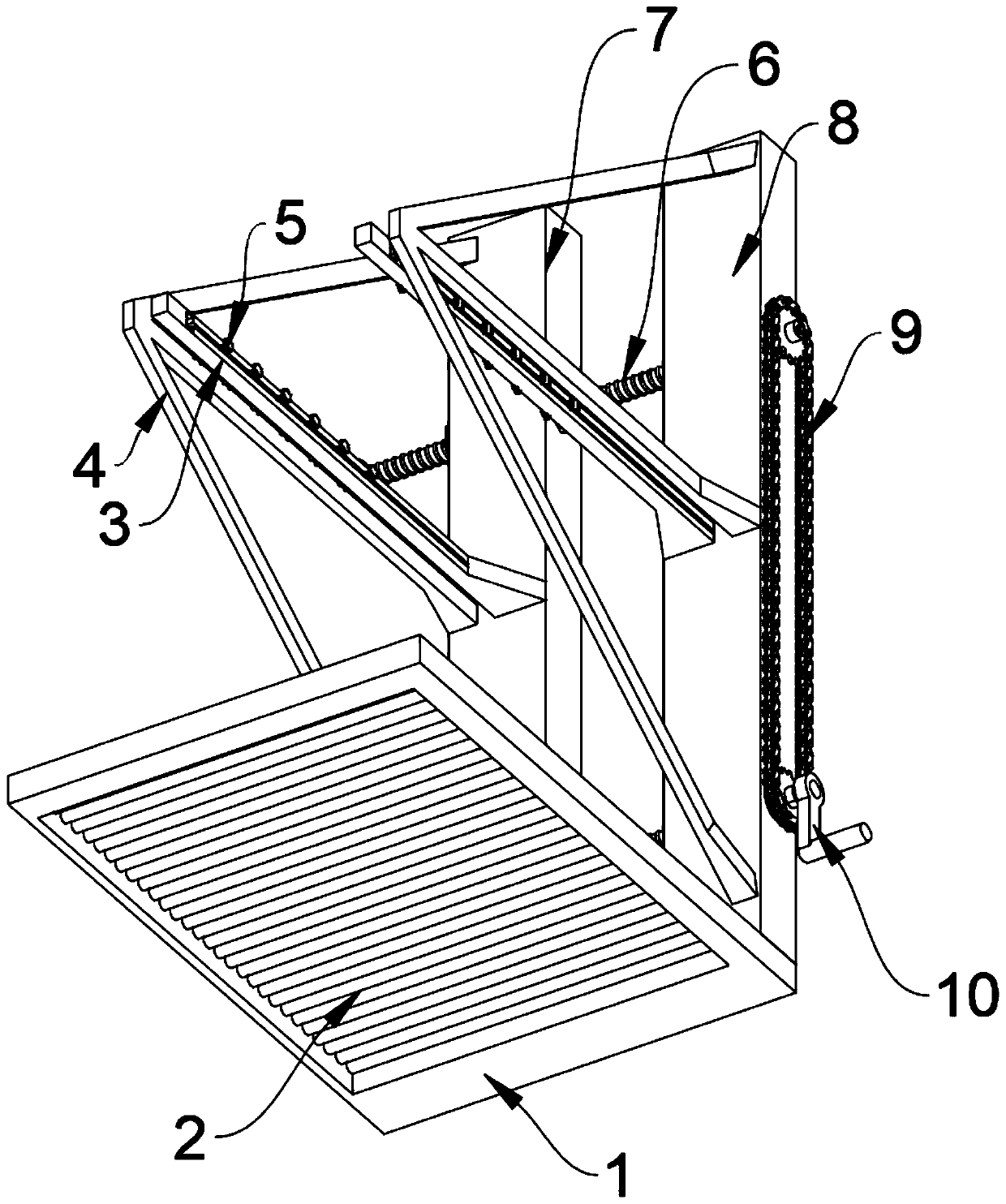

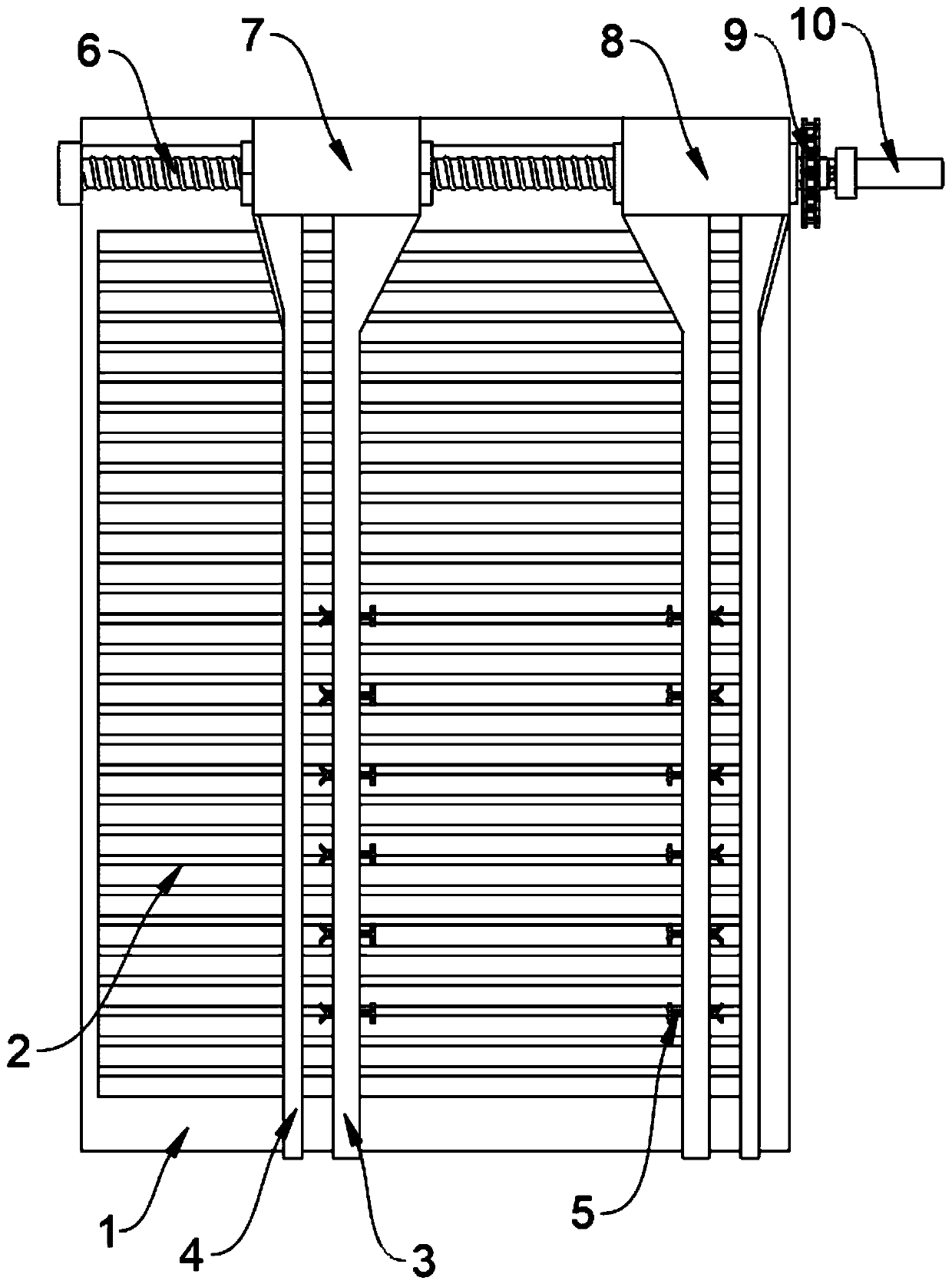

[0038] as attached figure 1 to attach Figure 9 Shown:

[0039]The present invention provides a positioning and welding integrated mechanism for building pouring frames, which includes: a fixed base 1 and a fixed support column 8; The frame moving roller group 2 is installed on the inner side of the groove, and the design of the frame moving roller group 2 is convenient for rolling and moving the frame pouring cage body for welding on the upper side, thereby effectively improving the welding convenience of the frame; the fixed support column 8 is fixed Welding is arranged at one end corner of the fixed base 1, and the fixed base 1 on the adjacent side of the fixed support column 8 is also matched with a mobile support column 7, the bottom side of the mobile support column 7 is provided with a slider, and fixed The base 1 is provided with a matching chute, and the mobile support column 7 is slidably installed on the upper side of the fixed base 1 through the bottom slider, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com