Ignition device for heat-release welding

A technology of exothermic welding and ignition tube, applied in aluminothermic welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as safety accidents, increase welding cost, etc., to improve construction efficiency, reduce welding cost, and improve storage. and the effect of transport safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

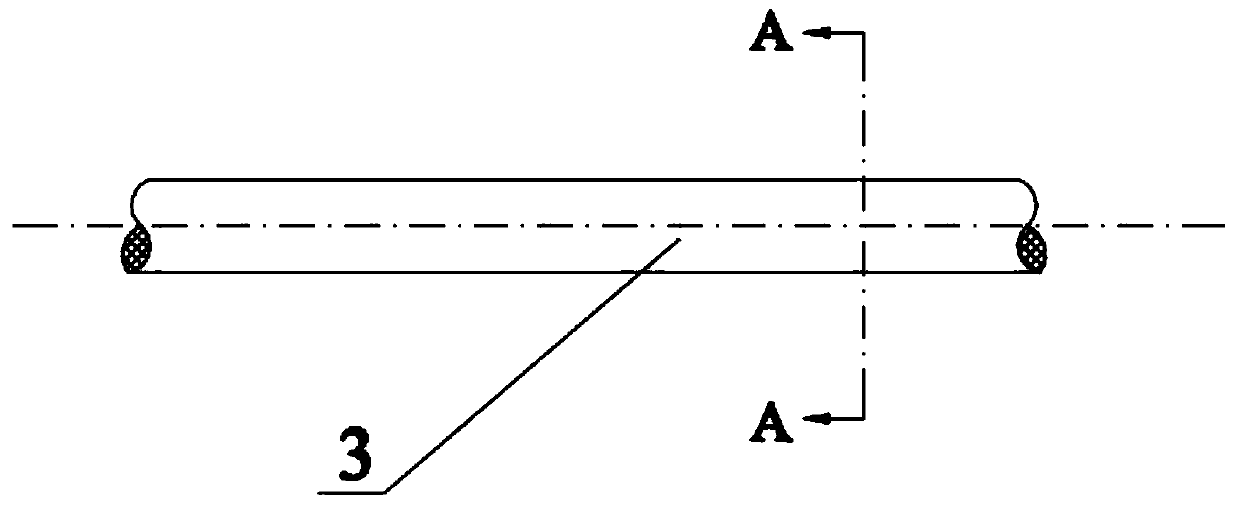

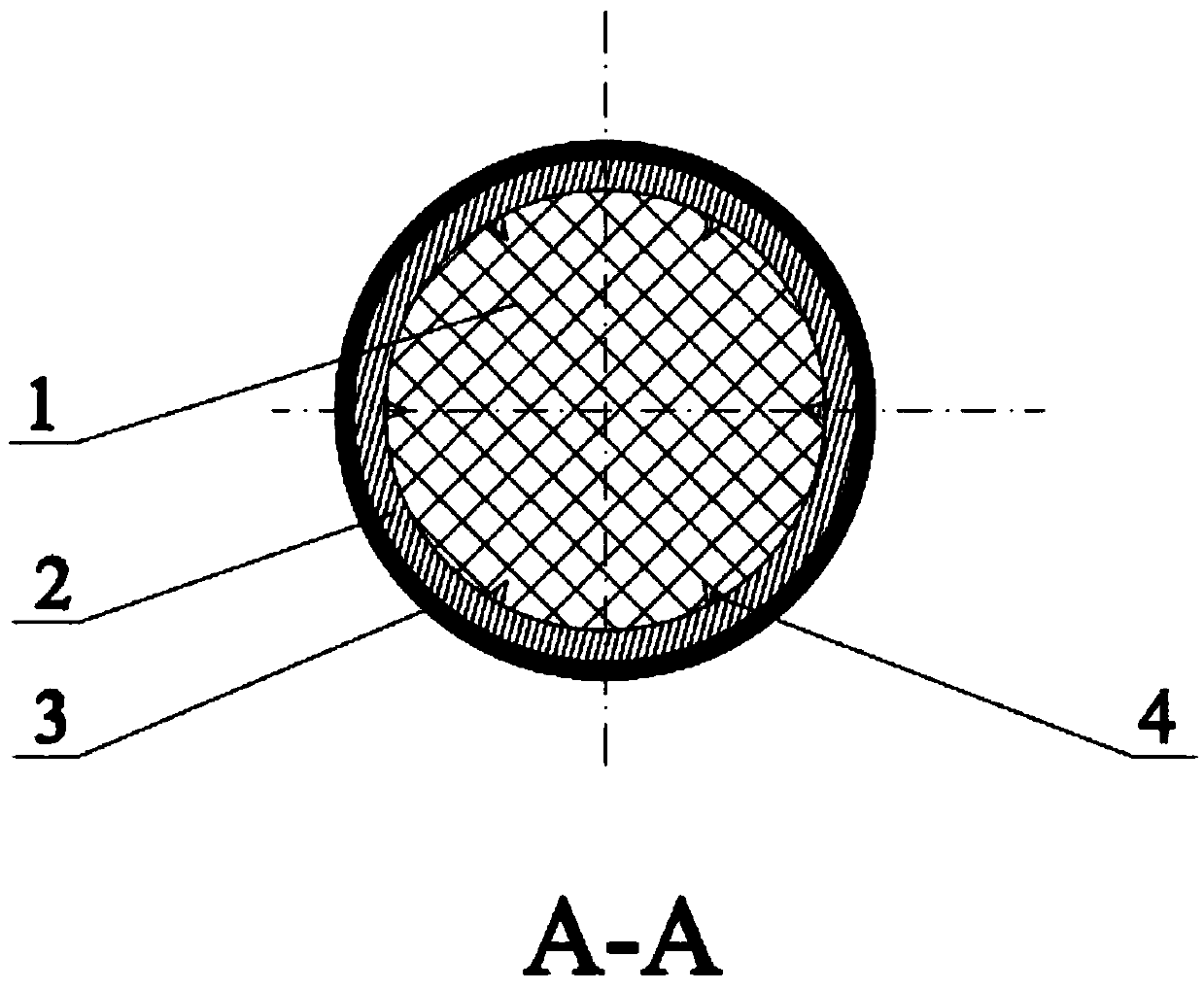

[0025] An ignition device for exothermic welding, comprising an ignition tube 2, an ignition core 1 and a heat insulation layer 3, the ignition core 1 is arranged in the ignition tube 2, and the ignition core 1 is gunpowder , the ignition tube 2 is any one of a round tube, a square tube, and a polygonal tube, the wall thickness of the ignition tube 2 is 5 to 40 in thickness ratio to the heat insulation layer 3, and the ignition tube 2 It is a magnesium tube, and the inner wall of the ignition tube 2 is provided with several protrusions 4, the bottom surface of the protrusions 4 is close to the inner wall of the ignition tube 2 and the central axis of the protrusion 4 is perpendicular to the The inner wall of the ignition tube 2, several of the protrusions 4 are evenly distributed on the inner wall of the ignition tube 2, the protrusions 4 are preferably conical, and the heat insulation layer 3 is arranged on the inner wall of the ignition tube 2. On the outer surface of the co...

Embodiment 2

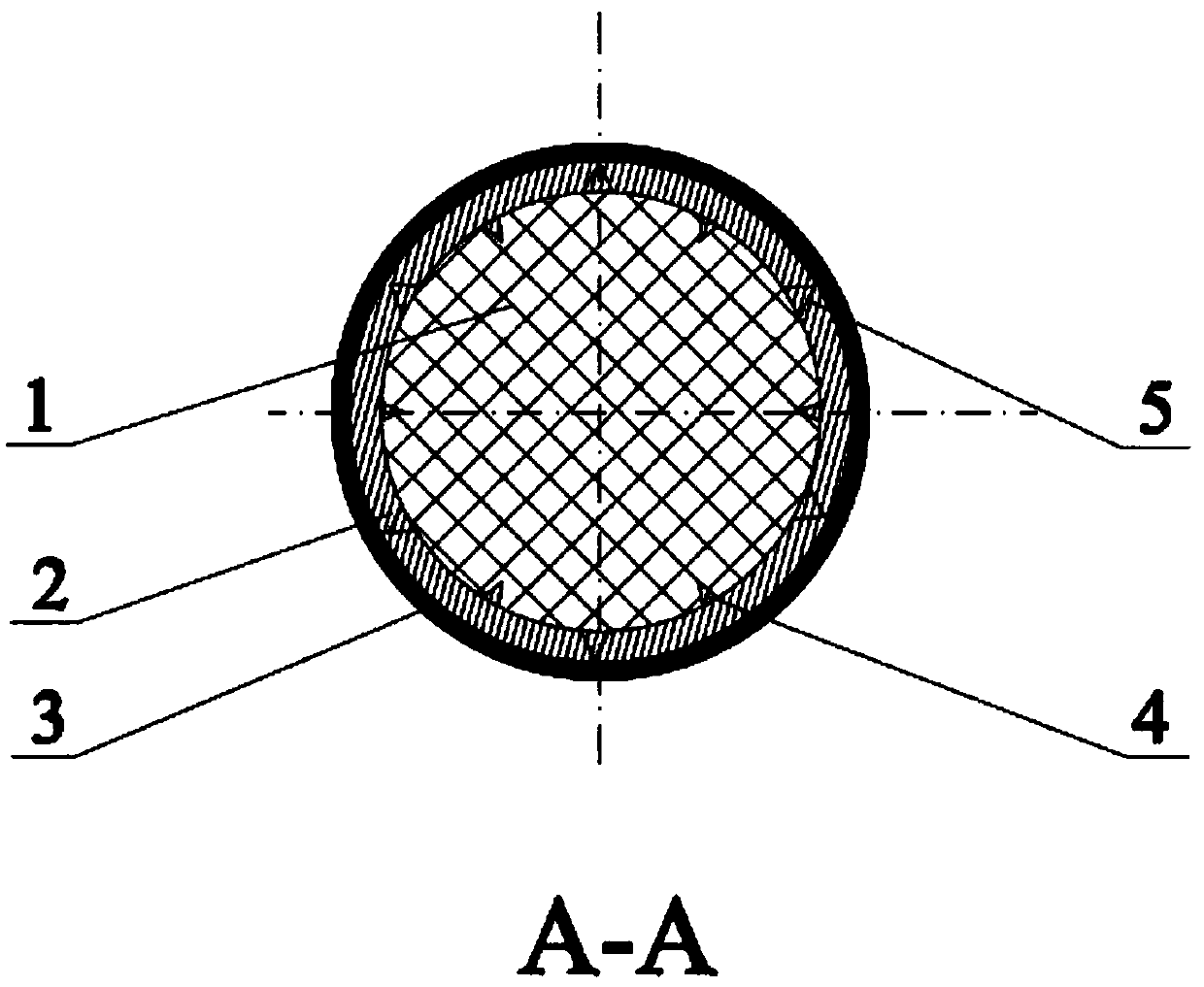

[0027] As shown in the drawings, an ignition device for exothermic welding includes an ignition tube 2, an ignition core 1 and a heat insulation layer 3, and the ignition tube 2 is any one of a round tube, a square tube, and a polygonal tube. One, the ignition tube 2 is a magnesium tube, and the slit magnesium strip is first drawn into a semicircular tubular shape with a thickness of 10-20 μm and a width of 7.5-10 mm by using a drawing die, and the A nickel layer 3 is plated on the outer wall, with a thickness of 0.5-2 μm; and then the ignition core 1 is filled into the ignition tube 2, and a seam core-shaped ignition material is formed after preliminary drawing. Finally, the preliminarily drawn drug core igniter is processed through drawing dies with different inner diameters, and finally a drug core igniter with a diameter of 2.5 to 3 mm is formed;

[0028] The ratio of the wall thickness of the ignition tube 2 to the thickness of the heat insulation layer 3 is 5-40, the ign...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com