Welding equipment for intelligent pantograph carbon slide plates and welding method thereof

A technology of pantograph carbon slide plate and welding equipment, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as damage to metal support brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

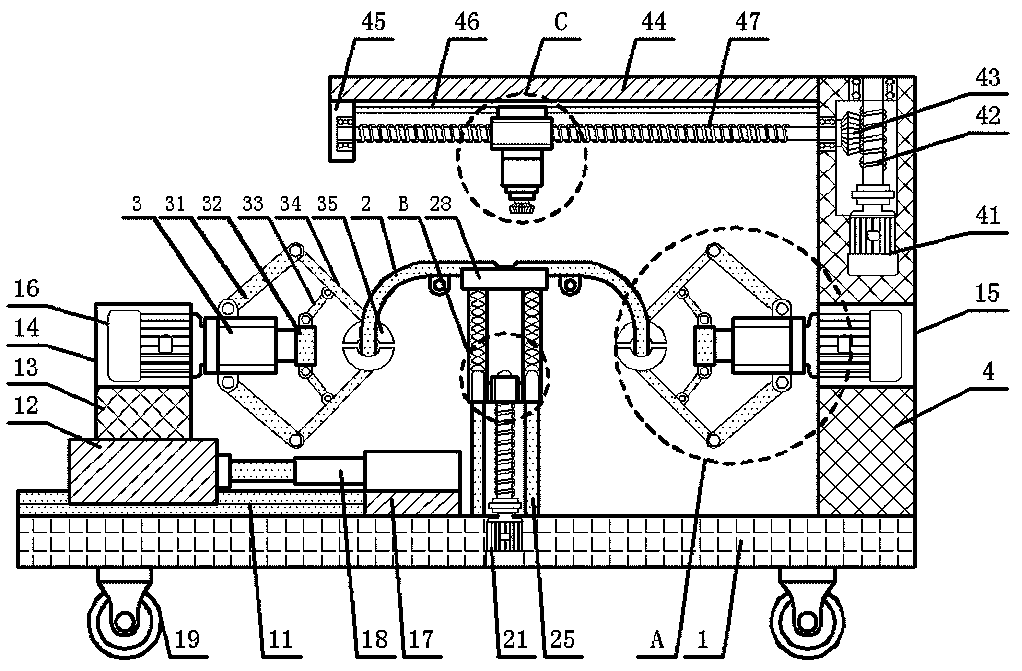

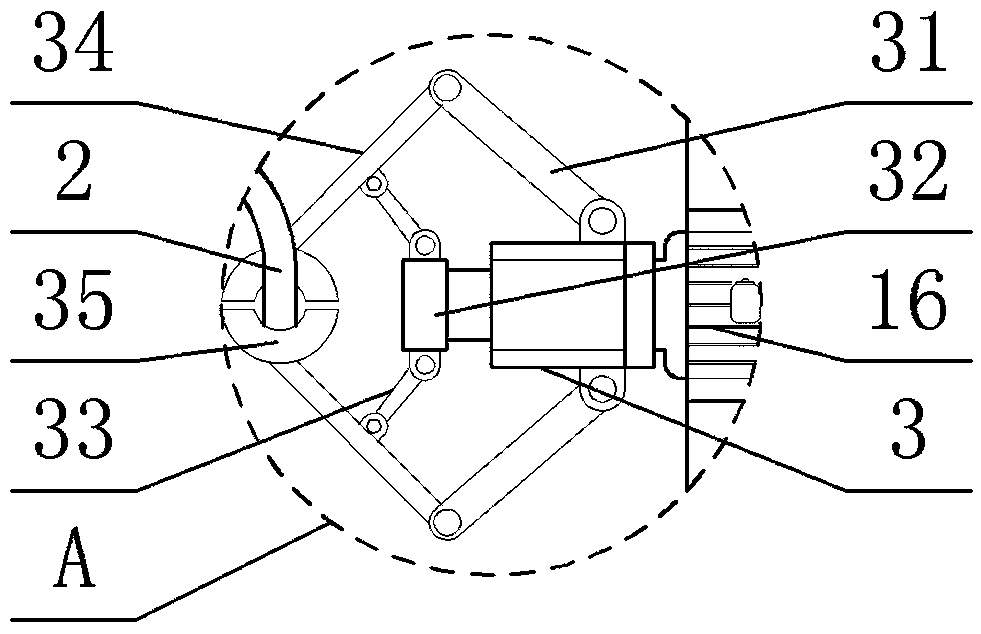

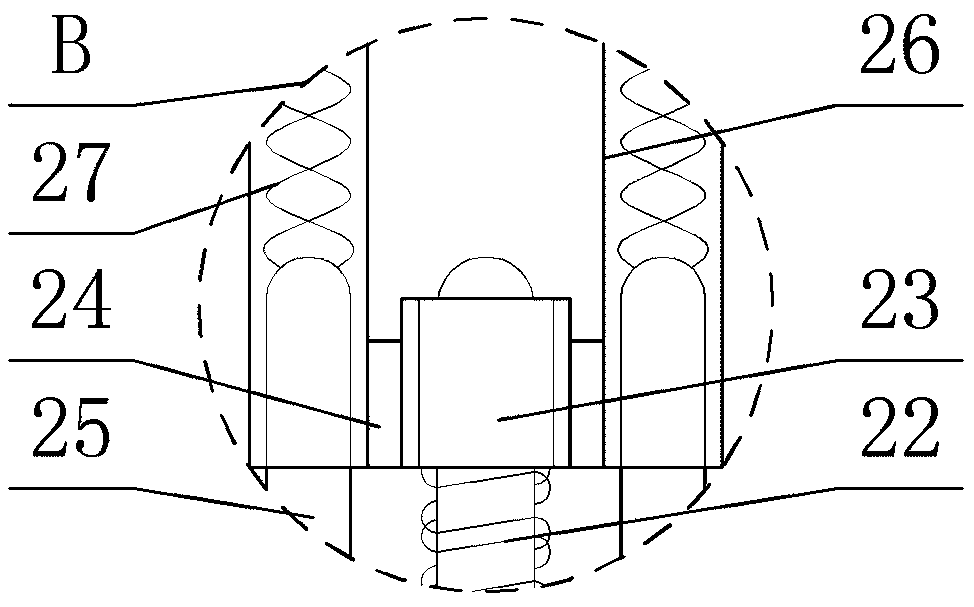

[0034] Embodiment 1: see Figure 1-4, a welding equipment for intelligent pantograph carbon slides, including a bottom plate 1, the bottom plate 1 is a rectangular long plate placed horizontally and horizontally, and the middle part of the top surface of the bottom plate 1 is provided with a suspension opening facing downwards. The carbon skateboard 2, the middle part of the top surface of the bottom plate 1 is recessed with a first motor slot, the first motor 21 with the output end facing up is installed in the first motor slot, the model of the first motor 21 is YPNX90L, the The first motor 21 is movably connected to the middle part of the bottom surface of the carbon slide plate 2 through a lifting mechanism; one side of the top surface of the bottom plate 1 is provided with a limit slide rail 11 placed horizontally, and the limit slide rail 11 is a T-shaped strip, so The top surface of the limit slide rail 11 is clamped with a limit slide plate 12, the bottom surface of th...

Embodiment 2

[0043] Example 2: see Figure 5 , in the present embodiment, the present invention also proposes a welding method for welding equipment of intelligent pantograph carbon slide plate, comprising the following steps:

[0044] Step 1: Set the middle part of the bottom surface of the carbon slide plate 2 to be welded in the limit long slot on the top surface of the limit long plate 28, control the rotation of the motor shaft of the first motor 21, and drive the first thread cylinder through the first threaded rod 22 23 lifts, and then drives the two sliding cylinders 26 to move up and down along the slide bar 25 under the cooperation of the carbon slide 27, thereby driving the position-limiting long plate 28 to lift, so that the two ends of the carbon slide 2 are at the same height as the clamping block 35;

[0045] Step two, control the expansion and contraction of the telescopic rod of the first telescopic cylinder 18, drive the limit slide plate 12 to move laterally along the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com